Rivtec RT-C2 User manual

RT-C2

Air Hydraulic Rivet Tool

OPERATOR’S MANUAL

IMPORTANT

Read this Operator’s Manual

carefully before operation.

Keep this manual for future

reference.

TROUBLE SHOOTING

Tool not operating Tool not connected to air supply

Air pressure is insufcient or too

high

Hydraulic oil level is low

Connect to an air supply.

Adjust air supply pressure to

recommended level.

Fill hydraulic oil (Refer to the

“Hydraulic Oil Filling” section).

Indication Cause Solution

Tool not returning Swarf jammed in jaw assembly Clean and lubricate the jaw

assembly (Refer to the “Front

End Service” section).

Tool losing stroke Hydraulic oil level is low Fill hydraulic oil (Refer to the

“Hydraulic Oil Filling” section).

Jaws slipping on

mandrels

Jaws dirty

Jaws worn

Clean and lubricate jaws (Refer

to the “Front End Service”

section).

Replace jaws.

Jaws fail to open Dirty outer sleeving, jaw case or

jaws

Jaw assembly loose

Internally clean the outer sleev-

ing and the jaw assembly (Re-

fer to the “Front End Service”

section).

Tighten the jaw assembly.

Rivet can not be in-

serted into nosepiece

Incorrect nosepiece Install correct nosepiece (size

is marked on nosepiece hex).

Rivet mandrel does

not break

Rivet not fully set

Insufcient air pressure

Hydraulic oil level is low

Repeat stroke, or change rivet

Adjust air supply pressure to

recommended level.

Fill hydraulic oil (Refer to the

“Hydraulic Oil Filling” section).

INTRODUCTION

Rivtec®RT-C2 Air Hydraulic Rivet Tool is a high performance economical air hydraulic rivet tool.

It utilises a lightweight ergonomic design and installs rivets from Ø3.2mm to Ø6.4mm (steel).

SPECIFICATIONS

Weight .............................................. 1.15kg

Pulling Force .......................................10KN

Air Pressure .................................... 5-7 bar

Stroke ................................................18mm

PACKAGE ACCESSORIES

■RT-C2 Rivet Tool

■Operator’s Manual

■Nosepiece for 3.2mm rivets

■Nosepiece for 4.0mm rivets

■Nosepiece for 4.8mm rivets

■Nosepiece for 6.4mm rivets

■Spare Jaw Case

■Spare Jaws (set of 3)

■Spare Jaw Spreader & Spring

■Syringe

■3mm Hex. Key

TOOL DIMENSIONS

124 mm

Ø 102 mm

292 mm

Ø 23 mm

64 mm 285 mm

Ø 54 mm

2

SAFETY INSTRUCTIONS

Caution! To ensure proper functioning and safe operation, read this Operator’s

Manual carefully before operating the RIVTEC® RT-C2 tool

■The rivet tool should be used exclusively to set blind rivets.

■DO NOT overload the tool – work within the prescribed work capacity

■ALWAYS wear eye protection when working with the tool. Personal protection such as

clothes, gloves, safety helmet, non-slipping shoes, ear protectors and protection against

fall are highly recommended.

■This tool is NOT designed for use in explosive atmospheres.

■DO NOT use the tool as a hammer.

■Ensure the tool is not damaged before connecting to the air supply.

■Repair work must be carried out by trained personnel. In case of doubt, ALWAYS send

back the tool to the supplier.

■ALWAYS disconnect the air supply when adjusting, servicing or removing any part of the

tool.

■Keep ngers off the trigger when connecting the air supply or if the air supply fails.

■Keep ngers away from the front of the tool when connecting the air supply or setting

rivets.

■DO NOT point the tool at anyone.

■DO NOT operate tool with the nose housing removed.

■DO NOT operate tool without the mandrel collector.

■DO NOT modify the tool in any way. Modication could damage the tool.

■The operating pressure must not exceed 7 bar.

■DO NOT direct tool exhaust towards anyone.

■Wash hands if exposed to hydraulic uid or lubricant.

■Keep hair, ngers and loose clothing away from moving parts of the tool.

3

BASIC TOOL OPERATION

1. Inspect tool for damage or oil leaking – do not use tool if it is damaged or leaking oil.

2. Ensure correct nosepiece is installed and tightened with a 12mm spanner. (The size of

the nosepiece is marked on the edge of the nosepiece)

3. Ensure the outer sleeving (3) is tightened, by using a 24mm spanner.

4. Connect tool to an air supply.

5. Ensure the mandrel collector (28) is installed.

6. Insert a correct rivet into nosepiece.

7. Pull trigger to install the rivet.

8. Release trigger – When releasing the trigger the jaw assembly returns to the start

position automatically.

