RLS Wacon SYCON 2702 User manual

Operating manual

SYCON 2702

Analyzer for automated monitoring

of total hardness, residual hardness or carbonate hardness in process water

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ i[email protected] 2

General notes......................................................................................................................................................................... 4

Safety instructions and used symbols .................................................................................................................... 4

Transport............................................................................................................................................................................ 5

Storage ............................................................................................................................................................................... 5

Instruction on disposal................................................................................................................................................. 5

SYCON 2702 in detail.......................................................................................................................................................... 6

Scope of supply............................................................................................................................................................... 6

Device description.......................................................................................................................................................... 8

Principle of function ...................................................................................................................................................... 9

General specification..................................................................................................................................................... 9

Technical data................................................................................................................................................................10

Analysis properties.......................................................................................................................................................10

Inputs/outputs...............................................................................................................................................................11

Maintenance interval...................................................................................................................................................11

Reagents for monitoring total hardness..............................................................................................................12

Reagents for monitoring carbonate hardness...................................................................................................12

Installation.............................................................................................................................................................................13

Wall mounting without housing.............................................................................................................................14

Wall mounting with housing....................................................................................................................................15

Work on pressurised water lines.............................................................................................................................16

Operation with unpressurised sample water .....................................................................................................17

Electrical installation..........................................................................................................................................................18

Connection of supply voltage..................................................................................................................................19

Connection of the relay outputs.............................................................................................................................20

Current interface contact...........................................................................................................................................21

Input contact..................................................................................................................................................................22

Connection of external components...........................................................................................................................23

Switch for starting the analysis externally...........................................................................................................24

Flow switch......................................................................................................................................................................25

Intervall reset..................................................................................................................................................................26

Reagent light / horn ....................................................................................................................................................27

Regeneration system for demand-controlled regeneration triggering...................................................28

Analogue measuring device.....................................................................................................................................28

Operating status via analogue current interface..............................................................................................29

Operation...............................................................................................................................................................................30

Display and keypad......................................................................................................................................................31

Display menu..................................................................................................................................................................32

Menu languages ...........................................................................................................................................................32

Display during a measurement ...............................................................................................................................33

Display of measured value history (history) .......................................................................................................34

Display of selection menu.........................................................................................................................................34

Content

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 3

Display of selection list...............................................................................................................................................34

Display with value entry.............................................................................................................................................35

Configuration.......................................................................................................................................................................36

Factory settings .............................................................................................................................................................36

Configuration assistant...............................................................................................................................................37

Menu structure..............................................................................................................................................................50

Mode.......................................................................................................................................................................................51

Manual and automatic mode...................................................................................................................................51

Main menu......................................................................................................................................................................51

Info display......................................................................................................................................................................52

Behaviour in the event of power failure...............................................................................................................52

SD-card.............................................................................................................................................................................53

Maintenance and service.................................................................................................................................................55

Cleaning the measuring chamber ..........................................................................................................................56

Inserting the "Maintenance set for SYCON 2702" ...........................................................................................58

Reset the maintenance counter..............................................................................................................................60

Changing the reagent bottle....................................................................................................................................61

Good- and bad counter .............................................................................................................................................62

Calibrating the device.................................................................................................................................................63

Changing the battery..................................................................................................................................................64

Software update............................................................................................................................................................64

Diagnosis functions ...........................................................................................................................................................65

Display ..............................................................................................................................................................................65

Sensor ...............................................................................................................................................................................65

Solenoid valve................................................................................................................................................................65

Reagent pump...............................................................................................................................................................65

Agitator blade................................................................................................................................................................66

Relay 1 and 2..................................................................................................................................................................66

Current interface...........................................................................................................................................................66

Input ..................................................................................................................................................................................66

Error analysis ........................................................................................................................................................................67

Analysis does not start................................................................................................................................................67

Zero sample is faulty ...................................................................................................................................................67

Titration is not carried out correctly......................................................................................................................67

Measurement deviates ...............................................................................................................................................67

Annex ......................................................................................................................................................................................68

Spare parts......................................................................................................................................................................68

Maintenance sets..........................................................................................................................................................70

Accessories......................................................................................................................................................................71

Declaration of conformity .........................................................................................................................................72

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ i[email protected] 4

General notes

This operating manual describes the installation and operation of the online Analyzer SYCON 2702.

