RLH Industries T1 Mux User manual

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 1

2 Channel T1 Mux!

DIN Fiber Link System

SYSTEM INSTALLATION INFORMATION

Description

The T1 Multiplexer (or Fiber Mux System) transports up to two T1

lines over two strands of fiber. It has B8ZS and AMI compatibility,

with LED status indicators for system monitoring, alarm and dual

power inputs.

It provides cost effective, high density regenerated T1 over fiber

in a compact DIN form factor. This hardened, rugged system is

covered by our Limited Lifetime Warranty.

Key Features

• Applications for critical, high voltage, remote or un-manned!

locations that must remain operating 24/7/365.

• Simplex 60mA line powered on the drop side from the T-1 span

or HDSL NIU/RT unit, eliminating costly external power !

arrangements.

• Compatible with 2 Channel T1 Fiber Link Card.

• May be powered externally with 24~56VDC 100mA local power

on dual redundant power connectors.

• Environmentally hardened to operate in -40°F to +158°F !

(-40°C to +70°C) environments.

• Accommodates up to two incoming T-1 4 wire copper lines over

one fiber pair.

• Ideal for T-1 applications where available fiber strands, enclosures

or mounting space are limited.

• The same module may be used at either end of the fiber system,

simplifying spares and ordering.

• Operates from any HDSL-1, HDSL-2 or HDSL-4 NIU/RT signal.

• RJ48C T1 connections.

• Loop back features with independent channel testing.

• Provides simultaneous multiplexing and de-multiplexing of two

asynchronous T-1 channels.

• Frame integrity LED and remote T1 channel fault LEDs.

• Compact modules are DIN rail or wall mountable.

• Can be used within or beyond customer premise!

environment.

• Covered by our Limited Lifetime Warranty

U-023 2019A-1017

Compliance Information

The RLH 2 Channel T-1 Mux DIN Fiber Link System is

compliant with the following industry standards:

•FCC PART-15

•FCC PART-68B

•IEEE-487

•IEEE-1590

•Motorola R56

•BR 876-310-100 BT (Telcordia)

•Bellcore SR-3966

•GR-1089

•GR-63

Contents

Description & Key Features !1_______________

General Safety Practices !2_________________

Application!3_____________________________

Installation !5_____________________________

Connections !6___________________________

Powering the System!6____________________

Switch Settings!7_________________________

LED Indicators!8__________________________

NIU Compatibility !10______________________

Specifications!11_________________________

Ordering Information !12___________________

Technical Support !12_____________________

The leader in!

rugged fiber optic

technology.

USER GUIDE

RLH Industries, Inc.

2 Channel T1 Mux DIN Mount Module

General safety practices

The equipment discussed in this document may require tools designed for the purpose being described.

RLH recommends that service personnel be familiar with the correct handling and use of any installation

equipment used, and follow all safety precautions including the use of protective personal equipment as

required.

Caution - Severe Shock Hazard!

• Never install during a lightning storm or where unsafe high voltages are present.

• Active T1 lines carry high DC voltages up to 56V. Use caution when handling T1 wiring.

• Active UHDSL lines carry high DC voltages up to 210V. Use caution when handling UHDSL wiring.

Warning!

The intra-building port(s) of the equipment or subassembly is suitable for connection to intrabuilding or

unexposed wiring or cabling only. The intra-building port(s) of the equipment MUST NOT be metallically

connected to interfaces that connect to the OSP or its wiring. These interfaces are designed for use as

intra-building interfaces only (Type 4 ports as described in GR-1089-CORE, Issue 4) and require isolation

from the exposed OSP cabling. The addition of Primary Protectors is not sufficient protection in order to

connect these interfaces metallically to OSP wiring.

Guidelines for handling terminated fiber cable

• Do not bend fiber cable sharply. Use gradual and smooth bends to avoid damaging glass fiber.

• Keep dust caps on fiber optic connectors at all times when disconnected.

• Do not remove dust caps from unused fiber.

