RITEWAY SHR-4100 Installation and operation manual

Operation &

Maintenance

Manual

Contents

SECTION 1 PAGE

INTRODUCTION & MANUAL INFORMATION 4,5

PRE-DELIVERY INSPECTION / NOTES 6

SPECIFICATIONS 7

SERVICE AND WARRANTY INFORMATION 8,9

SAFETY SUGGESTIONS 10,11

DECAL LOCATIONS 12,13

MAINTENANCE / GREASE LOCATIONS 14,15

OPERATING INSTRUCTIONS 16-18

GRADE CHART 19

TORQUE CHART 20

SECTION 2 PAGE

PARTS 3-19

4

We are pleased to welcome you as an owner of a product from RITE WAY

MFG. This machinery is the culmination of years of agricultural and engineering

experience and has been designed to deliver you with many years of successful

operation service.

For the most efficient operation of your Swing Hitch Roller we have provided

this owner’s manual. In this manual we have included proper maintenance and

functional procedures to offer maximum longevity for your new equipment. Before

operating we urge a careful study of this manual to provide a thorough under-

standing of your new Swing Hitch Roller. We also recommend that you take care

of this manual so it will be available for future reference. Should your manual be-

come lost or destroyed a new copy can be obtained from your Rite Way Manufac-

turing dealer. We will also be happy to answer any questions you might have con-

cerning the use or care of this product.

Rite Way Manufacturing Co. Ltd.

P.O. Box 328

Imperial, Saskatchewan, Canada

S0G 2J0

PH: 306-963-2180

Fax: 306-963-2660

Web Site: www.ritewaymfg.com

Email: [email protected]

Thank you for making the decision to purchase a RITE WAY product!

5

Unit Model Number SHR-4100

Manual Revision Number 1.3

Manual Revision Date Feb. 10, 2020

Manual Serial Number Range 18-41-2357 – Current

Owner / Equipment Information

Serial Number of Unit

Date of Purchase

Dealer Name

Dealer Address

Dealer Phone Number

Salesman Name

Salesman Phone Number

Notes

The area below is provided for the owner / end-user to make notes regarding the equipment.

6

Pre-delivery Inspection Completed By (Sign Below)

Pre-delivery Inspection Confirmed By (Sign Below)

Remove wrapping and wash unit, removing all road debris. (Road salt, mud, snow, etc.)

Inspect paint, decals and general appearance of unit.

Verify that the owners manual is in the manual storage tube.

Verify ‘SLOW MOVING VEHICLE’ sign (SMV) is on unit

Verify that jacks are with the unit and function properly.

Check wheel bolts for proper torque.

Check for proper tire pressure (PSI).

Verify that the wheel hubs are lubricated.

Verify that locking pins and / or ram locks are in place.

Lubricate all components as per operators manual recommendation.

Check that all bolts and fasteners are at the proper torque specifications.

(NOTE: All cap screws that have lock nuts joining moving pieces should not be tightened completely,

they must allow movement. i.e. Spring pressure kits, rock shaft connector, draft arm, etc.

Check sprocket alignment and chain tension. (If applicable)

Check locking collars and set screws for proper tension. (If applicable)

Verify operation of lights. (If applicable)

Verify the unit moves ‘IN’ and ‘OUT’ of transport without any binding.

Verify that tires are tracking properly when in transport mode.

Insure that all hydraulic hoses and lines are routed properly and secured.

Verify that all hydraulic fittings / hoses are secure and there are no oil leaks.

Inspect all cylinders for leakage and the cylinder shaft for rust, pits, or scratches.

Verify operation of all hydraulic functions - Cycle hydraulic cylinders to remove air from the system.

Verify that ‘The customer is aware of warning decals and proper jack placement for transport.’.

Verify that ‘The customer is aware of proper operation and transportation of the unit’.

Verify that ‘The customer has received an operators manual’.

Explain all maintenance and service intervals to the customer (From operators manual).

Advise the customer of grease zerk locations and maintenance schedules.

Level the unit per operators manual and instruct the customer on the proper procedures.

Level the unit per operators manual and instruct the customer on the proper procedures.