The installation and commissioning are to be carried out by an authorised specialist.

The device may only be operated under the conditions described in this operating manual. The

device may be used only for the specified purpose of use. For the installation and operation of the

Analyzer, all the provisions applicable on site (such as EN, DIN, VDE, UVV) are to be followed.

The Analyzer is used for automatic determination of total water hardness or carbonate water

hardness in process water. Proper operation can only be guaranteed if the reagents and spare parts

recommended by us are used.

Modifications to the electrical wiring and the programming may only be made by a trained

specialist.

The water connection pipes to the device should be kept as short as possible and should not be

laid together with network lines or in their immediate vicinity. In the vicinity of strong

electromagnetic emitters, the analysis can become disturbed. In this case, separate interference

suppression measures are to be taken; in particular the EMC directives are to be followed.

It is recommended to always have access to the analyzer when familiarising oneself with these

operating instructions in order to understand the described relationships and functions

immediately. Since certain areas are built upon one another, it is advisable to work through the

chapter in the specified order.

If there are any questions when using the analyzer, you will receive support from our partners or us.

You can reach us by phone during normal business hours or by email. You will find complete

contact details of our technicians and our partners on our website.

Safety instructions and used symbols

This operating manual contain various safety instructions that indicate possible risks when using

the analyzer. This specifically concerns hazards for

•people,

•this product or related devices and installations,

•the working environment.

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 5

Various symbols in this manual indicate special hazards in order to avoid personal injury and

equipment damage. Please read the entire text in full before starting work.

This symbol indicates useful tips for a better understanding of the device.

This symbol is a general warning that indicates circumstances that need to be

considered.

Pressure

This symbol is a warning that you must expect lines under pressure.

Voltage

This symbol indicates the risk of electric current and the endangerment of

people and electronic components and assemblies.

Transport

Check immediately after receipt that the device is complete and free from

transport damage. The analyzer is shipped in a manner safe for transport.

Nevertheless, damage may occur during transport. Instruct the deliverer

immediately about damage during transport.

Protect the analyzer from possible damage during transport. If necessary,

remove any liquids still in it in advance. Remove the reagent bottle and close

it to prevent the reagent from leaking.

Storage

Store the analyzer in a dry place at temperatures between 0 - 45° C and

without direct sunlight.

Instruction on disposal

The device must not be disposed of as residual waste. Bring the device to a collection point. The

battery should be disposed of separately.

Alternatively, you can return the analyzer to your dealer or us for disposal.

General notes

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 6

SYCON 2702 in detail

The SYCON 2702 online analyzer has the following features:

•reliable, accurate and fully automatic analyzer

•monitoring of a programmable limit value

•total hardness or carbonate hardness can be measured with the same analyzer

•simple commissioning via configuration wizard

•BOB operation (72 hours)

•self-calibrating and self-monitoring

•easy maintenance and cleaning

•compact design

•multicoloured, multilingual graphic display

•relay output for limit value

•relay output for error message

•analogue output 0/4 - 20 mA for measured value or status message

•digital input for start analysis, flow switch or interval reset

•Measurement data memory and measurement data protocol on SD card

•no condensation in the optics

•Software updates via SD card

The SYCON 2702 is not a system that prevents hardness irruption.

Scope of supply

The SYCON 2702 is available in two versions:

1. Wall-mounted analyzer

The analyzer consists of a controller and the measuring chamber. Both are mounted on a

wall bracket. This version is fully functional and includes connections for the water inlet and

-outlet and a holder for holding an reagent bottle (Figure 1).

Article name

Article no.

Analyzer SYCON 2702 with wall mounting

230 V version

30-010 162

Operating manual (English)

33-099 723

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 7

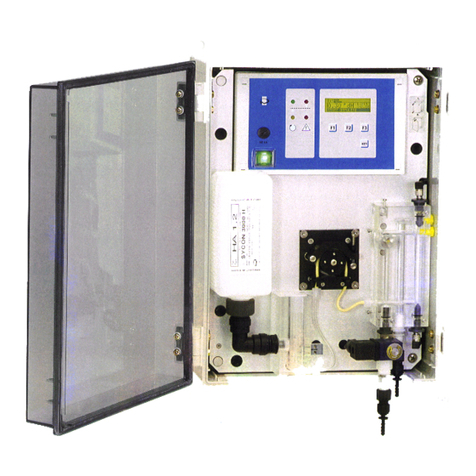

2. Analyzer in housing

Optionally for wall-mounted analyzer, a plastic housing is available in order to use the

analyzer in locations where more severe contamination is expected (Figure 2). The analyzer

on the wall mount can be quickly mounted in the housing with 4 screws. If the analyzer and

the housing are ordered together, the device is already mounted in the housing.