9. Eject the spent mandrel by tilting to the rear into the mandrel collector.

10. When the collector is half full, do not use the tool. Disconnect the air supply, unscrew the

collector and empty it.

HYDRAULIC OIL FILLING

It is important that the tool be properly maintained. If the hydraulic oil level is low, the tool will

not work properly.

Caution! Disconnect the air supply while relling the hydraulic oil. Keep the tool

upright during all operations.

1. Unscrew oil screw (69) from the body by using the 3mm Hex. Key (supplied). Check

whether the o ring (29) remains in the hole.

2. Fill the syringe (supplied) with hydraulic oil.

3. Screw the lled syringe up to the o ring in the hole. Then slowly inject the oil into the

tool. Ensure no air is injected. Adequate oil has been added as soon as resistance is

sensed. The excess oil will ow back when the syringe is release if more oil is added

than necessary.

4. Unscrew and remove the syringe from the body. Check whether the o ring remains in

the hole.

5. Screw the oil screw into the hole with the Hex. Key.

6. Wipe off any excess oil.

FRONT END SERVICE

Nosepiece (1)

Outer Sleeving (3)

Jaws (6)

Jaw Case (5)

Lock Ring (9)

Jaw Spreader Housing (10)

Set Nut (12)

Head Assembly (15)

Caution! Disconnect the air supply while servicing front end to avoid injury.

1. Remove outer sleeving (3)

Unscrew the outer sleeving with a 24mm spanner and slide the sleeving off the jaw

assembly.

2. Remove jaw case (5) to access jaws and internal parts

Unscrew and remove the jaw case by using a 17mm spanner on jaw case and a

16mm spanner on jaw spreader housing (10). Remove jaws (6), jaw spreader (7),

spring (8) and lock ring (9).

3. Cleaning

Clean jaws, jaw spreader, spring, lock ring and the thread of the jaw case. Apply

lubricant on jaws and the thread area. Replace jaws if worn or damaged.

4. Re-assemble jaws, internal parts and outer sleeving

Place the jaws into the jaw case and slide the jaw spreader, spring and lock ring

into the jaw case. Apply lubricant to the thread of jaw spreader housing. Screw the

jaw case onto the jaw spreader housing by using the 17mm spanner and the 16mm

spanner. Slide the outer sleeving onto the jaw assembly and tighten with the 24mm

spanner.

If the oil level is too low and the tool fails to operate, service is required by a qualied service

person.

Oil Screw (69)