7

Weight 8,000 lbs. / 3,630 kg

Transport Width and Length Width of 7’-7” / 3.31 m

Length of 26’-5” / 8.34 m

Working Width and Length Width of 20’-00” / 6.0 m

Length of 18’-8-1/2” / 5.71 m

Tires 12.5L x 15 D

Hitch Multi-Position, Hydraulic Swing,

Perfect Hitch

Standard Equipment:

• Multi-position Hydraulic Swing Hitch

• Adjustable hitch height c/w perfect hitch clevis

• Over-center wing lockups

• Triple Lip Seal Bearings

• Large diameter drum with premium heavy wall:

• 42” diameter; 0.50” wall thickness (1067mm x 13mm)

• Heavy Duty Frame

• 8” x 4” x 0.250” (200 mm x 100 mm x 6 mm)

• Taper lock replaceable drum shafts

• Safety Chains

• Light Package

Optional Equipment:

• Acre Meter

• Mud Scraper Kit

8

Rite Way Manufacturing Co. Ltd. (hereafter referred to as Rite Way) warrants each new machine

to be free from defects in materials and workmanship for a period of one (1) year from date of pur-

chase under normal agricultural use and service. In addition, Rite Way will supply at no charge, (F.O.B

Rite Way Factory) any part that has failed within the 2nd year. Rite Way’s obligation under this warran-

ty is limited to the repair or replacement of any defective parts of the equipment at its own discretion.

Any alterations, modifications or additions done to a finished product will void this warranty un-

less prior written permission from Rite Way is obtained.

Items that are not manufactured by Rite Way are covered by the warranty of the supplier of these

items. We will therefore extend, without assuming any responsibility, any warranty given to us by our

suppliers.

This warranty shall-not apply to any machine, that in the company’s judgment has be subjected to

misuse, negligence or accident. In no event shall the owner be entitled to recover costs for incidental,

special or consequential damages such as, but not limited to; Loss of crop, loss of profit or revenue,

other commercial losses, inconvenience or rental costs.

This warranty shall not apply unless Rite Way or its designated dealer is promptly notified of

claimed defects and the allegedly defective part is held for inspection.

Repair parts purchased for machines ‘Out of Warranty’, are warranted to be free from defects in

material and workmanship under normal use and service for a period of ninety (90) days from the date

of delivery to the customer.

The warranty shall only become valid when delivery notification for warranty is received by Rite

Way within 20 days of the completion of sale.

OWNER’S / USERS OBLIGATION: It is the responsibility of the user to read the Operators Manual and

understand the safe and correct operating procedures as it pertains to the operation of the product,

and to lubricate and maintain the product according to the maintenance schedule in the Manual.

The user is responsible for inspecting the machine, and for having parts repaired or replaced

when continued use of the product could cause damage or excessive wear to any other parts. It is the

user’s responsibility to deliver their machine to a Rite Way dealer for service or replacement of defec-

tive parts which are covered by the standard warranty.

Rite Way will not by held responsible for charges such as transportation, fuel, lodging when a

dealer / dealer representative travels to a customer location for warranty or inspection.

9

1. All claims must be handled through a dealer / distributor. All claims must be submitted on a proper-

ly completed claim form within 30 days of the date of repair.

2. A warranty registration claim form must be on file at Rite Way Mfg. to validate a warranty claim.

3. Defective parts are to be held at the dealer / distributor’s place of business until the warranty claim

form has been processed. Rite Way will advise when parts can be released.

4. Parts that require inspection by Rite Way personnel must be accompanied by a Return Goods

Form number, and must be sent by pre-paid freight. Rite Way will refund pre-paid freight charges

on any items determined to be defective.

5. Rite Way will not assume responsibility for repairs or expenses incurred without authorization. War-

ranty labour in excess of $150.00 must be authorized before such work is performed and photo-

graphs before and after repairs are required.

6. Warranty labour is to be claimed on the warranty claim form, only if the warranty labour was per-

formed by the dealer. Travel time is not covered by warranty and should not be included. Rite Way

reserves the right to adjust or allocate labour times and values based on its experience.

7. It is the responsibility of the dealer to ensure that the warranty registration forms are properly com-

pleted and returned to Rite Way Mfg., Imperial, SK.

10

1. Read the manual thoroughly and understand before operating or working on

the machine.