Article name

Article no.

Analyzer SYCON 2702 with wall mounting

230 V version

30-010 162

Operating manual (German)

33-099 722

Housing for SYCON 2702 including wall mounting straps

33-099 005

The analyzer can be operated intuitively via menu using the graphic display and 8 keys on the

controller housing.

Figure 1:

Wall mounted SYCON 2702

Figure 2:

Wall mounted SYCON 2702 in housing

The wall mounted SYCON 2702 analyzer is mounted in the housing with 4

supplied screws.

SYCON 2702 in detail

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 8

Device description

The analyzer consists of the following components: The controller with graphic display and control

panel is on the left side of the device. 4 cable bushings are provided on the lower controller

housing. The dosing pump is on the right side and the measuring chamber is below the dosing

pump.

The dosing pump is plugged onto the motor shaft of the motor and snaps into the receptacle. It

can be removed without tools. The measuring chamber is attached to 2 guide pins on the

controller housing. This can also be removed without tools and is undone with 2 captive locking

pins. Dosing plugs, actuator plugs, inlet- and outlet plugs are attached to the measuring chamber

in the same way and can be quickly undone.

The measuring chamber, which is always depressurised and always filled to prevent germs, is in the

middle. The actuator plug with a white high-power LED is in the middle of the measuring chamber.

The sensor system is located in the housing. The agitator (magnetic agitator), which is firmly

connected to the housing, is below the measuring chamber.

The water connections for hoses with an outer diameter of 6 mm are below the reagent bottle.

Inlet with sample water (left) and outlet (right). Both are firmly bolted to the wall bracket.

There is a solenoid valve in the supply line behind the reagent bottle.

Figure: View of the solenoid valve (no reagent bottle installed)

For a more detailed description of the components, see page 30.

SYCON 2702 in detail

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 9

Principle of function

The SYCON 2702 based on the SYCON series is an online analyzer for the automatic determination

of water parameters according to the colorimetric titration method. By adding an reagent to the

water sample, a colour reaction is produced. Depending on the reagent used, the device evaluates

the colour intensity. By changing the colour of the sample during the addition of the reagent, the

SYCON 2702 calculates the concentration of the substances in water. The device can only

determine one parameter at a time. Parameters and measuring range are determined by the

reagent used.

General specification

Parameter

Value/range

Voltage supply

(230 V version)

85 - 305 VAC (47...440 Hz)

Power consumption

25 VA (in operation)

3.5 VA (standby)

Load capacity

Load capacity of the relays with internal current supply of 1 A

from terminals 5 to 8

Load capacity of the relays with external current supply of 2.5 A

Protection class

open wall mounting IP43

Installation in the housing IP54

Storage temperature

0 °C –45 °C

Ambient temperature

10 °C –45 °C

Measuring water

temperature

5 °C –40 °C

Air humidity

20 –90 % RH (without ice or condensate)

Pressure of inlet water

min: 0.5 bar - max: 5 bar - recommendation 1 - 2 bar

General inlet water

clear, colourless, free of solids, without gas bubbles

Requirements for the water

quality when measuring the

water hardness

pH:

4 - 10

Iron:

< 3 ppm

Copper:

< 0.2 ppm

Aluminium:

< 0.1 ppm

Manganese:

< 0.2 ppm

Acid capacity:

KS 4.3 < 5 mmol/l

Note on oxidizing agents:

Oxidizing agents, e.g. calcium hypochlorite, chlorine, chlorine dioxide, sodium hypochlorite or

ozone beyond the limits permitted in "TrinkwV 2012" attack the dye contained in the reagent and

interfere with the measurement. An exact determination of the water hardness is no longer

guaranteed. An activated carbon filter upstream of the analyzer can remove these oxidants from

the sample water and thus allow the correct determination of the water hardness.

