RLH Industries 16 Channel T1 Over Ethernet Multiplexer... User manual

4 Wire T1

Fiber Link Card System

User Guide

U-001 2019A-0816

RLH Industries, Inc."

Copyright © 2019 RLH Industries, Inc. All rights reserved."

No part of this document may be copied or distributed without

permission.

The RLH logo may not be used for commercial purposes without the

prior written consent of RLH and may constitute trademark infringement.

Other company and product names mentioned herein are trademarks of

their respective companies. Mention of third-party products is for

informational purposes only and constitutes neither an endorsement nor

a recommendation. RLH assumes no responsibility with regard to the

performance or use of these products.#

The information contained in this document is the property of RLH

Industries, Inc. and my not be reproduced or disseminated to third

parties without the express written permission of RLH.#

Every effort has been made to ensure that the information in this

document is accurate. RLH is not responsible for printing or clerical

errors. Because we are constantly seeking ways to improve our

products, specifications and information contained in this document are

subject to change without notice.#

RLH Industries, Inc."

936 North Main Street"

Orange,CA 92867"

"

Ph. 714 532-1672"

email: info@fiberopticlink.com"

www.fiberopticlink.com#

2

Contents

Important information

General Safety Practices%5#

Standards compliance%5#

Description and application%6#

Acronyms%6#

LED status indicators%7#

Before installing

Observe special handling requirements%8#

Set up for installation%9#

Installing card housing%11#

Installing into card housing%11#

Required test equipment%11#

Copper wiring requirements%12#

Verify your installation environment%13#

Installation when T-1 service is available

Connect CO card 14

Set CO card gain 18

Verify CO card operation 19

Connect CO fiber cables 19

Connect Sub card 20

Connect loopback jumpers and power 20

Verify Sub card operation 22

Connect customer premises equipment 23

Installation prior to T1 service availability

Set up CO card 25

Verify CO card operation 27

Connect CO fiber cables 27

Connect Sub card 28

Connect loopback jumpers and power 28

Verify Sub card operation 30

Contents 3

Troubleshooting

Common Issues%31#

CO side troubleshooting%32#

Sub Side troubleshooting%32#

Power supply issues%33#

Verifying fiber cable%34#

Connecting T1 service after installation%36#

NIU Compatibility%36#

Ordering Information

4 Wire T1 Cards%37#

RJ-48C Adapters%37#

Specifications

General Specifications%38#

Support

Technical Support%39#

Contact Information%39

Contents4

Contents

Important information

Intended Audience

This manual is intended for use by field engineering, installation, operation and repair personnel. Every effort has

been made to ensure the accuracy of the information in this manual is accurate. However, due to constant product

improvement, specifications and information contained in this document are subject to change without notice.

Conventions

Symbols for notes, attention, and caution are used throughout this manual to provide readers with additional

information, advice when special attention is needed, and caution to prevent injury or equipment damage.

Notes: Helpful information to assist in installation or operation.

Attention: information essential to installation or operation.

Caution: Important information that may result in equipment damage or injury if ignored.

General Safety Practices

The equipment discussed in this manual may require tools designed for the purpose being described. RLH

recommends that service personnel be familiar with the correct handling and use of any installation equipment

used, and follow all safety precautions including the use of protective personal equipment as required.

Caution - Severe Shock Hazard#

•Never install during a lightning storm or where unsafe high voltages are present.#

•Active T1 lines carry high DC voltages up to 56V. Use caution when handling T1 wiring.#

•Active UHDSL lines carry high DC voltages up to 210V. Use caution when handling UHDSL wiring.#

•Copper power supply wiring may carry high voltages. Remove power from local wiring before servicing.#

Standards compliance

The RLH T1 Fiber Link Card System is compliant with the following industry standards.

