2Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com To order parts and supplies: 800.345.1178 >> eastwood.com 3

STAPLE SELECTION

• FLAT STAPLES are best for smaller cracks in rigid plastics and bridging tears in flexible

plastics or pulling together pre-stressed, difficult to close cracks.

• WAVE STAPLES are best for larger, longer cracks and complete breaks in rigid plastic.

• CORNER STAPLES are excellent for reinforcing cracks at inside corners, curved areas and

other complex shapes where a Flat or Wave Staple will not fit.

MAKING REPAIRS

• Plug the power cord into a 120V AC, 60Hz grounded

outlet.

• Switch the main Power Switch on the side of the

Power Unit to the “On” position.

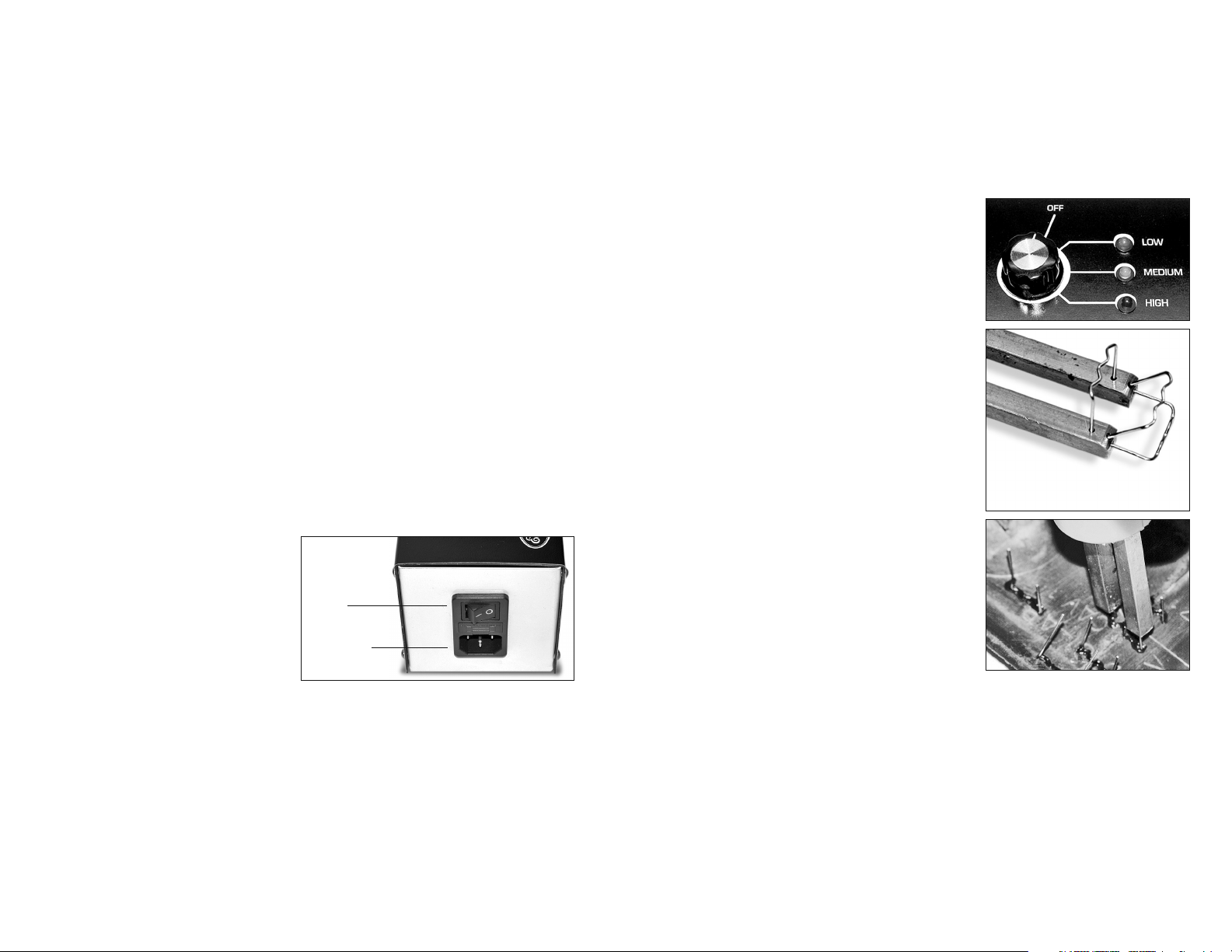

• Set the Temperature knob to suit the material being

repaired (FIG 2). NOTE: Testing on a scrap piece of

similar material is advisable to determine the correct

heat setting.