The capacity of an activated carbon filter consumes during operation. Therefore, the activated

carbon filter must be replaced at regular intervals. The effectiveness of the charcoal filter can be

checked using Caldur® test kits.

SYCON 2702 in detail

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 10

SYCON 2702 in detail

Technical data

Parameter

Value/range

Installation

Wall mounting in closed rooms

Dimensions

without housing:

274 x 275 x 129 mm (W x H x D)

with housing:

332 x 345 x 190 mm (W x H x D)

Weight

without housing:

approx. 1.9 kg

with housing:

approx. 3.8 kg

Analysis properties

Parameter

Value/range

Measurement

method

Titration with colour change

Measurement

range

Total hardness

Carbonate hardness

°dH

0.012 …30

0.3 …22.5

°f

0.021 …53.6

0.5 …40.2

ppm CaCO3

0.21 …535.7

5.4 …401.8

mmol/l

0.0021 …5.36

0.11 … 8.04

°e

0.015 …38.6

0.39 …28.9

°Ж

0.0043 … 10.7

0.21 … 16.1

The measuring range is defined by the reagent used. The entire measuring

range of the total hardness is achieved by using different reagents. (The

following units are available for the analysis value: °dH, °f, ppm CaCO3,

mmol/l, °e, °Ж these are shown in the display).

Accuracy

Measuring accuracy: ± 5% of the maximum reading of the respectively used

reagent.

Repeat accuracy: ± 2.5% of the maximum reading of the reagent used

Please note: Depending on the substances in the water, there may be shifts

in the reading that affect the measurement accuracy. In such cases, we

recommend performing a hardness measurement by hand titration and

calibrating the analyzer to this reading.

Current interface

± 0.3 mA

Reagent

consumption

approx. 0.05 - 0.5 ml/analysis, depending on the measured water hardness

Measuring duration

approx. 3 min, depending on the water hardness and the set flushing time

Number of

analyses

max. approx. 10,000 analyses / 500 ml of reagent at low water hardness. The

consumption depends on the measured water hardness and the reagent

used.

Shelf life of the

reagents

at least 2 years with proper storage (<25° C, dark)

Water

consumption

approx. 1 l/analysis with 2 bar

The water consumption varies depending on the inlet pressure and the set

flushing time.

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 11

Inputs/outputs

Parameter

Value/range

2 relay outputs

max. 250 VAC / VDC 1 A (For more information, see page 9)

as potential-free outputs NC/NO

The relays provide the following functions:

•Limit alarm

•Device error

•Standby

Signal input

electrically separated contact input

•Start analysis

•Flow switch

•Interval reset

Analogue output

0 –20 mA / 4 –20 mA

Resolution: < 100 μA

max. load: 750 Ω

Maintenance interval

Interval

Maintenance works

every 6 months

Cleaning of measurement chamber

At high ambient- and water temperatures or water with high organic

load, the cleaning intervals may need to be shortened.

every 30,000 analyses or

after 2 years of

operation

Cleaning of measurement chamber (as above),

Installation of maintenance kit: Changing the peristaltic pump

cartridge and the gaskets

SYCON 2702 in detail

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 12

SYCON 2702 in detail

Reagents for monitoring total hardness

Name

Reagent

Measurement ranges

Art.-no.

500 ml bottle

Art.-no.

4 x 500 ml

bottles

°dH

ppm CaCO3

°f

H25-0,02

0.012 ... 0.12

0.21 ... 2.14

0.021 ... 0.214

32-084 115

32-484 115

H25-0,05

0.02 ... 0.2

0.36 ... 3.57

0.036 ... 0.357

32-084 125

32-484 125

H25-0,1

0.03 ... 0.3

0.54 ... 5.36

0.054 ... 0.536

32-084 135

32-484 135

H25-0,2

0.06 ... 0.6

1.1 ... 10.7

0.11 ... 1.07

32-084 145

32-484 145

H25-0,3

0.09 ... 0.9

1.6 ... 16.1

0.16 ... 1.61

32-084 155

32-484 155

H25-0,5

0.15 ... 1.5

2.7 ... 26.8

0.27 ... 2.68

32-084 165

32-484 165

H25-1

0.3 ... 3.0

5.4 ... 53.6

0.54 ... 5.36

32-084 175

32-484 175

H25-2

0.6 ... 6.0

10.7 ... 107.1

1.1 ... 10.7

32-084 185

32-484 185

H25-3

0.9 ... 9.0

16.1 ... 160.7

1.6 ... 16.1

32-084 195

32-484 195

H25-5

1.5 ... 15

26.8 ... 267.9

2.7 ... 26.8

32-084 205

32-484 205

H25-10

3 ... 30

53.6 ... 535.7

5.4 ... 53.6

32-084 215

32-484 215

(The following units are available for the analysis value: °dH, °f, ppm CaCO3, mmol/l, °e, °Ж these

