RLS Wacon SYCON P-value User manual

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 2 Subject to change without notice

General notes ......................................................................................................................................................... 4

Safety instructions and symbols used ..........................................................................................................4

Transport............................................................................................................................................................ 5

Storage................................................................................................................................................................ 5

Disposal note.....................................................................................................................................................5

SYCON P in detail.................................................................................................................................................. 6

Scope of delivery..............................................................................................................................................6

Device description............................................................................................................................................8

Operating principle...........................................................................................................................................9

General specification .......................................................................................................................................9

Technical data .................................................................................................................................................10

Analytical properties......................................................................................................................................10

Inputs/outputs of the 24 V AC/DC and 230 VAC version....................................................................11

Maintenance intervals ...................................................................................................................................11

Reagents for monitoring the p-value..........................................................................................................12

Installation.............................................................................................................................................................13

Wall mounting without housing ..................................................................................................................14

Wall mounting with housing ........................................................................................................................15

Work on pressurised water pipes ...............................................................................................................16

Operation with unpressurised sample water............................................................................................17

Electrical installation ...........................................................................................................................................18

Main board 230 VAC version.......................................................................................................................19

Main board 24 V AC/DC version................................................................................................................20

Connection of the supply voltage...............................................................................................................21

Connecting the relay outputs ......................................................................................................................22

Current interface and RS-485......................................................................................................................26

Input contacts 1 and 2...................................................................................................................................27

Connection of external components ...............................................................................................................28

Switch for external analysis start ................................................................................................................30

Connection of a water meter for analyses at volume intervals ............................................................31

Flow monitor / timer......................................................................................................................................32

Interval reset....................................................................................................................................................33

Input 2 (Input 2) Connection of a switch Error RESET ...........................................................................34

Reagent lamp/horn ........................................................................................................................................34

Connecting a control for reagent level warning.......................................................................................36

Relay function analysis active ......................................................................................................................36

Limit value mode ............................................................................................................................................37

Analogue current interface...........................................................................................................................38

Operating status via analogue current interface......................................................................................39

Operation ..............................................................................................................................................................40

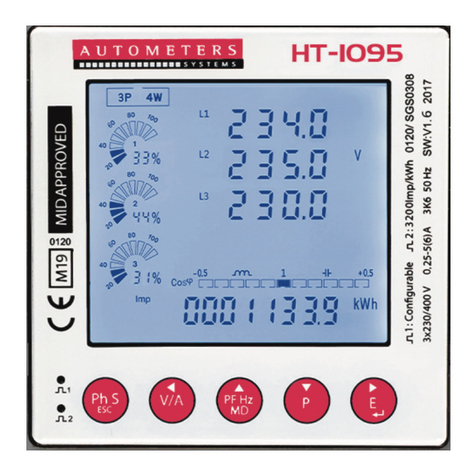

Display and keypad ........................................................................................................................................41

Display Menu ..................................................................................................................................................42

Menu languages..............................................................................................................................................42

Display indication during a measurement .................................................................................................43

Display of measured value history..............................................................................................................44

Display Selection menu.................................................................................................................................44

Display Selection list......................................................................................................................................44

Display with value input................................................................................................................................45

Content

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 3

Configuration........................................................................................................................................................46

Factory settings ..............................................................................................................................................46

Configuration wizard .....................................................................................................................................47

Menu structure ...............................................................................................................................................61

Operation ..............................................................................................................................................................62

Manual and automatic operation ................................................................................................................62

Main menu.......................................................................................................................................................62

Info display.......................................................................................................................................................63

Behaviour in the event of a power failure.................................................................................................63

SD card .............................................................................................................................................................64

Maintenance and service ...................................................................................................................................65

Cleaning the measuring chamber................................................................................................................65

Inserting the "Maintenance Set for SYCON P..........................................................................................66

Reset maintenance counter..........................................................................................................................68

Changing the reagent bottle ........................................................................................................................68

Good and bad counters.................................................................................................................................69

Calibrating the unit.........................................................................................................................................69

Change battery................................................................................................................................................70

Software update .............................................................................................................................................70

Diagnostic functions............................................................................................................................................71

Display ..............................................................................................................................................................71

Sensor ...............................................................................................................................................................71

Solenoid valve .................................................................................................................................................71

Reagent pump .................................................................................................................................................71

Stirrer blade .....................................................................................................................................................72