• Keep fiber ends and fiber connectors clean and free from dust, dirt and debris. Contamination will cause signal loss.

• Do not touch fiber ends.

• Store excess fiber on housing spools or fiber spools at site

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 2

Application

The 2 Channel T1 Mux combines up to two incoming DS1 data signals at 1.544Mbps, and optically

transmits this signal over fiber optic cable to the module at the opposite end, which converts the signals

back into the original DS1 signals at regenerated DS1 levels.

Below are sample system diagrams illustrating typical T1 connections to and from the system. The 2x1 T1

Mux system may be powered by a single T1 line carrying span power, or optionally by a local power

source on the CO side. The SUB side requires a local power source for operation.

2 Channel T1 System Diagram

"

Central

Office /

Switch

HDSL/T1 NIU

with 60mA Span

Through Power

Line Powered Line Powered

CO Side SUB Side

CFJ

CFJ

Local Powered

22-56VDC

Power

Supply

CPE

4-Wire

Copper T1

Requires only 1

line to power

HDSL/T1 Span

Requires only 1

line to power

Fiber Optic

Cable

4-Wire

Copper T1

RXTX

RX TX

Central

Office /

Switch

Line Powered

CO Side SUB Side

Local Powered Local Powered

T1 NIU

Smartjack

4-Wire Copper

T1 Span

Fiber Optic

Cable

4-Wire

Copper T1

RXTX

RX TX

22-56VDC

Power

Supply

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 3

The CO side

The 2 Channel T1 Mux DIN Fiber Link system provides the interface between one or two Telco Central

Office T-1 copper 4-wire lines over two strands of fiber optic cable.

The SUB Side

The 2 Channel T1 Mux DIN Fiber Link system provides the interface between one or two Subscriber side

(SUB) equipment T-1 copper 4-wire lines over two strands of fiber optic cable. The SUB side permits the

use of the alarm feature which monitors all system functions, and may use dual power inputs for

redundant powering.

!

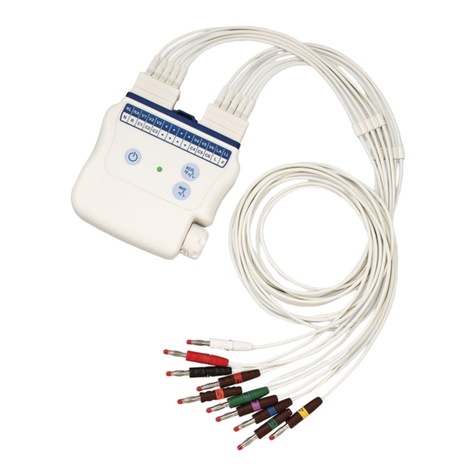

Front Panel Layout

CH2 CH1

CH2 CH1

FRM ALARM (Y)

FIBR FRM (G)

RLH Industries, Inc.

BPV

ON

CH2

CH1

SYS DC OK

REM CH

ALARM

LLOOP

RLOOP

B8ZS/AMI

6

5

4

SW1 SW2

T1

TX

RX

CH1

PWR2PWR1

P/N 2TD-XX-1

ACTIVE (G)

AIS (R)

ON

ALARM

FIBER

CH1

CH2

LBO-15

LBO-7.5

LBO-7.5

LBO-15

NOT USED

LLOOP

RLOOP

B8ZS/AMI

3

2

1

CH2

1 2 3 4 5 6

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

T1 FIBER

MUX

Local Power and alarm contact!

Connection Terminal

Power Indicators

Remote Channel Alarm Indicator

Line Buildout

Attenuation Switches

Alarm Contact Enable Switch

T1 Line Connectors

Local Loopback, Remote

Loopback and B8ZS/AMI

Switches

Fiber Optic !

Connectors

Fiber Optic Receive FrameValid !

& Frame Alarm Indicator

Receive BPV!