are shown in the display).

Reagents for monitoring carbonate hardness

Name

Reagent

Measurement range

Art.-no.

500 ml bottle

Art.-no.

4 x 500 ml

bottles

°dH

mmol/l

°f

C25-1

0.3 ... 7.5

0.11 ... 2.68

0.5 ... 13.4

32-086 125

32-486 125

C25-1,5

0.5 ... 11.5

0.16 ... 4.11

0.8 ... 20.5

32-086 135

32-486 135

C25-2

0.6 ... 15.0

0.21 ... 5.36

1.1 ... 26.8

32-086 145

32-486 145

C25-3

0.9 ... 22.5

0.32 ... 8.04

1.6 ... 40.2

32-086 155

32-486 155

(The following units are available for the analysis value: °dH, °f, ppm CaCO3, mmol/l, °e, °Ж these

are shown in the display).

The measured value to be monitored should be as close to the middle of the

measuring range of the reagent as possible.

One bottle of reagent suffices for at least 10,000 analyses if the measurement point is in the lower

range of the reagent type used.

The exact number of possible analyses with an reagent bottle depends on the respective degree of

hardness and the reagent used.

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 13

Installation

The installation should be done in the following steps to avoid errors:

•Install the analyzer in a dry, easily accessible and easily visible location.

•Fix the analyzer or housing stably with screws according to the manual.

•Connect the device electrically and pay attention to the correct input voltage. Ensure this

using the nameplate.

•Connect inlets and outlets according to the installation manual. Pay attention to a correct

inlet pressure and free, short outlet.

•Insert the reagent and connect it to the dosing pump. Make sure that the connecting hoses

are not twisted.

•Do not switch on the device until all preliminary works have been completed and the

housing is closed.

•Now set the device settings on the device.

The sample water must be clear and free of solids. Otherwise, a filter should

be provided in front of the analyzer. Solids in the water can damage the

solenoid valve or prevent it from closing. If the solenoid valve blocks or does

not open or close any longer, the measuring chamber will not be flown-

through properly. This leads to incorrect measurements.

Temperature of the sample water must be between 5 and 40 °C.

If the sample water has a higher temperature, a sample cooler should be

used. This is available as an accessory.

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 14

Installation

Wall mounting without housing

The SYCON 2702 must be installed upright. The wall bracket has four 6 mm holes for attaching the

analyzer.

Figure: Drill guide for attaching the analyzer without housing

Position

Description

A

Cable glands for electrical connection

B

Water inlet connection for hose with 6 mm outer diameter

C

Water outlet connection for hose with 6 mm outer diameter

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 15

Wall mounting with housing

The analyzer is optionally supplied with a matching housing. As accessories kit you will receive 4

mounting lugs with 6.5 mm holes, which are attached to the rear side of the housing.

To open the device, the available free space should be at least 450 x 350 mm (W x H).

Figure: Drill guide for attaching the analyzer in the housing

Position

Description

A

Cable glands for electrical connection

B

Water inlet connection for hose with 6 mm outer diameter

C

Water outlet connection for hose with 6 mm outer diameter

D

Door stop

E

Door locks

Installation

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 16

Installation

The mounting lugs can be attached perpendicularly, as shown in the picture, or as rotated by 45° or

90°.

Figure: Rear view of the housing with vertically

mounted mounting lugs

Work on pressurised water lines

Pressure

Maintenance and repair works should only be carried out by qualified

personnel.

•Before starting work, make sure that all lines are depressurised.

•Hoses, connections and gaskets must be regularly checked and, if necessary, preventively

replaced, even if they show no visible damage. Maintenance intervals must be complied

with.

