IMPORTANT SAFETY INSTRUCTIONS

CAUTION - To reduce risk of electrical shock or electrocution:

- Do not disassemble. Do not attempt repairs or modications. Refer to qualied service agencies

for all service and repairs.

- Do not use this product in an area where it can fall or be pulled into water or other liquids.

- Do not reach for this product if it has fallen into liquid.

- Use this compressor with 12-Volt (P/N 15010) or 24-Volt (P/N 15018) DC systems only.

- This product should not be left unattended during use.

WARNING - To prevent injuries:

- Never allow children to operate this compressor. Close supervision is necessary when this

compressor is being used near children.

- This compressor will become very hot during and immediately after use. Do not touch any part of this

compressor with bare hands other than the ON/OFF switch during and immediately after use.

- Do not use this product near ames or explosive materials or where aerosol products are being used.

- Do not operate this product where oxygen is being administered.

- Do not pump anything other than atmospheric air.

- Never use this product while sleepy or drowsy.

- Do not use any tools or attachments without rst determining maximum air pressure for that

tool or attachment.

- Never point any air nozzle or air sprayer toward another person or any part of the body.

- This air compressor is equipped with an Automatic Reset Thermal Protector, and can automatically

restart after the thermal protector resets. Always cut o power source when thermal protector

becomes activated.

- Wear safety glasses or goggles when operating this product.

- Use only in well ventilated areas.

INSTALLATION

Please read and follow the Installation Instructions carefully to avoid injury or damage to the

compressor and your vehicle.

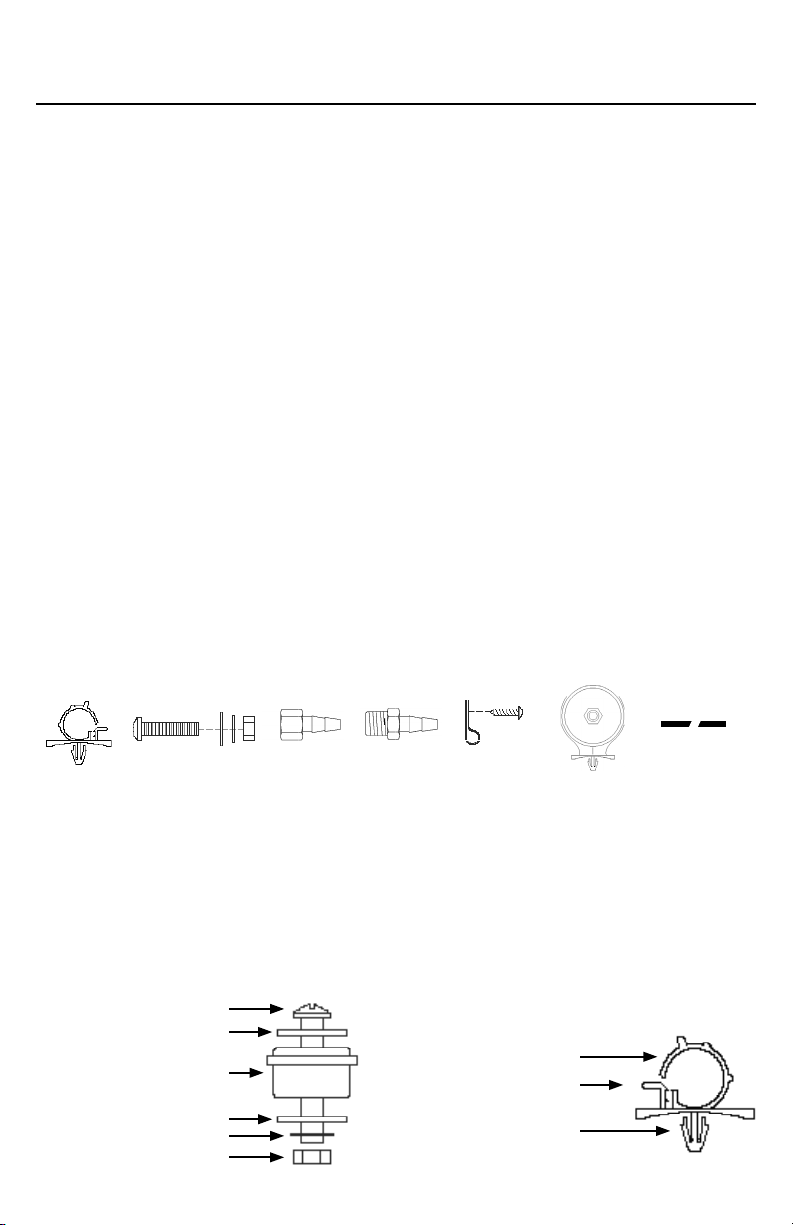

Each air compressor has been carefully produced and packaged. Before installation, please

familiarize yourself with Installation Parts List (Fig. 1) of this manual.

Guidelines for Selecting Mounting Location:

The selection of proper mounting location for your air compressor will help ensure a long and trouble

free compressor service life. Please note the following guidelines:

1. Select a FLAT, UPRIGHT AND SECURE location where the compressor can be mounted.

2. To maximize air compressor performance, locate compressor as CLOSE TO THE BATTERY as

possible so that length of positive lead wire required is at a minimum.

3. Choose mounting location that is as cool as possible and AWAY FROM HEAT SOURCES.

The cooler the ambient temperature, the less chance the compressor will overheat.

4. This compressor is moisture & splash resistant, but NOT WATERPROOF. Do not mount

compressor in locations where the unit is likely to come in contact with water.

5. For compressors with remote lter mounting, select compressor’s mounting location where air line

can be routed from compressor air inlet to remote inlet air lter. Make sure Remote Inlet Air Filters

are located in dry locations, away from water sources.

6. Select compressor’s mounting location where the leader hose bracket can be mounted to secure

the stainless steel braided leader hose.

7. If it is necessary to mount the air compressor further away from the battery, such as inside your

vehicle or in the bed of your pickup, use a larger gauge positive lead wire for remote installation.

Refer to the recommended wire gauge guide on the back of this manual.

8. Do not mount compressor near areas where ammable liquids are stored.

9. Use thread sealant for proper tting installation. Thread tape is not recommended.

Properly sealed, recommended torque is 12 to 15 ft. lbs

USER MANUAL

150C-IG COMPRESSOR KIT