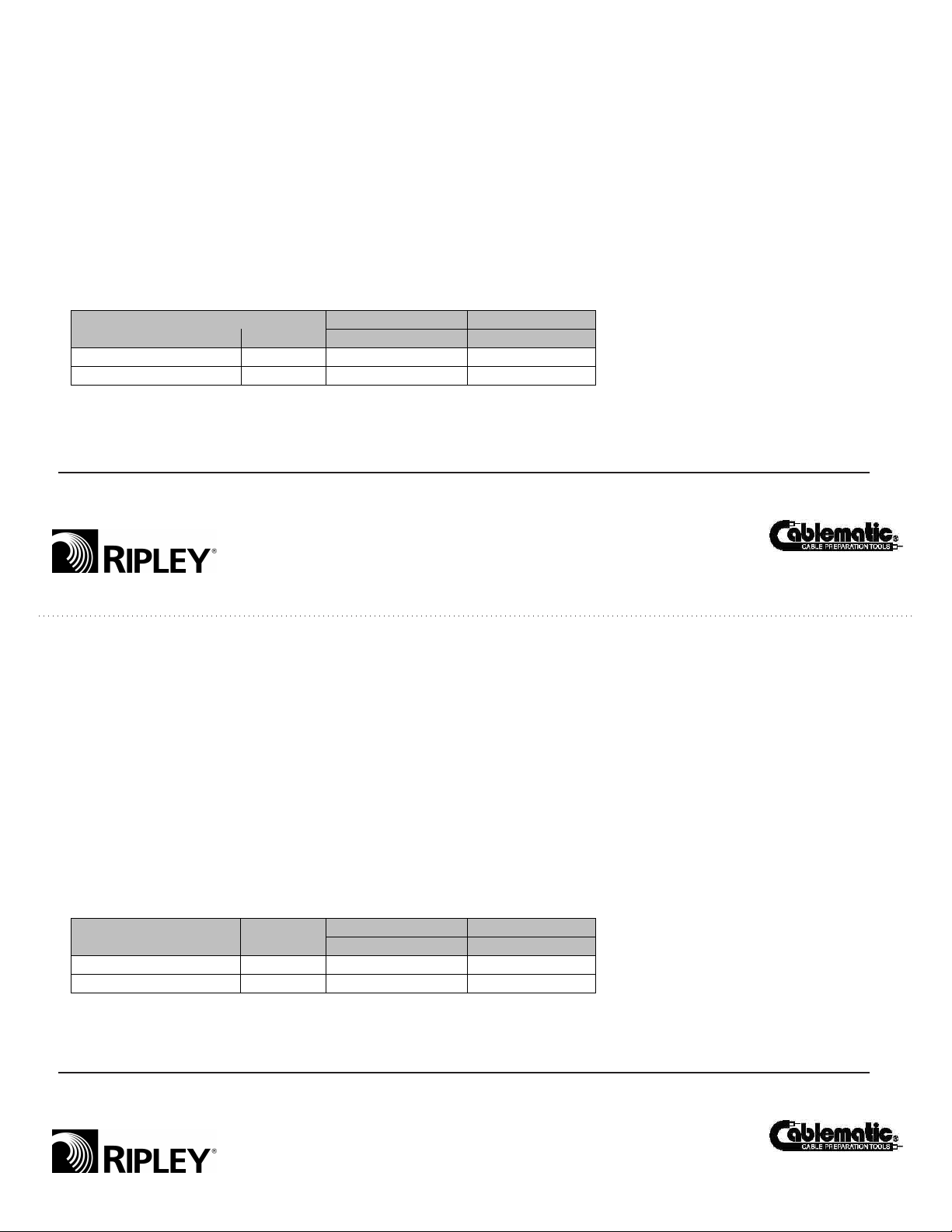

Torque set

Wrench size

Model

Part No.

In-lbs

(N-m)

Inch

(mm)

TW 227

RA-120 mm*

43225

22

(2.49)

7/16

(11.1)

TW 307 RA

43235

30

(3.39)

7/16

(11.1)

43238 instru table 12-09-10.doc

Part number explanation. For

example model number TW-307RA:

The first two numbers (30) indicate

the torque value in inch pounds. The

7 indicates 7/16 wrench size.

* This model is made with an extended security tool wrench that

measures 120mm (4.7”) from the yoke to the wrench end.

Standard wrench length is 2.47”

46 Nooks Hill Road, Cromwell, CT 06416 USA ~ Phone: 800-528-8665 ~ Int’l: (01) 860-635-2200

Fax: (01) 860-635-3631

~ E-mail:

[email protected] ~ Internet: www

.ripley-tools.com

43238rev.3 06-01-17 ff

WARRANTY: RIPLEY warrants its products against defective materials and workmanship for a period of one

year from date of shipment from the RIPLEY factory provided the product is utilized in accordance with

instructions and specified ratings.

46 Nooks Hill Road, Cromwell, CT 06416 USA ~ Phone: 800-528-8665 ~ Int’l: (01) 860-635-2200

Fax: (01) 860-635-3631

~ E-mail:

[email protected] ~ Internet: www

.ripley-tools.com

43238rev.3 06-01-17 ff

WARRANTY: RIPLEY warrants its products against defective materials and workmanship for a period of one

year from date of shipment from the RIPLEY factory provided the product is utilized in accordance with

instructions and specified ratings.