(Bipolar Violation) detection

DS1 signal detection and Re-

ceive AIS (Alarm Indication

Signal) detection

Ground Screw

Ground Screw

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 4

Installation

Prior to installation:

• Check for shipping damage

• Check the contents to ensure correct model and fiber type

• Have a clean, dry installation environment ready

• Ensure that the fiber type at the site matches the system type

If damage is discovered file a claim immediately with the carrier, then contact RLH customer service.

Required for installation:

•24-56VDC (60mA@24VDC minimum) line or local power source at the TX side.

•24-56VDC (60mA@24VDC minimum) line or local power source at the RX side.

•Suitable wall or DIN rail space

•Active T1 line

•T1 Analyzer (T-BERD)

•Multimeter

Measure power source

Measure the DC voltage of the source power to ensure that it is 24-56VDC. All electrical and fiber optic

connection are made directly into the module. The 2 Channel T1 Mux DIN Fiber Link system is designed

to be installed onto any standard DIN rail, plugged in and ready to transmit.

DIN rail mounting

To install the module onto the provided DIN rail, hook the mounting clip over the bottom part of the rail

flange first, then rotate and snap the clip onto the top rail flange. To remove, lift up on the module and

disengage the top of the DIN rail clip first.!

!

DIN Rail Mounting#

DIN Rail

DIN Rail

2 Ch. T1

2 Ch. T1

Hook bottom of

DIN clip first

Rotate and snap into position

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 5

Connections

Connect fiber optic cable

DIN Fiber Link systems are equipped with two optical connectors. Connect the fiber to the Transmit and

Receive fiber connectors. The transmit port is marked TX, and the receiver port is marked RX. Verify that

the TX fiber at one module is connected to the RX port on the opposite end. Connecting TX to TX will not

function properly.

Fiber cables should be routed loosely avoiding tight bends to prevent excessive optical loss.

Connect copper T1 send and receive pairs

The T-1 pairs from the Telco connect to the RJ-45C connectors on the face face of the module.

Note: At the CO side, the 2 Channel T1 Mux DIN Fiber Link system is designed to operate on standard

T-1 lines that are current limited at 60mA. Open circuit voltage on T-1 lines can vary from 30V to

130V across send and receive pairs depending on the number of repeaters in the line. However,

voltage across the module when operating will be 30VDC or less.

RJ Connector Pinout Diagram

Optional connection - Ground wire

Ground wire attachment screws are located on both the top and the bottom of the housing. Ground the

system appropriately for the application.

Powering the System

Powering at the CO end

Typically, the CO module is span powered by a single 60mA simplex current sources derived from the T1

Telco Span Transmit and Receive copper pairs. A single simplex current source will support both T1

channels.

Note: Alarm function requires 24-56VDC 100mA power source. (Turn SW2 ALARM off if line powered.)

The CO side module may also be powered externally by connecting a 24-56VDC 100mA power source to

the power terminal on the top of the unit. There are 2 power inputs and either or both may be used for a

redundant power system. The 2 Channel T1 Mux DIN Fiber Link system iss polarity insensitive to all

electrical connections.

RJ-45 Port

1 RX (Input)

5 TX (Output)

2 RX (Input)

6 NC

3 NC

7 NC

4 TX (Output)

8 NC

PIN 8

PIN 1

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 6

Powering at the SUB end

To span power the SUB side module you must have a minimum of one 60mA simplex current source on

the T-1 Send and Receive pairs on a working circuit.

For remote power, connect a 24-56VDC 100mA power source to the power terminal on the top of the

unit. There are 2 power inputs and either or both may be used for a redundant power system. The 2

Channel T1 Mux DIN Fiber Link system is polarity insensitive to all electrical connections.

Note:!The CO and SUB units must be powered by separate isolated power sources to maintain high

voltage protection characteristics.

T-1 Surge Protection

Thermistors, and Sidactors limit transients appearing between the Tip and Ring of each pair. Transients

appearing at the power terminals or between input and output pairs are limited by PTC thermistors and a

metal oxide varistor.

Switch Settings

B8ZS or AMI Encoding

The B8ZS/AMI DIP switch is used to establish the selection of B8ZS (bit 8 zero substitution) or AMI

(alternate mark inversion) line encoding for each of the T-1 inputs.

