Page 5

VIS500 User Guide

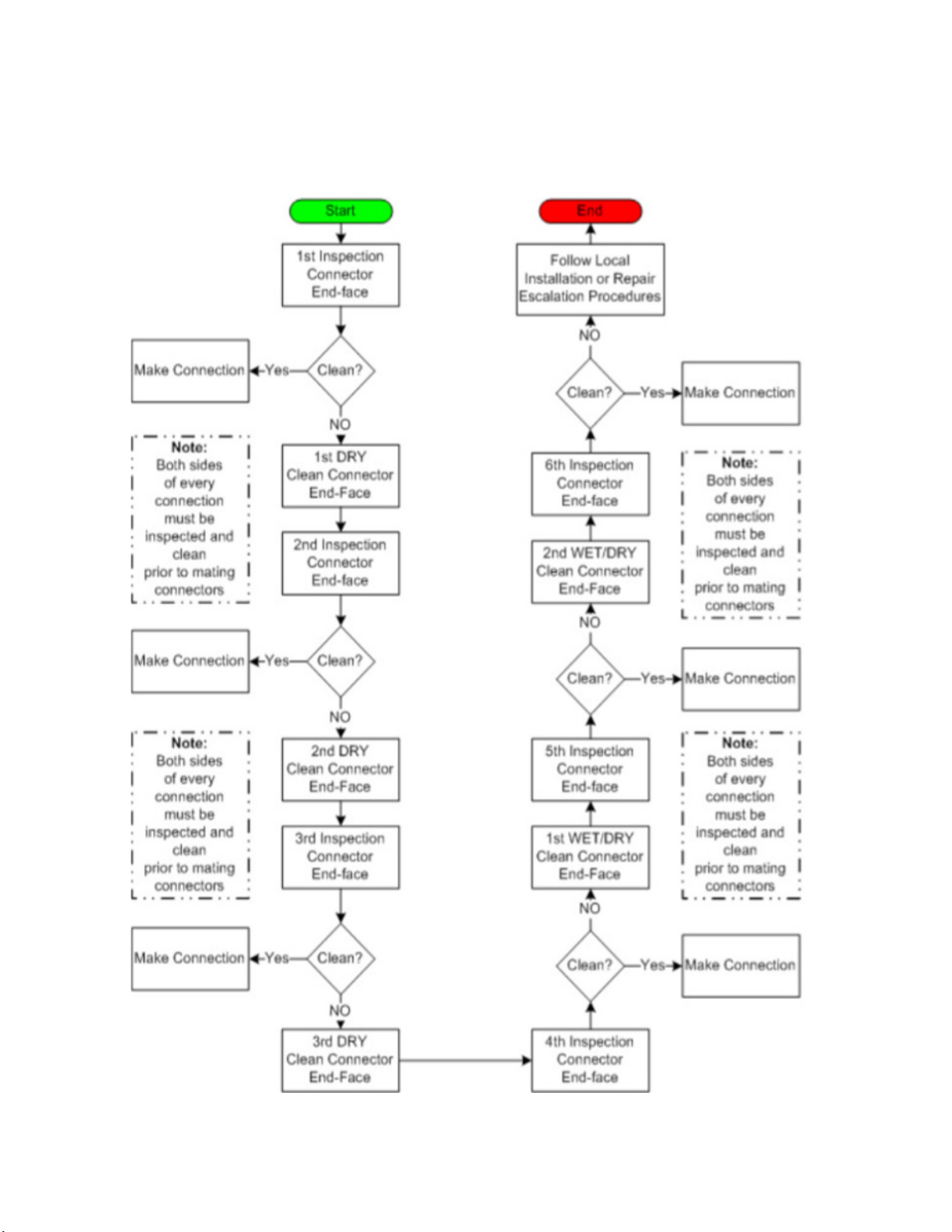

Endface Cleaning and Inspection Procedure

Intro

Nearly 95% of all ber optic system failures can be attributed to dirt on the ber endface. Such situations are often

entirely avoidable if proper cleaning procedures are followed. The International Electro technical Commission (IEC) has

created a standard of ber endface cleanliness, as well as a thorough ber cleaning procedure used to achieve that

standard. Industry best practices dictate strict adherence to this procedure in order to achieve optimal optical links