2. Study all safety and warning decals on the implement.

3. Most accidents occur because of neglect or carelessness.

4. Do not allow riders on the tractor or implement during operation.

5. Do not allow children on or near the machine.

6. Connect the implement hitch to the tractor before operating the hydraulic

system.

NOTE: Be aware of any hydraulic leaks.

7. Always throttle the tractor down and use caution when connecting the imple-

ment to the tractor hitch.

NOTE: Never stand between the tractor and implement.

8. Lower the hitch jack onto firm ground and chock the tires when unhooking

implement from tractor.

NOTE: Ensure the unit is on level ground prior to unhooking tractor.

9. Exercise extra caution when working on hillsides or near ditches.

10. Ensure that the tractor draw-bar is pinned during transport.

11. Maximum speed while transporting the unit is 18 mph (29 km).

12. Do not work on this machine when hydraulic system is under pressure.

13. Observe all laws and regulations when transporting unit on public roads.

14. Do not transport this machine on public roads unless all safety & mainte-

nance checks have been completed.

15. Ensure that safety chains are secured prior to transporting.

This machine will provide years of trouble-free & safe operation IF

all maintenance and safety instructions are followed.

11

12

13

UNIT SERIES

UNIT SIZE

MODEL YEAR

UNIT NUMBER

F1-20 SH 20-41-0001

Item # Part # Description Qty

1060-0009 Amber - Reflector (3 x 2) 8

2060-0011 Caution - escaping fluid hazard, escaping hydraulic …. 1

3060-0015 Important - Block wheels before Unhooking 1

4060-0022 Red - Reflector (3 x 2) 2

5060-0028 Warning - Lower or Block Elevated Components …. 1

