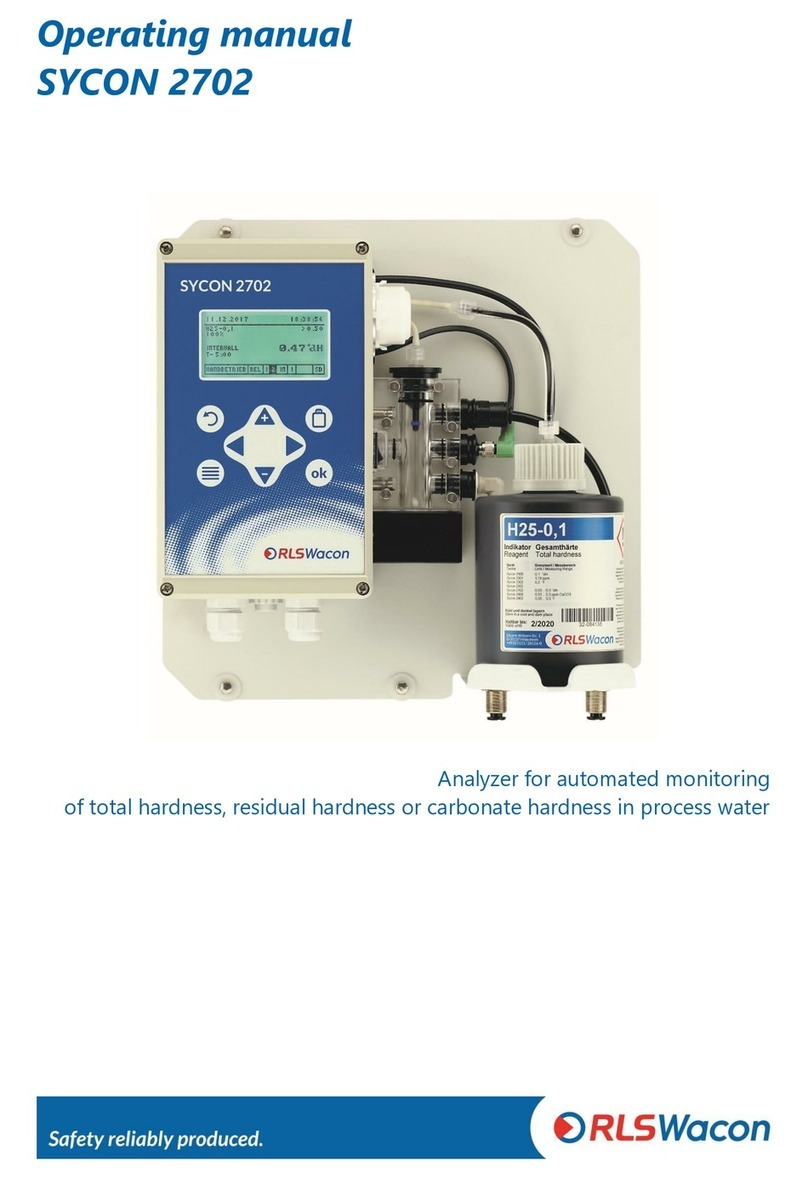

RLS Wacon Aqua Inform Sycon 2501 Fe User manual

Sycon 2501 Fe

On-line Analysis

of the Iron Content in Water

V24.02.2015

US E R MA N U A L

INTRODUCTION

PAGE 3

INTRODUCTION

We appreciate your purchase of a Limit Analyser type Sycon 2501 Fe for the on-

line monitoring of the iron content of water.

The Limit Analyser is part of a water treatment plant. Distribution of this manual is

intended for the manufacturer and the owner of this plant.

This user’s manual covers instructions for the use of your Limit Analyser. Please

read through this manual and understand the contents before using the system.

We recommend that the manual be kept nearby for reference when operating the

Limit Analyser system.

Operate the system only in accordance with the instructions given in this manual.

Under no circumstances whatsoever will we be liable for damages arising from the

user’s failure to follow the instructions given in this manual.

•Some details of the instructions contained in this manual may be different

from the actual system purchased. The instructions are also subject to

change without prior notice.

The Limit Analyser based on the Sycon 2501 series is an on-line analysis

system. It can automatically monitor iron leakage in water treatment plants

and issue an iron leakage alarm.

It is not a system that remedies iron leakage itself.