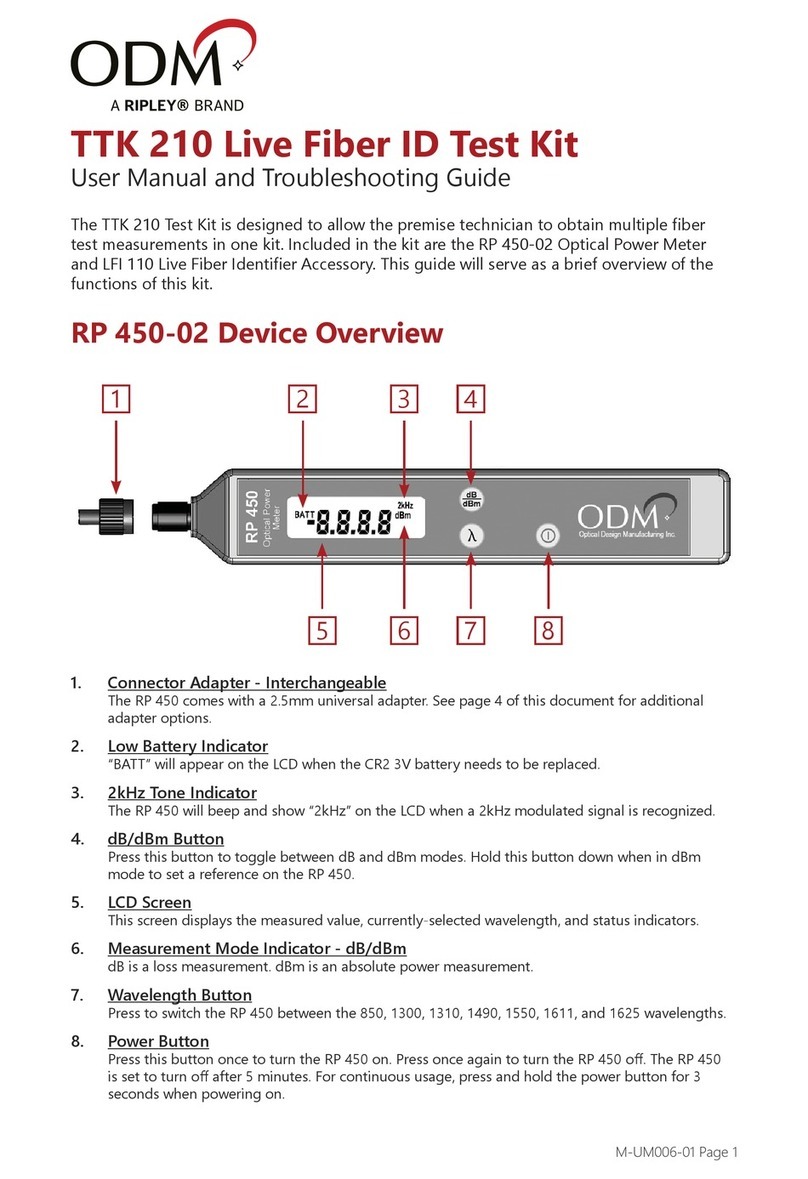

Fibers like the one shown in the “Before Cleaning” image (above) are c ommonly seen before installation. When bers

are improperly protected dust and debris can make their way onto the endface. The problem of dirt on ber enfaces can

be compounded by the presence of adhesive residue due to poor ber storage techniques. The IEC has laid out a dry

and wet/dry cleaning process that accounts for both the supercial and more stuborn debris that may be found on ber

endfaces.

