RLS Wacon SYCON 3000 C User manual

OPERATING MANUAL

SYCON 3000 C

Analytical Instrument to Measure the

Carbonate Hardness of Water

Table of Contents

Functional description..........................................................................................................................1

Operating displays ................................................................................................................................2

LED control lamps................................................................................................................................ 2

LCD display.......................................................................................................................................... 3

INFO displays....................................................................................................................................... 4

Indicator type and hardness unit ...................................................................................................... 4

Service telephone number ............................................................................................................... 4

Input states ....................................................................................................................................... 4

Output states .................................................................................................................................... 4

Analysis result counter ..................................................................................................................... 4

Software status................................................................................................................................. 4

Internal measurement and blank value ............................................................................................4

Manual control.......................................................................................................................................5

Analysis start........................................................................................................................................ 5

Start extra flush .................................................................................................................................... 5

Start servicing ...................................................................................................................................... 5

Test output relays................................................................................................................................. 5

Acknowledge horn................................................................................................................................ 5

End....................................................................................................................................................... 5

Acknowledge relays ............................................................................................................................. 5

Messages................................................................................................................................................6

Refill indicator....................................................................................................................................... 6

Indicator lack analysis stop .................................................................................................................. 6

Error blank value.................................................................................................................................. 6

Internal measurement too high ............................................................................................................ 6

Internal measurement too low.............................................................................................................. 6

Water hardness over/underrun ............................................................................................................ 6

Permanent signal 1 .............................................................................................................................. 6

Permanent signal 2 .............................................................................................................................. 6

Input functions.......................................................................................................................................7

Start analysis........................................................................................................................................ 7

Stop analysis........................................................................................................................................ 7

Reset relay ........................................................................................................................................... 7

Water meter ......................................................................................................................................... 7

Output functions....................................................................................................................................8

Pulse signal.......................................................................................................................................... 8

Permanent signal 1 .............................................................................................................................. 8

Permanent signal 2 .............................................................................................................................. 8

Analysis active ..................................................................................................................................... 8

Signal relay .......................................................................................................................................... 8

Recorder outputs...................................................................................................................................9

Recorder output RC 1 .......................................................................................................................... 9

Recorder output RC 2 .......................................................................................................................... 9

Changing and calling up the programme data.................................................................................10

1. Reagents and limit value................................................................................................................ 11

Indicator type .................................................................................................................................. 11

Physical unit of water hardness...................................................................................................... 11

Correction factor ............................................................................................................................. 11

Limit value of the water hardness................................................................................................... 11

Limit value monitoring .................................................................................................................... 11

2. Analysis sequence ......................................................................................................................... 12

Flush time ....................................................................................................................................... 12

Analysis interval 1........................................................................................................................... 12

Analysis interval 2........................................................................................................................... 12

3. Selection of the programmable input functions.............................................................................. 13

Input: IN 1 ....................................................................................................................................... 13

Input: IN 2 ....................................................................................................................................... 13

Activation of the input functions...................................................................................................... 13

4. Parameters of the input functions.................................................................................................. 14

Input function "START" .................................................................................................................. 14

Delay time Analysis start ............................................................................................................ 14

Input function "STOP" .................................................................................................................... 14

Delay time Analysis stop ............................................................................................................ 14

Input function "Reset relay"............................................................................................................ 14

Delay time Delete relay .............................................................................................................. 14

Input function "Water meter" .......................................................................................................... 14

Water volume 1 between the analyses ...................................................................................... 14

Water volume 2 between the analyses ...................................................................................... 14

Pulse interval of the water meter................................................................................................ 14

5. Selection of the programmable output functions ........................................................................... 15

Output: OUT 1................................................................................................................................ 15

Output: OUT 2................................................................................................................................ 15

Output: OUT 3................................................................................................................................ 15

Activation of the output function..................................................................................................... 15

6. Parameters of the output functions................................................................................................ 16

Output function: Pulse signal ......................................................................................................... 16

Pulse length................................................................................................................................ 16

Number of bad messages .......................................................................................................... 16

Output function: Permanent signal 1 ................................................................................................. 16

Automatic delete function 1 ........................................................................................................ 16

Number of the bad messages .................................................................................................... 16

Output functions: Permanent signal 2........................................................................................... 17

Automatic delete function 2 ........................................................................................................ 17

Number of the bad messages .................................................................................................... 17

Activation through a fault............................................................................................................ 17

Output function: Analysis is running............................................................................................... 17

Analysis delay............................................................................................................................. 17

Output function: Signal relay.......................................................................................................... 18

Fault messages .......................................................................................................................... 18

7. Activation of the buzzer ................................................................................................................. 18

8. Recorder ........................................................................................................................................ 19

Recorder output RC1 = operational sequence........................................................................... 19

Recorder output RC2 = water hardness..................................................................................... 19

9. Entering a code number ................................................................................................................ 20

Service setting 1 and 2 ....................................................................................................................... 21

1. Switching the metering pump on and off.................................................................................... 21

2. Initiating a flush procedure and adjusting the electronics .......................................................... 21

Test of the output relays..................................................................................................................... 22

Activating and deactivating relays.................................................................................................. 22

Installation of the instrument............................................................................................................. 23

Commissioning the instrument ......................................................................................................... 23

Dimensions and drilling plan for the assembly ............................................................................... 24

Measurement diagramme................................................................................................................... 24

Terminal plan....................................................................................................................................... 25

Internal connections ........................................................................................................................... 25

Notes on connections......................................................................................................................... 26

Mains input......................................................................................................................................... 26

Mains output ...................................................................................................................................... 26

Inputs ................................................................................................................................................. 26

Relay outputs..................................................................................................................................... 27

Recorder interface ............................................................................................................................. 28

Connection and programming examples ......................................................................................... 28

Replacing components....................................................................................................................... 31

Instrument maintenance..................................................................................................................... 31

Spare parts list..................................................................................................................................... 32

Technical data...................................................................................................................................... 33

Functional description

1

SYCON

3000 C

Functional description

The analytical instrument of the type SYCON

3000 C is used for the fully automatic measure-

ment of the carbonate hardness of water.

Instrument models are also available to measure

the total hardness Typ SYCON 3000 H and the

Minus m-value Typ SYCON 3000 M.

Measurements can be initiated as follows:

1. Press the "START" button on the instrument

control panel.

2. Activate an external remote switch.

3. Automatic - in programmable time intervals.

4. Automatic – after a programmable flow rate

(volume).

After the value of a predetermined limit is ex-

ceeded (overrun) or fallen below (underrun), a

shorter time interval or a lesser flow rate can be

programmed for the following automatic meas-

urement.

One-component reagents are used for different

measurement ranges. This enables high meas-

urement accuracy with minimum use of reagents,

tailored to the specific case of application. These

reagents can be kept for at least 2 years if stored

appropriately.

Water samples with a temperature over 45 °C

must be cooled prior to analysis. In order to cool

down the test water over a cooler only when the

sample is taken, it is possible to trigger a cooling-

water valve before the input valve is opened.

Each measurement begins with an adjustable

flushing phase. This ensures that the water from

the treatment plant is measured and not the water

that has remained in the supply line since the last

measurement.

Subsequently, the measuring chamber is filled

with a new sample, and the optical value is ascer-

tained without the addition of the reagent (blank

value).

During the measurement of the water hardness,

the reagent is continually added – regulated by a

stepping motor – until a colour transition is regis-

tered. The quantity of reagent used is a measure

of the water hardness.

Signal devices and valves can be switched if a

programmable limit is exceeded or fallen below

and a programme mechanism can be addressed

for the regeneration of a treatment plant.

An analogue output 0(4)-20mA signals the differ-

ent states of the instrument. A further analogue

output delivers a signal in proportion to the

measured water hardness.

In order to suppress undesired bad-water mes-

sages, the first bad messages can be ignored.

Following the measurement, the measuring

chamber is flushed immediately. This prevents a

premature contamination of the measuring

equipment through the colourants of the reagent.