WARNING

PAGE 4

TABLE OF CONTENT

TABLE OF CONTENTS

PAGE

SUMMARY SYCON 2501 SERIES

6

CHAPTER 1

SAFETY WARNINGS /PRECAUTIONS /SYMBOLS USED

7

CHAPTER 2

SPECIFICATION AND OVERVIEW

2.1 SPECIFICATION AND INTENDED USE

→GENERAL SPECIFICATION

→TECHNICAL DATA

→MONITORING CAPABILITIES

→WATER INLET AND OUTLET

→AVAILABLE REAGENTS

→ACCESSORIES

2.2 OVERVIEW AND CONFIGURATION

2.3 DISPLAY AND CONTROL BUTTONS

2.4 SPARE PART LIST

2.5 OPERATION PRINCIPLE

2.6 FUNCTIONS

11

11

13

14

15

16

17

CHAPTER 3

INSTALLATION AND COMMISSIONING

3.1 INSTALLATION REQUIREMENTS

3.2 INSTRUCTIONS FOR INSTALLATION

3.3 MOUNTING IN 4STEPS

→TERMINAL CONNECTION TABLE

→INSTRUCTION FOR WIRING AND CONNECTION

→MOUNTING DIMENSIONS

3.4 CONNECTING RELAY-OUTPUT

3.5 CONNECTING DIGITAL INPUTS

19

19

19

20

25

26

CHAPTER 4

OPERATION AND USE

4.1 SUMMARY OF SYCON 2501 SYSTEM

4.2 BEFORE INITIAL OPERATION

4.3 PROGRAMME SWITCHES

4.4 SETTING THE PROGRAMME SWITCHES

→FLUSH TIME

→DELAY INTERVALS

→ANALYSIS INTERVALS

→ANALYSIS REPETITION

→RELAY FUNCTION

→MEASUREMENT-PARAMETERS

4.5 COMMISSIONING IN 5STEPS

4.6 OPERATION OF THE UNIT

→AUTOMATIC OPERATION

→MANUAL OPERATION

27

27

28

29

30

36

37

TABLE OF CONTENT

PAGE 5

CHAPTER 5

MAINTENANCE AND SERVICE

→CHANGING PERISTALTIC DOSING PUMP

→CLEANING OF THE MEASURING-CHAMBER

→CHANGING WORN PARTS

→CHANGING REAGENT BOTTLE

→CHANGING SPARE PARTS

41

CHAPTER 6

DIAGNOSTIC FUNCTION

TEST OF →LEDS

→CONTROL-BUTTON

→DIP SWITCH

→POTENTIOMETER

→RELAY 1+2

→SOLENOID VALVE

→ACTUATOR LED

→DOSING PUMP

→MAGNETIC AGITATOR

→‘IN’CONTACT

→ZERO-TRANSMISSION

→COLOUR DETECTION

48

PAGE 6

SUMMARY

SUMMARY SYCON 2501 SERIES

With the Limit Analyser, RLS Wacon offers a very compact and easily operated water

analyser for automatic on-line monitoring of water treatment plants. The system

controls selectable limit values according to the colorimetric principle. A broad range

of functions guarantee reliable field-operation. Units can be supplied in standard as

well as tailor-made housings

Application:

→Limit monitoring (below and above limit detection)

→suitable for operation without permanent supervision (BOB)

Order numbers

Limit Analyser

SYCON 2501 Fe

30-010321

Standard enclosure

33-099005

Reagents

Fe-LRS

0.03 –0.6 mg Fe/l

32-080320

Fe-HRS

0.3 –6.0 mg Fe/l

32-080330

CHAPTER 1

SAFETY INSTRUCTIONS

PAGE 7

CHAPTER 1 SAFETY WARNINGS AND PRECAUTIONS

This Chapter explains the dangers, precautionary signs and notes that apply to

the handling, installation, wiring and maintenance of the SYCON 2500 series Limit

Analyser. These instructions are not a substitute for vocational training.

This manual describes the installation and operation of the on-line analyser of

type Limit Analyser Fe based on SYCON 2501 series. Installation and

commissioning must only be performed by qualified personnel.

Operate the system only in accordance with the instructions given in this manual.

In particular, the system has to be protected against humidity and moisture. Avoid

direct contact with splash or condense water. The device may only be used for

the specified purpose. When installing and operating the equipment, the relevant

standards (e.g. EN, DIN, VDE, UVV) and applicable local regulations must be

complied with.

The analyser is used to monitor the limits of the iron content in process water.

Proper operation can only be guaranteed with the manufacturer's recommended

reagents and spare parts.

Changes to the electrical connections and the programming should only be

performed by a qualified person.

If it is necessary to connect cables for the sensors they should be kept as short

as possible and not run together with power cables. The vicinity of a strong

electromagnetic field may lead to deviations of evaluation and measurement

results. In such cases, appropriate measures must be taken to suppress

interferences. EMC-directives are especially applicable.

When working with this manual, it is recommended to have access to the

operational instrument in order to understand the functions described

immediately. Read the chapters in the order given.

If you have questions regarding the operation of the instrument, or when

problems occur, please contact us or one of our distributors. Try to locate

problems as accurately as possible. Also describe what actions you have taken

and which conditions lead to the problem. We will then be in a better position to

help you.

Labour protection

Rules for

accident

prevention

of

government

and industrial

safety

organisations

Operating Manual

PAGE 8

SAFETY INSTRUCTIONS

CHAPTER 1

Safety instructions and symbols used

In this manual you will find specific safety instructions to indicate the unavoidable

residual risks when operating the unit. These residual risks imply dangers to

●People

●Product / Plant / Machinery

●Environment

The symbols used in the instructions draw attention in particular to the safety

instructions!

The main objective of the safety precautions is to prevent personal injury.

The symbol used in each case cannot replace the text of a safety warning.

Therefore, the text must always be read completely.

This symbol indicates a potential danger to persons.

→mortal danger

→risk of injury

●A safety notice with warning triangle DANGER points out that risks to plant,

machinery, materials, environment and people are not excluded

This symbol indicates a potential danger to product, plant and machinery

●A safety notice with warning triangle WARNING points out that risks to

plant, machinery, materials and/or environment are not excluded.

Danger to persons is not necessarily to be expected.

This symbol points to hydraulic and pneumatic systems and indicates

pressurised systems.

This symbol indicates electric and electronic systems.

This symbol indicates no safety information, but information to improve

understanding of the plant or machine processes.

