65-2422RK-05 H2S Transmitter • 5

If the H2S detector is mounted to the junction box, skip to step 5. If not, continue with

step 2.

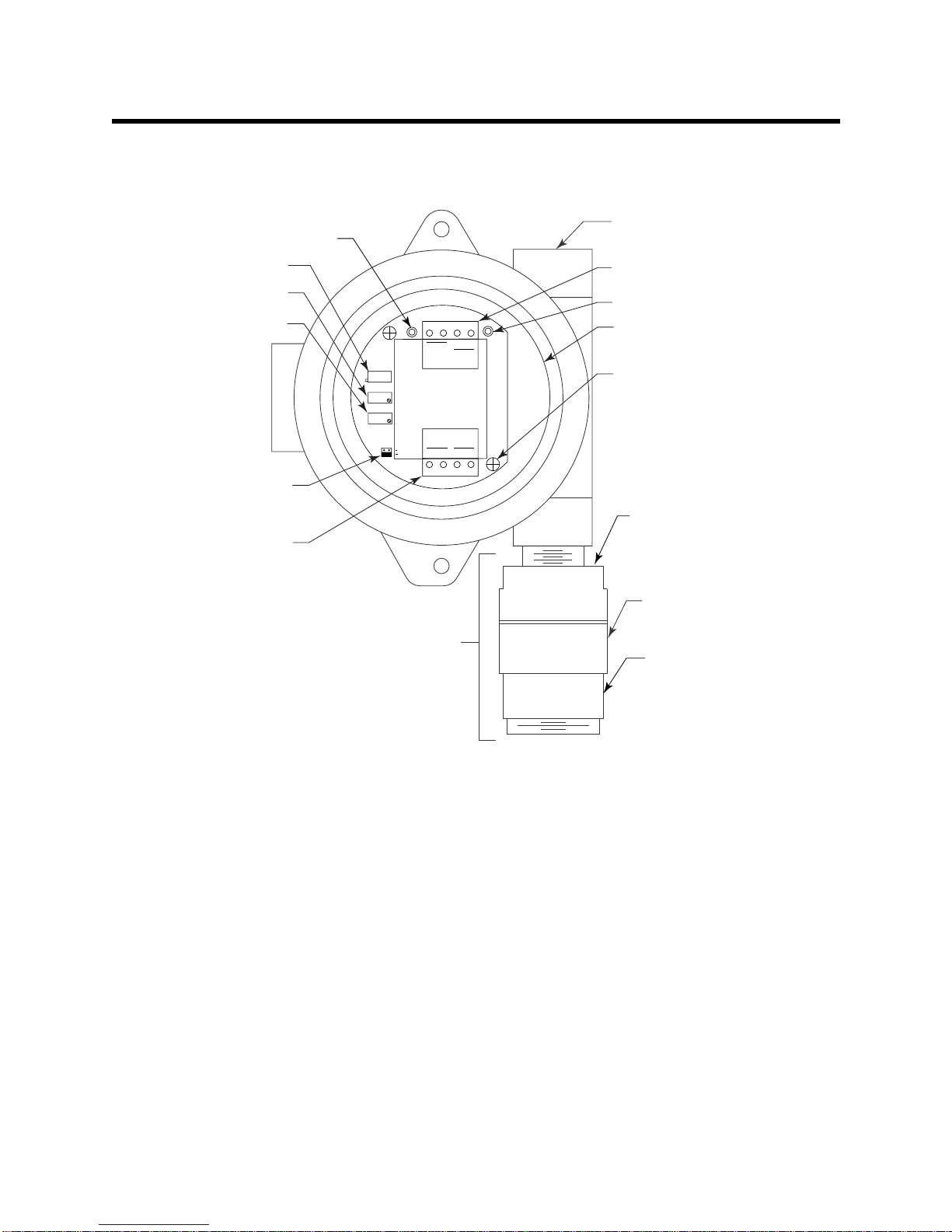

NOTE: The H2S detector is normally provided with a Killark HKB junction box and an

HFC lid rated explosion proof for Class I, Groups B, C, and D. This combination

is shown in Figure 2 above. Any junction box with an internal volume less than

or equal to 69 cubic inches and rated explosion proof for ClassI, Groups B, C, and

D may be used.

2. Remove the junction box cover.

3. Guide the two wires that extend from the top of the H2S detector through the bottom

conduit hub of the junction box.