The built-in feed valve is closed during the ana-

lytical pauses to prevent unnecessary water con-

sumption.

Water softening plant SYCON 3000 C

Analytic al Instrument to Measure the Carbonate Hardness of Water

Installation example

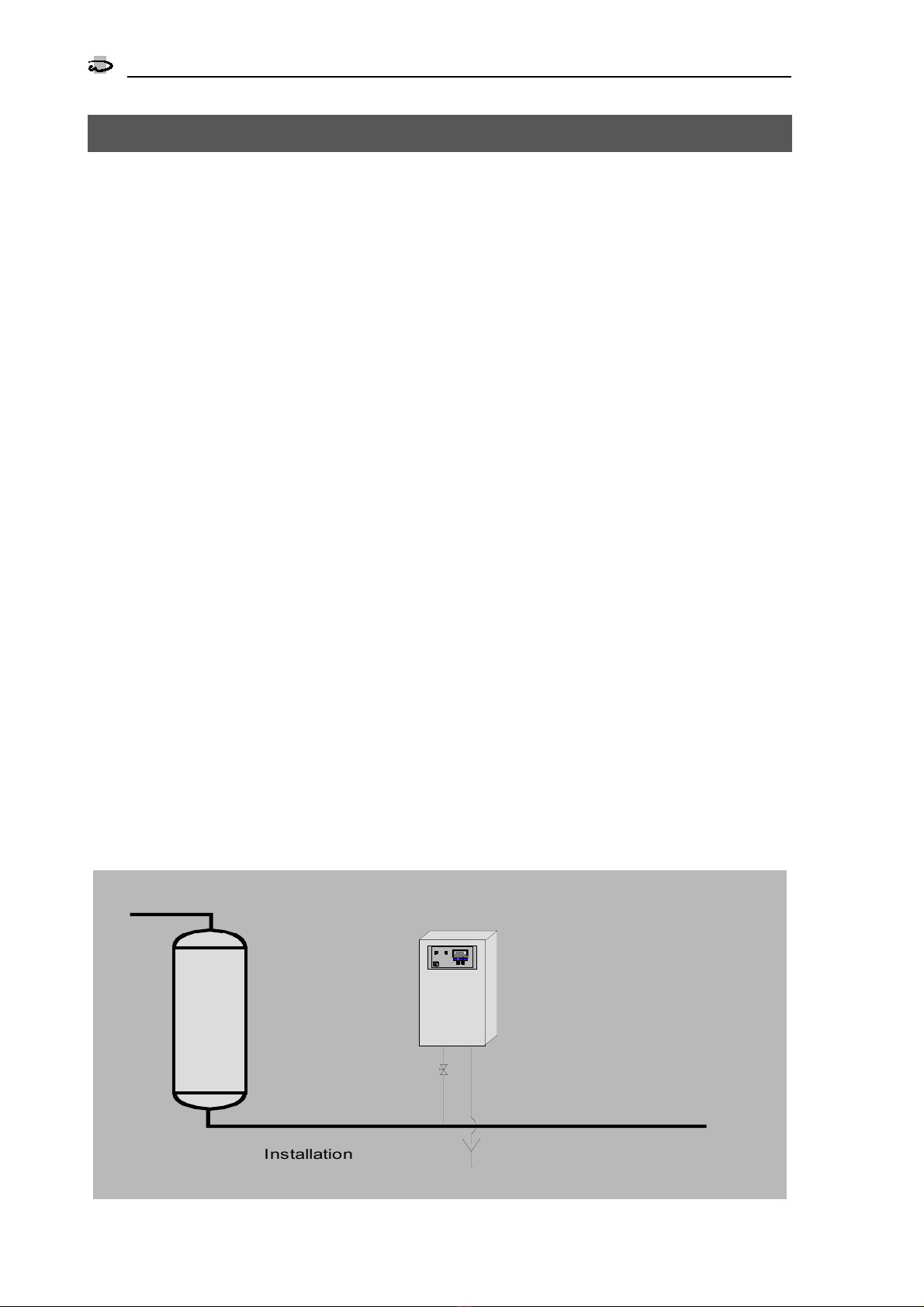

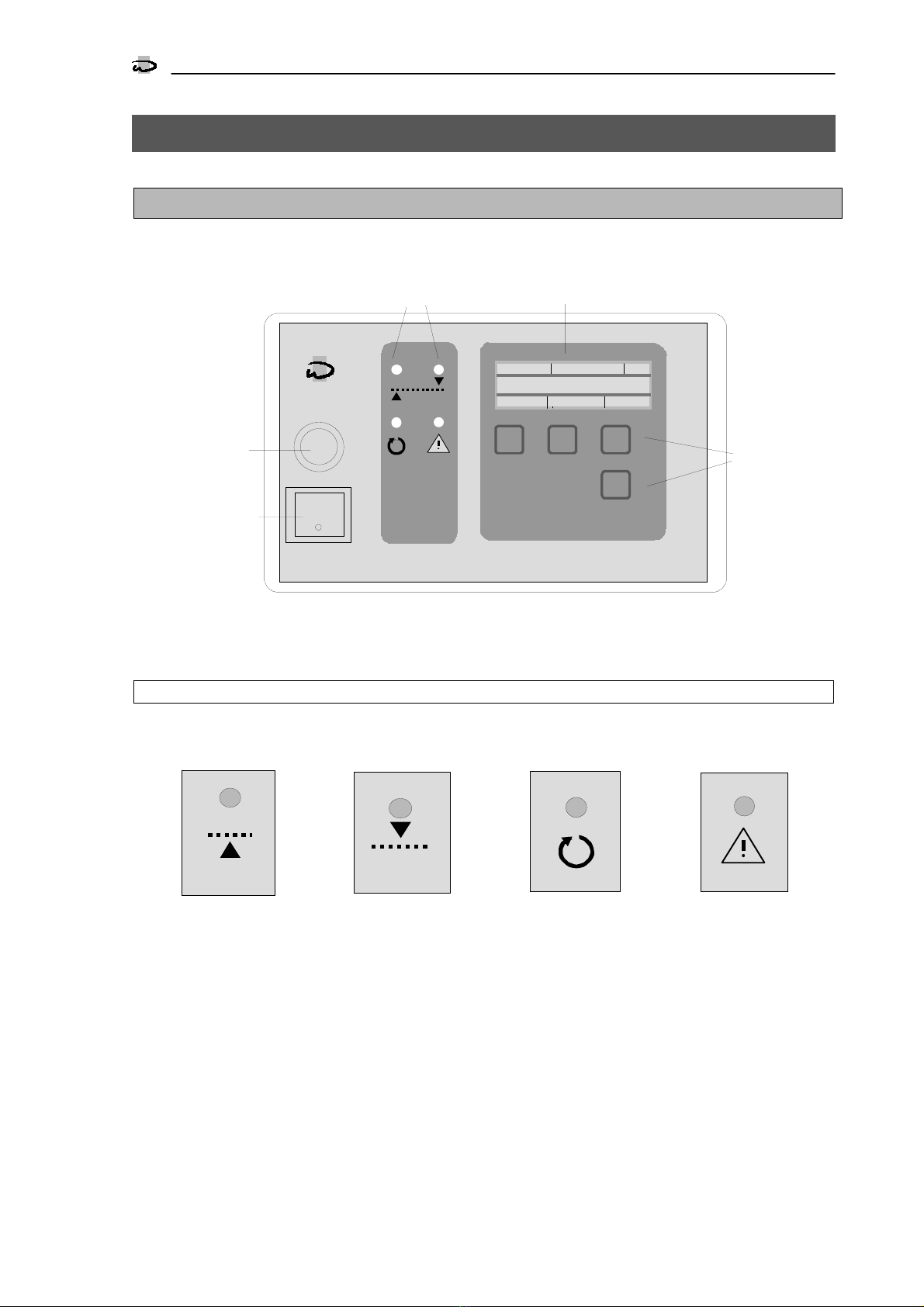

Operating displays

LED control lamps

2

SYCON

3000 C

Operating displays

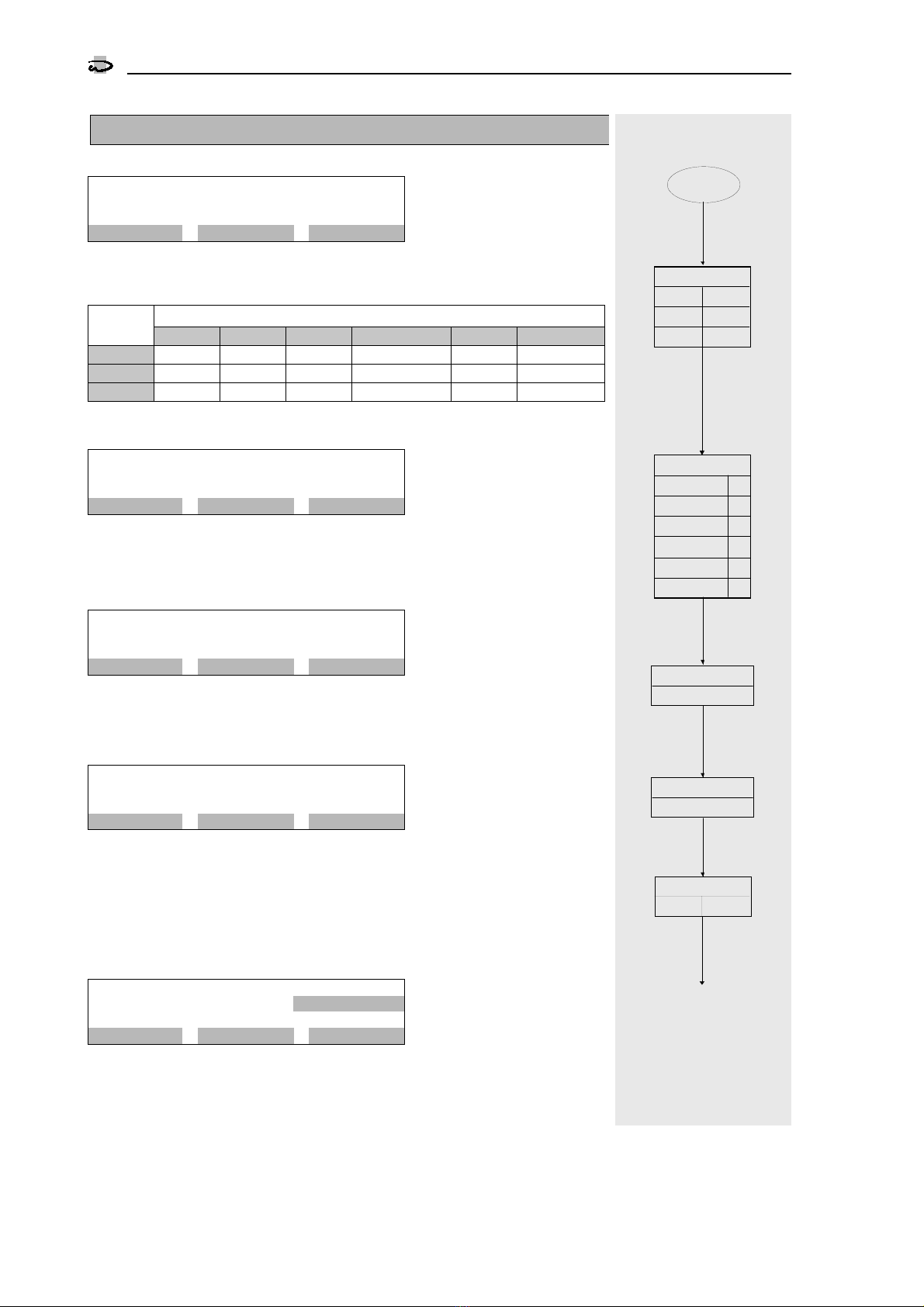

LED control lamps

Coloured control lamps indicate the most important operating states:

The control lamps "Soft water" and "Hard water" display the result of the last analysis.

During a new analysis, the control lamps "Analysis“ and the lamp displaying the last result (i.e. "Soft water" or

"Hard water") blink.

If both the control lamps "Soft water" and "Hard water" are blinking, no analysis result is available, e.g. after

the instrument has been switched on.

In the event of a malfunction or disorder, the control lamp "Fault" blinks.

Additional information can be found on the LCD display.

MT 4A

ON

F1

START FLUSH

10 m 2 *

F2 F3

0.90°m g/l

Limit

> 0.5

KEY

Fuse

Power switch

LED - control lamps LCD - display

Keys

Soft water (green)

Hard water (red)

Fault (red)

Analysis (yellow)

Operating displays

LCD display

3

SYCON

3000 C

LCD display

Displays between the analyses

9m

| 5 , 3 1 c b m

| 2 *

L i m i t

1 7 m g / l

> = 9 . 0

S T A R T F L U S H

In the upper line of the LCD display, the time re-

maining until the next analysis is shown on the left

(e.g. 9 minutes). If the instrument has been pro-

grammed accordingly, the flow-rate volume until

the next analysis is also displayed alongside the

time (e.g. 5.31 cbm).

If the display "Stop" is shown instaed of the mini-

ute value, an imminent analysis is delayed by the

activated input "STOP".

An analysis can be started manually at any time.

If, for example, the display 1* appears on the

right in this line, this indicates that, when the limit

value is next exceeded or fallen short of, the pro-

grammed output function e.g.

"Impulse signal" will be activated.

If, for example, the display 2* appears, the func-

tion will only be activated after 2 successive

over/underruns of the limit.

In the middle of the display, the last measured

water hardness is displayed (e.g. 17 mg/l. Values

outside the measuring range are designated by

the symbols < and > and by a specification of