NEBS Level 3 FCC PART-15 FCC PART-68B"

IEEE-487 IEEE-1590 Motorola R56"

BR 876-310-100 BT (Telcordia) Bellcore SR-3966 GR-1089"

GR-63 ANSI T1.403

Important Information 5

•Verify or repair before continuing

Description and application

The Fiber Link T1 Model 2 (backwards compatible with the Model 1) System processes incoming bipolar signals

(7.2 V P-P Max) within a bandwidth of 100 KHz to 10 MHz T1 (1.544MbpS) or (CCITT 2.048MbpS), optically

transmits these signals over fiber optic cable and converts the signal to the original electrical signal with minimal

gain or loss.

Output to the copper line is automatically maintained at a nominal level. The Fiber Link system is compatible with

European E1. Transient voltages appearing on or between the 4 wire pairs and/or power supply input are limited by

thermistors, gas tubes and MOVs.

Acronyms

Commonly used acronyms and abbreviations

Color abbreviations

Acronym/Abbreviation

Description

B8ZS

Bipolar 8 Zero Substitution

AMI

Alternate Mark Inversion

CFJ

Copper Fiber Junction (also referred to as Demarc)

CO

Central Office

CPE

Customer Premises Equipment

Demarc

Location of RLH CO equipment and Telco connection

GPR

Ground Potential Rise

LED

Light Emitting Diode

Sub

Subscriber

NIU

Network Interface Unit

RX

Receive

TX

Transmit

P-P

Peak-to-peak (Commonly used with voltage measurements)

Abbreviation

Color

BLU

Blue

GRN

Green

ORG

Orange

RED

Red

YEL

Yellow

Important Information6

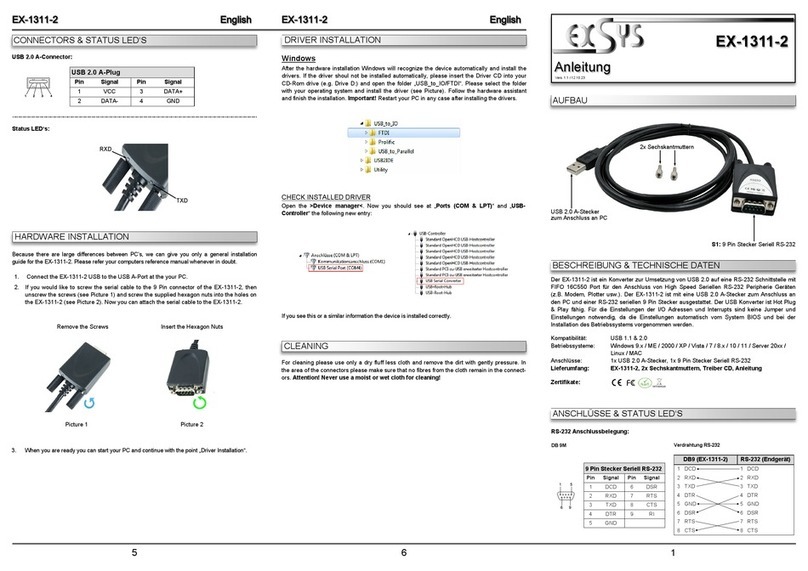

LED status indicators

!

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

YEL - FIBER

RED - ALARM

GRN - RCV

BLU - PWR

ORG - LIMIT

GRN - XMIT

LED

Color

ON condition

OFF condition

FIBR"

(Fiber Test)

YEL

•“Fiber signal” switch SW2 is ON at !

the far end card.

•Fiber test signal is being received.

•Normal operation!

(“Fiber Signal” switch is !

OFF at the far end card)

•If SW2 is ON on far end card,

check fiber continuity

ALRM"

(Alarm)

RED

Signal is below minimum operating level

Normal operation

RCV"

(Receive)

GRN

Signal is received from fiber

Normal operation

XMIT!

(Transmit)

GRN

Signal is received at copper input

Normal operation

LIMIT

ORG

Copper input signal overload

Normal operation

PWR!