- “Low” for thinner and softer plastics.

- “Medium” for thicker and semi-rigid plastics.

- “High” for thick and hard plastics.

• Place the desired staple configuration into one of

three hole locations in the Contact Prongs, choosing

the hole location that provides the best access to the

damage (FIG 3).

• Press and hold the Heat Button on the Staple Gun for

10 seconds allowing the Staple to achieve full heat.

• Carefully press the heated staple gently into the

plastic keeping the staple parallel and square to the

surface (FIG 4) while continuing to hold the Heat

Button.

CAUTION: On thinner and softer materials, it is very easy

to burn through to the outer surface, do not use excessive

force. NOTE: On harder and thicker materials only, it may

be helpful to slightly “twist” the staple into the material.

•

When the Staple is satisfactorily burrowed into the material, release the Heat Button, wait several

seconds to allow the molten plastic to firm up then withdraw the Staple Gun from the Staple.

• NOTE: For longer cracks, it is best to start on the open end and work toward the unbroken

area. Place staples at approx. 1” apart, filling with additional staples if required. For complete

breaks, start at the ends of the break and work toward the center alternating sides as you go.

Place staples at approx. 1” apart, filling with additional staples if required.

• When done, the Staple legs can be cut off with side cutters then ground down to the repaired

surface area. CAUTION: Wear appropriate eye protection. If not grinding away remainders of

legs, exercise care when handling part to avoid scratches and cuts from sharp cut staple legs.

The EASTWOOD HOT STAPLER is a precision engineered, professional plastic repair system designed

to create solid, permanent repairs of breaks, cracks and tears in rigid and flexible plastic parts. Repair

bumper covers, door panels, consoles, plastic toolboxes, housings and more all with one convenient,

fully equipped kit. A three-level heat setting feature enables strong repairs in virtually any plastic

material, hardness or thickness. Just plug it in and go.

WARNINGS

• BURN HAZARD! This tool generates high heat in the dual prong and staple area which can

exceed 400°F. Use extreme caution when mounting staples and never touch dual prongs or

staples when switch is on. Allow sufficient time for cooling before touching repaired area.

• Wear appropriate, heat resistant work gloves and protective clothing

• Wear appropriate eye protection.

• Use in a well ventilated area and avoid breathing fumes from melted plastic.

• Do not use on or near flammable materials.

• Keep away from wet or damp areas.

INCLUDES

• (1) Hot Staple Gun.

• (1) Power Unit.

• (1) Power Cord.

• (100) #13650A, 0.8mm Heavy Duty, “Flat” Stainless Steel Staples.

• (100) #13650B, 0.8mm Heavy Duty, “Wave” Stainless Steel Staples.

• (100) #13650C, 0.8mm Heavy Duty, “Corner” Stainless Steel Staples.

• (1) Storage Case.

ASSEMBLY

• Plug the 6’ Power Cord into the

receptacle on the switch side of

the Power Unit (FIG 1).

PREPARATION

• Always clean the plastic part surface being repaired of any grease, dirt, film or other

contaminates before beginning.

• Support the part being repaired with all pieces or cracks in the original configuration. Clamping

or “blocking” parts into place may be helpful. Modeling clay or putty can be used to support

irregular shaped parts.

• Plan your work before beginning, deciding which type of staple will work best on specific

damage. If possible, test operation on a scrap piece of similar material.

Fig. 1

Power

Switch

Power Cord

Receptacle

Fig. 2

Photo to illustrate location purposes

only – only load one staple at a time

Fig. 3

Fig. 4