the measurement range limit

(e.g. <8 mg/l).

Next to this, the programmed limit value appears

with the symbols "<=" for an underrun of this

limit and, with the corresponding programming,

">=" for an overrun of the limit value

(e.g. >=160 mg/l).

After the instrument has been switched on, the

value "----" is displayed until the first measure-

ment.

The lower line gives information on the possible

functions of the buttons arranged beneath it (e.g.

"START" and "FLUSH").

Displays during the analyses

B l a n c v a l u e 2 s 1 *

L i m i t

1 7 m g / l

> = 9 . 0

E N D

During an analysis, the phases Flush, Blanc value,

Titration and Wash with the remaining times are

displayed in the upper line (e.g. Blanc value 2

seconds).

T i t

L i m i t

1 7 m g / l

> = 9 . 0

E N D

During titration, however, the display "Tit" is

shown with two bars alongside it. The lower bar

designates the limit value of the optical measure-

ment dependent on the titration progress. The

upper bar designates the current measured value.

As soon as the upper bar attains the length of the

lower bar, the measured value is saved and, after

a short delay, the newly measured water hardness

is then displayed.

Additional displays

I n d i c a t o r

refill

P o s s i b l e a n a l y s e s 2 4

H O R N

Different messages or fault indications alternate

with the displays between and during the analyses

(see the section "Messages" on page 6).

Note

With the help of the "KEY" button on the right, fur-

ther functions for the "F3" button can be called

up.

Operating displays

INFO display

4

SYCON

3000 C

INFO displays

With the help of the INFO key, different information or values can be requested. Modifications will be de-

scribed – as far as possible – in the programme section "Changing and reading out the programme data".

Only the Service telephone munber can be altered during the display.

Press the KEY key repeatedly until the key function INFO is displayed for the right-hand key F3.

Press the INFO key. The first information is displayed.

Other information can be obtained by further pressing the INFO key.

9 m 5 , 3 1 c b m 2 *

L i m i t

1 7 m g / l

> = 8 0

S T A R T I N F O

Indicator type and hardness

unit

I n d i c a t o r C A 9

R a n g e : 8 - 1 6 0

H a r d n e s s u n i t : m g / l

E N D I N F O

The programmed indicator type, the associated

hardness range and the unit of hardness are dis-

played.

