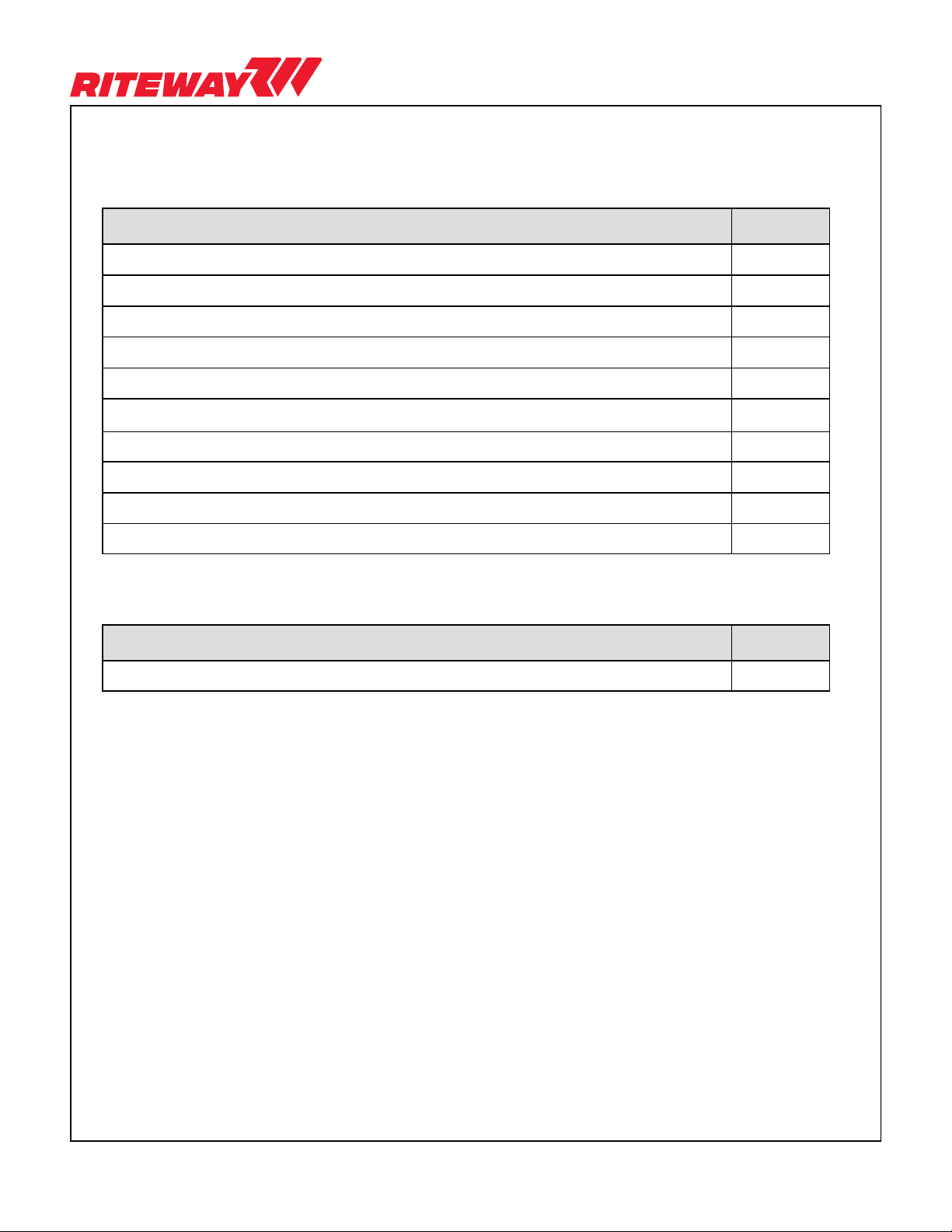

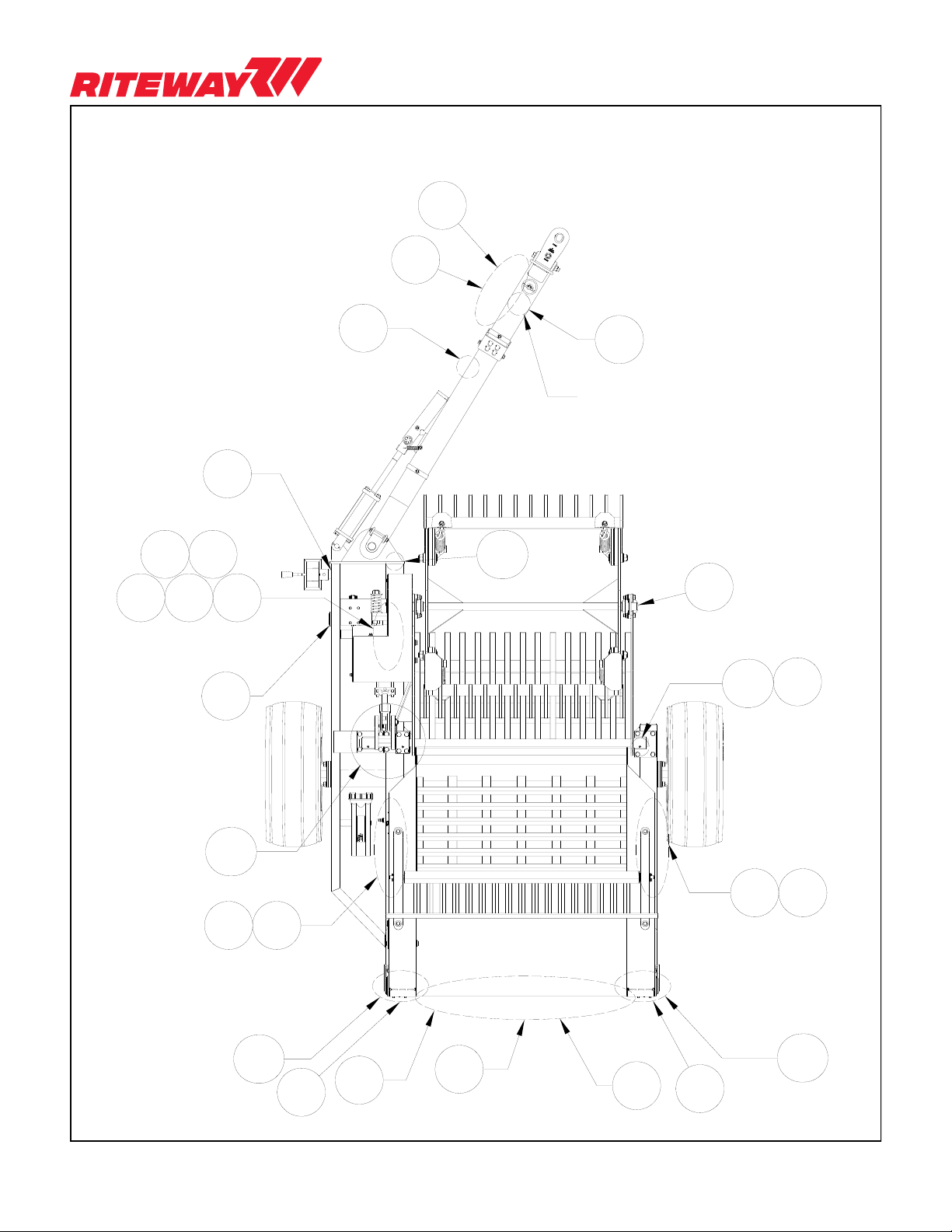

RITEWAY ROCK PICKER 250 User manual

This manual suits for next models

1

Table of contents

Other RITEWAY Farm Equipment manuals

RITEWAY

RITEWAY HH-8290 User manual

RITEWAY

RITEWAY F Series Installation and operation manual

RITEWAY

RITEWAY RH-9222 User manual

RITEWAY

RITEWAY HH-8200NT User manual

RITEWAY

RITEWAY ROCK PICKER 900 User manual

RITEWAY

RITEWAY SHR-4100 Installation and operation manual

RITEWAY

RITEWAY ROCK WINDROWER 1200 Installation and operation manual

Popular Farm Equipment manuals by other brands

Tatu Marchesan

Tatu Marchesan 9009T DODH-F instruction manual

Redexim

Redexim Level-Spike 1700 Operator and parts manual

Raven

Raven SBGuidance Onland Plough installation manual

AC Air Technology

AC Air Technology T1X3 instruction manual

Kongskilde

Kongskilde Z 685 Pro Operator's manual

KUHN

KUHN Venta 3030 Operator's manual

Amazone

Amazone Cayena 6001 operating manual

Newstripe

Newstripe 4600 SP Airless product manual

Schaffert

Schaffert Rebounder Mounting instructions

Blue Diamond

Blue Diamond MOLDBOARD PLOW 440012 Operation and maintenance manual

Avantco

Avantco A36935 Operator's manual

Tube-Line

Tube-Line TL1700SR Operator's manual

Rock Hound

Rock Hound 72B Operation & maintenance manual

Blue Diamond

Blue Diamond Power Rake Heavy Duty 2 Series Operation and maintenance manual

Euro Systems

Euro Systems M150RG Translation of original user instructions

Avantco

Avantco 300 Series Operator's manual

DALBO

DALBO ROLLOMAXIMUM XL manual

Tube-Line

Tube-Line TL60ECV Operator's manual