DANGER

WARNING

PRESSURE

ELECTRICITY

NOTE

CHAPTER 1

SAFETY INSTRUCTIONS

PAGE 9

Work on hydraulic and pneumatic equipment

●Maintenance and repair of hydraulic and pneumatic equipment should be

carried out by specially trained personnel!

●Before all maintenance and repair work, the pneumatic and hydraulic

equipment of the system / machine must be depressurised!

●During preventive maintenance, pipes should be changed regularly, even

if there is no visible damage (Please note the information provided by the

manufacturer).

●Before starting up after maintenance or repair work,

→Check the screw connections for a tight fit and that push-in fittings are

secured.

→Ensure that the container lid, screens or filters are re-installed in the

correct order.

●After completion of the maintenance and repair services, and before the

resumption of operation, make sure that…

→…all the materials, tools and other equipment required for the execution of

maintenance or repair work are removed from the work area!

→…any leaked fluids are removed!

→…all safety devices of the system work properly again!

Transportation

Use appropriate equipment to transport the system to prevent damage during

transport.

●Transport equipment carefully and do not throw it!

●Choose a cool and dry storage location.

●Pay attention to the permitted ambient temperatures!

●Check the entire delivery immediately upon receipt for completeness and

shipping damage

●Devices are packed in a transport-safe packaging. Nevertheless, damage

could occur during transit. Please tell the transport company and the

manufacturer in writing IMMEDIATELY - no later than eight days after

receiving the goods - of the details of the damage. In this case, you must

keep the instrument and the packaging for inspection for the further

processing of the complaint.

WARNING

PRESSURE

NOTE

PAGE 10

SAFETY INSTRUCTIONS

CHAPTER 1

Storage

We recommend storing equipment no longer than a year to avoid loss of the

warranty. Store the equipment under the following conditions.

●Cool and dry location.

●Ambient temperature between 0 and 45 °C.

Shipment

Shipment consists of:

●Equipment in accordance with the confirmation of order,

●Operating Manual

Check that all parts were delivered.

Obvious damage and / or missing components must be reported in writing within

8 days of receipt of goods. After that, no complaints will be accepted

Installation

►Install the system in accordance with the following sequence will save you

time and avoid damage which could lead to malfunction.

●Mount the device:

→Place the unit in a dry, easily accessible and conspicuous place.

→Drill holes in the wall according to template (typically, these are four

holes) and mount the device using suitable screws (usually four screws).

●Connect the initiators (e.g. level sensor)

●Connect the actuators (for example pumps, valves)

●Connect the power.

Make sure that the supply voltage is correct

for example: 230 VAC or 115 VAC or 24 VAC

For correct supply voltage, refer to the serial number label of the unit

●Program the device (setting of parameters and conditions).

→Note the information in the manual

NOTE

NOTE

WARNING

CHAPTER 2

SPECIFICATION AND OVERVIEW

PAGE 11

CHAPTER 2 SPECIFICATION AND OVERVIEW

The Limit Analyser is used for the automatic monitoring of hardness in water. We

recommend that the user read this chapter before installation of the device for

safe operation.

2.1 General Specifications

Power-supply

85 … 264 VAC 47… 63 Hz

Power consumption

25 VA (in operation)

Protection class

IP 54

Ambient operating

temperature

5C …45C

Raw water temperature

5C … 40C

Humidity

20%RH …90%RH

(without ice or condensation)

Feed water pressure

approx. 0.5…5 bar (1…2 bar recommended)

Feed water condition

clear, colourless, free of suspended solids, no gas

bubbles

→Technical data

Installation location

indoor wall mount

External dimensions

without enclosure: 280 [W] 250 [L] 140 [D] mm

with enclosure: 300 [W] 300 [L] 190 [D] mm

Mass

approx. 2.0 kg

→Analysis characteristics

Evaluation

colorimetric method

Limit value alarm is

defined by the reagent

used

→bottles volume

500 ml

Limit-Value-Reagents LR:

0.03 mg/l 0.05 mg/l, 0.1 mg/l, 0.2 mg/l, 0.3 mg/l,

0.4 mg/l, 0.5 mg/l, 0.6 mg/l

Limit-Value-Reagents HR:

0.3 mg/l 0.5 mg/l, 1.0 mg/l, 2.0 mg/l, 3.0 mg/l,

4.0 mg/l, 5.0 mg/l, 6.0 mg/l

Reagent consumption

approx. 0.4 ml / analysis

Reagent shelf life

2 years

Relay outputs

3 x Relays

250 VAC / VDC 4 A

potential free outputs NC/NO

1. Limit alarm

2. Unit failure

3. Analysis

Remote signal input

potential free contacts (load 24 V;10 mA)

Water usage

approx. 1000 ml/analysis

→Drainage volume may vary depending on feed water pressure

and flush time

→Water inlet and outlet

Water inlet connection

For connecting 6 mm outer diameter pipe

Water outlet connection

→ atmospheric

pressure / open funnel

For connecting 6 mm outer diameter pipe

→Inlet and outlet pipes are not attached to the device. Please

use specified pipes. Using tubes other than those specified

may cause leakage. → Please contact our distributors.