Service telephone number

S e r v i c e t e l e p h o n n o .

0 5 1 2 1 1 2 3 4 5 6 7 8

▲

►# I N F O

The Service telephone number is displayed.

Altering the telephone number:

SELECTING DIGITS:

Press the key with the "

!

" symbol.

CHANGING DIGITS:

Press the key with the "

#

" symbol.

Input states

I n p u t s t a t e s

S T A R T = - S T O P = -

E N D I N F O

The functions of the inputs IN1 and IN2 with their

current switching states are displayed.

A horizontal line "-" alongside the designation

means: Input not active.

A vertical line "|" alongside the designation

means: Input active.

Output states

O u t p u t s t a t e s

P u l s e =

- P e r m a n . 1 = -

M e s s a g e = -

E N D I N F O

Programmed functions of the outputs OUT1,

OUT2 and OUT3 with their current switching

states are displayed.

A horizontal line "-" alongside the designation

means: Output not active.

A vertical line "|" alongside the designation

means: Output active.

Analysis result counter

A n a l y s e s c o u n t e r

S O F T : 1 4 3 6

H A R D : 4 5

E N D I N F O

In the first line the number of all analyses con-

ducted with the result Water SOFT and in the

second line the number with the result Water

HARD is displayed.

The max. number totals 9'999'999. Thereafter,

the counters are reset to zero.

Software status

S o f t w a r e v e r s i o n

S Y C O N 3 0 0 0 C 0 1 0 1 . 2 5

E N D I N F O

The software is continuously serviced in the fac-

tory. Modifications are made as the need arises to

bring the product in line with new findings and

requirements.

The version number and the software imple-

mented are displayed.

Internal measurement and

blank value

I n t e r n a l M e a s u r m . 1 0 1 %

L a s t b l a n k v a l u e 9 9 %

E N D I N F O

The LED in the measurement chamber is activated

and in the first line the current value of the optical

measurement is displayed (range 0-121%).

In the second line the value of the last blank value

is displayed (range 0-121%).

Manual control

5

SYCON

3000 C

Manual control

The three keys F1, F2 and F3 under the display are characterised as softkeys. These keys have a changing

function instead of a fixed function. The function that the key has at the moment is shown above the key in

the inverse colour scheme in the lower display line. In some operating states you can call up further functions

for the F3 key with the aid of the KEY button.

Several key functions are triggered after a time delay to prohibit unintended reactions. The running time de-

lay is highlighted in the third LCD line.

Analysis start

A T T E N T I O N !

A n a l y s i s s t a r t

4 s e c o n d s

S T A R T

Press the Start key. After 4 seconds a new analysis

sequence begins with a flush operation.

Attention: A new analysis can also be started

when an error message is displayed.

Start extra flush

A T T E N T I O N !

S t a r t e x t r a f l u s h

4 s e c o n d s

F L U S H H

It is possible to initiate an additional flushing pro-

cess. In so doing, no current values such as e.g.

the analysis interval are reset.

An additional flush is terminated again after 10

seconds plus the flush time entered in the pro-

gramme step 1.1.

By pressing the "END" key a flush operation is

prematurely aborted.

Warning!

Inadequate flushing can lead to an incorrect

evaluation.

Start servicing

A T T E N T I O N !

S t a r t s e r v i c e

4 s e c o n d s

S E R V

Press the "SERV" key. After 4 seconds the servicing

phase is initiated. You can recalibrate the elec-

tronics and switch the metering pump on and off.

See also the section Service setting 1 and 2 on

page 21.

You switch back to normal operation by pressing

the "END" key.

Test output relays

A T T E N T I O N !

T e s t o u t p u t r e l a y s

4 s e c o n d s

T E S T

Press the "TEST" key. After 4 seconds the phase Test

Output relays is initiated. You can switch the 3 output

relays on and off. see also the section "Testing the output

relays" on page 22..

Acknowledge horn

A T T E N T I O N !

T r o u b l e b l a n k v a l u e

A n a l y s i s s t o p

H O R N

If a message appears in the LCD display and the

integrated signal tone generator sounds at the

same time, the tone can be deleted by pressing

the "HORN" key.

Attention! The display of the message in the LCD

display cannot be deleted. It disappears auto-

matically as soon as the cause of the message is

remedied or a new analysis has been started.

End

F l u s h

L i m i t

1 7 m g / l

> = 9 . 0

E N D

Whenever the key function "END" is displayed, the

current function can be ended.

Acknowledge relays

A T T E N T I O N !

A c k n o w l e d g e P e r m . r e l 1

A n a l y s i s s t o p

R E L A Y

When the key function "RELAY" is displayed, one

of the following relays can be deleted:

1. Permanent relay 1

2. Permanent relay 2

3. Signal relay

If the "RELAY" key is pressed, the relay concerned

is displayed and deleted after 6 seconds.

If the display "Analysis stop" appears, an analysis

must be started by hand.

If programmed accordingly, the start of a new

analysis can also occur by means of an external

switch.

Messages

6

SYCON

3000 C

Messages

If the integrated buzzer is activated in the course of a message, you can delete it by pressing the "HORN"

key. The message in the LCD display is only removed when the cause of the message is remedied or a new

analysis is started manually.

You acknowledge an activated relay by pressing the "RELAY" key.

In the case of the display "Analysis stop", you must start a new analysis manually. See the section "Manual

control" on page 5.

Refill indicator

I n d i c a t o r

refill

P o s s i b l e a n a l y s e s 2 4

H O R N

Indicator must be refilled. On the lower right-

hand side the probable number of possible analy-

ses is displayed.

As soon as this message is displayed, a certain amount of in-

dicator is available. As the indicator required per analysis is

dependent on the water hardness, the probable number of

analyses cannot be determined exactly in advance. In calculat-

ing the display value, soft water with a water hardness of

0 mg/l is assumed.

After each analysis this value is recaluculated with the actual

amount of indicator that still remains.

If there is no indicator when the instrument is

switched on, the display "Indicator lack Analysis

stop" appears immediately.

Indicator lack analysis stop

A T T E N T I O N !

I n d i c a t o r l a c k

A n a l y s i s s t o p

H O R N

Automatically no further analyses are started.

Refill indicator.

Error blank value

A T T E N T I O N !

E r r o r b l a n k v a l u e

A n a l y s i s s t o p

H O R N

Automatically no further analyses are started.

Possible causes:

Instrument or sample contaminated

No flush occurred

No water inflow

Calibration necessary

Electrical defect (check connector)

Internal measurement too high

A T T E N T I O N !

I n t r . m e a s u r . t o o h i g h

A n a l y s i s s t o p

H O R N

Automatically no further analyses are started.

Possible causes:

Indicator has not been metered out

No water inflow

Calibration necessary

Electrical defect (check connector)

Internal measurement too low

A T T E N T I O N !

I n t r . m e a s u r e . t o o l o w

A n a l y s i s s t o p

H O R N

Automatically no further analyses are started.

Possible causes:

Mögliche Ursachen:

No water inflow

Calibration necessary

Electrical defect (check connector)

Water hardness over/underrun

A T T E N T I O N !

W a t e r h a r d n e s s

e x c e e d e d

H O R N

According to the programming in program step

1.5, the overrunning or underrunning of the water

hardness is displayed.

Example: Hard water = Limit value exceeded.

Permanent signal 1

A T T E N T I O N !

P e r m a n e n t s i g n a l 1

A n a l y s i s s t o p

R E L A Y

Following an overrun or underrun of the water

hardness (see programming step 1.5), the activa-

tion of the relay "Permanent signal 1" is displayed.

It is also displayed whether an analysis stop has

occurred or whether analyses continue to be con-

ducted (see program step 6.3).

Permanent signal 2

A T T E N T I O N !