Relay 1 to 4......................................................................................................................................................72

Current interface ............................................................................................................................................72

Entrance 1 and 2.............................................................................................................................................72

Error messages .....................................................................................................................................................73

Analysis does not start ..................................................................................................................................73

Error message E11 reagent ..........................................................................................................................73

Error message E12 Water flow....................................................................................................................73

Error message E13 Optics ............................................................................................................................73

Error message E14 Titration.........................................................................................................................74

Appendix................................................................................................................................................................75

Spare parts.......................................................................................................................................................75

Maintenance sets ...........................................................................................................................................77

Accessories ......................................................................................................................................................78

Notes.................................................................................................................................................................79

Maintenance and service ..............................................................................................................................79

Settings:............................................................................................................................................................80

Document changes: .......................................................................................................................................81

Declaration of conformity ............................................................................................................................82

Content

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 4 Subject to change without notice

General notes

These operating instructions describe the installation and operation of the online analyser SYCON

P. Installation and commissioning must only be carried out by an authorised specialist.

The unit may only be operated under the conditions described in these operating instructions. The

unit may only be used for the specified purpose. When installing and operating the analyser, all

locally applicable regulations (such as EN, DIN, VDE, UVV) must be observed.

The switch of the analyser does not disconnect the mains terminals from the power supply. The

installation of a suitable electrical disconnecting device is the responsibility of the system operator.

Before opening the housing, disconnect the unit from the power supply and secure it against

unintentional reconnection.

The analyser is used for the automatic determination of the p-value in the process water. Proper

operation can only be guaranteed if the reagents and spare parts recommended by us are used.

Changes to the electrical wiring and programming may only be carried out by a designated

specialist.

The water connection lines to the unit should be kept as short as possible and should not be laid

together with mains lines or in their immediate vicinity. In the vicinity of strong electromagnetic

radiators, interference with the analysis may occur; in this case, separate interference suppression

measures must be taken, in particular the EMC guidelines must be observed.

It is recommended to always have access to the analyser when familiarising oneself with the help of

these operating instructions in order to be able to understand the explained correlations and

functions immediately. Since certain areas build on each other, it makes sense to work through the

chapters in the given order.

If you have any questions about the use of the analyser, you will receive support from our partners

or from us. You can reach us by telephone during normal business hours or by email. The contact

details of our technicians and our partners can be found on our website.

Safety instructions and symbols used

In this operating manual you will find various safety instructions that point out possible risks when

handling the analyser. This concerns in detail dangers for

•People,

•this product or associated equipment and installations,

•the working environment.

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 5

Various symbols in these operating instructions indicate special dangers to prevent personal injury

and damage to the appliance. Please read the entire text completely before starting work.

This symbol draws your attention to useful tips that contribute to a better

understanding of the unit.

This symbol is a general warning that indicates circumstances that must be

observed.

Print

This symbol is a warning that you must expect pipes under pressure.

Voltage

This symbol indicates the danger of electric current and the danger to

persons and electronic components and assemblies.

Transport

Immediately after receipt, check that the unit is complete and has no

transport damage. The analyser is delivered in a transport-safe condition.

Nevertheless, damage may occur during transport. Immediately inform the

delivery person of any transport damage.

Protect the analyser from possible damage during transport. Remove any

liquids still in it beforehand. Remove the reagent bottle and close it to

prevent the reagent from leaking.

Storage

Store the analyser in a dry place at temperatures between 0 - 45 °C and out

of direct sunlight.

Disposal note

The appliance must not be disposed of with residual waste. Take the unit to a collection point. The

battery must be disposed of separately.

Alternatively, you can return the analyser to your dealer or to us for disposal.

General notes

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 6 Subject to change without notice

SYCON P in detail

The SYCON P online analyser is characterised by the following features:

•Reliable, accurate and fully automatic analyser

•Monitoring of two programmable limit values

•Simple commissioning through configuration wizard

•Self-calibrating and self-monitoring

•Easy maintenance and cleaning

•Compact design

•Multicolour, multilingual graphic display

•Relay output for limit value 1

•Relay output for limit value 2 or reagent alarm

•Relay output for fault indication

•Relay output for feed pump, reagent alarm or cooling water valve

•Analogue output 0/4 - 20 mA for measured value or status message

•2 programmable digital inputs

•Measurement data memory and measurement data log on SD card

•No formation of condensate in the optics

•Software updates via SD card

Scope of delivery

The SYCON P is available in two versions:

1. Analyser on wall mount

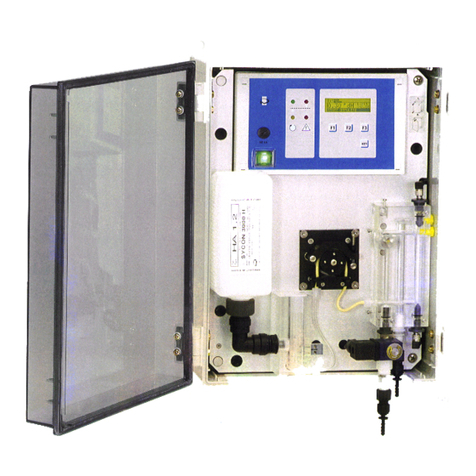

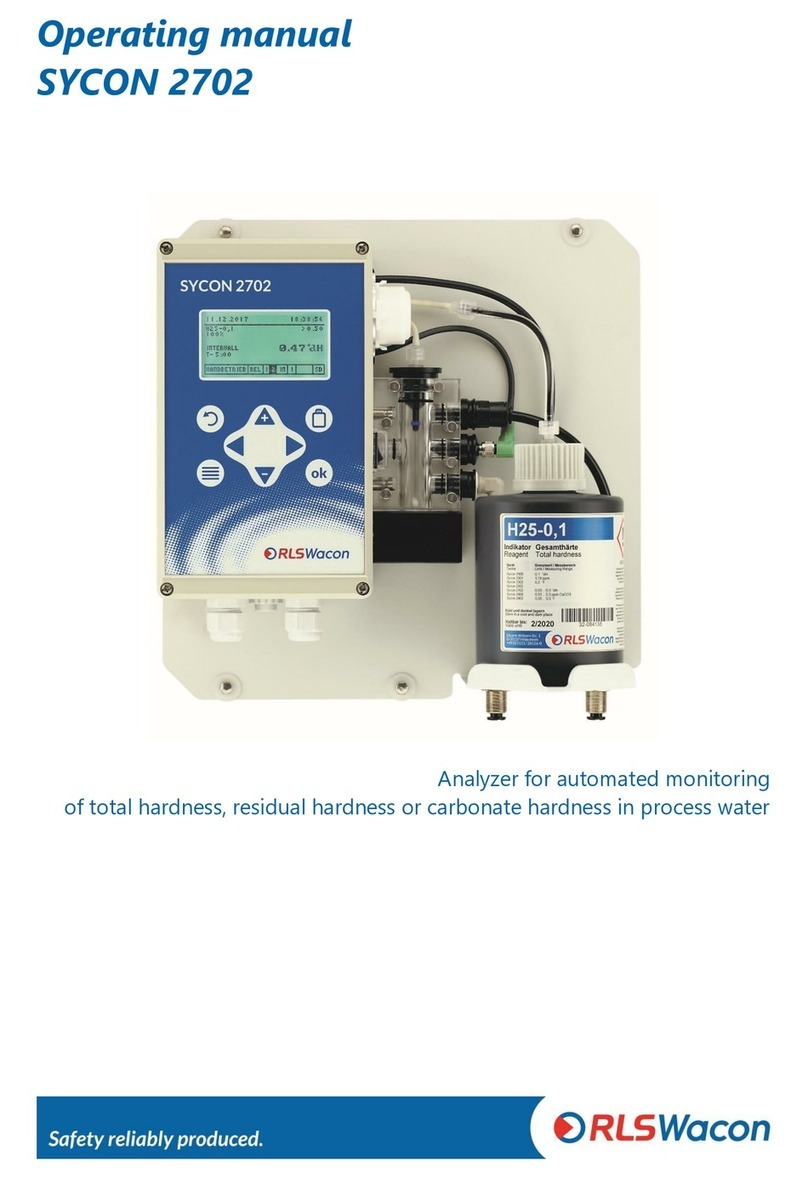

The analyser consists of a control unit and the measuring chamber. Both are mounted on a

wall bracket. This version is completely functional and contains the connections for the

water inlet and outlet as well as a holder to accommodate an reagent bottle (Figure 1).