4. Screw the H2S detector into the bottom conduit hub of the junction box.

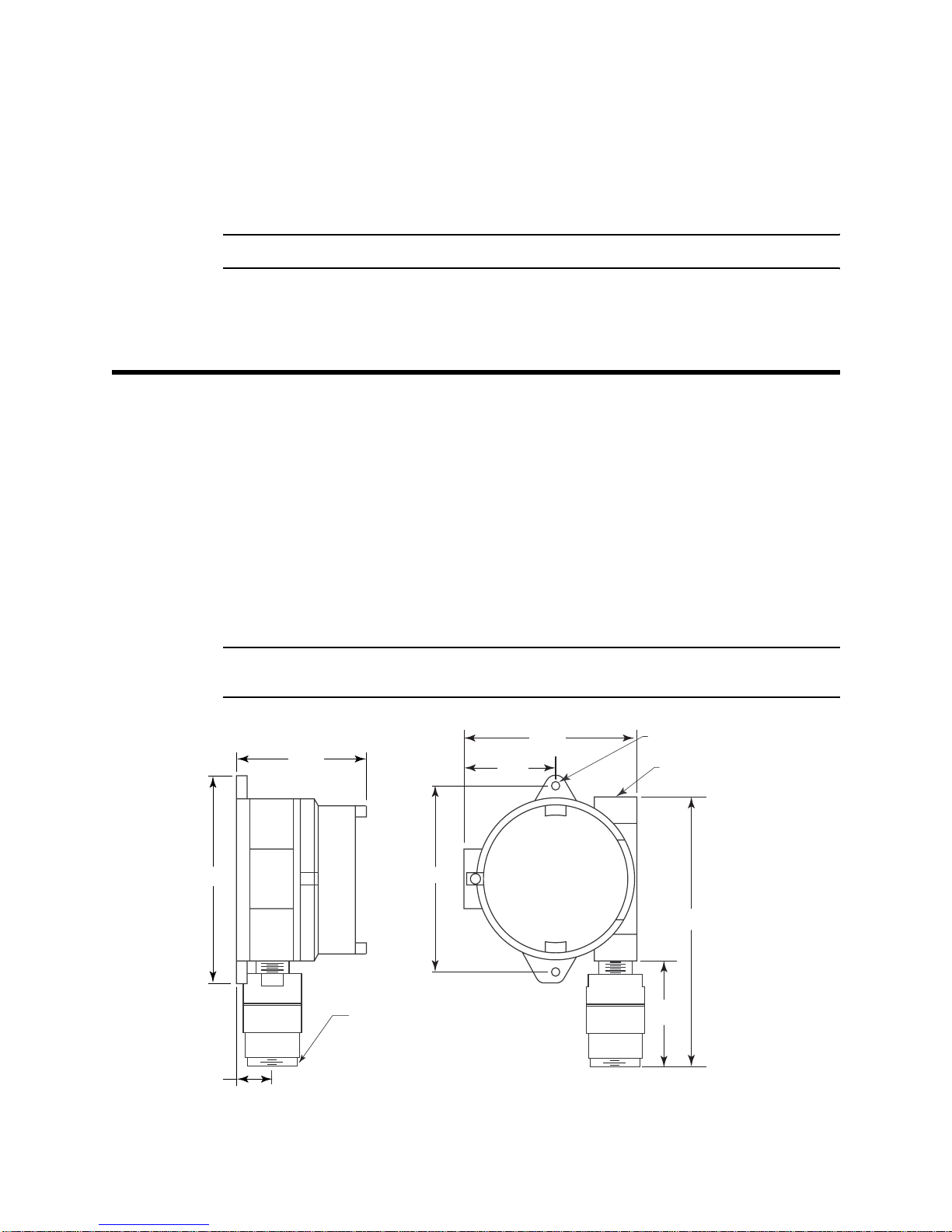

5. At the monitoring site, use #10 screws through the junction box’s two mounting holes

to secure the junction box to a vertical surface.

CAUTION: Mount the H2S transmitter with the detector facing down (see Figure 2).

Wiring the H2S Transmitter to a Controller

WARNING: Always verify that the power source is OFF before you make wiring

connections.