Dry Cleaning

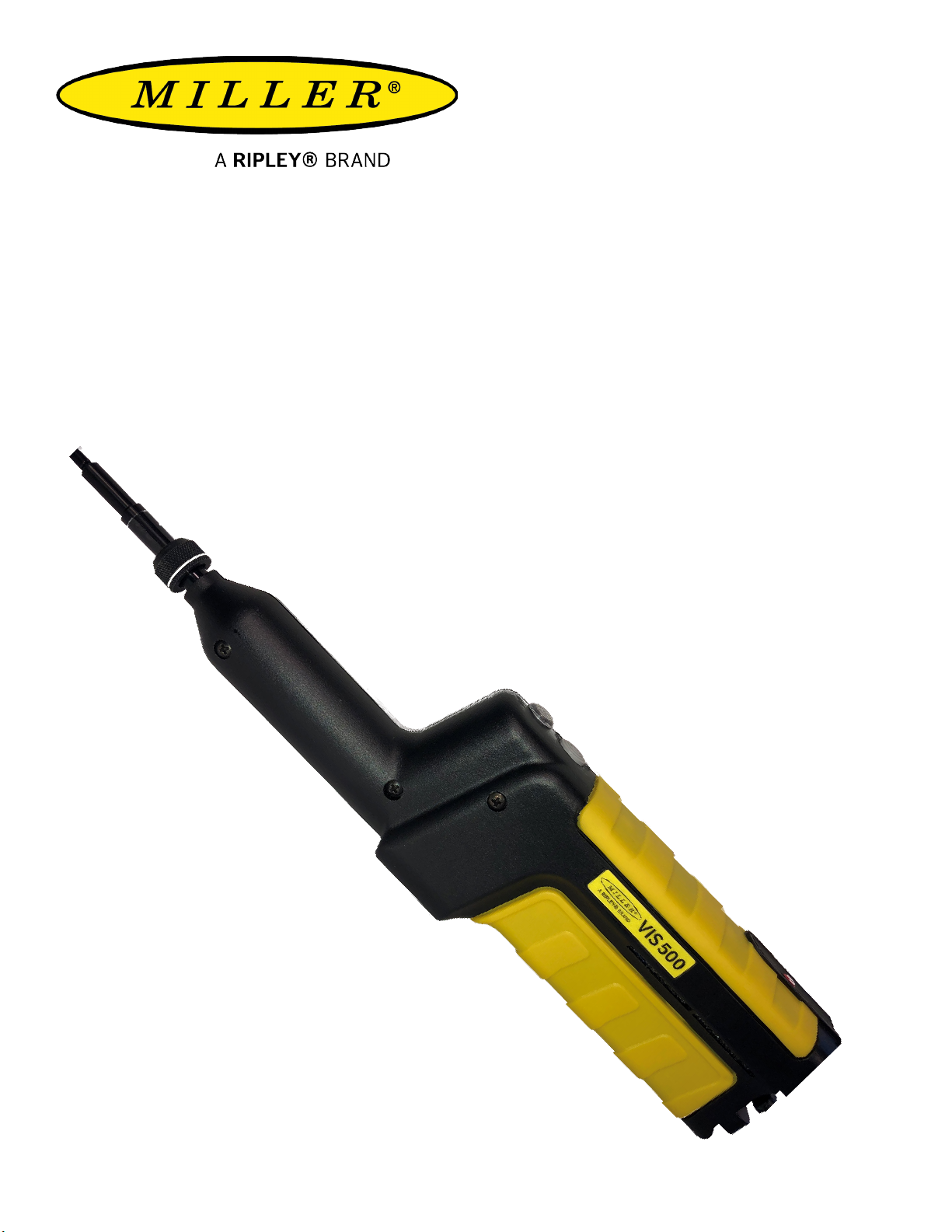

Dry cleaning connector endfaces is accomplished using a one-click or cletop cleaner. the one-click cleaner is used by

simply inserting a ber into the adapter cap and pushing until the unit clicks. The cletop cleaner can be used by retracting

the door on the body of the device to reveal a lint-free dry pad, and then rmly pressing the ber endface into the pad

and dragging downward. Both methods will most likely remove dust and other moveable debris.