6060-0029 Warning - Stand Clear Of Hitch Tongue When Unhooking…. 1

7060-0034 Riteway Serial Number Plate 1

8060-0038 Attention - Ensure That All Cylinder Shafts Are Retracted 1

9060-0046 Grease - Every 8 Hours 3

10 060-0061 Important - Hydraulic Hose Application (three colours) 1

11 060-0067 Warning - Check and Tighten Hub and Wheel Bolts 1

12 060-0121 Riteway Mfg. (Large) 2

13 060-0083 4100 - White 1

14 060-0122 Riteway Mfg. (Small Decal, 9 x 4 - White) 2

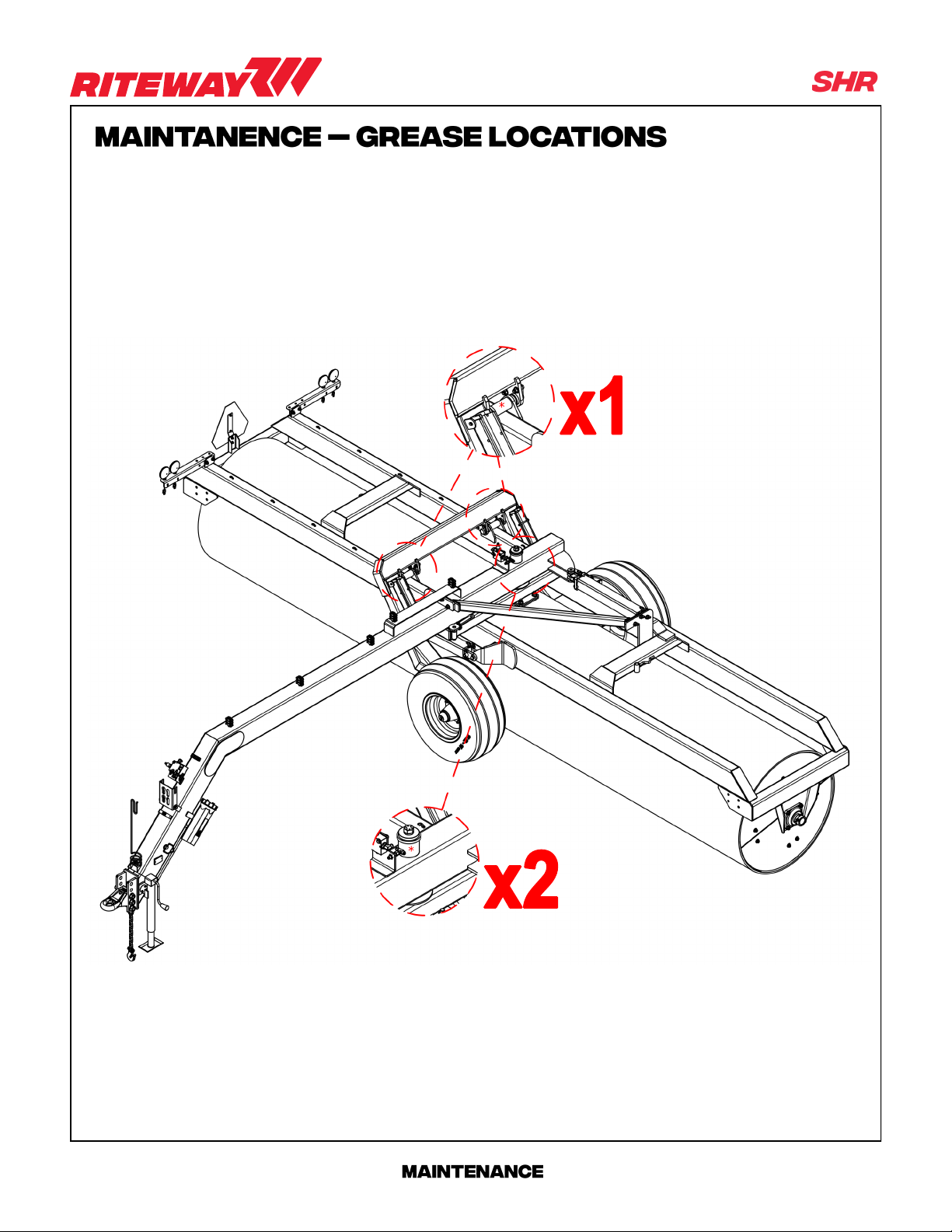

14

• Repack the wheel hubs after the first 500 travel miles; then yearly thereafter.

• Visually inspect the wheel bolts for tightness each day. Riteway torque recommendation to

110 ft - lbs after the first few hours of operation and frequently there after, (manufactures

torque recommendations 90 to 131 ft - lbs).

• Requires 3-1/2 to 4-1/2 HP per foot.

• Grease all pins and knuckles. (See page 15 for detailed diagram).

• Visually inspect hydraulic hoses & fittings for leaks or damage.

• Inspect lighting system and electrical harness for damage

• Inspect wheel bearings / hubs and grease.

• Check wheel bolts and re-torque.

• Check tire pressure, follow tire manufactures inflation recommendations.

• Visually inspect unit for loose, worn or damaged components.

• Coat any exposed cylinder shafts with thick oil or grease.

• Ensure that parking jacks are situated on firm ground.

• NOTE: If jack pads sink into ground, it will be difficult to hook up unit.

• Lock all applicable safety pins into place.

15

16

NOTE: Always choose a level area when raising and lowering unit into or from transport position.

NOTE: Lubricate all pins, axles and bearings regularly to prevent premature failure of

components.

