Table of contents

41 Operating principles

1.1 Scope of delivery 4

1.2 General

information

4

1.3 Signs and symbols

used

6

1.4 Structure of the warnings 7

1.5 Technical terms and abbreviations used 7

1.6 Intended use 8

1.7 Improper use 8

1.8 Duties of the operator 9

1.9 Duties of personnel 9

1.10 Training of personnel 10

1.11 Guarantee and liability 10

1.12 Copyright 11

12 2 General safety information for power tools

2.1 Occupational safety 12

2.2 Electrical safety 13

2.3 Safety of people 13

2.4 Use and handling of power tools 14

2.5 Use and handling of battery tools 15

2.6 Service 16

17 3 Important information about this tool

3.1 Handling the associated lithium ion battery 17

3.2 Information on the associated charger 18

3.3 Structural modifications 18

3.4 Cleaning the device and disposal 19

20 4 Start-up and use

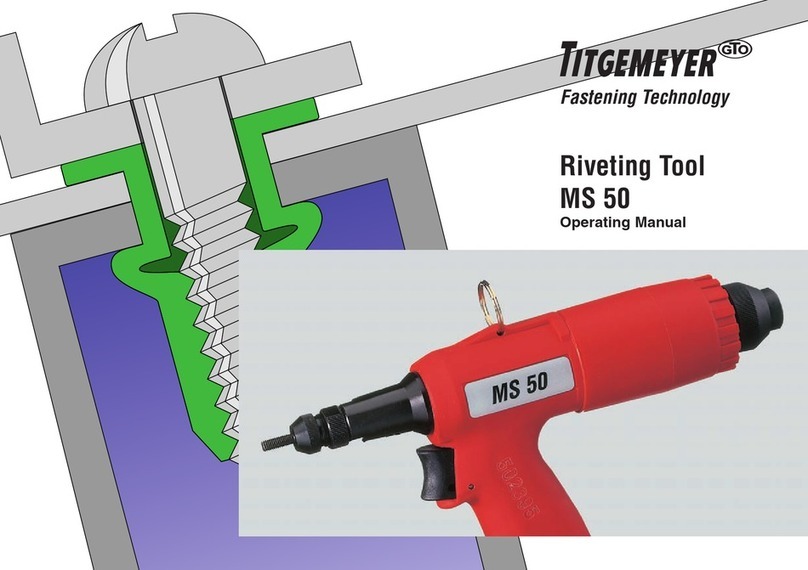

4.1 Tool structure 21

4.2 Operation 22

4.2.1 Inserting and removing the battery 22

4.2.2 Press start button 23

4.2.3 Front LED 23

4.2.4 LED indicator at the back and sound signals 24

4.2.5 OLED display 24

4.2.6 Empty remaining collection

container

25

4.2.7 Reducing pipes 27

4.2.8 Selection of nose piece 27

4.2.9 Selection of nose assembly 28

4.2.10 Set fastener 29

4.2.11 Contact pressure

sensor

30

4.2.12 QuickRiv-Technology 31

4.2.13 Overload 32

4.2.14 Standby and Shut-down mode 32

4.2.15 Charge state of the battery 33