Wet/Dry Cleaning

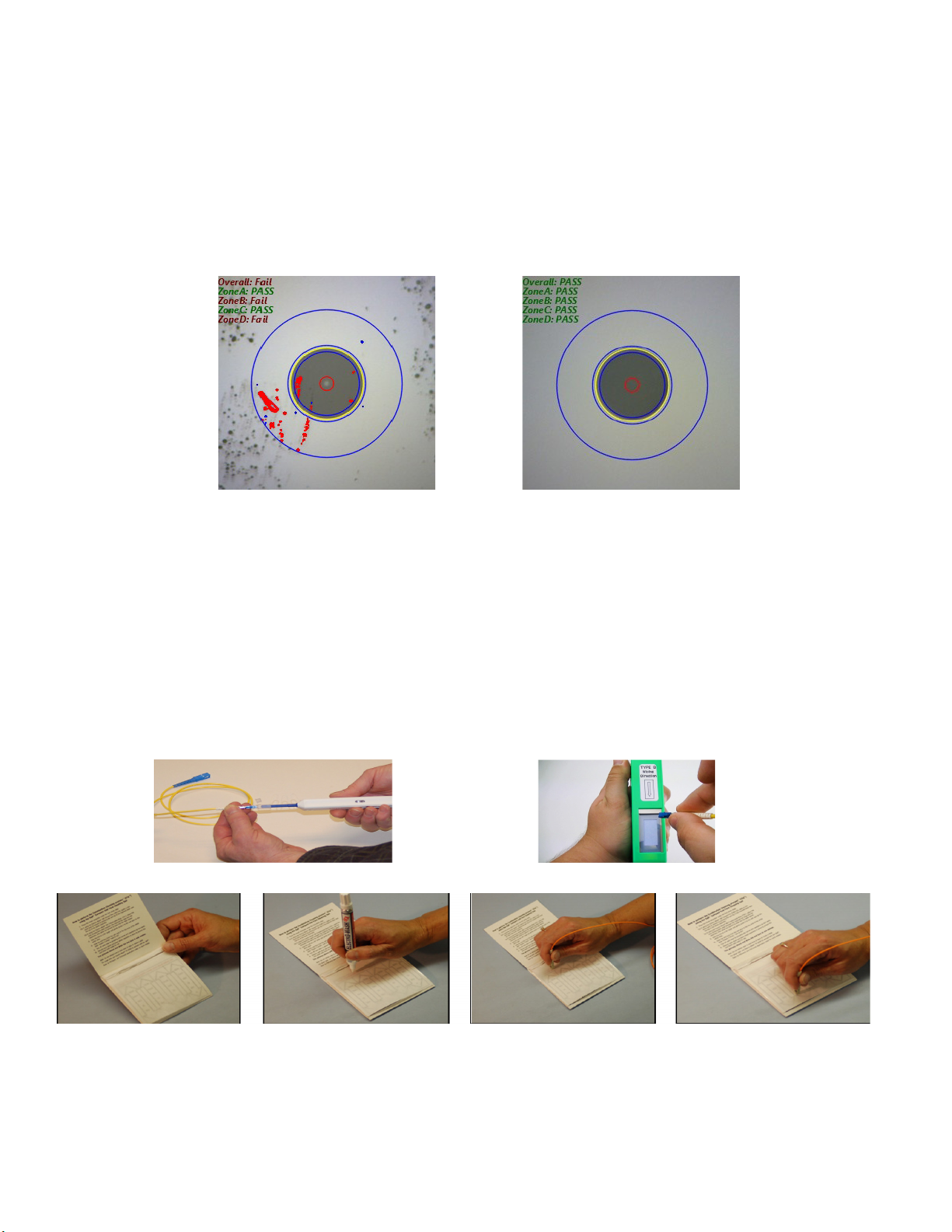

The wet/dry method (shown above) utilizes a lint-free pad and a ber wash pen lled with a solution of alchohol. To use

this method:

1. isolate a pad so it is on top of the laminated arrow sheet

2. place a coin sized spot of solution on the wipe using the pen

3. rub the ber endface into the wet portion of the pad.