2. Analyser in housing

A plastic housing is available as an option for the analyser on the wall bracket in order to use

the analyser in places where more contamination is to be expected (Figure 2). The analyser

on wall bracket can be quickly mounted in the housing with 4 screws. If the analyser and

housing are ordered together, you will receive the analyser already mounted in the housing.

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 7

SYCON P in detail

Article description

Article number

SYCON P analyser on wall mount

230 VAC version

30-010 210

SYCON P analyser on wall mount

24 V AC/DC version

30-011 211

SYCON P analyser in housing

230 VAC version

30-210 210

SYCON P analyser in housing

24 V AC/DC version

30-211 210

Enclosure for SYCON series including wall mounting brackets

33-099 005

The operation of the analyser is menu-driven and intuitive via the graphic display and the 8 keys on

the control housing.

Figure 1:

SYCON P on wall bracket

Figure 2:

SYCON P in the housing

The SYCON P analyser on wall bracket is fixed in the housing with 4 screws

supplied.

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 8 Subject to change without notice

Device description

The analyser consists of the following components: The control unit with graphic display and

control panel is located on the left side of the unit. There are 4 cable feed-throughs on the lower

control housing. On the right side is the dosing pump and below it the measuring chamber.

The dosing pump is attached to the motor shaft of the motor and engages in the receptacle. It can

be removed without tools. The measuring chamber is attached to 2 guide pins on the control

housing. It can also be removed without tools and is released with 2 captive locking pins. The

metering plugs, actuator plugs, inlet and outlet plugs are attached to the measuring chamber in the

same way and can be released quickly.

In the middle is the measuring chamber, which is basically pressureless and always filled to avoid

contamination. In the middle of the measuring chamber is the actuator plug with a white high-

power LED. The sensor system is located in the housing. Below the measuring chamber is an

agitator (magnetic stirrer) that is firmly connected to the housing.

Under the reagent bottle are the water connections for hoses with an outer diameter of 6 mm: inlet

with sample water (left) and outlet (right).

Both are firmly screwed to the wall bracket.

Behind the reagent bottle there is a solenoid valve in the supply line.

Figure 3: View of the solenoid valve (no reagent bottle installed)

A more detailed description of the components can be found from page 40.

SYCON P in detail

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 9

Operating principle

The SYCON P based on the SYCON series is an online analyser for the automatic determination of

water parameters according to the colorimetric titration method. By adding an reagent to the water

sample, a colour reaction is generated. Depending on the reagent used, the device evaluates the

intensity of the colour. Through the colour change of the sample during the addition of the reagent,

the SYCON P calculates the concentration of the water ingredient. The device can only determine

one parameter at a time. Parameter and measuring range are determined by the reagent used.

General specification

Parameter

Value / Range

Power supply

(230 VAC version) 100 - 240 VAC (50/60 Hz)

(24 V AC/DC version) 21.6 - 26.4 V AC/DC (50Hz)

Power consumption

25 VA (in operation)

8 VA (measuring mode)

3.5 VA (standby)

Resilience

Load capacity of the relays with internal power supply 1 A from

terminals 1 to 4

Load capacity of the relays with external power supply 2.5 A

Protection class

Open wall mounting IP43Mounting

in enclosure IP54

Storage temperature

0 °C - 45 °C

Ambient temperature

10 °C - 45 °C

Measured water temperature

5 °C - 40 °C

Humidity

20 - 90 % RF (without ice or condensation)

Inlet water pressure

min: 0.5 bar - max: 5 bar / recommendation 1 - 2 bar

Inlet water in general

clear, colourless, free of solids, without gas bubbles

Water quality requirements

for the measurement of the

p-value

pH:

> 8,2

Note on oxidising agents:

Oxidising agents such as calcium hypochlorite, chlorine, chlorine dioxide, sodium hypochlorite or

ozone above the limits permitted in "TrinkwV 2012" attack the dye contained in the reagent and

interfere with the measurement. This means that an exact determination of the measured value is

no longer guaranteed. An activated carbon filter connected upstream of the analyser can remove

these oxidants from the sample water and thus enable the correct determination of the measured

value.

The capacity of an activated carbon filter is consumed during operation. Therefore, the activated

carbon filter must be replaced at regular intervals. The effectiveness of the activated carbon filter

can be checked with the help of Caldur® test sets.