(Power)

BLU

DC power is connected

No DC power is connected

Important Information 7

Before installing

Observe special handling requirements

1.1 Be careful when handling electronic components

!

•This product contains static sensitive components. #

•Handle the T1 cards at their edges only.#

•Follow proper electrostatic discharge procedures.#

This card utilizes circuitry that can be damaged by static electricity. When transporting the card, carry it in an ESD safe

container such as the antistatic bag provided with the card. Before handling cards, discharge yourself of static electricity by

physical bodily contact with earth ground. When handling cards, hold by outer edges and avoid touching circuitry. Failure to

follow ESD precautions may cause serious damage to the card and prevent proper operation.#

1.2 Guidelines for handling terminated fiber cable

!

•Do not bend fiber cable sharply. Use gradual and smooth bends to avoid damaging glass fiber.#

•Keep dust caps on fiber optic connectors at all times when disconnected.#

•Do not remove dust caps from unused fiber.#

•Keep fiber ends and fiber connectors clean and free from dust, dirt and debris. Contamination will cause "

signal loss.#

•Do not touch fiber ends.#

•Store excess fiber on housing spools or fiber spools at site#

•Do not staple fiber cable to back boards or over tighten cable ties. Excess pressure on fiber can cause damage.#

ATTENTION

ELECTROSTATIC

SENSITIVE

DEVICES

Before Installing8

1.

Set up for installation

2.1 Check for shipping damage

Contact RLH immediately if any components are damaged or missing. Electronic components, fiber optic cable,

and accessories have special handling requirements to prevent damage and enhance system reliability.

