RM STKD 11 User manual

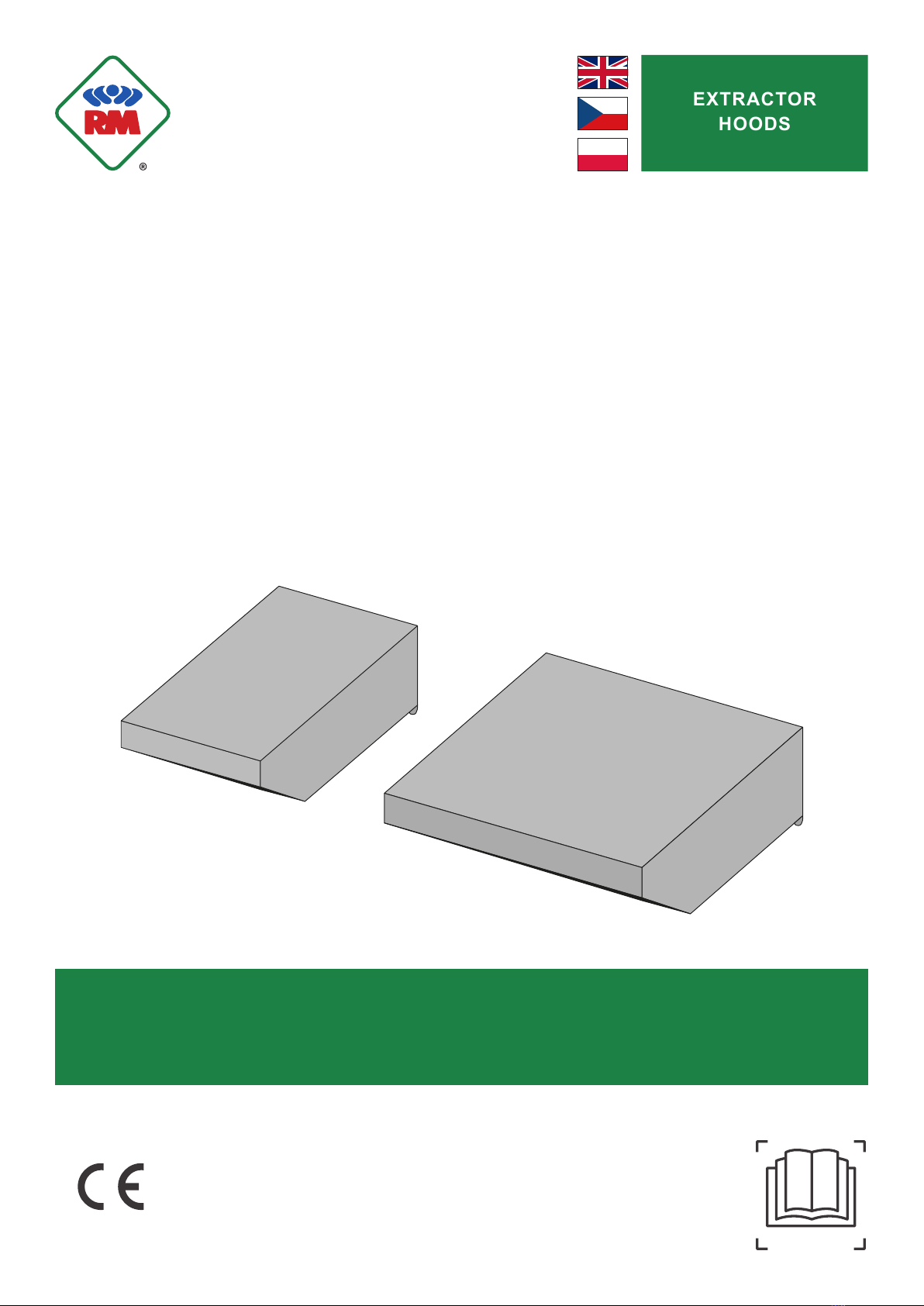

EXTRACTOR

HOODS

1015-22

STKD 11, STKD S 11

www.rmgastro.com

INSTRUCTION FOR INSTALLATION AND USE

NÁVOD K OBSLUZE A INSTALACI

INSTRUKCJE MONTAŻU I OBSŁUGI

2023-08-24

CONTENT

General and safety warnings

Instruction for use

Cleaning and maintenance

7

9

10

OBSAH

Všeobecná a bezpečnostní upozornění

Návod k použití

Čistění a údržba

17

19

20

TREŚĆ

Ostrzeżenia ogólne i dotyczące bezpieczeństwa

Instrukcja obsługi

Czyszczenie i konserwacja

27

29

30

5

INSTRUCTION FOR INSTALLATION AND USE

6

Dear Customer,

Thank you for purchasing

one of our products.