P e r m a n e n t s i g n a l 2

A n a l y s i s s t o p

R E L A Y

Following an overrun or underrun of the water

hardness (see program step 1.5), the activation of

the relay "Permanent signal 2" is displayed. This

relay can be activated even in the case of a fault

according to the programming in program step

6.7. It is also displayed whether an analysis stop

has occurred or whether analyses continue to be

conducted (see program step 6.3).

Input functions

7

SYCON

3000 C

Input functions

From the 3 available input functions, maximally 2 can be programmed for the two inputs of the analyser in

the programme steps 3.1 and 3.2. Each function can only be implemented once.

In programme step 3.3, it is determined whether the inputs are to be active with open or closed contact.

Start analysis

An analysis of the water can only be started from

this input if the instrument is in the stand-by posi-

tion and indicator is available.

A currently running analysis is not interrupted. The

input is deactivated during this time.

In programme step 4.1, a delay time period can

be entered.

The delay time of the input is only reset at the start

of an analysis. Several successive impulses are

summated chronologically between the analyses.

Example: Connection of a flow monitor

Programme step 4.1 = 10 seconds

An analysis is initiated if the contact of the flow

monitor is active for longer than 10 seconds.

An analysis is also initiated if the contact was suc-

cessively active 5 times for 2 seconds because

water was only drawn for a short period.

Stop analysis

If the input is activated, no analyses are initiated

by a time interval, by a volume interval or over

the input "Start analysis". Only the manual trigger-

ing over the "START" button is possible. A running

analysis is aborted by a flushing operation.

In programme step 4.2, a delay time can be en-

tered.

Applications:

No analyses should be conducted in the case of

water shortage or pressure deficiency.

Analyses should only be performed if a storage

reservoir is filled or if an osmosis system is in op-

eration.

Analyses should only be conducted at certain

times (external timer).

Reset relay

With this input it is possible to clear the relays of

the output functions "Permanent signal 1", "Per-

manent signal 2", "Signal relay" and the built-in

signal tone generator from a switch station.

In programme step 3.3, a delay time can be en-

tered.

Attention!

The display of the message in the LCD display is

not deleted. It disappears automatically as soon

as the cause of the message is removed or a new

analysis has been started.

If the display "Analysis stop" appears, an analysis

must be started manually.

With the corresponding programming, the start of

a new analysis can also occur through an external

switch (see Start analysis).

Water meter

An analysis can also be started after the passage

of a certain volume of water. To this end, the Wa-

ter volume 1 and the Water volume 2 are entered

in the programme steps 4.4 and 4.5. The Water

volume 1 is taken into consideration if, after an

analysis, the limit value has not been exceeded

and the Water volume 2 if the limit value has

been exceeded. This allows, after an overrun of

the limit value, the following analyses to be exe-

cuted in shorter intervals.

In programme step 4.6, the pulse interval of the

water meter is entered.

The resetting of the programmed flow rate occurs

at each analysis start and is corrected according

to the Water volume 2 in the event of the limit

value being exceeded.

Note:

In several quantity-dependent controls for soften-

ing plants, a floating (potential-free) relay contact

is available that simultaneously connects to the

contact of the water meter. This relay contact can

also be implemented.

A maximum of 3 pulses per second are regis-

tered.

Output funktions

8

SYCON

3000 C

Output functions

Of the 5 available output functions, maximally 3 can be programmed for the outputs of the analyser. The

output function "Permanent signal" is available in 2 different versions. With the output function "Permanent

signal 2" the relay can also be activaterd in the case of a disturbance in function.

The activation of the outputs Pulse signal and Permanent signal can occur with hard water or soft water ac-

cording to the programming in programme step 1.5.

In programme step 5.4, it is determined whether the outputs are active when the electrical voltage is switched

off or when live.

Pulse signal

The signal serves to trigger signal devices, pro-

gramme mechanisms or PLC controls.

The pulse duration can be selected in programme

step 6.1 between 1 and 999 seconds.

Im programme step 6.2, the number of bad mes-

sages is programmed after which the signal is ac-

tivated.

Permanent signal 1

The signal serves to trigger valves, horns or signal

devices that require a permanent contact after the

limit value over/underrun.

In programme step 6.3, it is programmed whether

the relay is deactivated again, if on the next

analysis the result "Water good" occurs, or if no

further analyses are to be made. In this case, a

deletion must take place by hand or via the input

"Reset relay".

In programme step 6.4, the number of bad mes-

sages is programmed after which the signal is ac-

tivated.

Permanent signal 2

The signal serves to trigger valves, horns or signal

devices that require a permanent contact during

the limit value over/underrun.

The function corresponds to the output function

"Permanent signal 1". However, the output relay

can also be activated in the event of disturbances

in instrument functioning (programming 6.7).

A connected shut-off valve is then closed not only

with an over/underrun of the water hardness, but

also in the event of a functional disturbance.

In programme step 6.5, it is programmed whether

the relay is deactivated again, if on the next

analysis the result "Water good" occurs, or if no

further analyses are to be made. In this case, a

deletion must take place by hand or via the input

"Reset relay".

In programme step 6.6, the number of bad mes-

sages is programmed after which the signal is ac-

tivated.

Analysis active

This output function is activated during an analy-

sis, during the extra flushing and on calibration.

Valves or pumps can be triggered to supply the

analyser with water.

A valve for the cool-water inflow of a cooler can

also be controlled. In order to cool down the test

water initially, the opening of the input valve in

the analyser can be delayed within the range of

0-999 seconds (programme step 6.8).

Indicator or signal devices can also be connected

to display the analysis process.

Signal relay

In programme step 6.9, it is determined with

which fault messages this relay is activated.