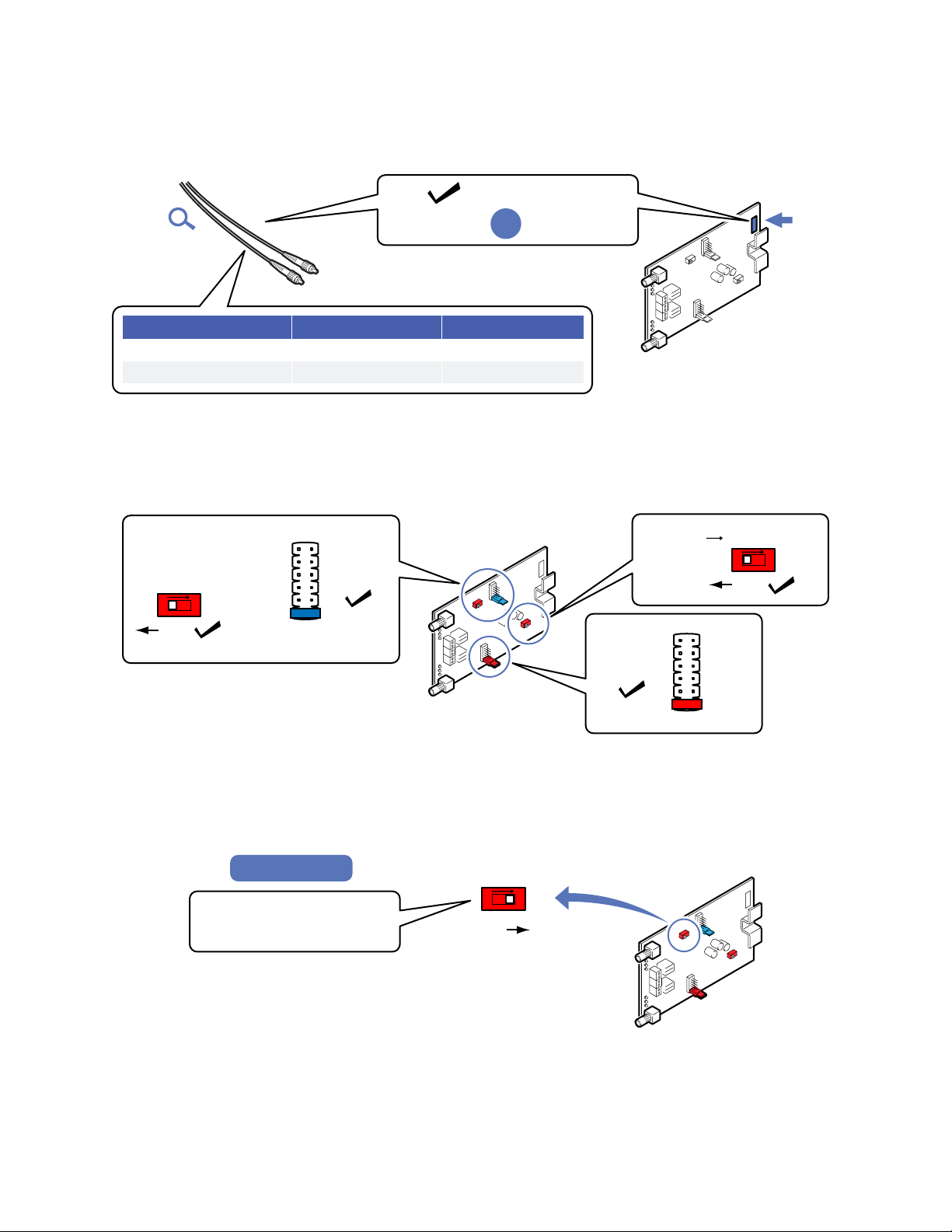

2.2 Verify T1 System Contents

#

Refer to the Ordering Information section for part numbers.

2.3 Verify matching connector types on fiber cable and T1 cards

Fiber Jumper

Fiber Coupler

Copper Jumper

Store together in bag at site

RJ Jumper

CO Card Sub Card

Accessory Loop-back

Test Kit

ST

Connectors

T-1

Fiber Optic

Link Card

T-1

Fiber Optic

Link Card

SC

Connectors

OR

Before Installing 9

2.

2.4 Verify matching card and fiber modes

Fiber mode and card mode must be the same.

!

2.5 Set default T1 card settings

Settings are the same for both CO and Sub cards.

!

2.6 For extended distance multimode systems

!

Fiber Type

Color

Identifier

Single Mode

Yellow

9/125

Multimode

Orange

62.5/125

Multimode

Same Fiber Mode:

Fiber Optic

Cables

T-1 Fiber Optic

Link Card

Mode

Label

Single Mode

OR

1

2

3

4

5

6

LOSS

SELECT

(Blue

Jumper)

(Red)

(Red)

(Red

Jumper)

1

2

3

4

5

6

GAIN

ON

OFF

ONOFF

FIBER SIGNAL SW2

ON

OFF

ONOFF

FIBER LOSS

<4dB>

OFF

Position 1

OFF

T-1

Fiber Optic

Link Card Position 1

ON

OFF

ONOFF

FIBER LOSS

<4dB>

Set FIBER LOSS switch to ON

for fiber over 4,000 feet

(loss of 4dB)

Multimode Only

ON

Before Installing10

Installing card housing

3.1 Mount housing in equipment rack or attach to backboard.

Leave room for the door to open, and enough slack in wiring and fiber to allow for card access.

Installing into card housing

4.1 Note card orientation in housing during installation

Handle card by edges. Install in slot 1 or next available card slot. Install card into housing before connecting

copper wiring or fiber cable.

!

Required test equipment

5.1 You will need a T1 analyzer such as a T-BERD and a multimeter

Be familiar with the test settings. Some analyzers have line power and multimeter capability. For installation where

no T-1 signal is available, the analyzer must be capable of generating a quasi-random T-1 signal.

!#

Can generate a quasi-random T1 signal

OK

OK

BATT

T1 Analyzer

OK

OK

BATT

Multimeter

Before Installing 11

3.

4.

5.

5.2 Required power sources if installing before T-1 service is available at the site

You will need to power the system to test it. Use a separate power source for powering the CO and Sub side card.