4. drag the ber downward to the dry part of the pad, applying steady pressure. This method is helpful for removing

stubborn debris

Before Cleaning After Cleaning

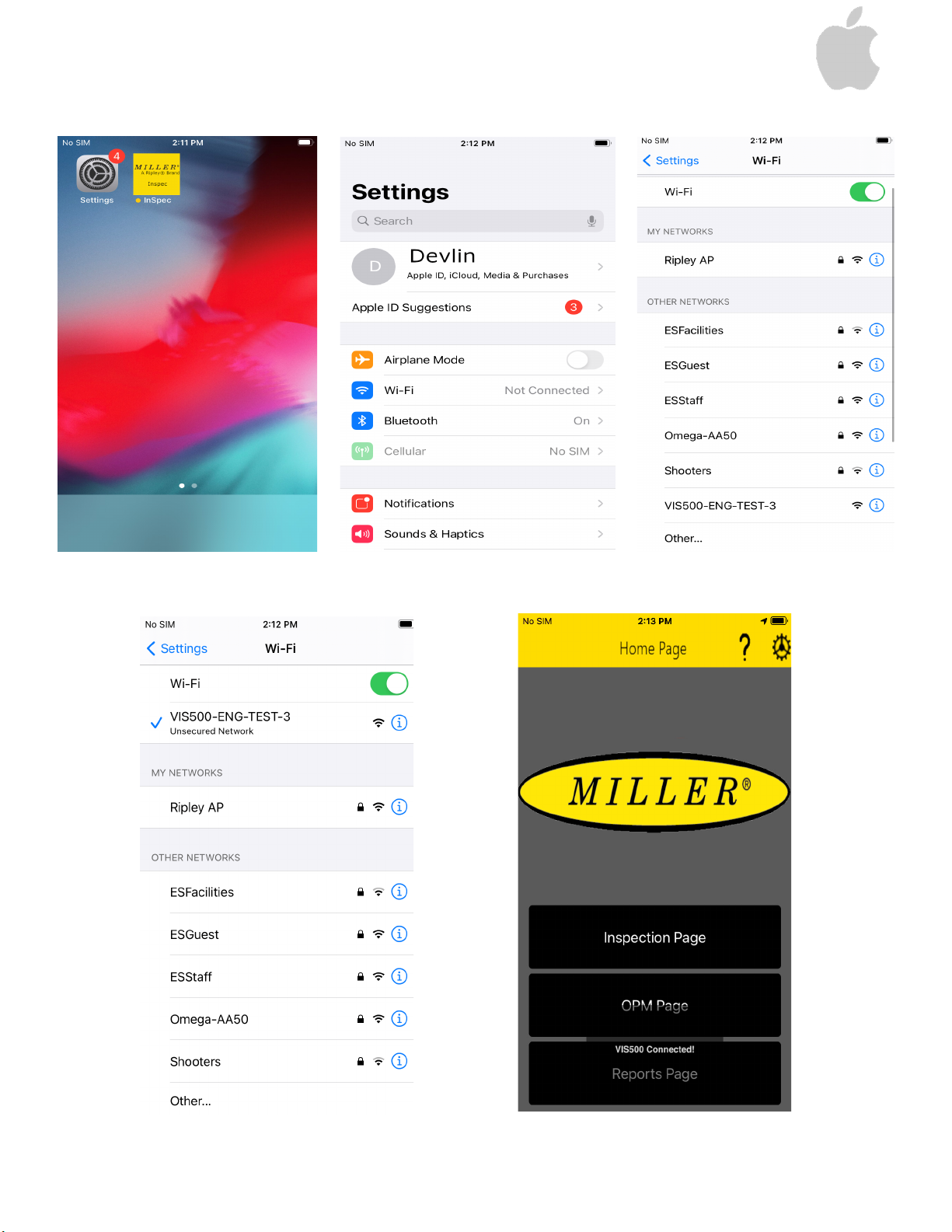

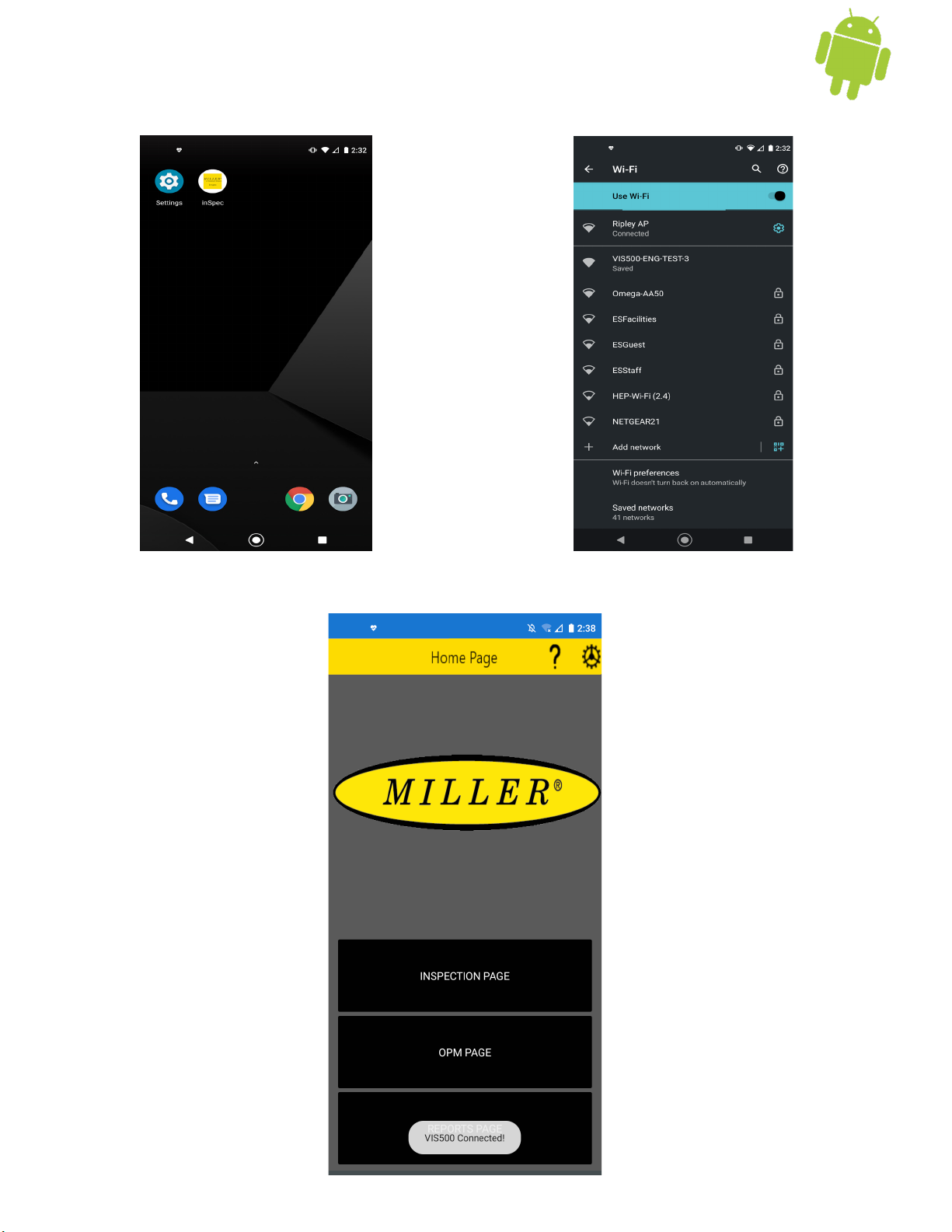