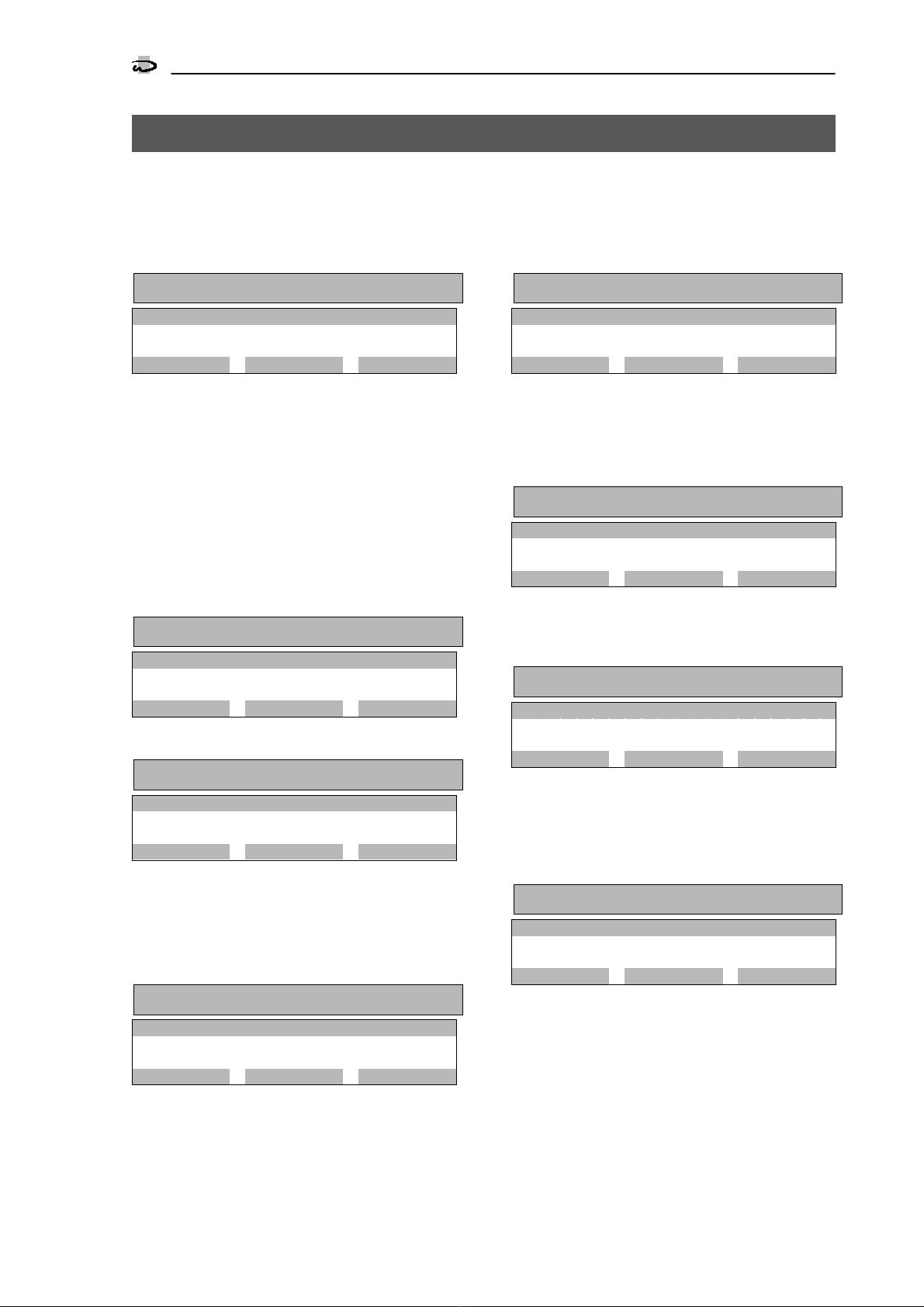

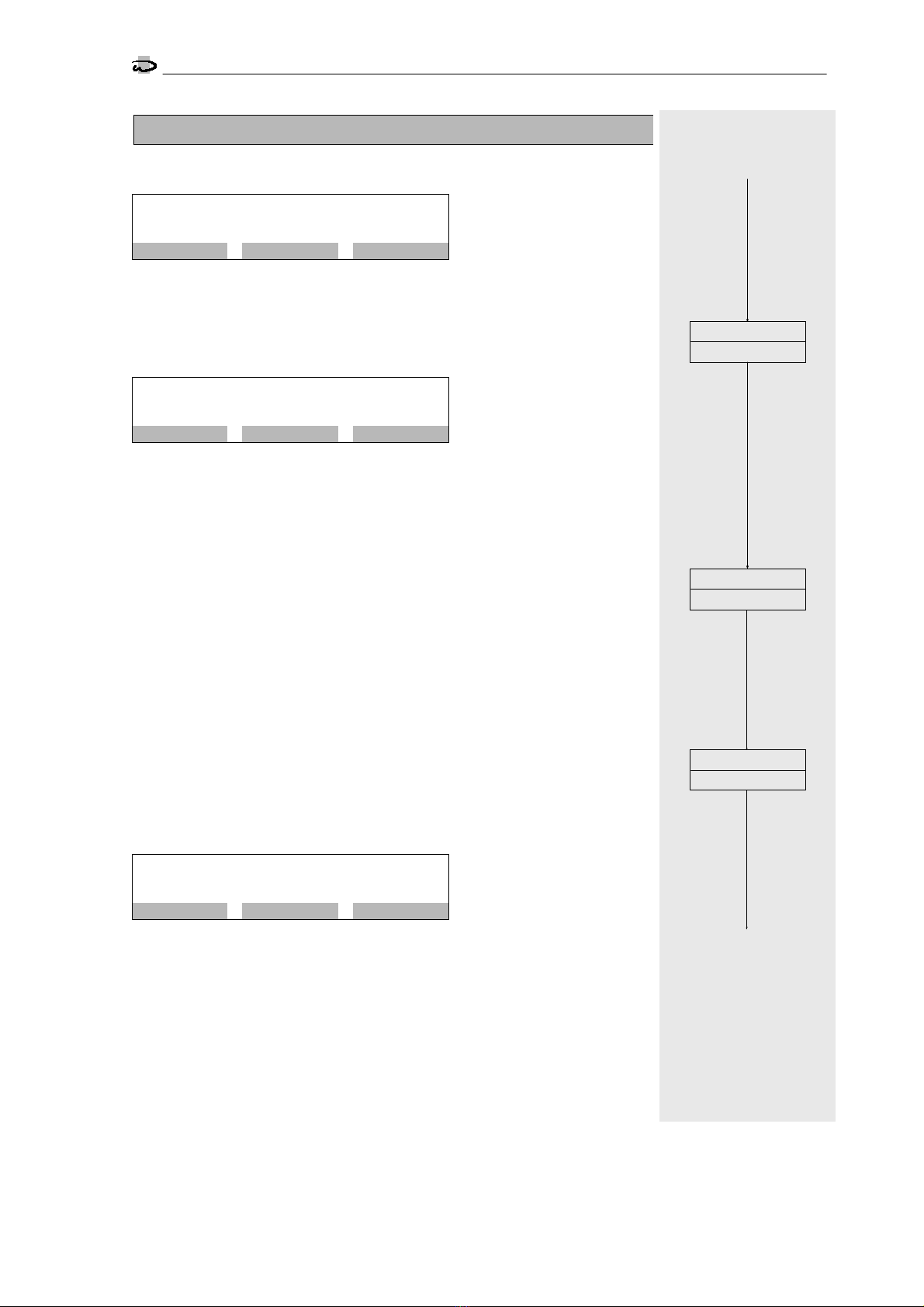

Recorder outputs

9

SYCON

3000 C

Recorder outputs

At the recorder outputs RC1 and RC2, line recorders or dot printers with a current input of 0 - 20 mA or 4-

20 mA can be connected. Programming occurs in programme steps 8.1 and 8.2 respectively.

Recorder output RC 1

A recorder at this output registers the following states of the analyser:

1. Analysis active, servicing or instrument has been switched on 4. Refill indicator

2. Analysis result: water soft or beneath the limit value 5. Fault

3. Analysis result: water hard or above the limit value

The individual states can be accorded current values from 0 to 20 mA in programme step 8.1.

After the instrument has been switched on, during an analysis and in the Servicing setting, the following is

displayed:

"Analysis active".

After each analysis the result "Water soft" or "Water hard" is displayed.

If indicator has to be refilled, the display "Refill indicator" appears instead of the display "Analysis active".

As a collective fault the display "Fault" appears.

The following 4 faults are possible: Indicator shortage, blank value too low, measured value too high, meas-

ured value too low. These faults effect an analysis stop, which must be deleted by hand.

Recorder output RC 2

A recorder at this output permanently registers the displayed water hardness. An alteration can only take

place after a new analysis. The display can be scaled as desired. Initial and final values are laid down in

programme step 8.2.

The displayed current value is calculated by the following formula with the hardness unit mg/l :

Examples for the initial values

0 and 4 mA with a final value of 20 mg/l and 16 mg/l

The lower measurement range limit – according to the limit of the indicator used – is displayed on switching

on the instrument and when the limit has been fallen below (underrun). The upper measurement range limit

is displayed when the measurement range is exceeded (overrun) and in the event of a fault.

0

Example diagramme Recorder output RC1und RC2

Ana lys is

= 4 mA

(RC 1)

2 4 6

Water Soft

= 8 m A

(RC 1)

Water Hard

= 12 mA

(RC 1)

Refill indicator

= 16 mA

(RC 1)

Fault

= 20 mA

( RC 1)

810 12 14 16 18 20

Water hardness

(RC 2)

Po w e r ON

States = RC 1

Water hardness = RC 2

0 10 mg/l 20 mg/l

0 10 mA 20 mA

0 8 mg/l 16 mg/l

4 mA 12 mA 20 mA

][][20(

]/[ ]/[.

)[ mAvalueinitialmAvalueinitialmA

lmgvaluefinal lmgvaluehardnmeasured

mAvalueCurrent +−∗=

Changing and calling up the programme data

10

SYCON

3000 C

Changing and calling up the programme data

General information on programming and on entering the national language

On commissioning the analyser is programmed

according to the desired mode of operation.