PAGE 12

SPECIFICATION AND OVERVIEW

CHAPTER 2

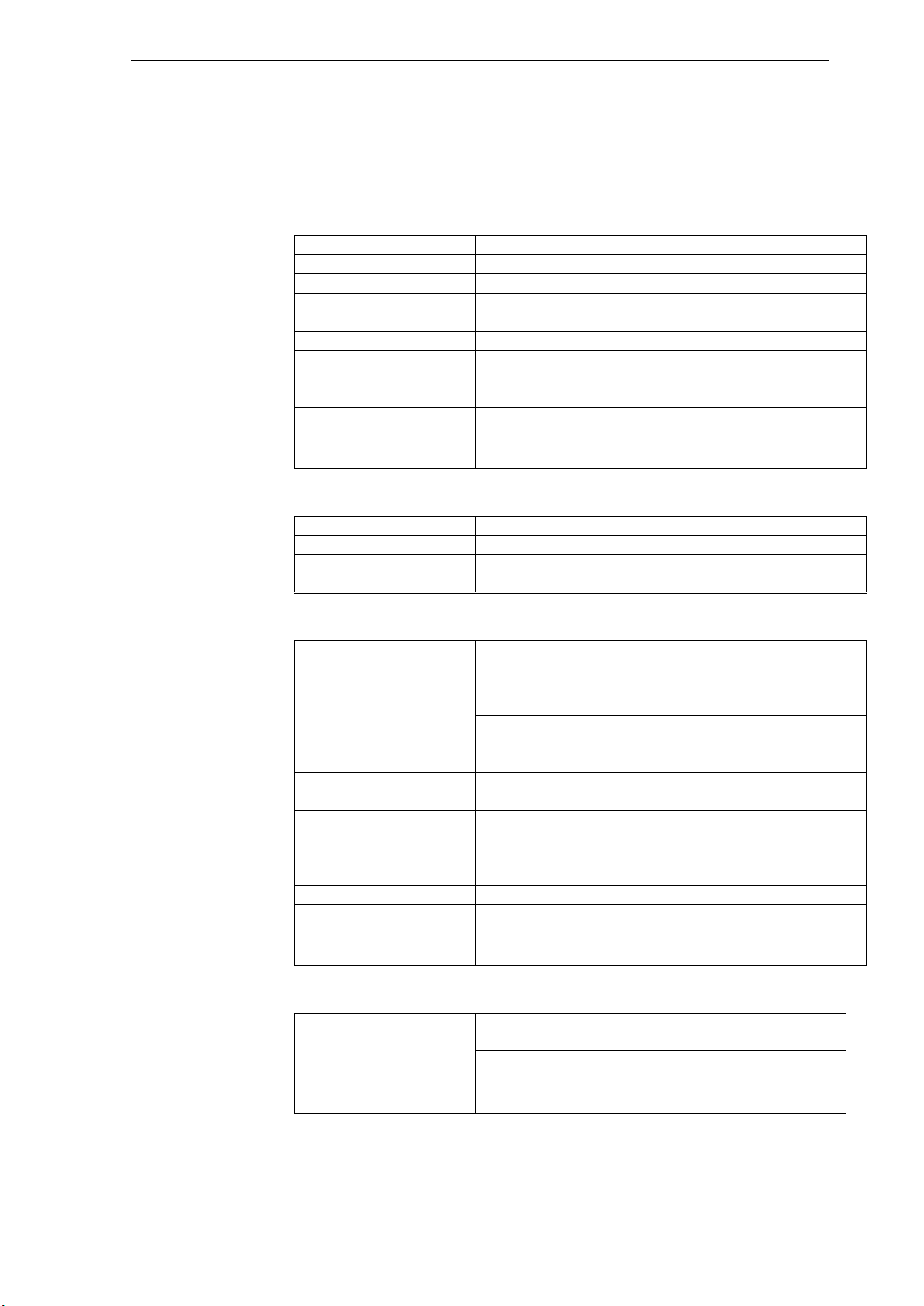

Order numbers for unit and reagent

Limit Analyser

SYCON 2501 Fe

30-010321

Standard enclosure

33-099005

Reagents

Fe-LRS

0.03 –0.6 mg Fe/l

32-080320

Fe-HRS

0.3 –6.0 mg Fe/l

32-080330

The system works with one-component reagents with different limit values.

Shelf-life of the reagents is 2 years if properly stored (not opened; cool; dark).

After opening, bottles should be used within twelve months.

Sample waters with temperatures over 45°C must be cooled down before

analysis takes place!

If the programme switch S9 is set to ‘ON‘, the analysis evaluation will be

reversed. That means there will be an error warning when the test result is below

the limit.

→Accessories SYCON CLEAN order no. 30-010 900

Cleaning set for acryl glass measuring-chambers

→1000 ml cleaning solution FIT 3000

→5 pairs of gloves

→2 brushes, funnel, container

→manual

FIT 3000 order no. 32-089 100

Cleaning solution for acryl glass measuring-chambers

→1000 ml cleaning solution FIT 3000

→Sample cooler PC 200 order no. 30-015 100

PC 400 order no. 32-015 200

For details please refer to our home page

www.rls-wacon.de

NOTE

NOTE

CHAPTER 2

SPECIFICATION AND OVERVIEW

PAGE 13

FIG.2.1 2.2 Overview –limit analyser –configuration

INLET PRESSURE OF

WATER SAMPLE

APPROX.0.5 -5.0 BAR

1-2BAR

RECOMMENDED

MAGNETIC STIRRER

WATER TREATMENT

PLANT

E.G.DEFERRIZATION

CONTROL-UNIT

REAGENT

BOTTLE 500 ML

DOSING-PUMP

DOSING-PLUG

WATER-OUTLET-PLUG

OPTICAL PATH WITH

LIGHT SOURCE AND

RECEIVER

WATER INLET-PLUG

SOLENOID VALVE

(BEHIND BOTTLE)