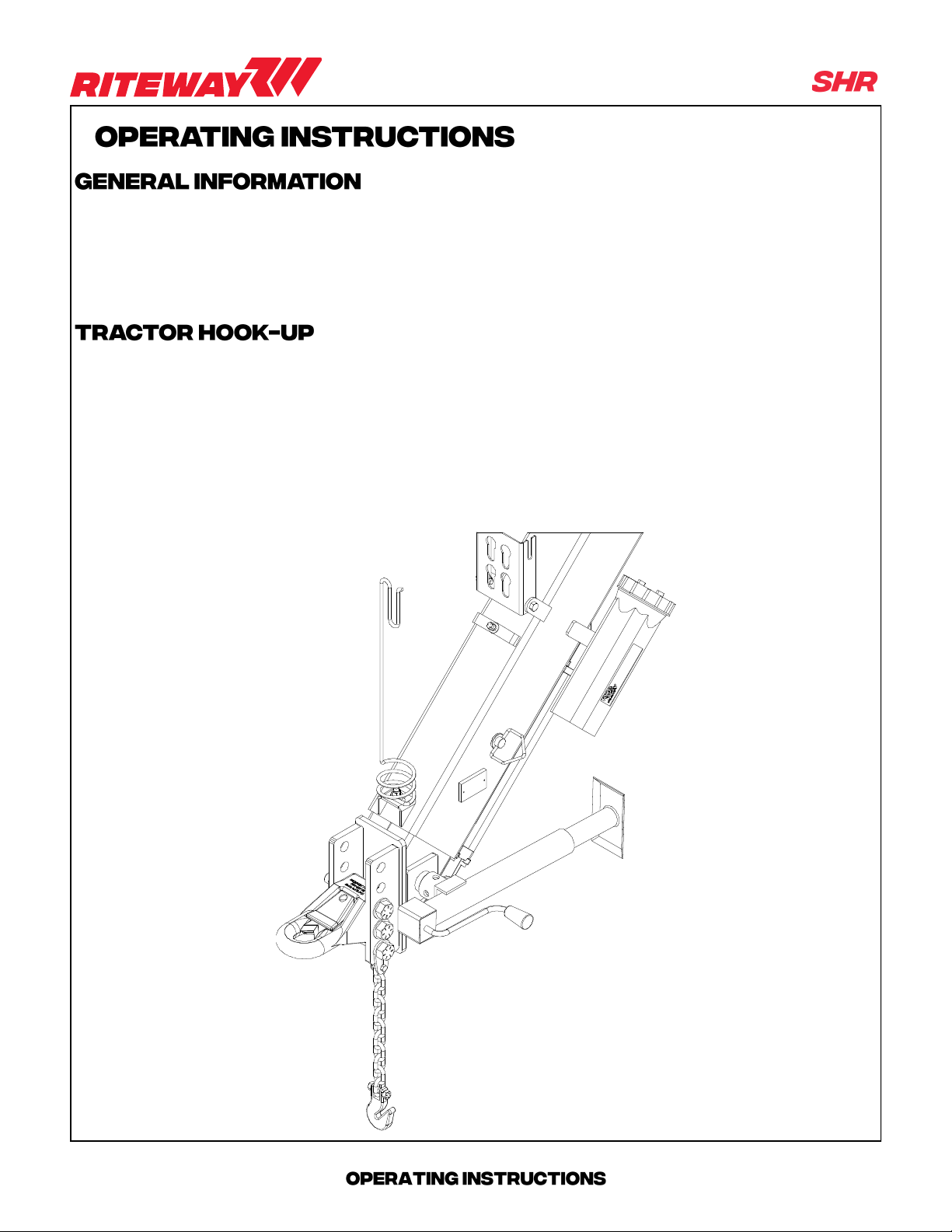

• Move tractor into position where pin can be dropped in place through draw bar hitch

NOTE: Use a clevis type tractor hitch with a retained type of hitch pin.

• Retract parking jack and secure in transport position prior to moving machine

NOTE: Ensure that parking jack handle is secured by chain prior to moving the machine (Failure

to do so will destroy the jack handle).

17

1. Park on level ground.

2. Remove each transport frame hydraulic cylinder lock up and pin into position.

3. Remove the swing hitch lock pin.

4. Remove tongue extension lock pin.

5. FROM INSIDE THE TRACTOR, lower the unit until the drum and frame are parallel to the ground

and just off the ground surface.