A battery may be used.

!

Copper wiring requirements

6.1 Copper wiring to the T1 cards

The connectors on the T-1 cards are designed for specific wire sizes and mechanical connections at the terminals.

•Use 22~24AWG solid copper wire#

•Stripping length: 8mm#

•Connector tightening torque: 0.5~0.6 Nm. Do not over-tighten screw down wire terminals.#

'

+

–

24 - 56VDC

AC Volts

Power SourcePower Source

24 - 56VDC

AC Volts

OK

BATT

+

–

Multimeter Multimeter

OK

BATT

Sub Side

CO Side

Use 22~24AWG solid wire for power supply connections.

Refer to the power supply connection and use information for fuse or circuit breaker requirements. Use caution

when handling copper wiring. Power connections may carry high voltages.

Fuses must be installed within a finger safe housing to prevent electric shock from accidental contact or during

fuse replacement.

Use 22~24AWG

solid copper wire

only.

Wire Stripping 8mm

0.3 in.

T1 wires

T1 card

0.5~0.6Nm max.

Screwdriver

Screw down

terminals

Before Installing12

6.

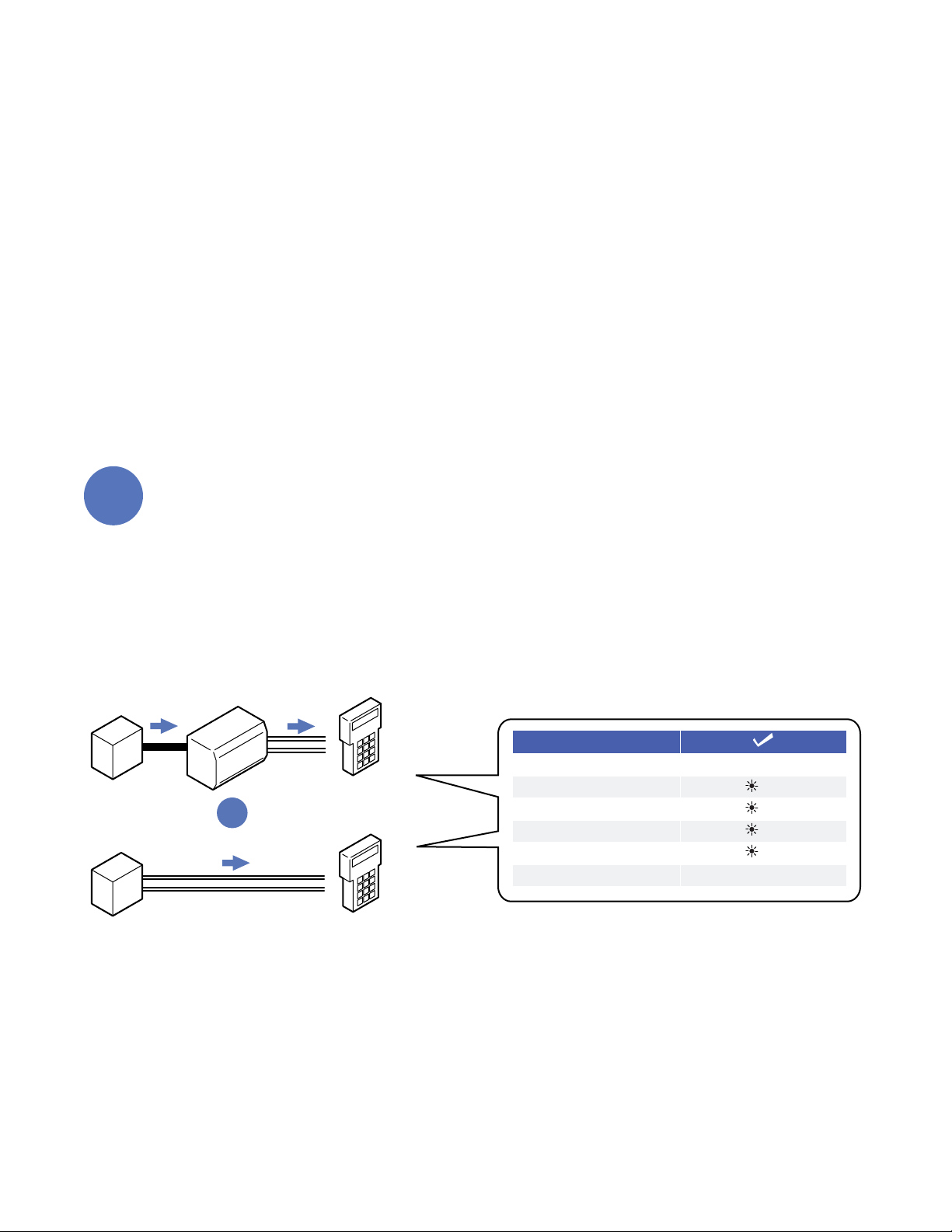

Verify your installation environment

7.1 Typical T1 application environments

Fiber optic cable needs to be installed at the location prior to connecting T1 Fiber Link Card system.

!

Central

Office /

Switch

HDSL/T1 NIU

with 60mA Span

Through Power

Line Powered Line Powered

CO Card Sub Card

CFJ

CFJ

Local Powered

24-56VDC

Power

Supply

CPE

4-Wire

Copper T1

HDSL/T1 Span

Fiber Optic

Cable

4-Wire

Copper T1

RXTX

RX TX

Central

Office /

Switch

Line Powered

CO Card Sub Card

Local Powered Local Powered

24-56VDC

Power

Supply

T1 NIU

Smartjack

4-Wire Copper

T1 Span

Fiber Optic

Cable

4-Wire

Copper T1

RXTX

RX TX

Before Installing 13

7.

Installation when T-1!

service is available

Also see Installation prior to T1 service availability on page 23.

!Connect CO card

1.1 Verify acceptable T1 signal