These programme data can be changed at a later

stage. They are not erased in the event of a power

failure.

"A change in the programme data should only

be carried out by an authorised specialist.

"Make a note of the programme data in the

blank fields of the following flow diagramme

and keep this guide in a safe place for the op-

erating and servicing personnel.

"If changes are made during an analysis se-

quence, the analysis is interrupted and re-

started.

1. Press the " KEY " key as often as necessary until

the function "PROGRM" is displayed for the

"F3" key.

9m

| 5 , 3 1 c b m

|2 *

L i m i t

1 7 m g / l

> = 9 . 0

S T A R T F L U S H P R O G R M

2. Press the "PROGRM" key. If in programme step

9.1 the question pertaining to a code number

has been answered with Yes, you must enter a

code number with the help of the "!"and "#"

keys.

C o d e n u m b e r

* * * *

▲

P R O G R M ►#

Only after this, press the "PROGRM" key. The next

display appears.

However, if no code number has been pro-

grammed in programme step 9.1, you must keep

the "PROGRM" key pressed for approx. 5 seconds

until this display appears.

C H A N G E

p r o g r a m m / l a n g u a g e

P R O G R M L A N G U A E N D

3. Should you wish to change the language of

the LCD display, press the "LANGUA" key.

ENGLISH

E F D Nl

▲

►E N D

With the help of the "!" key, move the cursor un-

der the letter representing the country of the de-

sired language.

4. If you wish to commence the programming,

press the "PROGRM" key.

General information on the key functions:

Key " #"

You reach the next programme step.

Key " $"

You move backwards step-by-step.

Key " !"

In the case of Yes/No decisions, you answer a

question with YES by using this key to position the

cursor beneath the "Y" for Yes; you answer NO by

positioning the cursor beneath the "N" for No.

For numerical entries, move the cursor under the

digit to be changed.

Key " # "

To change a numerical value and to toggle be-

tween the displays " - " and " | ".

Key " NEXT "

To change to the next display in the same pro-

gramme step.

Key " KEY "

To display an alternative key function for the "F3"

key.

Key " END "

The programming mode is exited.

If required, further functions are explained at the

individual programme steps.

Attention!

The programming mode is automatically exited

approx. 2 minutes after the last key operation.

Changing and calling up the programme data

Reagents and limit value

11

SYCON

3000 C

1. Reagents and limit value

Indicator type

S t e p n o . : 1 . 1

Typ: CA9

8 - 1 6 0 m g / l

▼N E X T ▲

Through different indicators, different measurement ranges can be determined.

There are 5 indicator types available. With the help of the "NEXT" key, select the

indicator used in the instrument.

Measurement rangeIndicator

type ° dH °E °F mg/LCaCO3gpg mmol/Lit.

CA 3 0.15-3.00 0.19-3.75 0.27-5.34 2.7-53.4 0.16-3.12 0.027-0.534

CA 9 0.45-9.00 0.6-11.2 0.8-16.0 8-160 0.47-9.30 0.08-1.60

CA 30 1.5-30.0 1.9-37.5 2.7-53.4 27-534 1.6-31.2 0.27-5.34

Physical unit of water hardness

S t e p n o . : 1 . 2

H a r d n e s s u n i t : m g / l

▼N E X T ▲

Using the "NEXT" key, choose the unit in which the water hardness is to be dis-

played:

°dH, °E, °F, mg/l CaCO3, gpg or mmol/ltr.

Correction factor

S t e p n o . : 1 . 3

C o r r e c t i o n f a c t o r 1 , 0 0

▼►#

Due to component tolerances it may be necessary to adjust the displayed water

hardness to the actual water hardness. You can enter a correction factor within

the range from 0.50 to 1.50 .

Limit value of the water hardness

S t e p n o . : 1 . 4

L i m . v a l u e : 9 . 0 m g / l

▲

▼►#

Determine the value of the limit at which a message is to occur when the water

hardness is over- or underrun (see programme step 1.5).

Attention: The limit value of the water hardness is dependent on the choice of

the indicator type and the water hardness. Check the limit value of the water

hardness if you have changed programme step 1.1 or 1.2. If a recorder is used,

the scale in programme step 8.2 must also be re-assessed.

Limit value monitoring

S t e p n o . : 1 . 5

L i m . v a l u e : M i n / M a x

▲

▼►▲

It can be laid down whether the signalisation of the limit monitoring occurs in

the event of an underrun = soft water (MIN) or an overrun = hard water (MAX)

of the limit value.

Example:

In monitoring an ion exchanger, the overrun is selected (MAX).

In monitoring a blending facility, the underrun (MIN) can be programmed if one wishes to monitor a minimum water

hardness.

2.1

START

1.5

CA 3

1.1

Monitoring

Min Max

CA 9

CA 30

Indicator type

1.3

Correction factor

°dH

°E

°F

mg/l CaCO

gpg

Water hardness

3

mmol/ltr

1.2

1.4

Limit value

Changing and calling up the programme data

Analysis sequence

12

SYCON

3000 C

2. Analysis sequence

Flush time

S t e p n o . : 2 . 1

F l u s h t i m e 6 0 s

▲

▼►#

Prior to every extraction of a test sample, the supply line to the instrument is

flushed. Flush times from 10-999 seconds can be entered.

Analysis interval 1

S t e p n o . : 2 . 2

A n a l . i n t e r v a l 1 5 m

▲

▼►#

Analyses can be conducted at fixed intervals. Enter an Analysis interval 1 in the

range from 3 to 9'999 minutes. With the commencement of analysis, the inter-

val timing is restarted.

Attention!

The shortest time between two analyses arises from the rigidly predetermined

analytical cycle, the flush time set in programme step 1.1, the duration of titra-

tion and – insofar as it has been programmed in programme step 6.8 – from

the analysis delay entered.

A new analysis is only started if the previous one has been completed. For this

reason, an analysis interval can be greater than that programmed in this sec-

tion.

Note:

If a water meter is used, a quantity-dependent analytical sequence can also be

selected. The chronological analytical order is always active for reasons of secu-

rity.

Analyses are not automatically started, however, if the input "Analysis stop" is

active.

Analysis interval 2

S t e p n o . : 2 . 3

A n a l . i n t e r v a l 2 3 m

▲

▼►#

If the limit value is exceeded in an analysis, the interval time is redetermined with

the Analysis interval 2 taking into account the time expired. This allows the sub-

sequent analyses to be conducted at shorter time intervals after a limit value has

been exceeded.

This interval should therefore be smaller than the Analysis interval 1. Times in

the range from 3-9'999 minutes can be entered.

2.2

Analysis interval 1

1.4

m

2.1

Flush time

s

3.1

2.3

Analysis interval 2

m

Changing and calling up the programme data

Selection of the programmable input functions

13

SYCON

3000 C

3. Selection of the programmable input functions

From the 4 available input functions, maximally 2 can be programmed to the

two inputs IN1 and IN2 of the analyser. Each input function can only be used

once. In programme step 3.3, it is determined whether the inputs are active with

open or closed contact.

Parameters – such as a response delay – must still be entered for the selected

inputs in programme steps 4.1- 4.5.

A description of the inputs can be found in the chapter Input functions on page

7.

Input: IN 1

S t e p n o . : 3 . 1

S t a t S t o p R e s t W a t M e

I N P U T 1 = S t a r t A n a l y s i s

▼►▲

Select the desired input function for the input INPUT 1 (IN1) with the help of the

"►" key.

Stat = Start analysis Rest = Reset relay

Stop = Stop analysis WatMe = Water meter

Input: IN 2

S t e p n o . : 3 . 2

S t a t S t o p R e s t W a t M e

I N P U T 2 = S t o p A n a l y s i s

▼►▲

Select in accordance with programme step 3.1 the desired input function for the

input INPUT 2 (IN2) with the help of the "►" key.

Activation of the input functions

S t e p n o . : 3 . 3

S T A R T | S T O P |

▲

▼►#

Select the way the inputs are activated for the inputs selected in the programme

steps above.