This oven is part of a series of electrical

equipment designed for the food sector.

Our ovens are easy to use, ergonomic

and enable cooking control, while boasting

a pleasant and modern design.

The oven has a 12-month warranty

that covers any manufacturing defects

from the date indicated on the Bill

of Sale. The warranty covers normal

operation of the oven and does not

include consumables (lamps, seals etc.)

and damage caused by incorrect installation,

wear, maintenance, repair, incorrect cleaning

and descaling, tampering and improper use.

7

• Read this manual carefully before installing and using

the appliance since it gives important instructions

regarding its safe installation, use and maintenance.

• Keep the manual in a location that can be easily

accessed by the operators for further consultation.

• Always include the manual if the appliance

is transferred; if necessary, request a new copy

from the authorised dealer or directly from the

manufacturer.

• As soon as the packaging is removed, make sure

the appliance is in good condition and there is no

damage caused during transportation. Never install

or use a damaged appliance; if in doubt, contact the

after-sales technical assistance or your local dealer

immediately.

• As the packaging material is potentially dangerous,

it must be kept out of the reach of children or animals

and disposed of correctly in compliance with local

regulations.

• Before installing the equipment, check that the

systems are compliant with the regulations in force

in the country of use and with that stated on the

information plate.

• Installation or maintenance dierent to those

indicated in the manual can cause damage, injury

or fatal accidents.

• Installation, extraordinary maintenance and repair

operations on the equipment must only be performed

by professionally qualied personnel and following

the manufacturer‘s instructions.

• During assembly of the equipment, the transit or

permanence of sta not assigned to installation is not

permitted in the work area.

• The appliance must only be used by personnel who

have been appropriately trained in its use. To avoid

the risk of accidents or damage to the equipment,

it is essential that the sta is constantly trained with

regard to safe operation.

• The appliance must not be used by persons with

reduced physical, sensory or mental capacities or by

those who do not have the necessary experience or

knowledge unless they are supervised or instructed

in the use of the equipment by a person who is

responsible for their safety.

• The appliance must be placed in a suitably ventilated

room to prevent the excessive accumulation

of harmful substances in the air.

• Children must be supervised to ensure they neither

play with nor use the appliance.

• During operation, it is necessary to pay attention to

the hot areas of the external surface of the appliance.

• The use of hearing protection is not necessary

as the sound pressure level of the oven is lower than

70 dB(A).

• In the event of failure or malfunctioning, the

equipment must be deactivated; any repairs

must only be performed by an assistance centre

authorised by the manufacturer and original spare

parts must be used.

• Disconnect the appliance from the electric

power supply before performing any installation

or maintenance intervention.

• Interventions, tampering or modications not

expressly authorised, which do not respect that

stated in this manual, will make the warranty null and

void.

• Do not deposit or use ammable substances

near the equipment.

• In the event of prolonged lack of use, the electricity

must be turned o.

• Before commissioning the appliance, make sure

that all parts of the packaging have been removed,

making sure they are disposed of in compliance

with current legislation.

• Any changes to appliance installation that become

necessary must be approved and performed by

authorised technicians.

• The appliance is intended for professional use only.

• No changes of any kind are permitted to the wiring

of the equipment.

• Failure to comply with the previous warnings

can compromise both your safety and the safety

of the equipment.

• The information plate provides important technical

information: these are essential if interventions

must be requested for maintenance or repairs

of the appliance; therefore, it must not be removed,

damaged or modied.

• The equipment complies with the essential

requirements of the Machinery Directive 2006/42/EC.

• The equipment complies with the essential

requirements of the Electromagnetic Compatibility

Directive 2014/30/EC.

• The equipment complies with the essential

requirements of the Low Voltage Directive

2014/35/EC.