SYCON P in detail

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 10 Subject to change without notice

SYCON P in detail

Technical data

Parameter

Value / Range

Installation

Wall mounting in closed rooms

Dimensions

without housing:

274 x 275 x 129 mm (W x H x D)

with housing:

332 x 345 x 190 mm (W x H x D)

Weight

without housing:

approx. 2.0 kg

with housing:

approx. 4.0 kg

Analytical properties

Parameter

Value / Range

Measuring method

Titration with colour change

Measuring range

P25-5

P25-20

mmol/l

0,2 ... 5

0,8 ... 20

The measuring range is defined by the reagent used.

Accuracy

Measuring accuracy: ± 5 % of the maximum measured value of the

respective reagent used

Repeatability: ± 2.5 % of the maximum measured value of the respective

reagent used

Please note: Depending on the ingredients in the water, there may be shifts

in the measured value that affect the measurement accuracy. In such cases,

we recommend carrying out a comparison measurement by hand titration

and calibrating the analyser to this measured value.

Power interface

± 0.3 mA

Reagent

consumption

approx. 0.05 - 0.6 ml / analysis, depending on the measured p-value

Measuring time

approx. 3 min, depending on the p-value and the set flushing time

Durability of the

reagents

min. 12 month with proper storage (< 25 °C, dark)

Water

consumption

approx. 1 l / analysis at 2 bar

The water consumption varies depending on the inlet pressure and the set

flushing time.

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 11

Inputs/outputs of the 24 V AC/DC and 230 VAC version

Parameter

Value / Range

4 relay outputs

max. 250 VAC / VDC 1 A

as potential-free outputs NC/NO

the relays provide the following functions:

•Limit value alarm 1

•Limit value alarm 2

•Device error

•Analysis active with switchable delay time

•Reagent message

2 signal inputs

galvanically isolated contact input

•Start analysis

•Water meter

•Flow monitor

•Interval reset

Analogue output

0 - 20 mA / 4 - 20 mA

Resolution: < 100 μA

max. load: 750 Ω

RS-485

Modbus RTU protocol

Registers and programming of the interface can be found in the

separate manual for the Modbus RTU

Maintenance intervals

Interval

Maintenance work

every 6 months

Cleaning the measuring chamber

In case of high ambient and water temperatures or water with a high

organic load, the cleaning intervals may have to be shortened.

every 30,000 analyses or

after 2 years of

operation

Cleaning the measuring chamber (as above),

Installation Maintenance kit: Change the hose pump cassette and the

seals. Resetting the maintenance counter.

SYCON P in detail

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 12 Subject to change without notice

SYCON P in detail

Reagents for monitoring the p-value

Designation

Reagent

Measuring range

Item no.

500ml bottle

Item no.

4 x 500 ml

bottles

mmol/l

P25-5

0,2 ... 5

32-086 353

32-486 353

P25-20

0,8 ... 20

32-086 354

32-486 354

The measured value to be monitored should be as close as possible to the

middle of the measuring range of the reagent.

The number of possible analyses with one reagent bottle depends on the respective p-value and the

reagent used.

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 13

Installation

The installation should be done in the following steps to avoid errors:

•Install the analyser in a dry, easily accessible and easily visible place.

•Secure the analyser or the housing stably with screws according to the instructions.

•Connect the unit electrically and make sure that the input voltage is correct. Check the type

plate to make sure.

•Connect the inlet and outlet according to the installation instructions. Make sure that the

inlet pressure is correct and that the outlet is kept free and short.

•Insert the reagent and connect it to the dosing pump. Make sure that the connecting hoses

are not twisted.

•Do not switch on the unit until all preliminary work has been completed and the housing is

closed.

•Now make the unit settings on the unit.

The sample water must be clear and free of solids. Otherwise, a filter must be

provided upstream of the analyser. Solids in the water can damage the

solenoid valve or prevent it from closing. If the solenoid valve blocks or no

longer opens or closes, the flow through the measuring chamber will not be

correct. This leads to incorrect measurements.

The temperature of the sample water must be between 5 and 40 °C.

If the sample water has a higher temperature, a sample cooler must be used.

This is available as an accessory.

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 14 Subject to change without notice

Installation

Wall mounting without housing

The SYCON P must be installed in an upright position. There are four 6 mm holes in the wall

bracket for mounting the analyser.