Remote Loopback

The remote (RLOOP) loopback DIP switches are provided to allow for remote loop back of each of the T-1

channels for trouble shooting purposes.

The loop back function begins at the T-1 receive twisted pair, through the T-1 LIU (Line Interface Unit), and

then back out the T-1 transmit twisted pair. Normal operating position is OFF for All switch positions.

RLOOP (Remote Loopback) Switch Diagram

Signal Loop

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

OUT

IN

RX

TX

RX

RX

TX

TX

CO Side Module

(Remote Side)

SUB Side Module

(Local Side)

T-1 TEST

EQUIPMENT

Fiber

SW1

CH2

CH1

ON

SW1

CH2

CH1

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

•Turn on RLOOP switch to

check copper wire connection!

• CH 1 shown in ON position

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

OUT

IN

RX

TX

RX

RX

TX

TX

CO Side Module

(Remote Side)

SUB Side Module

(Local Side)

T-1 TEST

EQUIPMENT

Fiber

SW1

CH2

CH1

ON

SW1

CH2

CH1

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 7

Local Loopback

The local (LLOOP) loopback DIP switch is provided to allow for local loop back of each of the T-1 lines for

troubleshooting purposes.

The loop back function begins with the 2 Channel T-1 transmitter data coming from the remote side

module, through the fiber cable to the local side, then back out through the fiber cable to the remote side.

Normal operating position is OFF for All switch positions.

LLOOP (Local Loopback) Switch Diagram

Note: The LEDs will indicate the matching conditions upon detection of errors or alarms. The LEDs will

remain ON until the error condition has been removed.

Line Build Out

The Line Build Out switches simulate cable loss of the signal for compatibility with different installation

scenarios. There are 2 switches corresponding to -7.5dB and -15dB attenuation levels. Select a level

appropriate for your particular application by setting one of the switches to the ON position.

Only one switch may set to ON at a time. The default position is 0 set to OFF, -7.5 and -15 set to OFF.

!

LED Indicators

Remote Channel Alarm

The REM CH ALARM (yellow) LED indicates that the far end unit has detected a loss of fiber signal, BPV,

or AIS fault condition from one of its T-1 LIUs.

Fiber Optic Receive Frame Valid / Frame Alarm

The FIBR FRM (green) LED will remain ON as long as the fiber optic receiver stays in frame with the far

end 2 Channel T1 Mux DIN Fiber Link. Only if there is a problem with the receive frame does the green

LED turn yellow. When this LED does turn yellow then both of the system end units will begin a system

resynchronization. This resynchronization requires about ten milliseconds to accomplish.

The LED is continuously ON if the local receiver cannot detect receive frame from the fiber. The loss of the

far end receive frame will cause this LED to blink on and off.

OUT

IN

RX

TX

RX

RX

TX

TX

CO Side Module

(Remote Side)

SUB Side Module

(Local Side)

T-1 TEST

EQUIPMENT

Fiber

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

SW1

CH2

CH1

ON

SW1

CH2

CH1

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

Signal Loop

•Turn on LLOOP switch to

have fiber loop back or to

check for fiber connection.!

• CH 1 shown in ON position

OUT

IN

RX

TX

RX

RX

TX

TX

CO Side Module

(Remote Side)

SUB Side Module

(Local Side)

T-1 TEST

EQUIPMENT

Fiber

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

LLOOP

RLOOP

B8ZS/AMI

SW1

CH2

CH1

ON

SW1

CH2

CH1

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 8

Alarm Contact Connection Terminal

The alarm terminal has 3 corresponding terminals (common, normally closed and normally open). System

is ok when the output on the relay is normally open.

Power Indicator

The PWR1 and PWR2 (green) LED will be ON when acceptable power is detected at the fiber ink. Span

power or a local power source can provide enough power for the system. When the power LED is off, the

system is not detecting enough power to operate.

T1 Activity

The ACTIVE (green) LED will be ON when a valid DS1 signal is detected at the RJ connector.