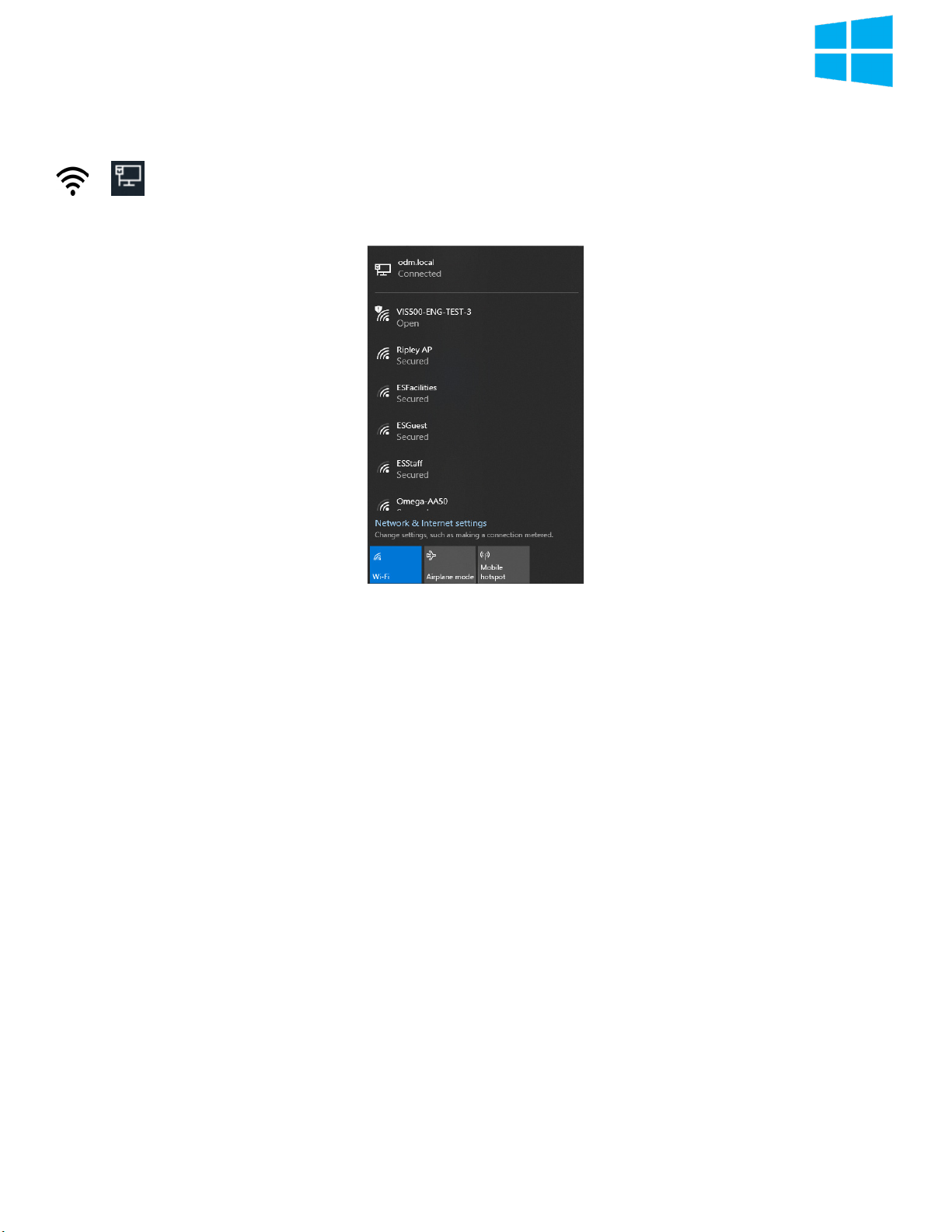

Auto Analyzed images from the VIS500 and the windows inspec

software