1. Turn off the controller.

2. Turn off or unplug incoming power at the controller.

3. Remove the junction box cover.

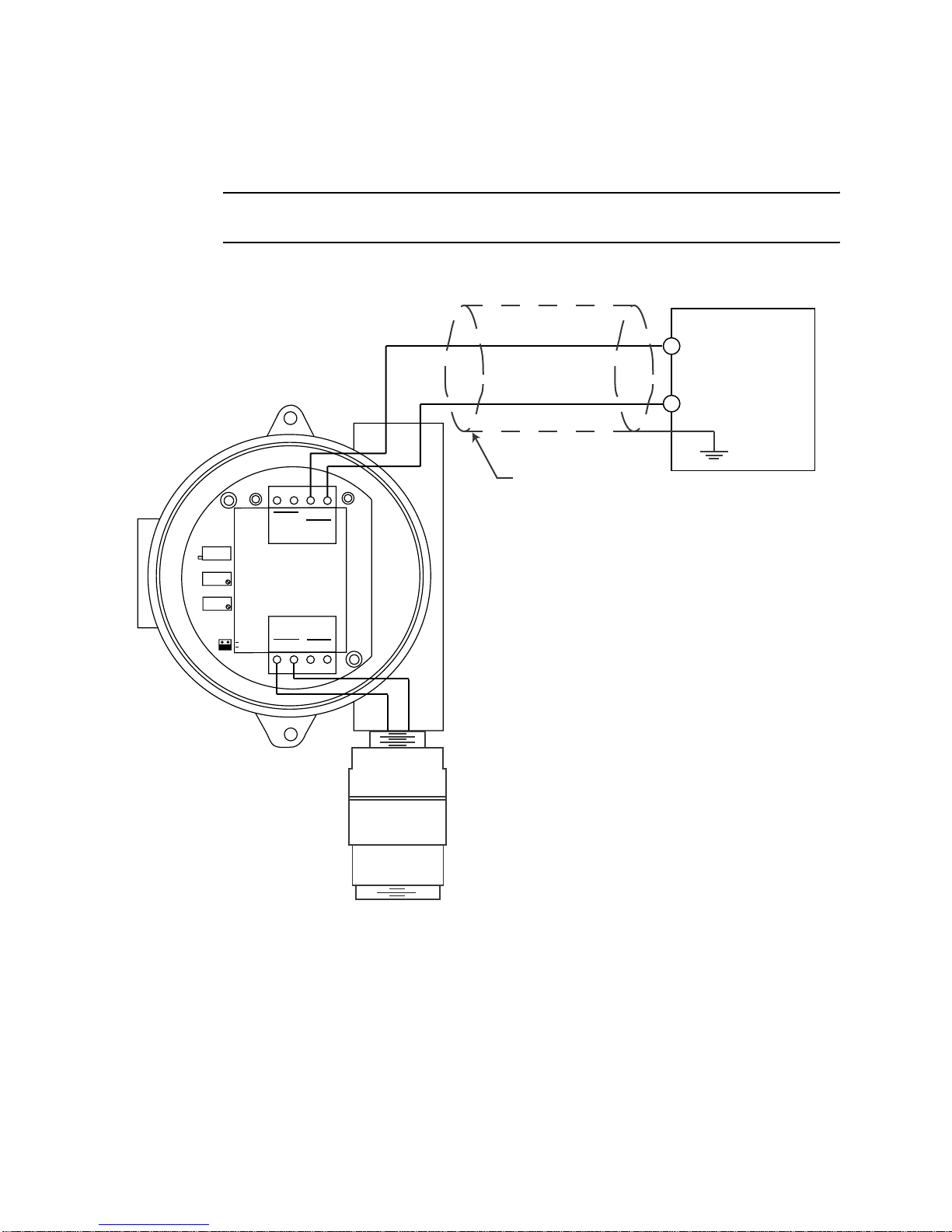

4. Verify that the detector leads are wired to the amplifier’s detector terminal strip.

If necessary, connect the detector leads to the detector terminal strip as shown in

Figure 3.

5. Verify that the jumper block is installed over the TOXIC selector of the amplifier type

selector as shown in Figure 3.

6. Guide a two-conductor, shielded cable or two wires in conduit through the top

conduit hub of the junction box.

WARNING: To maintain the explosion proof classification of the H2S detector/junction

box combination, a conduit seal must be used within 18 inches of the

junction box conduit hub used for wiring to the controller.

7. Connect the two wires to the interconnect terminal strip as follows (see Figure 3).

• Connect the positive wire to the terminal labeled 24V +.

• Connect the feedback wire to the terminal labeled 4/20 FB.

CAUTION: If using shielded cable, leave the drain wire insulated and disconnected at the

transmitter. You will connect the opposite end of the cable’s drain wire at the

controller.