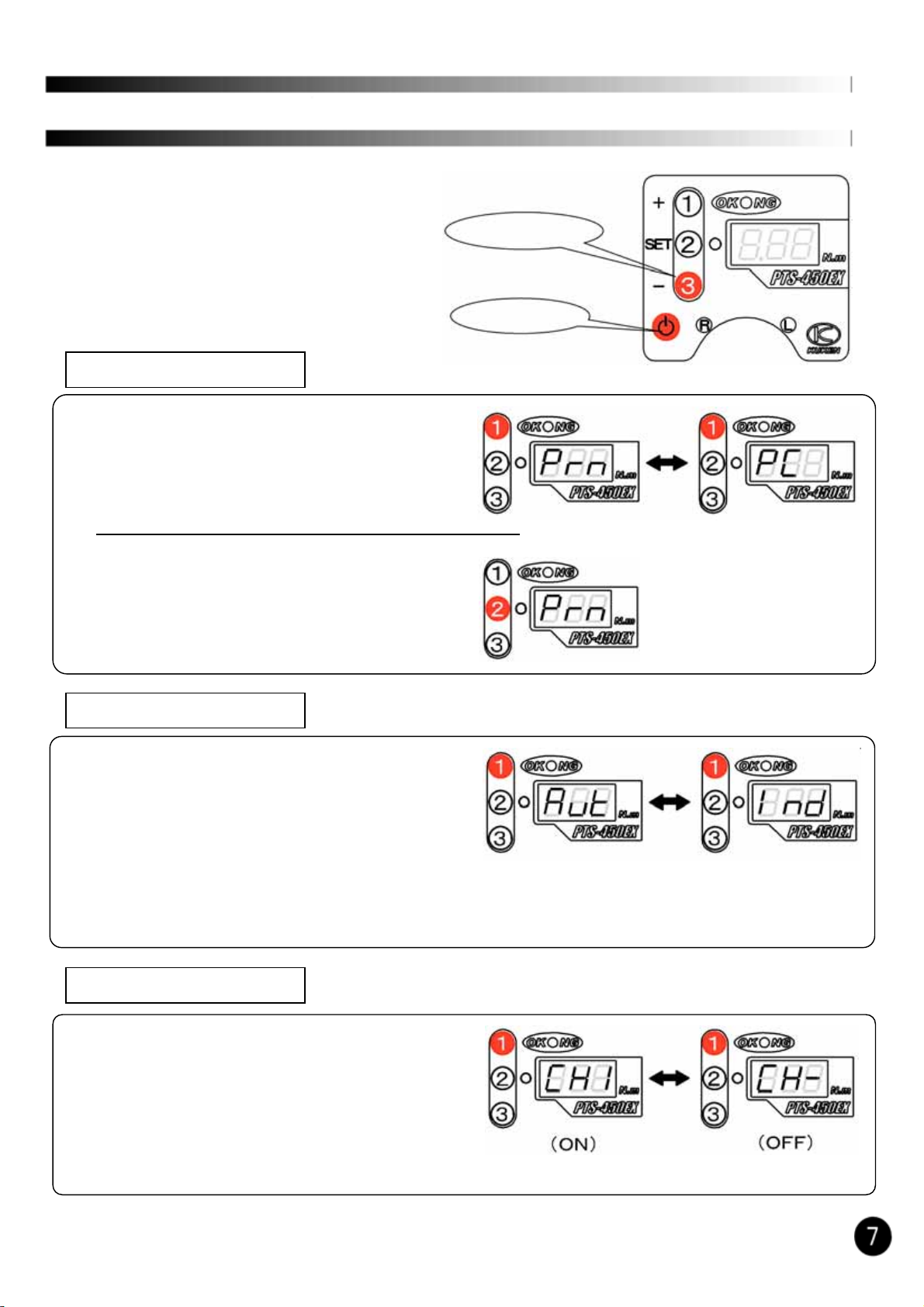

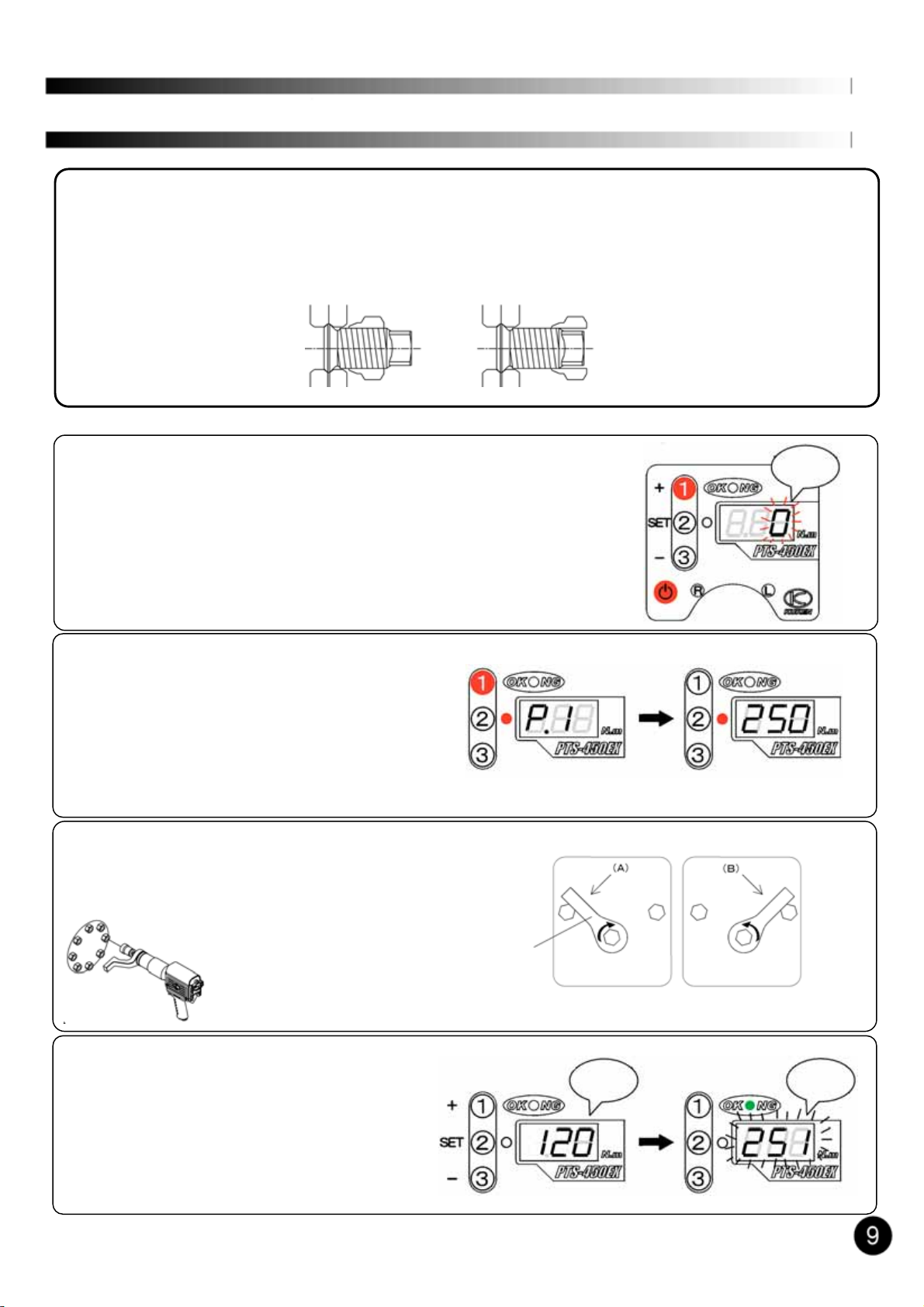

① PRE-SETFUNCTIONS

3differenttorquescanbesetandstored(Pre-settorques).

Incaseofpre-tighteningandfinal-tighteningworks,thetoolcanbeusedforvariousworks.

② AUTO-STARTandAUTO-POWEROFF

Bypressingthethrottlelever,theCPUstartsautomatically.

Ifnotoperatingforacertainperiodoftime,thepowerwillbeturnedoffautomatically.

③ REALTIMEDISPLAY

Thetorquecanbeshownonthepanelinrealtimeandeasytounderstandthesituation.

④ LOOSENINGFUNCTION

AUTOMOTIVEMODEandINDUSTRIALMODEcanbeselectedforlooseningoperations.

⑤ JUDGMENTLAMP

Thefasteningresultcanbejudgediftheoperationissuccessfulornot.

Iftheoperationissuccessfullycompleted,thejudgmentlampturnsgreen.

Iftheoperationissuspendedorstopped,theNGlampturnsandalertitsunder-torque.

⑥ AUTOSHUTOFF

Thesolenoidvalveshutsoffandstopsthemachinewhentheoperationiscompletedsuccessfully

andthejudgmentlampturnsgreen.

① FailSafeFunction

Incasebatteriesareexhaustedorverylow,theCPUwillnotbeoperatedandthespindleturns

veryslowlytoreversedirection.

Operatorscaneasilyrecognizethetrouble.

② ErrorDetectionFunction,AbnormalFasteningDetection[CH1]

Thisfunctiondetectsboltstretchingbeforehandandforcestostopthemachine.

Thisfunctioncanbeturnedon/offdependingonworks.

③ FunctiontoPreventOperationalError

Thisfunctionistopreventanoperationalerror.Ifthekeywhichisset[---]selectedby

mistake,itwillneverbeactivated.

① PowerSource

CPUisoperatedbybatteriesandbatteries.

Pleaseuse4ofAAdrycellbatteries.Alkaline(recommended)andalsoNi-MHisavailable.

② DataTransmission(Option)

PTScanbeconnectedtoacomputerortheprinter(option)withtheoriginal

transmissioncable(option)totransferresults.

PTSmustbethetransmissionmodel(option)inordertotransferdata.

UniqueFunctions

AdditionalFunctions

SafetyFunctions

OtherFunctions