Alarm Indication Signal

The AIS alarm (red) LED will be ON whenever a series of unframed all-ones are received at the input of

any of the T-1 LIUs. This alarm indicates that equipment down the line from the T1 receiver has detected

a loss of signal and is transmitting an unframed all-ones alarm signal.

Bipolar Violation

The BPV alarm (yellow) LED will be looking for any bipolar violations at the receive T1 LIU. The LED will

remain ON for a visible period per detected event. BPV detection can indicate loss of line integrity at the

receiver. It should be noted that if the transmitting equipment is using encoded B8ZS, and the 2x1 MUX

module is configured for AMI, the channel BPV alarm LED will turn ON.

CH2 CH1

CH2 CH1

FRM ALARM (Y)

FIBR FRM (G)

RLH Industries, Inc.

BPV

ON

CH2

CH1

SYS DC OK

REM CH

ALARM

LLOOP

RLOOP

B8ZS/AMI

6

5

4

SW1 SW2

T1

TX

RX

CH1

PWR2PWR1

P/N 2TD-XX-1

ACTIVE (G)

AIS (R)

ON

ALARM

FIBER

CH1

CH2

LBO-15

LBO-7.5

LBO-7.5

LBO-15

NOT USED

LLOOP

RLOOP

B8ZS/AMI

3

2

1

CH2

1 2 3 4 5 6

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

T1 FIBER

MUX

2 Channel T1 LED Indicators

Note Bi-color LEDs

CH2 CH1

CH2 CH1

FRM ALARM (Y)

FIBR FRM (G)

RLH Industries, Inc.

BPV

ON

CH2

CH1

SYS DC OK

REM CH

ALARM

LLOOP

RLOOP

B8ZS/AMI

6

5

4

SW1 SW2

T1

TX

RX

CH1

PWR2PWR1

P/N 2TD-XX-1

ACTIVE (G)

AIS (R)

ON

ALARM

FIBER

CH1

CH2

LBO-15

LBO-7.5

LBO-7.5

LBO-15

NOT USED

LLOOP

RLOOP

B8ZS/AMI

3

2

1

CH2

1 2 3 4 5 6

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

T1 FIBER

MUX

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 9

NIU Compatibility

Check for compatible NIU systems that supply Span Through-Power to the 2 Channel T-1 Fiber Link

Cards. Contact RLH for T-1 compatibility with systems not listed.

NIU

NIU

Card

Part

Number

HDSL/T1 Span Through Power NIU Compatibility Chart

Manufacturer

Part Number

Description and Material ID

CLEI Code

HDSL1

Adtran

1246026L4

T200 HTU-R (VZ# 594993)

T1L2C8J8AA

Adtran

1246026L5

T200 HTU-R (BST# 98001580)

T1L3KD5AAA

Adtran

1245024L1

T400 HTU-R

T1L2C8J8AA

Adtran

1247026L1

T200 HTU-R,

ADC

SPX-HLXRD11

T400 HLXR

SND1FJRAAA

HDSL2

Adtran

1223024L1

H2TU-R (VZ# 11018736)

T1L6VR8B_ _

HDSL4

Adtran

1223424L1

H4TU-R (VZ# 11018731)

T1L6EYHB_ _

Repeated T1

Adtran

1181315L1-5B

T1 NIU, Total Access

T1L3PU0A

Hyperedge

520-10-SWI3

T200 T1 NIU (BST# 300058336)

Westell

DNI5760LNI3

T1 NIU (VZ# NCIUV9A)

NCIUV9A4AA

Westell

A90-3128-70

T1 NIU (VZ# T1L3P96)

T1L3P96CAA

Westell

A90-3115-31

T1 NIU (VZ# T1S1AEF)

T1S1AEFAAA

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 10

General Specifications

Transmission method

Amplitude modulated light via two optical fibers

Multimode:

850nm (Tx level: -16dB ± 1dB)

Single-mode:

1310nm (Tx level: -23dB ± 1dB)

Single-mode Long Haul:

1310nm (Tx level: -8dB ± 2dB)

Maximum Fiber Attenuation /

Distance *

Multimode:

10dB / 1.2 miles (2 km)

Single-mode:

8dB / 9 miles (15 km)!