6. Use the hydraulic swing to rotate roller 90°, and then lock it with swing hitch lock pin.

7. Raise the transport frame completely.

8. Lock tongue with tongue extension lock pin.

9. Begin rolling in field position.

Swing hitch lock pin

Transport frame hydraulic cylinder lock up

18

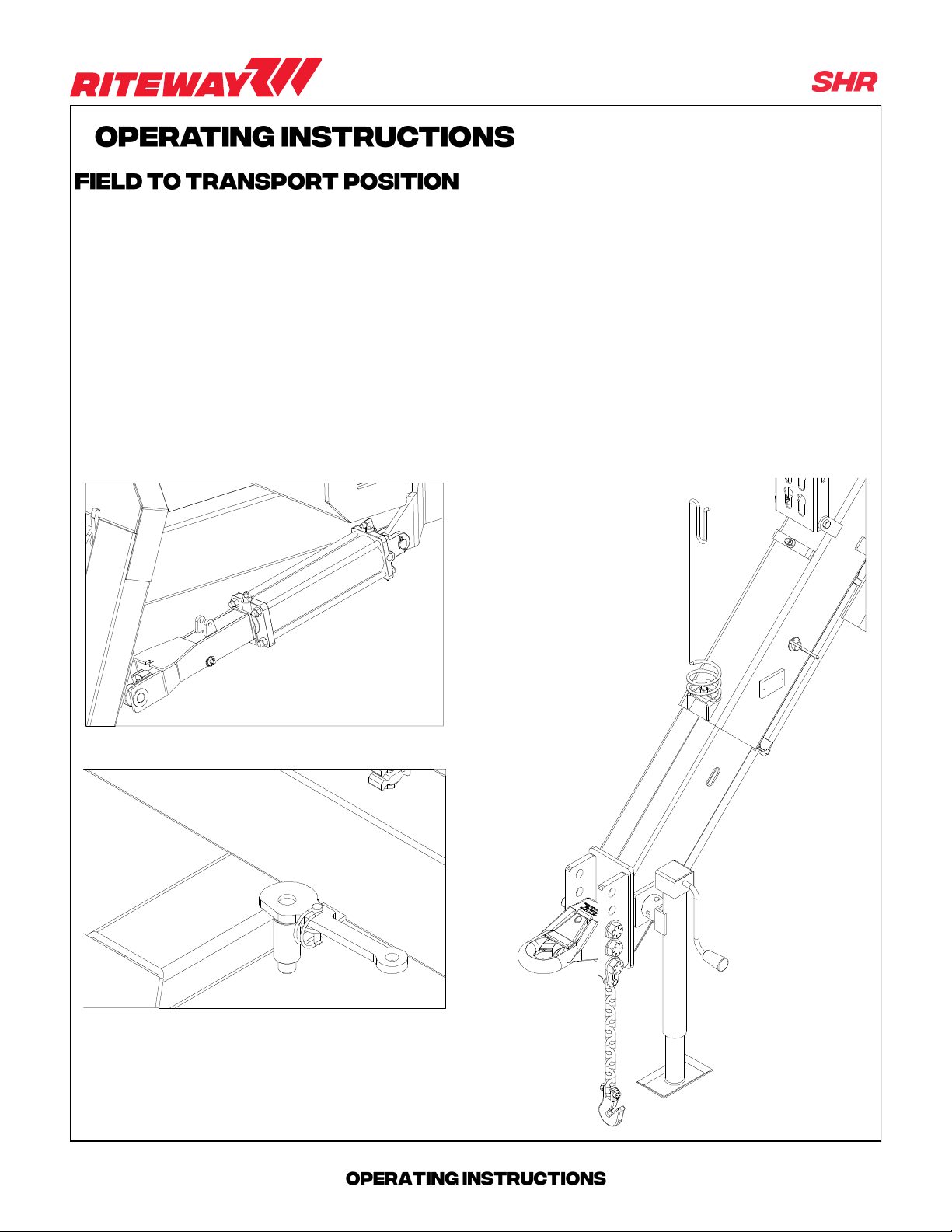

1. STOP the tractor before trying to lift up the LAND ROLLER

2. Remove the tongue extension lock pin and swing hitch lock pin.

3. Lift the unit slowly just off the ground.

4. Swing the roller into transportation position.

5. Extend the transport frame cylinders completely.

6. Place each transport frame cylinder lock up in place.

7. Place the swing hitch lock pin back and pin.

8. Place tongue extension lock pin.

9. Unit is now ready for transportation.

Swing hitch lock pin

Transport frame hydraulic cylinder lock up

Table of contents

Other RITEWAY Farm Equipment manuals

RITEWAY

RITEWAY ROCK PICKER 900 User manual

RITEWAY

RITEWAY F Series Installation and operation manual

RITEWAY

RITEWAY ROCK PICKER 250 User manual

RITEWAY

RITEWAY RH-9222 User manual

RITEWAY

RITEWAY HH-8200NT User manual

RITEWAY

RITEWAY HH-8290 User manual

RITEWAY

RITEWAY ROCK WINDROWER 1200 Installation and operation manual