Repair the T1 lines if service is not acceptable. Check for NIU Compatibility in the Troubleshooting section.

!

1

Test

PEAK TO PEAK VOLTAGE

0.19V ~ 9.0V

T1 PULSES

PATTERN SYNC

FRAME SYNC

BZ8S or AMI

BIT ERRORS

NONE

OK

OK

OK

OK

NIU

T1

Central

Office

T1

Analyzer

T1

Central

Office

T1

Analyzer

OR

Installing when T1 service is present Installation14

1.2 Connect T-1 pairs to card terminals

Install into housing for connecting and testing. Refer to Installing into card housing on page 9.!

All LEDs will be ON for approximately 5 seconds after span power is first applied.

!!

Pair #

First wire

Second wire

1

White

Blue

2

Orange

3

Green

4

Brown

5

Gray

6

Red

Blue

7

Orange

8

Green

9

Brown

10

Gray

11

Black

Blue

12

Orange

13

Green

14

Brown

15

Gray

16

Yellow

Blue

17

Orange

18

Green

19

Brown

20

Slate

21

Violet

Blue

22

Orange

23

Green

24

Brown

25

Gray

Standard 25-Pair Color Code

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

Connect

TX pair

Connect

RX pair

RED ALARM

LED = ON

Will go off

once system

is connected.

Use 22~24AWG

solid copper wire

only.

T1 wires

Gently tug after securing

into terminal to ensure

wire isn’t damaged.

Installation Installing when T1 service is present 15

1.3 Connection using optional RJ connector

RJ connector may be pre-installed or obtained separately.

!

1.4 Verify power at the T1 card

Test for Span power.

!

Pin 1

Pin 8

Use jack marked CO

Optional RJ-45 jack

CO

CO

CO

CO

CO

RX pair, pins 1,2

TX pair, pins 4, 5

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

PWR LED indicates that

power is OK

60mA span power

22V minimum

Multimeter

BLU = ON

Installing when T1 service is present Installation16

1.5 Connect local power if Span power is not present

All LEDs will be ON for approximately 5 seconds after power is first applied.

