Table of Contents

1. Product Overview ...................................................................................................1

2. Specifications..........................................................................................................2

Module Specification .....................................................................................22.1

Digital Input Specification ..............................................................................22.2

Digital Output Specification ...........................................................................22.3

3. LED Indicators .........................................................................................................3

AX1 LED ..........................................................................................................33.1

Run/Error/Warn LED ......................................................................................33.2

I/O LED ...........................................................................................................33.3

4. Error Handling.........................................................................................................4

Function Block Error.......................................................................................44.1

Warning..........................................................................................................44.2

Error ...............................................................................................................54.3

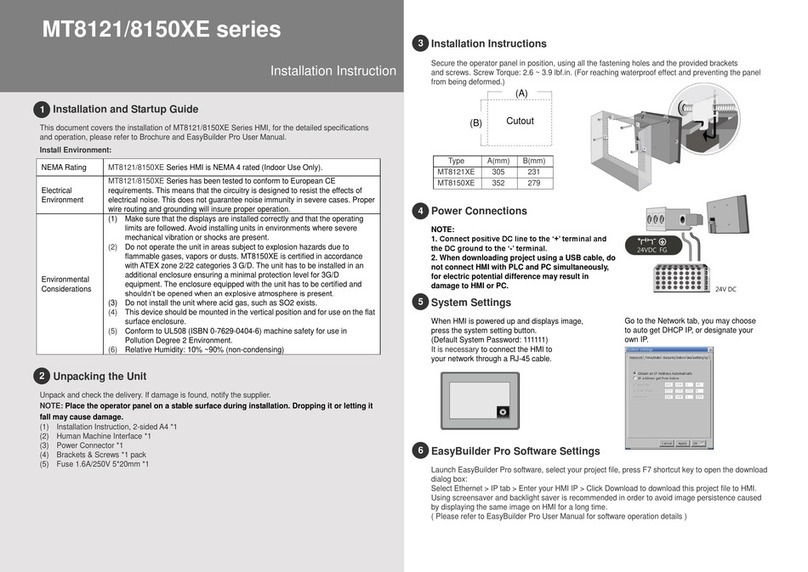

5. Wiring .....................................................................................................................6

Notes on Wiring .............................................................................................65.1

Digital Input / Output Wiring .........................................................................65.2

Differential Output Wiring .............................................................................75.3

Differential Input Wiring ................................................................................85.4

6. Connecting a Coupler .............................................................................................9

iR-COP ............................................................................................................96.1

Slot and Axis...................................................................................................96.2

7. Features ................................................................................................................10

Feature List...................................................................................................107.1

High Speed Pulse Output .............................................................................107.2

High Speed Pulse Input (Encoder) ...............................................................127.3

Positioning Control (Buffer Mode Supported).............................................137.4

Velocity Control............................................................................................147.5

Homing.........................................................................................................157.6

Synchronized Motion (Gear / MPG).............................................................157.7

Digital Cam Switch .......................................................................................157.8

Capture.........................................................................................................167.9

Configurable I/O...........................................................................................167.10

Motion Control working with I/O Control....................................................167.11

8. Object Dictionary..................................................................................................17

Manufacturer Specific Profile Area (5500h - 58FFh) ...................................178.1

8.1.1 Digital Input:5500h ...........................................................................20

8.1.2 Pulse Input Method:5501h ...............................................................21