MEASURING-CHAMBER

WATER SAMPLE

DIRECTION OF FLOW

OPEN FUNNEL

(ATMOSPHERIC PRESSURE)

PAGE 14

SPECIFICATION AND OVERVIEW

CHAPTER 2

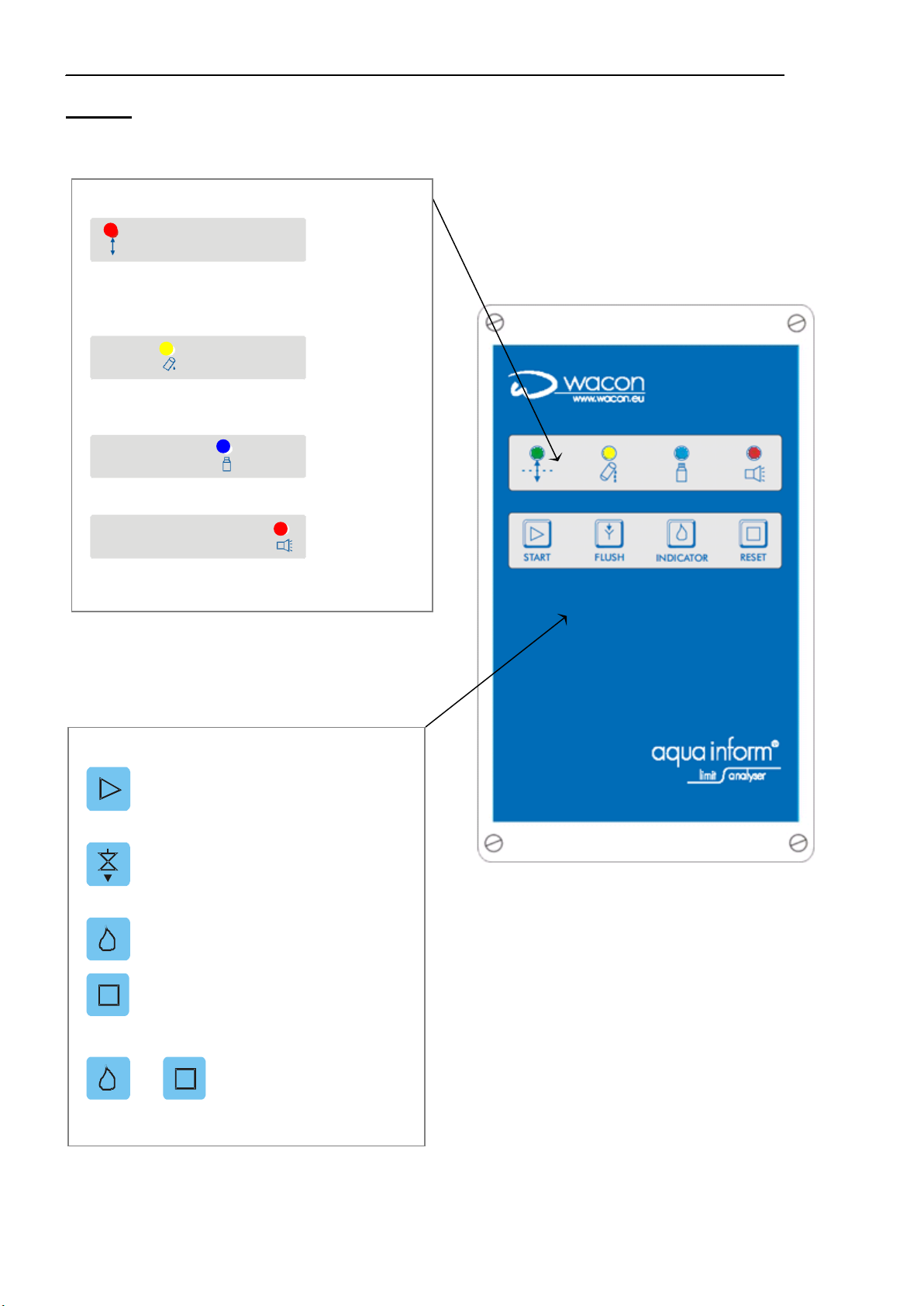

FIG.2.2 2.3 LIMIT ANALYSER –DISPLAY AND OPERATING PANEL

CONTROL BUTTONS

START START ANALYSIS

MANUALLY

FLUSH RINSE MEASURING-

CHAMBER MANUALLY

INDICATOR DOSE REAGENT MANUALLY

RESET QUIT ALARM

+NEW REAGENT BOTTLE

LED DISPLAY

TEST RESULT:

GREEN GOOD CONDITION /POWER ON

RED BAD CONDITION

YELLOW ANALYSIS ACTIVE

BLUE LACK OF REAGENT

RED ALARM /UNIT FAILURE

CHAPTER 2

SPECIFICATION AND OVERVIEW

PAGE 15

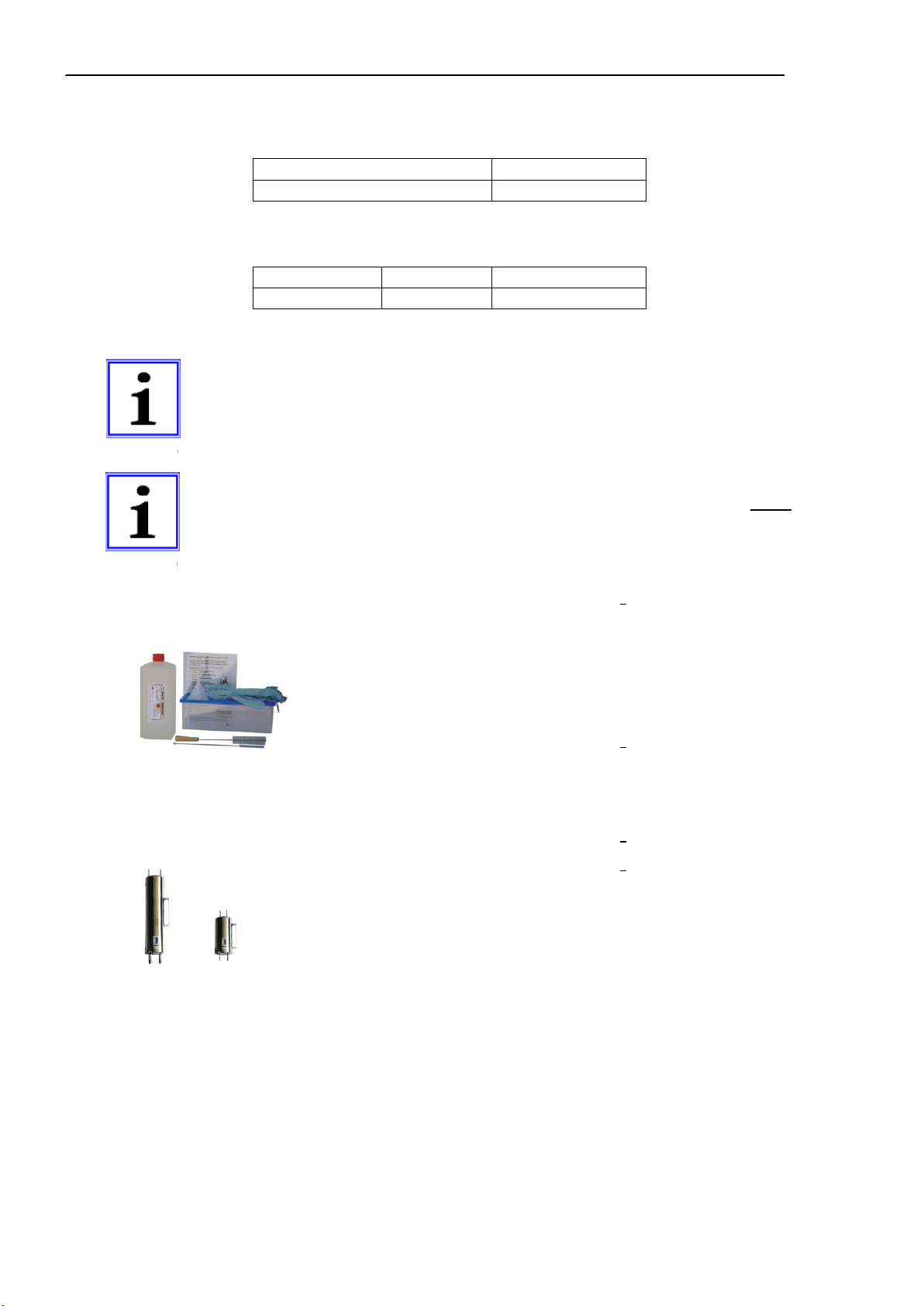

2.4 SPARE PARTS LIST FIG 2.3

Order No.

Description

33-090 002

Magnetic stirrer

33-090 008

Bottle Adapter

33-090 009

Bottle adapter

33-090 011

Suction lance

33-090 013

Inlet connection ¼"

33-090 014

Solenoid valve 24V complete

33-090 015

Outlet connection 6mm

33-090 016

Bulkhead fitting 6mm

33-090 038

Cartridge of peristaltic pump

33-090 044

Bulkhead fitting 6mm with threaded

connector

33-090 056

Activator for magnetic stirrer

33-090 210

O-Ring 9 x 1,5

33-090 217

O-Ring 17x2

33-090 218

O-Ring 3,2 x 2,5

33-090 700

Measuring-chamber complete

33-090002, 33-090701, 33-090711,

33-090712, 33-090713, 33-090716

33-090 701

Measuring-chamber

33-090 711

Inlet plug ¼"

33-090 712

Outlet plug ¼"

33-090 713

Actuator (LED)

33-090 716

Dosing plug

33-093 060

Bottle cap

33-090 023

Power supply circuit board 85-264 V

33-090 028

MAINTENANCE –KIT

33-090 024

Main board complete

1x 33-090 038

Cartridge of peristaltic pump

33-090 025

Control unit complete 85-264 Volt

1x 33-090 008

Bottle connector

33-090 026

Peristaltic pump complete

1x 33-090 011

Suction lance

33-099 007

Housing for control unit with lid

1x 33-090 217

O-ring 17 x 2

33-099 700

Operating manual German

3x 33-090 210

O-ring 9x1,5

33-099 701

Operating manual English

1x 33-090 218

Dosing-O-ring 3,2 x 2,5

PAGE 16

SPECIFICATION AND OVERVIEW

CHAPTER 2

2.5

Operation principle of Sycon 2501

An analysis cycle consists of 5 steps

[1]

Start delay:

The analysis start can be delayed by between

1 and 30 min (0 = no delay)

When monitoring hot water, it is necessary to cool the

water before it can be analysed. A cool water valve can

be opened via REL 3. The delay time should be set to

ensure that the water is cool enough before the inlet

valve is opened and the analysis begins.