General and safety warnings

INSTALLATION

8

Positioning

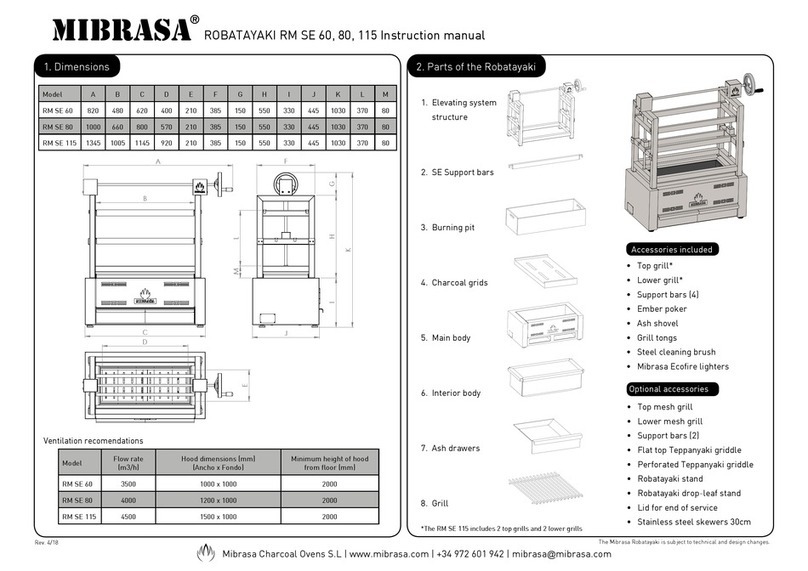

• The new condensation extractor for Steambox and

Kompatto ovens is easy to install: it requires only an

electrical connection and a connection to a drain for

„white water“.

• The extractor must be placed on the oven cover and

it must be secured with two brackets to the back

of the oven itself (by drilling a hole in the back and

inserting two self-tapping screws) as in g.1.

• It is preferable to connect the extractor to an external

fume evacuation duct.

Electric connection

• The electrical connection provides for the connection

of a 3x1.5mm2 cable to the terminal board located

inside the junction box (g. 2) (reachable from the

upper part of the extractor). The cable must be

connected to a wall outlet.

• WARNING: the user must protect the wall outlet with

a bipolar switch.

Connection to the drain

• On the back of the extractor there is a exible hose

which must be inserted in the oven condensate

discharge pipe; when the extractor is on, it is always

under slight depression so it conveys the exhausted

fumes through the condensator as shown in g.3.

• It is not necessary to connect the appliance to the

water supply since the operating principle of this

unit is based on an aluminium condensator (g. 4)

through which the fumes captured by the suction

pass. The dierence in temperature between the

fumes (hot) and the aluminium sheet (cold) produces

condensation, which is collected by the tray placed

under the condensator and drained through a pipe

which must be connected to the drain (g. 1 - page 9)

INSTALLATION

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

Fig. 3

Fig. 4

Fig. 2

Fig. 1

9

The user can turn the extractor on when required

(by means of the switch as shown above): the extractor

will be activated at the minimum speed: in this condition,

the removal of the rear fumes. In the presence of

moisture (for example when the door is opened),

the extractor will increase the suction force to capture

the most fumes possible.

The rst removal of the vapours that come out of the door

is performed by the labyrinth lter located on the front

of the extractor. (g.5)

The unit features an automatic moisture detection

system which adjusts the rotation speed of the motor

and therefore the suction force. (g. 6)

INSTRUCTION FOR USE

Fig. 6

Fig. 5

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

10

Disconnect the appliance from the electric power

supply before performing any cleaning or maintenance

intervention.

The appliance must never be cleaned with direct or high

pressure jets of water. Moreover, the appliance should

not be cleaned with wire sponges, ordinary steel brushes

or scrapers; eventually, you can use stainless steel wool,

wiping the appliance in the direction of sheet metal grain.

To clean it, use warm soapy water.

It is advisable to clean the sensor periodically (g.6).

To clean the sensor, remove it, clean the slots delicately

being careful not to ruin the internal sensor, and the put

the external sensor back in place.

Also clean the condensator periodically (g.4), by

unscrewing the 4 screws. Wash using a mild cleansing

agent and then clean the basin below using a degreaser.

Drain the residual liquid.