Press the "►" key to select the input functions programmed for the inputs IN1

and IN2 and the "#" key to choose between "|" or "-".

"|" Activation of the selected input function when the contact is closed (NO con-

tact)

"-" Activation of the selected input function when the contact is open (NC con-

tact)

4.1

3.3

Stat Stop Rest WatMe

Input IN 2

3.2

Activatio n

Stat Stop Rest WatMe

Input IN 1

2.3

3.1

Changing and calling up the programme data

Parameters of the input funktions

14

SYCON

3000 C

4. Parameters of the input functions

In line with the selection made in programme step 3.1 and 3.2, supplementary

data must be entered in the form of parameters for the inputs IN1 and IN2.

Input function "START"

Delay time Analysis start

S t e p n o . : 4 . 1

D e l a y s t a r t : 7 s

▲

▼►#

Enter for the input function "Start" a delay time in the range of 1 to 99 sec-

onds.

Input function "STOP"

Delay time Analysis stop

S t e p n o . : 4 . 2

D e l a y s t o p : 3 s

▲

▼►#

Enter for the input "Analysis stop" a delay time in the range of 1 to 99 sec-

onds.

Input function "Reset relay"

Delay time Delete relay

S c h r i t t N r : 4 . 3

D e l a y r e l a y : 3 s

▲

▼►#

Enter for the input "Reset relay" a delay time in the range of 1 to 99 sec-

onds.

Input function "Water meter"

Water volume 1 between the analyses

S c h r i t t N r : 4 . 4

W a t e r v o l 1 1 . 0 0 c b m

▼►#

Enter the Water volume 1 after which a new analysis is to be started. You can

programme values in the range from 0.01 to 650.00 cbm.

Water volume 2 between the analyses

S t e p n o . : 4 . 5

W a t e r v o l 2 0 . 1 0 c b m

▼►#

After an overrun of the limit value, the following analysis is started in accor-

dance with Water volume 1 instead of Water volume 2. You can programme

values in the range from 0.01 to 650.00 cbm.

Pulse interval of the water meter

S t e p n o . : 4 . 6

W a t e r m e t e r 1 0 0 . 0 L / I

▼►#

Enter the pulse train of the water meter. You can enter values from 0.1 to 5'000.0 Ltr./ Imp.

5.1

Input

Delay

4.1

s

Analysis start

?

Delay

4.2

s

Pulse interval

4.6

L/I

Input

Analysis stop

?

Water volume 1

4.4

cbm

Input

Water

?

Delay

4.3

s

Input

relay

?

3.3

yes

no

yes

no

Res et

yes

no

volume

5.1

no

yes

Water volume 2

4.5

cbm

Changing and calling up the programme data

Selection of the programmable output functions

15

SYCON

3000 C

5. Selection of the programmable output functions

Of the 5 available output functions, maximally 3 can be programmed to the

outputs OUT1, OUT2 and OUT3 of the analyser. The output function "Perma-

nent signal" exists twice (PR1 and PR2). With the output function PR2, the relay

can be activated in the event of a fault as well as when the preset water hard-

ness is exceeded. In programme step 5.4 it is determined whether the outputs

are active when the electrical voltage is switched off or live.

Parameters – such as the pulse length – must also be entered for the selected

output functions in programme steps 6.1 to 6.11. A description of the outputs

can be found in the chapter Output functions on page 8.

Output: OUT 1

S t e p n o . : 5 . 1

I M P P S 1 P S 2 A N A S I G

O U T 1 = P u l s e s i g n a l

▼►▲

Choose the desired output function for the output OUT1.

Press the INFO key to display the abbreviation in plain text.

IMP = Pulse signal ANA = Analysis is running

PS1 = Permanent signal 1 SIG = Signal relay

PS2 = Permanent signal 2

Output: OUT 2

S t e p n o . : 5 . 2

I M P P S 1 P S 2 A N A S I G

O U T 2 = P e r m a n e . s i g n a l 1

▼►▲

Select according to programme step 5.1 the desired output function for the

output OUT2.

Output: OUT 3

S t e p n o . : 5 . 3

I M P P S 1 P S 2 A N A S I G

O U T 3 = S i g n a l r e l a y

▼►▲

Select the desired output function for the output OUT3 in accordance with pro-

gramme step 5.1.

Activation of the output function

S t e p n o . : 5 . 4

I M P | P S 1 | S I G

-

▲

▼►#

Select the activation of the output functions for the outputs selected in pro-

gramme steps 5.1 to 5.3.

"-" Activation of the selected output function with relay inoperative (dropped-

out)

"|" Activation of the selected output function with relay operative (pulled-in).

General note:

In deciding whether e.g. a valve is active when live i.e. open or not, one considers the reaction of

the treatment plant in a current-free state. In such a case no undesired functions should occur in the

plant.

Example flush valve: When the analyser is switched off, a rinse valve must not be open, even if it is

triggered by an external supply voltage.

Choose a flush valve that opens when carrying voltage and programme "|".

Example fault message: When the analyser has no electrical power, a fault message should occur. Programme "-".

6.1

4.*

5.4

5.2

5.3

IMP

Output: OUT 1

PS1 PS2 ANA SIG

5.1

Activation

IMP

Output: OUT 2

PS1 PS2 ANA SIG

IMP

Output: OUT 3

PS1 PS2 ANA SIG

Changing and calling up the programme data

Parameters of the output functions

16

SYCON

3000 C

6. Parameters of the output functions

In line with the selection made in programme steps 5.1 to 5.3, supplementary

data must be entered in the form of parameters for the outputs OUT 1 to OUT

3.

Output function: Pulse signal

Pulse length

S t e p n o . : 6 . 1

P u l s e l e n g h t 1 0 s

▲

▼►#

The length of the pulse signal can be laid down within the range from 1 to 999

seconds.

Number of bad messages

S t e p n o . : 6 . 2

N u m b e r m e s s a g e s 1 *

▼#▲

You can programme the number of bad messages after which the output func-

tion pulse signal is activated. Values from 1 to 5 can be entered. With a value

greater than 1, when the next analysis occurs is programmed in programme

step 6.10 or 6.11.

Note:

The pulse output is always activated as soon as a bad message is displayed after an analysis and

the number of successive bad messages is the same as or greater than the value entered in pro-

gramme step 6.2 .

In programme step 1.5, it is determined whether a bad message is to occur if the limit value is over-

run or underrun.

Attention!

If the output function "Permanent signal 1" or "Permanent signal 2" is so programmed that the ana-

lyser performs no more analyses before the value entered in programme step 6.2 is reached, no

further signal can be emitted.

Output function: Permanent signal 1

Activation only with a limit overrun or underrun

Automatic delete function 1

S t e p n o . : 6 . 3

A u t o m a t . d e l e t e 1 Y / N

▲

▼►▲

You can programme whether further analyses are carried out after the activa-

tion of the output function Permanent signal 1. If further analyses are con-

ducted, the relevant relay is automatically deactivated again if the result "Water

good" occurs in one of the next analyses.

If no further analyses are conducted, the relay must be deleted by hand or via

the input "Delete relay". Moreover, an analysis must be restarted.

Automatic deletion Yes: Consecutive analyses even after a bad message

Automatic deletion No: Analysis stop in the event of a bad mesaage

Number of the bad messages

S t e p n o . : 6 . 4

N u m b e r m e s s a g e s 2 *

▼#▲

You can programme the number of bad messages (limit overruns/underruns)

after which the output function is activated. Values from 1 to 5 can be entered.

With a value greater than 1, it is laid down in programme step 6.9 or 6.10

when the next analysis occurs.

6.5

Output

Pulse lenght

6.1

s

Pulse signal

?

Autom.delete1

6.4

Output

Permanent

signal 1

6.3

5.4

no

yes

no

?

yes

Yes No

Bad messages

6.2

*

6.5

Bad messages

*

Table of contents

Other RLS Wacon Measuring Instrument manuals