↓

[2]

Washing and rinsing measuring-chamber with

sample water.

Programmable rinsing time: 5 sec-10 min

When the inlet valve is opened, the measuring-

chamber and pipes are rinsed until all traces of the

previous analysis are removed and the new water

sample is in the chamber.

↓

[3]

Filling measuring-chamber with sample water.

Monitoring of zero transmission without injection

of reagent

Before an analysis begins, an internal calibration takes

place based on a water sample without reagent

content. If the LED is defect a fault will be reported.

↓

[4]

Stirring water sample and injecting reagent.

Homogenisation and reaction phase while

stirring

The dosing pump injects a defined amount of indicator

into the water sample. The stirrer coil, activated at the

same time, mixes water and reagent. The reagent

causes colouration of the water sample in accordance

with the hardness components of the water. Reagents

are calibrated to change colour at certain limit values.

When unreasonable values are registered –e.g. no

reagent - a fault will be reported.

↓

[4.1]

Monitor light transmitted through the sample

water.

Evaluation of water hardness limit value alarm

Results are shown by the red/green LED. If the limit is

exceeded, an alarm will be set off. The result of the

analysis is evaluated on the following basis:

Below the limit = Good (green)

Over the limit = Bad (red)

NB. The result is inverted if switch S9 is set to ‘ON’.

↓

[5]

Flushing and rinsing measuring-chamber

NB: During Interval measuring-chamber is kept filled

with water.

Analysis start:

A automatically in 4 programmable

intervals: (0)15 / 30 / 60 / 120 minutes

B manually by pushing the Start-button

C via an external switch if the

programmable switch S10 is ‘ON’

Attention! If the interval (0)15 is

programmed, analysis runs can only be

triggered through an external switch

(interval 0 minutes).

By means of a flow monitor or a timer, the analyses

can be suppressed during periods when the water

conditioning system is switched off or in

regeneration, or no samples are being taken.

In this case the programmable switch S10 must be in

‘OFF’ position.

CHAPTER 2

SPECIFICATION AND OVERVIEW

PAGE 17

2.6 Functions

The SYCON 2501 Fe system has the following features:

[1] Automatic detection of iron leakage in accordance with limit value reagent used.

The monitoring process is fully automated, saving a significant amount of work by

eliminating the need for complicated manual procedures.

[2] Requires no periodic calibration.

[3] The interval between each analysis can be set to 15; 30; 60 or 120 minutes. The

start of analysis can be triggered by an external switch

[4] Reliable detection of iron leakages by means of limit value reagents.

[5] Monitoring of limit values with higher accuracy

When a BAD condition is detected, a reference analysis may be made after 4

minutes.

[6] LED status display is independent of language.

[7] Alarm functions:

When a hardness leakage is detected, an alarm is issued by switching the potential

free relay –REL 1. This alarm output may be used, for example, to send a signal to

a control panel, to sound a buzzer, to close a valve or to control a programme for the

regeneration of a water softening plant.

[8] Diagnostic programme:

If a fault occurs in the system an alarm is issued by switching the potential free relay

–REL 2. Technicians may run step by step through the diagnostic program to check

functions and find faulty parts in the device (→ page 48).

[9] Requires minimal maintenance:

Depending on measurement intervals and frequency of analyses respectively the

measuring-chamber has to be cleaned and reagent pipes and o-rings changed once

or twice a year (→ page 42).

[10] Minimal reagent consumption:

The reagent bottle is easily replaced. The 500 ml bottle does not need to be replaced

for approximately three or four months in typical applications.

(Note that more frequent replacement may be necessary, depending on the

application.)

[11] Compact in design, easy to install:

The main unit is installed easily on a wall.

Installation is a simple process (→ page 19).

[12] Digital input ‘IN’:

PAGE 18

SPECIFICATION AND OVERVIEW

CHAPTER 2

WARNING

NOTE

WARNING

The potential free switch of a flow monitor, a timer or any other condition

switch can be connected to this input. (→ page 26). When the contacts are

open, no analysis will be carried out during the programmed interval. As

an alternative, this input can be used as a start input.

Three potential free Relay Outputs - REL 1 / REL 2 / REL 3

The potential free relay outputs can be used to transmit a limit alarm (REL

1), a unit failure (REL 2) or an active analysis (REL 3) to a control panel

for example (→ page 25). Alternatively, signalling units or valves may be

activated.

[13] ’BOB’- operation

The abbreviation BOB comes from the German Betrieb ohne Beobachtung (operation

without permanent supervision) and follows a regulation of German TÜV (technical

inspection authority) especially for boiler houses, which requires reliability of

instruments for at least 72 hours.

The REL 2 output may be used to transmit a warning to a remote location

when the reagent needs to be replaced.

Analytical devices of type SYCON 2501 were specially designed for BOB-

operation (operation without permanent supervision). Boiler houses,

running in BOB-operation, require a qualitative monitoring of water

hardness in the boiler feed water according to the technical guideline TRD

604 (`Technische Regeln für Dampfkessel` published by German TÜV).

Analytical devices of type SYCON 2501 record the consumption of

reagent in order to ensure that in periods of operation without supervision,

a sufficient amount of reagent for reliable analysis is available in the bottle.

The sufficient amount of reagent should be calculated independently of

set analysis intervals for the next 72-hour operation.

If the very next 72-hour BOB-operation cannot be reliably guaranteed, an

alarm “lack of reagent” is issued via relay REL 2.