•Before commissioning after maintenance, make sure all connections, threaded fittings, and

gaskets are properly installed. Check that all housing parts are closed and filters or other

parts connected to the device are installed correctly.

•Remove all tools, spare parts or other materials required for maintenance prior to

commissioning.

•Clean the device, take any leaked fluids and leave the device in a clean condition.

•Check that all safety devices are present and ready for operation.

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 17

The analyzer has 2 connections with bulkhead fittings for plastic hoses with

an external diameter of 6 mm for the water inlet (left) and water outlet

(right). These are only inserted into the screwed connections.

Figure: Connection of water inlet and -outlet

Pressure

The inlet pressure of the water sample must be between 0.5 and 5.0 bar.

The recommended inlet pressure of the water sample should be between 1

and 2 bar.

The hose length of the water outlet must not be longer than 2 m and must

lead away vertically downwards. The system must be able to relax freely

against the atmospheric pressure. There must be no back pressure greater

than the inlet pressure. The water is drained without pressure in an open

funnel or drain.

Operation with unpressurised sample water

If the sample water is depressurised, a pressure-controlled membrane or submersible pump is

required to transport the sample water into the measuring chamber of the analyzer.

Installation

Water inlet

Open funnel

Manual valve

(to be installed by customer)

Softening

Water outlet

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 18

Electrical installation

Voltage

Work on electrical connections may only be carried out by authorised

specialist personnel in compliance with the current regulations. All lines must

be de-energised. The permissible supply voltage is 85 - 305 VAC (47 –440

Hz).

Open the lid of the controller by loosening the four screws in the corners of the lid.

Figure: Back cover of the lid (left side), circuit board (right side)

Position

Description

A

Wi-Fi (optional)

B

Battery holder

C

Solenoid valve port

D

Reagent pump port

E

Display port

F

Actuator plug LED port

G

Main switch port

H

2 x relay

I

RGB sensor

K

Agitator port

L

Fuse (5 x 20 mm ) 1 A time-lag

M

SD card base

N

Sound emitting device

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 19

Connection of supply voltage

Figure: Terminals for the connection of the supply voltage (blue border)

Connection of supply voltage

Terminal designation

Description

1 PE

Earthing

2 PE

Earthing

3 L (power in)

Supply voltage between L and N 85 - 305 VAC (47 –440 Hz).

4 N (power in)

Output terminals which are connected via the device switch

Terminal designation

Description

5 L power out

Switched supply voltage

between L and N 85 - 305 VAC (47 –440 Hz).

6 L power out

7 N power out

8 N power out

Voltage

The maximum connected capacity of all loads must not exceed

250 VAC / 1 A.

Electrical installation

© RLS Wacon GmbH ∙ +49 (0)5121 28126 0 ∙ info@rls-wacon.de 20

Connection of the relay outputs

Figure: Terminals for connecting the relay outputs (blue border)

The relays are designed as change-over contacts, with a common connection and the switching

outputs NC and NO.

Output 1 water (relay 1): Water hardness notification

Terminal designation

Description

Connection

9 COM

Relay 1 COM common connection

see page 9

“Load capacity”

10 NC

Relay 1 NC normally closed

11 NO

Relay 1 NO normally open

Output 1 / relay 1 function (notification of water hardness):

If the measured value of the sample falls below the limit set in the SYCON, relay 1 is deenergised

and a connection from COM to NC is established. In addition, the symbol R1 is not marked in the

display.

If the measured value of the sample exceeds the limit set in the SYCON, relay 1 is energised and a

connection from COM to NO is established. In addition, the symbol R1 is highlighted in black on

the display.

Output 2 alarm (relay 2): Device error notification

Terminal designation

Description

Connection

12 COM

Relay 2 COM common connection

see page 9

“Load capacity”

13 NC

Relay 2 NC normally closed

14 NO

Relay 2 NO normally open

Output 2 / relay 2 function (device error notification):

If a device error occurs or the device is switched off, the relay 2 is deenergised (connection from

COM to NC). In addition, the symbol R2 is not marked in the display.

The relay 2 is energised in the error-free state of the device (connection from COM to NO), this

serves the wire break safety. In addition, the symbol R2 is highlighted in black on the display.

Electrical installation

Table of contents

Other RLS Wacon Measuring Instrument manuals