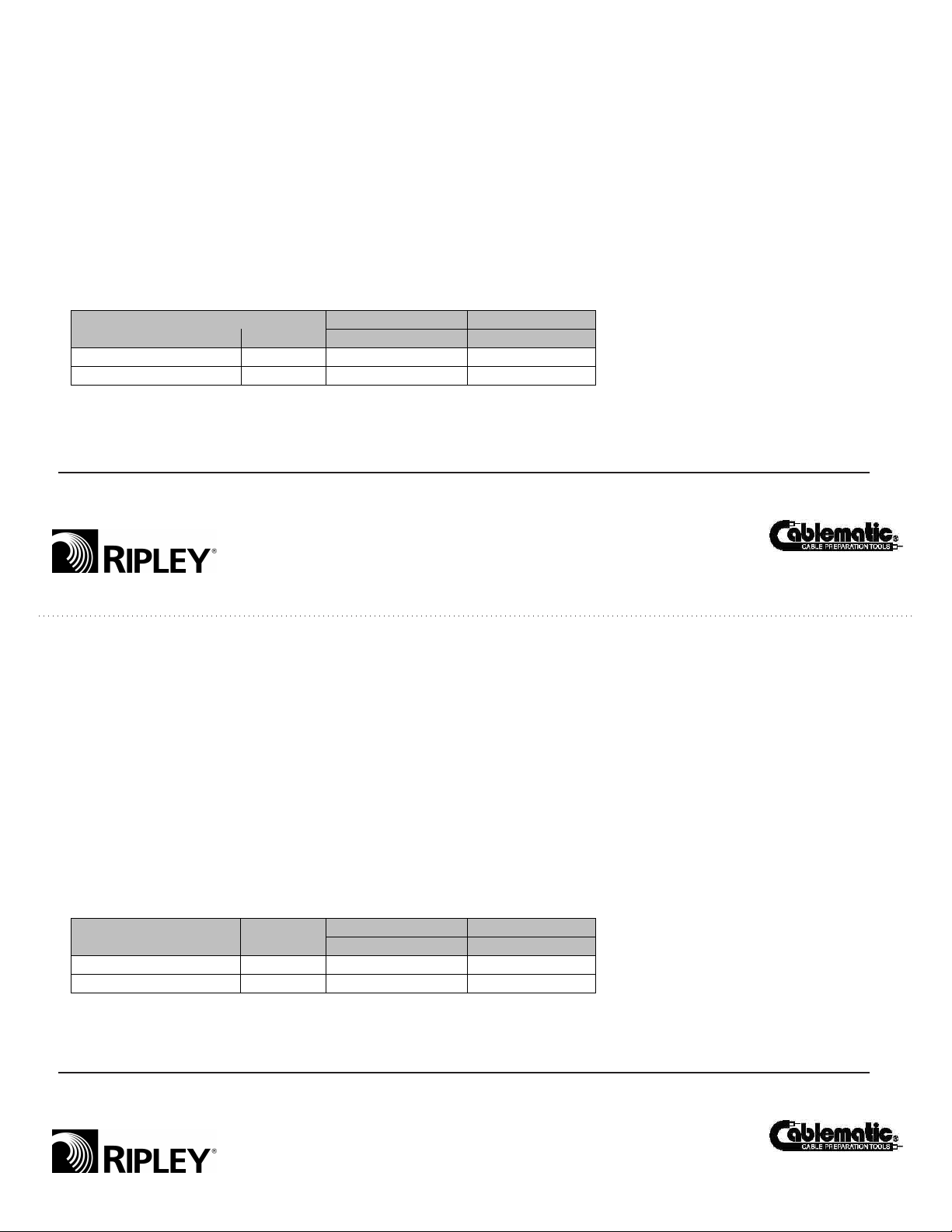

Torque set

Wrench size

Model

Part No.

In-lbs

(N-m)

Inch

(mm)

TW 227

RA-120 mm*

43225

22

(2.49)

7/16

(11.1)

TW 307 RA

43235

30

(3.39)

7/16

(11.1)

43238 instru table 12-09-10.doc

Part number explanation. For

example model number TW-307RA:

The first two numbers (30) indicate

the torque value in inch pounds. The

7 indicates 7/16 wrench size.

* This model is made with an extended security tool wrench that

measures 120mm (4.7”) from the yoke to the wrench end.

Standard wrench length is 2.47”

OPERATING INSTRUCTIONS

For Connector Assembly:

1. Install the shield on the tap port. Use tool to thread connector on the port finger tight. The handle can be pivoted

away for ease.

2. Pivot wrench handle, so it is at a right angle like photo above. Rotate clockwise. You will hear and feel a “click” in

the handle when the wrench reaches the pre-set torque level. At this point the connector is properly torqued on the

tap port. CAUTION: Do not continue rotating after the “click”. This will increase the applied force and damage the

connector and/or the wrench.

For Connector Removal:

1. Place wrench on the connector and rotate counter-clockwise until the connector loosens and continue to remove it

with the tool. Note: The wrench may “click” during this sequence to overcome the breakaway force of the tightened

connector. This is acceptable. However, if excessive force is used, damage will occur to the connector and/or

wrench

OPERATING INSTRUCTIONS

For Connector Assembly:

1. Install the shield on the tap port. Use tool to thread connector on the port finger tight. The handle can be pivoted

away for ease.

2. Pivot wrench handle, so it is at a right angle like photo above. Rotate clockwise. You will hear and feel a “click” in

the handle when the wrench reaches the pre-set torque level. At this point the connector is properly torqued on the

tap port. CAUTION: Do not continue rotating after the “click”. This will increase the applied force and damage the

connector and/or the wrench.

For Connector Removal:

1. Place wrench on the connector and rotate counter-clockwise until the connector loosens and continue to remove it

with the tool. Note: The wrench may “click” during this sequence to overcome the breakaway force of the tightened

connector. This is acceptable. However, if excessive force is used, damage will occur to the connector and/or

wrench