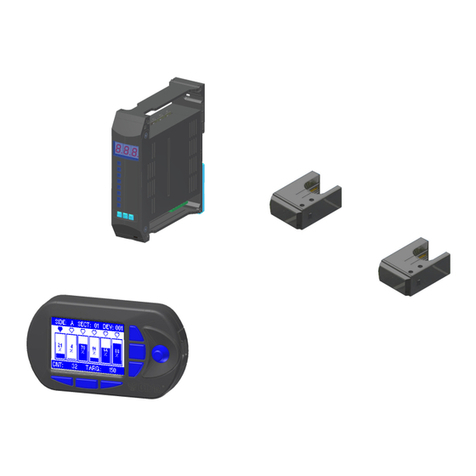

btsr MATRIX CUBE User manual

Other btsr Control System manuals

btsr

btsr SMART KTF 2000 User manual

btsr

btsr SMART 200 MTC User manual

btsr

btsr MULTIFEEDER User manual

btsr

btsr SMART WARP User manual

btsr

btsr IS3 User manual

btsr

btsr DIAPERFEEDER IP54 DUOLOOP User manual

btsr

btsr SMART WARP User manual

btsr

btsr SMART CLEARER User manual

btsr

btsr IS3 User manual

btsr

btsr SMART 200 TTS User manual

btsr

btsr SMART MATRIX QUILT User manual

btsr

btsr TS5 Series User manual

btsr

btsr WINDINGFEEDER User manual

btsr

btsr SMART MATRIX WINDINGFEEDER User manual

btsr

btsr ULTRAFEEDER User manual

btsr

btsr SMART MATRIX MTC User manual

btsr

btsr SMART MATRIX TWIST User manual

btsr

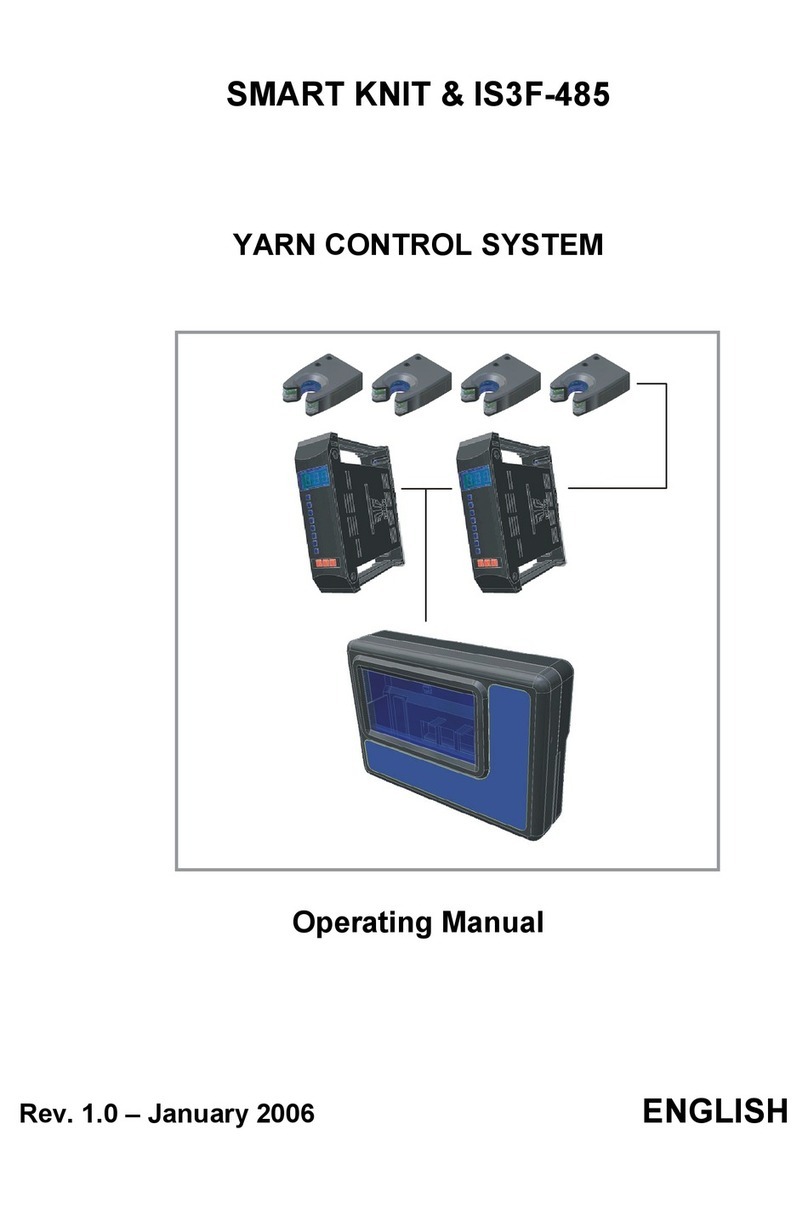

btsr SMART KNIT User manual

btsr

btsr SMART 3000TW User manual

Popular Control System manuals by other brands

Zonex

Zonex GEN II -VVT Installation and application manual

Altronics

Altronics K 9650 quick start guide

micro-trak

micro-trak RoadMaster Reference manual

micro-trak

micro-trak Calc-An-Acre II Reference manual

EMKO

EMKO TRANS-SYNCRO user manual

Dover

Dover TWG GC ELEMENT II Calibration and Troubleshooting Manual