3

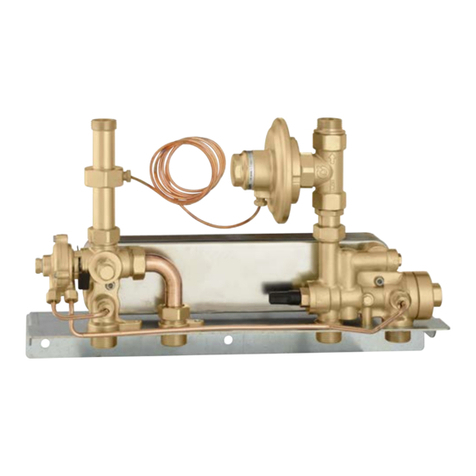

Dimensions

10

550

65282,5

15565

629

530

149 656550.5 50.5

3/4” M 3/4’’ F

SATK40103HE technical specifications

Medium: water

Maximum percentage of glycol: 30%

Maximum medium temperature: 85°C

Max. working pressure: - primary circuit: 1,6 MPa (16 bar)

- secondary circuit: 0,3 MPa (3 bar)

Nominal heat exchanger capacity: 15 kW

Maximum recommended primary circuit flow rate: 1,2 m3/h

Max. differential press. on modulating valve: Dp 150 kPa (1,5 bar)

Electric supply: 230 V (ac) ±10% 50 Hz

Maximum power consumption: 80 W

Protection class: IP 40

Pump: UPM3 15-70

Pump by-pass setting: 45 kPa (0.45 bar)

Actuators: stepper 24 V

Probes: NTC 10 k Ω

Safety relief valve setting: 0,3 MPa (3 bar)

Safety thermostat: 55°C ±3

Expansion vessel: - capacity 7 l

- pre-charge value: 0,1 MPa (1 bar)

Pressure switch: - opening 40 kPa (0,4 bar)

- closing 80 kPa (0,8 bar)

Materials

Components: brass EN12165 CW617N

Fitting pipes: steel

Frame: RAL 9010 painted steel

Protective shell cover: PPE

Heat exchanger: brazed stainless steel

Installation

The SAT series HIU is designed for installation in a protected

domestic (or similar) environment and must not therefore be

installed or used outdoors, i.e. in areas directly exposed to the

weather. Outdoor installation may cause malfunctioning and

hazards.

If the device is enclosed inside or between cabinets, sufficient

space must be provided for routine maintenance procedures.

It is recommended that electrical devices are NOT placed

underneath the HIU, as they may be damaged in the event of safety

relief valve activation if not connected to a discharge tundish, or in

the event of leaks occurring at the hydraulic fittings.

If this advice is not heeded, the manufacturer cannot be held

responsible for any resulting damage.

In the event of a malfunction, fault or incorrect operation, the device

should be deactivated; contact a qualified technician for

assistance.

Preparation

After having established the point where the appliance is to be

installed perform the following operations:

· Mark the holes required for securing the HIU to the wall

· Mark the position of the hydraulic connections

Check the measurements again and begin laying the following

lines:

Hydraulic (see page 4):

1. connection to the central system line

2. heating circuit connection

3. connection to domestic hot water storage

4. domestic cold water circuit connection (for filling)

5. conveyance of safety relief valve and charging unit backflow

preventer discharge

Electric (see page 9):

1. 230 V (ac) – 50 Hz electric supply line

2. chrono-thermostat/thermostat line (potential-free)

3. hot water storage thermostat line (live line)

4. centralised bus line for heat meter data transmission (if required)

5. centralised electric supply line for heat meter (if required)

N.B.: the wall anchors (not supplied) can only guarantee effective

support if inserted correctly (in accordance with good technical

practice) into walls built using solid or semi-solid bricks. If working

with walls built using perforated bricks or blocks, mobile dividing

panels or any masonry walls other than those indicated, a

preliminary static test must be carried out on the support system.

Heat meter installation

The HIU is designed to fit a compact heat meter (with incorporated

return probe) with 1” threaded connections and 130 mm gauge.

Before carrying out any maintenance, repair or part replacement

work, proceed as follows:

- cut off the electric supply

- remove the cover

- close the shut-off valves

- empty the HIU using the drain cocks provided

Proceed as described below to install the heat meter:

- remove the template (A)

- remove the cap (B)

- install the flow meter on the return pipe

- install the flow probe in the M10 pocket (B).

Please refer to the heat meter technical data sheets for further

information.

A

B