Single-mode Long Haul:

26dB* / 37 mi. (60 km), *min. required loss -8dB

*Note: Distances equated using industry standard fiber and connector attenuation of

3dB/Km. Fiber condition, splices and connectors may affect actual range.

Fiber Type

(ST or SC connectors) Multimode: 62.5/125µm, 50/125µm!

Single-mode: 8-9/125µm

Temperature Limits

-40°F to +158°F (-40°C to +70°C + maximum solar load)

Humidity

95% non-condensing

BER

<10-9

Surge Protection

Fuses, thyristors, PTC thermistors, zeners, and MOVs

Local Power Requirement

24-56 VDC,100mA

Powering Method

60mA line power simplexed on Send and Receive pairs, or an isolated DC power

source connected to power input terminals.

Power Connector

Dual redundant power Input via removable screw down terminal block

Mounting

Standard T35 DIN rail or wall mount with included brackets

Dimensions

H5” x W1.9” x D3.9” (127mm x 48mm x 100mm) - Not including connectors

Warranty

Limited Lifetime

Visit www.fiberopticlink.com for warranty details

Value

Min.

Type

Max.

Unit

T1 Output Pulse Amplitude (FCC Part 68)

2.7

3

3.3

Volts Pk

T1 Receiver Frequency Tolerance

±130

-

-

ppm

T1 Receiver Resistance

-

100

-

Ohm

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 11

Ordering Information

Each 2 Channel T1 Card is identified with a part number.

A complete system requires 2 modules.

Please contact your RLH sales representative for pricing and delivery information.

Technical Support

!

Contact Information

!

!

Optics

Description

Distance

Fiber

Part Number

Multimode SC

CO/SUB DIN Fiber Link

2km/ 1.2 mi

62.5/50 μm

2TD-01-1

Multimode ST

CO/SUB DIN Fiber Link

2km/ 1.2 mi

62.5/50 μm

2TD-02-1

Single-mode SC

CO/SUB DIN Fiber Link

15km / 9 mi.

8~9 μm

2TD-10-1

CO/SUB DIN Fiber Link

60km / 37mi.

8~9 μm

2TD-11-1

Single-mode ST

CO/SUB DIN Fiber Link

15km / 9 mi.

8~9 μm

2TD-20-1

CO/SUB DIN Fiber Link

60km / 37mi.

8~9 μm

2TD-21-1

Email:

support@fiberopticlink.com

24/7 technical support:

Toll Free 1-855-RLH-24X7

Toll Free 1-855-754-2497

Corporate Headquarters:

RLH Industries, Inc.

936 N. Main Street

Orange, CA 92867 USA

Phone:

(714) 532-1672

Toll Free 1-800-877-1672

Toll Free 1-866-DO-FIBER!

Fax:

(714) 532-1885

Email:

info@fiberopticlink.com

Web site:

www.fiberopticlink.com

RLH Industries, Inc.

936 N. Main Street, Orange, CA 92867 USA

T: (714) 532-1672

F: (714) 532-1885

Please contact your RLH sales representative for

pricing and delivery information.

Specifications subject to change without notice.

!RLH Industries, Inc. • Tel. 866-DO-FIBER • Fax 714 532-1885 • www.fiberopticlink.com!Page 12

Table of contents

Popular Control Unit manuals by other brands

Emerson

Emerson Fisher FIELDVUE DVC6200 SIS Mounting instructions

CALEFFI

CALEFFI SATK40 Series INSTRUCTIONS FOR INSTALLATION, COMMISSIONING AND MAINTENANCE

weintek

weintek iR-PU01-P user manual

Simplex

Simplex Foundation Series Operation guide

Graco

Graco Cleanshot 244162 instructions

Skipper

Skipper SB-100-SA Installation and operation manual