The reagent stocks can only be calculated correctly if the internal counter

is reset after installing a new 500 ml reagent bottle by pressing the RESET

key combination.

+ NEW REAGENT BOTTLE

•The device does not recognize the contents of the bottle, but resets

the counter of the metering pump, which then counts back starting

from 500 ml. You can reset the counter to zero only. If the keys are

pressed during an analysis without a new, full bottle of reagent being

installed, the reagent quantity will not be properly calculated, and the

alarm will not be issued on time or at the wrong time. This also applies

if the RESET action is forgotten.

Attention! If no iron is present in the water, no colour change will appear.

If no reagent is dosed, even for water with iron content no colour change

will appear and the reading will wrongly indicate no iron content.

CHAPTER 3

INSTALLATION AND COMMISSIONING

PAGE 19

CHAPTER 3 INSTALLATION AND COMMISSIONING

OF LIMIT ANALYSER

3.1 Installation Requirements

The analyser shall be used only to determine a parameter in the sample water.

Proper operation can only be guaranteed if reagents approved by the

manufacturer are used (→ page 12 or 27).

Changes to the electrical connections and the programming should only be

carried out by a qualified person.

The plant must meet the following conditions:

●The maximum allowable load capacity of the switching outputs and the overall

performance of the system must not be exceeded by the connected load (note

phase angle for inductive loads).

●All inductive loads (valves, motors, contactors, transformers) of the plant must

be equipped with suitable suppressors (e.g. RC element, varistor, diode, etc.)

●If the analyser could be influenced by external devices with high electro-

magnetic interference levels, these effects should be reduced by appropriate

measures. On the supply voltage input of the offending equipment appropriate

external interference suppression (line filter) should be fitted.

3.2 Instruction for Installation

When making connections to printed circuit boards, the following guidelines must

be followed:

●Do not apply excessive force to the terminals. Only apply the force necessary

to open the terminal (or to release the cable when disconnecting).

Push terminals are capable to receive single-strand conductors up to 1.5 mm².

However, multi-stranded conductors without cable shoes should not exceed

1.0 mm² and with cable shoes only 0.75 mm². According to the manufacturer,

use of cable shoes is not required.

To loosen a clamp, a small slot screwdriver, with a maximum blade width of

3mm is to be used.

●Observe all applicable electrical regulations.

●Work on electrical equipment of the plant / machinery must be performed by

a qualified electrician!

NOTE

WARNING

ELECTRICITY

PAGE 20

INSTALLATION AND COMMISSIONING

CHAPTER 3

3.3 Installation in 4 steps

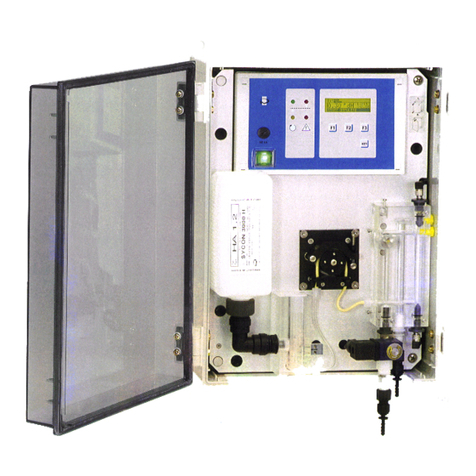

The analyser can be mounted with or without protective enclosure. The

manufacturer offers a standard enclosure. The mounting and dimensions are

described in this guide:

Custom-built or tailor made enclosures for the devices of the series Limit

Analyser /SYCON 2501 / SYCON 2800 as well as devices with custom names

and labels that are technically based on these ranges are not described in detail

in this manual.

►step I a mounting without enclosure

Use 4 screws (max. 6 mm) to mount the unit on a wall or suitable support structure.

For spacing of holes see (Fig. 3.3→ page 24)

Or ►step I b mounting with enclosure

Use the 4 brackets included to mount the unit (Fig. 3.4→ page 24). The tabs can

be rotated by 45 degrees or 90 degrees outside. Alternatively, the unit can be

mounted without the brackets from the rear on a plate (M6). For spacing of holes

see page 24

In both variants, avoid direct sunlight and strong artificial light sources

→ disturbance of the optical path in the measuring chamber

→electromagnetic interferences by artificial light source

Do not install under dripping pipes.

►step II establish sample and drain pipe line

Use flexible pipe 6x4. Between water treatment plant and analyser a manual shut-

off valve and particle filter (if necessary) should be installed. Drainage should be

fed via short connection into an open funnel → run off to atmospheric pressure.

Make sure that you connect the inlet and outlet properly

→ (Figure 2.1 in page 13)

►step III electrical connections

Refer to information in figure 3.1 (terminal connection (→ page 21) and figure 3.2

(connection instructions (→ page 22).

Work on electrical equipment of the plant / machinery must be performed by a

qualified electrician! Observe all applicable electrical installation rules

→ applicable supply voltage 85 - 264 VAC, 47 - 63 Hz

NOTE

NOTE

WARNING

ELECTRICITY

This manual suits for next models

1

Table of contents

Other RLS Wacon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Securitytronix

Securitytronix ST-IP-TEST user manual

AutomationDirect

AutomationDirect ProSense DPM3-E Series user manual

Ntron

Ntron SenzTx Short form User Manual

Aqualytic

Aqualytic CHECKIT Comparator instruction manual

Air Weigh

Air Weigh LOADMAXX installation guide

Master cool

Master cool 52233 user manual