!

Auxilliary power wires

Gently tug after securing

intoterminal to ensure

wire isn’t damaged.

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

PWR LED indicates that

power is OK

Multimeter

BLU = ON

Auxilliary Power Terminal

24-56VDC Local Power

Not polarity sensitive

24-56VDC

Use 22~24AWG

solid copper wire only.

Refer to the power supply connection and use information for fuse or circuit breaker requirements. Use caution

when handling copper wiring. Power connections may carry high voltages.

Fuses must be installed within a finger safe housing to prevent electric shock from accidental contact or during

fuse replacement.

Installation Installing when T1 service is present 17

!Set CO card gain

2.1 Set gain using red gain GAIN jumper

Set gain while T1 signal is present. Refer to the Specifications section for input signal requirements.

!

2

The blue LOSS SELECT jumper must remain at position 1.

1

2

3

4

5

6

GAIN

Move jumper to

next higher position.

Repeat until orange

LIMIT LED comes ON,

then stop.

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

ORG LED is ON when

copper signal is too high

RED

Jumper

1

2

3

4

5

6

GAIN

Move jumper

back one position.

Orange LIMIT LED

will go OFF.

Green XMIT LED

will stay ON.

Note final

jumper position

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

Amber LED turns OFF.

Gain is set at proper level.

1

2

GRN LED is ON when copper

signal is above minimum level

Each jumper position is equivalent to approximately 6dB of gain. Setting the CO gain at the correct level ensures

that the fiber optic transceiver system operates within normal levels.

The gain on the CO card is offset by setting a matching attenuation using the loss select jumper on the Sub card.

Installing when T1 service is present Installation18

!Verify CO card operation

3.1 Check CO card operation

Perform loopback test using fiber jumper

!

!Connect CO fiber cables

4.1 Connect fiber optic cable

Move on to Sub side after verifying LEDs.

!

3

Attach Test Kit

Simplex

Fiber Jumper OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

OFFRED

ALARM RCV XMIT PWR

ONGRN GRN BLUON ON

After using, store

fiber jumper with test kit

at convient site location.

• Do not discard fiber caps.

• Replace caps after use.

If both GREEN LEDs are not ON,

verify T1 signal, power and connections

4

OUTPUT 24-56VDC

AUX. P.S. INPUT

FIBR RCV XMIT LIMIT PWRALARM

RX TX

Fiber RX

Note fiber numbers

for RX and TX

Loose loops or use

fiber routing clips

Fiber TX

GRN ONRED ON BLU ON

Fiber Optic Cable

to SUB side

Card Housing

Push

“Click”

Installation Installing when T1 service is present 19

!Connect Sub card

5.1 Connect fiber cables

Flip or roll the fiber cables

!

!Connect loopback jumpers and power

6.1 Connect copper loopback jumpers

When using wire terminals.

'

5

TX fiber

connector

RX fiber

from CO side

RX TX

Flip fiber

connections

TX fiber

from CO side

RX fiber

connector

Do not touch fiber connector

ends which could cause

contamination and lower

signal performance.

Card partially

out of slot

during installation

Fiber Optic Cable

from CO side

Card Housing

6

Installing when T1 service is present Installation20

Other manuals for 16 Channel T1 Over Ethernet Multiplexer...

2

Table of contents

Other RLH Industries Media Converter manuals

RLH Industries

RLH Industries SED-03-2 User manual

RLH Industries

RLH Industries RLH 10 User manual

RLH Industries

RLH Industries 1+1 PORT SLIMLINE User manual

RLH Industries

RLH Industries 16 Channel T1 Over Ethernet Multiplexer... User manual

RLH Industries

RLH Industries Fiber Optic Link User manual

RLH Industries

RLH Industries 2 Channel 4 Wire Datawith E&M and I/O User manual