CLEANING

AND MAINTANCE

11

REF N. pcs SPARE PARTS HOOD MODEL HOOD CODE HOOD MODEL HOOD CODE HOOD MODEL HOOD CODE HOOD MODEL HOOD CODE

DESCRIPTION DIMENSIONS mm. HGRK01 7080521 HGRK02 7080519 HGRK03 7080522 HGRK04 7080523

1 1 Fan 230/1/50-60HZ W0.37 204 x 233 x 218 YES YES YES YES

2 2 Labirinth lter 1 350 x 350 x 20 YES NO NO YES

3 1 Labirinth lter 2 350 x 350 x 20 NO YES NO NO

4 2 Deector lter 3 356 x 338 x 20 NO NO YES NO

5 1 Charcoal lter 1 (optional) 360 x 173 x 20 YES NO NO YES

6 1 Charcoal lter 2 (optional) 360 x 173 x 20 NO YES NO NO

7 1 Condensator 1 603 x 214 x 122 YES NO NO YES

8 1 Condensator 2 403 x 214 x 122 NO YES NO NO

9 1 Speed Regulator 135 x 74 x 73 YES YES YES YES

SPARE PARTS

MANAGEMENT

10

3. MAINTENANCE and CLEANING

Disconnect the appliance from the electric power supply before

performing any cleaning or maintenance intervention�

The appliance must never be cleaned with direct or high pressure jets of

water� Moreover, the appliance should not be cleaned with wire sponges,

ordinary steel brushes or scrapers; eventually, you can use stainless

steel wool, wiping the appliance in the direction of sheet metal grain�To

clean it, use warm soapy water�

It is advisable to clean the sensor periodically (g.6)� To clean the

sensor, remove it, clean the slots delicately being careful not to ruin the

internal sensor, and the put the external sensor back in place�

Also clean the condensator periodically (g.4), by unscrewing the 4

screws� Wash using a mild cleansing agent and then clean the basin

below using a degreaser�

Drain the residual liquid�

4. SPARE PARTS MANAGEMENT

REF N�

pcs

SPARE PARTS HOOD

MODEL

HOOD

CODE

HOOD

MODEL

HOOD

CODE

HOOD

MODEL

HOOD

CODE

HOOD

MODEL

HOOD

MODEL

DESCRIPTION DIMEN-

SIONS mm�

HGRK01 7080521 HGRK02 7080519 HGRK03 7080522 HGRK04 7080523

1 1 Fan 230/1/50-

60HZ W0�37

204X233X218 YES YES YES YES

2 2 Labirinthlter1 350X350X20 YES NO NO YES

3 1 Labirinthlter2 350X350X20 NO YES NO NO

4 2 Deectorlter3 356X338X20 NO NO YES NO

5 1 Charcoallter1

(optional)

360X173X20 YES NO NO YES

6 1 Charcoallter2

(optional)

360X173X20 NO YES NO NO

7 1 Condensator 1 603X214X122 YES NO NO YES

8 1 Condensator 2 403X214X122 NO YES NO NO

9 1 Speed Regulator 135X74X73 YES YES YES YES

12

At the end of its life span, the appliance must be

disposed of in accordance with legal obligations.

The symbol in g.7 species that, at the end of its life

span, the appliance must be disposed of according

to the indications of the European Parliament Directive

2012/19/EU dated 04/06/2012.

Information regarding disposal in nations of the

European Union.

The European Community Directive regarding WEEE

equipment has been implemented dierently by each

nation, therefore if his appliance is to be disposed of,

we suggest you contact the local authorities or the dealer

to nd out the correct method of disposal.

DISPOSAL

OF THE APPLIANCE

Fig. 7

13

The manufacturer shall not be held liable for

any damages due to improper installation,

tampering with the appliance, misuse,

improper maintenance, failure to comply

with applicable standards and intended use.

The manufacturer reserves the right to make

changes to the product at any time it deems

necessary or useful.

15

NÁVOD K OBSLUZE A INSTALACI

16

Vážený zákazníku,

děkujeme Vám za zakoupení

jednoho z našich výrobků.

Tato trouba je součástí řady elektrických

zařízení určených pro potravinářský sektor.

Naše trouby se snadno používají, jsou

ergonomické a umožňují kontrolu pečení,

přičemž se mohou pochlubit příjemným

a moderním designem.

Na troubu je poskytována 12měsíční

záruka, která se vztahuje na případné

výrobní vady od data uvedeného na

prodejním dokladu. Záruka se vztahuje

na běžný provoz trouby a nevztahuje se

na spotřební materiál (lampy, těsnění atd.)

a na poškození způsobená nesprávnou

instalací, opotřebením, údržbou, opravami,

nesprávným čištěním a odstraňováním

vodního kamene, manipulací

a nesprávným používáním.

17

• Před instalací a používáním spotřebiče si pečlivě

přečtěte tento návod, protože obsahuje důležité

pokyny týkající se jeho bezpečné instalace,

používání a údržby.

• Příručku uchovávejte na místě, které je snadno

přístupné obsluze pro další konzultace.

• Vždy přiložte návod k obsluze, pokud je spotřebič

přenášen; v případě potřeby si vyžádejte nový výtisk

od autorizovaného prodejce nebo přímo od výrobce

• Jakmile odstraníte obal, ujistěte se, že je spotřebič

v dobrém stavu a že nedošlo k jeho poškození

během přepravy. Poškozený spotřebič nikdy

neinstalujte ani nepoužívejte; v případě pochybností

se ihned obraťte na poprodejní technickou pomoc

nebo na místního prodejce.