45

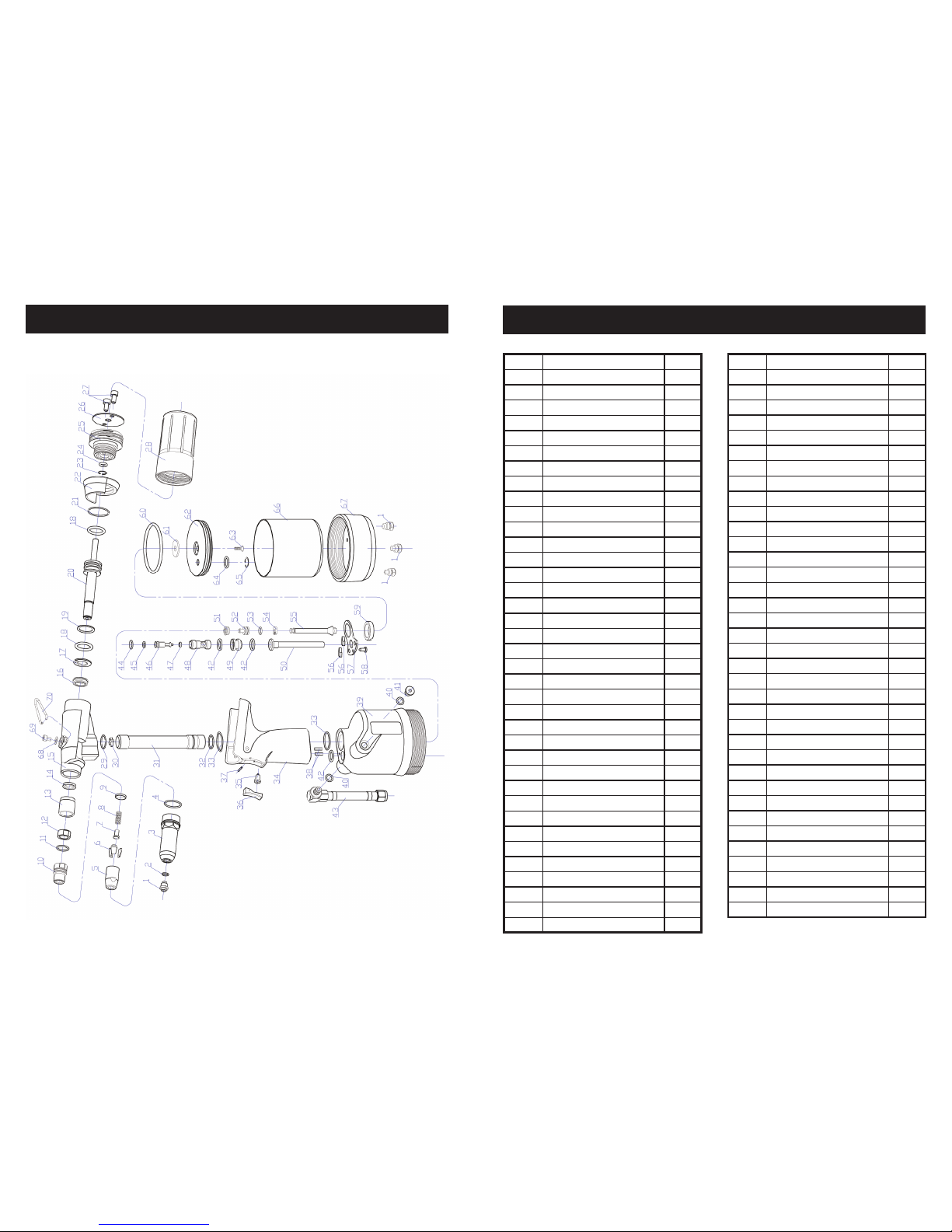

DIAGRAM

6

PARTS LIST

NO. DESCRIPTION QTY.

1NOSEPIECE 3.2MM 1

1NOSEPIECE 4.0MM 1

1NOSEPIECE 4.8MM 1

1NOSEPIECE 6.4MM 1

2O RING 1

3OUTER SLEEVING 1

4O RING 1

5JAW CASE 1

6JAWS 1

7JAW SPREADER 1

8SPRING 1

9LOCK RING 1

10 JAW SPREADER HOUSING 1

11 O RING 1

12 SET NUT 1

13 PLASTIC SEAL SLEEVING 1

14 SEALING RING 1

15 HEAD ASSEMBLY 1

16 LIP SEAL 1

17 SEAL RETAINER 1

18 O RING 2

19 PLASTIC RING 1

20 HEAD PISTON 1

21 O RING 1

22 STEM COLLECTOR ADAPTOR 1

23 CIRCLIP 1

24 O RING 1

25 END CAP 1

26 STEEL PLATE COVER 1

27 BOLT 2

28 MANDREL COLLECTOR 1

29 O RING 1

30 STAR WASHER 1

31 OIL TUBE 1

32 O RING 1

33 O RING 2

34 HANDLE 1

NO. DESCRIPTION QTY.

35 TRIGGER VALVE 1

36 TRIGGER 1

37 TRIGGER PIN 1

38 SPRING PIN 2

39 PLASTIC CYLINDER 1

40 O RING 1

41 SCREW 1

42 O RING 3

43 AIR INLET 1

44 O RING 1

45 O RING 1

46 VALVE CORE 1

47 O RING 1

48 VALVE BODY 1

49 VALVE BASE 1

50 TRANSFER TUBE 1

51 LIP SEAL 1

52 AIR TUBE PISTON 1

53 O RING 1

54 PISTON RING 1

55 PISTON ROD 1

56 SILENCER 2

57 CLAMP PLATE 1

58 TAPPING SCREW 1

59 SET NUT 1

60 O RING 1

61 WASHER 1

62 CYLINDER PISTON 1

63 BOLT 1

64 LIP SEAL 1

65 CIRCLIP 1

66 AIR CYLINDER 1

67 BASE COVER 1

68 WASHER 1

69 OIL SCREW 1

70 HOOK 1

7