Figure 4Drilling plan for mounting the analyser without housing

Position

Description

A

Cable glands for electrical connection

B

Water inlet - connection for hose with 6 mm outer diameter

C

Water drain - connection for hose with 6 mm outer diameter

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 15

Wall mounting with housing

The analyser is optionally supplied with a matching housing. As an accessory pack, you will receive

4 mounting brackets with 6.5 mm holes that are attached to the back of the housing.

To open the unit, the available free space should be at least 450 x 350 mm (W x H).

Figure 5Drilling plan for mounting the analyser in the housing

Position

Description

A

Cable bushings for electrical connection

B

Water inlet - connection for hose with 6 mm outer diameter

C

Water drain - connection for hose with 6 mm outer diameter

D

Door hinge

E

Door latches

Installation

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 16 Subject to change without notice

Installation

The fixing lugs can be fitted vertically, as shown in the picture, or rotated by 45° or 90°.

Figure 6: Rear view of the enclosure with mounting brackets mounted vertically

Work on pressurised water pipes

Print

Maintenance and repair work may only be carried out by skilled personnel.

•Before starting work, make sure that all pipes are depressurised.

•Hoses, connections and seals must be checked regularly and, if necessary, replaced as a

precaution, even if they show no visible damage. Maintenance intervals must be observed.

•Before commissioning after maintenance, make sure that all connections, screw connections

and seals are properly installed. Check that all casing parts are closed and filters or other

parts connected to the unit are correctly installed.

•Remove all tools, spare parts or other material required for maintenance before

commissioning.

•Clean the unit, absorb any spilled liquids and leave the unit in a clean condition.

•Check that all safety devices are in place and operational.

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 17

The analyser has two connections with bulkhead fittings for plastic hoses

with an outer diameter of 6 mm for the water inlet (left) and the water outlet

(right). These are simply plugged into the screw connections.

Figure 7: Connecting the water inlet and outlet

Print

The inlet pressure of the water sample must be between 0.5 and 5.0 bar.

The recommended inlet pressure of the water sample should be between 1

and 2 bar.

The hose length of the water drain must not be longer than 2 m and must

lead away vertically downwards. The system must be able to relax freely

against the atmospheric pressure. There must be no back pressure greater

than the inlet pressure. The water is drained without pressure into an open

funnel or drain.

Operation with unpressurised sample water

If the sample water is unpressurised, a pressure-controlled diaphragm or submersible pump is

required to convey the sample water into the measuring chamber of the analyser.

Installation

Water inlet

(Water inlet)

open hopper

Hand valve

(install on site)

Softening

Water drainage

(Water outlet)

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 18 Subject to change without notice

Electrical installation

Voltage

Work on electrical connections may only be carried out by authorised

specialist personnel in compliance with the current regulations. All lines must

be de-energised.

Open the cover of the control unit by loosening the four screws in the corners of the cover.

Illustration 8: Back of the cover

Position

Description

D

Display connection

L

SD card socket

M

Sound signal generator

© RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de July 2022

Subject to change without notice Page 19

Electrical installation 230 VAC version

Main board 230 VAC version

Figure 9Main board 230 VAC version

Position

Description

A

Battery holder

B

Solenoid valve connection

C

Reagent pump connection

D

Display connection

E

Actuator plug LED connection

F

Main switch connection

G

Fuse (5 x 20 mm)

2 A Inert

H

Fuse (5 x 20 mm)

400 mA Inert

I

4 x relay

J

Agitator connection

K

RGB sensor

July 2022 © RLS Wacon analytics GmbH +49 (0)5121 281260 info@rls-wacon.de

Page 20 Subject to change without notice

Electrical installation 24 V AC/DC version

Main board 24 V AC/DC version

Figure 10Main board 24 VAC version

Position

Description

A

Battery holder

B

Solenoid valve connection

C

Reagent pump connection

D

Display connection

E

Actuator plug LED connection

F

Main switch connection

G

Fuse (5 x 20 mm)

2 A Inert

H

Fuse (5 x 20 mm)

1 A Inert

I

4 x relay

J

Agitator connection

K

RGB sensor

Table of contents

Other RLS Wacon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Agilent Technologies

Agilent Technologies E5061B Configuration guide

ABB

ABB MagMaster user guide

ETCR

ETCR 6300D user manual

ACCEL DFI

ACCEL DFI Engine Analyzer Series Installation and instruction manual

BRUEL & KJAER

BRUEL & KJAER LAN-XI Notar BZ-7848-A quick start guide

ABB

ABB Endura AZ20 series instructions