• Vzhledem k tomu, že obalový materiál je potenciálně

nebezpečný, musí být uložen mimo dosah dětí nebo

zvířat a musí být správně zlikvidován v souladu

s místními předpisy.

• Před instalací zařízení zkontrolujte, zda jsou

systémy v souladu s předpisy platnými v zemi použití

a s předpisy uvedenými na informačním štítku.

• Instalace nebo údržba odlišná od té, která je uvedena

v návodu, může způsobit poškození, zranění nebo

smrtelné nehody.

• Instalaci, mimořádnou údržbu a opravy zařízení

smí provádět pouze odborně kvalikovaný personál

a podle pokynů výrobce.

• Během montáže zařízení není povolen průchod

nebo trvalý pobyt pracovníků, kteří nejsou určeni

k instalaci, v pracovním prostoru.

• Spotřebič smí používat pouze personál, který byl

řádně vyškolen k jeho používání. Aby se předešlo

riziku nehody nebo poškození zařízení, je nezbytné,

aby byl personál neustále školen s ohledem

na bezpečnou obsluhu.

• Spotřebič nesmí používat osoby se sníženými

fyzickými, smyslovými nebo duševními schopnostmi

nebo osoby, které nemají potřebné zkušenosti

nebo znalosti, pokud nejsou pod dohledem nebo

nejsou poučeny o používání zařízení osobou,

která odpovídá za jejich bezpečnost.

• Spotřebič musí být umístěn ve vhodně větrané

místnosti, aby se zabránilo nadměrnému hromadění

škodlivých látek ve vzduchu.

• Děti musí být pod dohledem, aby se zajistilo,

že si se spotřebičem nebudou hrát ani jej používat.

• Během provozu je nutné dávat pozor na horké oblasti

vnějšího povrchu spotřebiče.

• Použití ochrany sluchu není nutné, protože hladina

akustického tlaku trouby je nižší než 70 dB(A).

• V případě poruchy nebo špatné funkce musí být

zařízení deaktivováno; veškeré opravy smí provádět

pouze asistenční středisko autorizované výrobcem

a musí být použity originální náhradní díly.

• Před provedením jakéhokoli zásahu při instalaci

nebo údržbě odpojte zařízení od elektrické sítě.

• Zásahy, zásahy nebo úpravy, které nejsou výslovně

povoleny a které nerespektují to, co je uvedeno

v tomto návodu, mají za následek neplatnost záruky.

• V blízkosti zařízení neodkládejte ani nepoužívejte

hořlavé látky.

• V případě delšího nepoužívání je nutné vypnout

elektrický proud.

• Před uvedením spotřebiče do provozu se ujistěte,

že byly odstraněny všechny části obalu, a ujistěte

se, že byly zlikvidovány v souladu s platnými

právními předpisy.

• Veškeré změny v instalaci spotřebiče, které se

stanou nezbytnými, musí být schváleny a provedeny

autorizovaným technikem.

• Spotřebič je určen pouze pro profesionální použití.

• Na elektroinstalaci zařízení nejsou povoleny

žádné změny.

• Nedodržení předchozích upozornění může ohrozit

vaši bezpečnost i bezpečnost zařízení.

• Na informačním štítku jsou uvedeny důležité

technické informace: ty jsou nezbytné, pokud je

nutné požadovat zásahy při údržbě nebo opravách

spotřebiče; proto se nesmí odstraňovat, poškozovat

ani upravovat.

• Zařízení splňuje základní požadavky směrnice

o strojních zařízeních 2006/42/ES.

• Zařízení splňuje základní požadavky směrnice

o elektromagnetické kompatibilitě 2014/30/ES.

• Zařízení splňuje základní požadavky směrnice

o nízkém napětí 2014/35/ES.

Všeobecná a bezpečnostní upozornění

INSTALACE

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

8

1.2 Positioning

The new condensation extractor

for Steambox and Kompatto ovens

is easy to install: it requires only

an electrical connection and a

connection to a drain for "white water"�

The extractor must be placed on the

oven cover and it must be secured with

two brackets to the back of the oven itself

(by drilling a hole in the back and inserting

two self-tapping screws) as in g.1�

It is preferable to connect the extractor

to an external fume evacuation duct�

1.3 Electric connection

The electrical connection provides for

the connection of a 3x1�5mm2cable to

the terminal board located inside the

junction box (g. 2) (reachable from the

upper part of the extractor)�The cable

must be connected to a wall outlet�

WARNING: the user must protect

the wall outlet with a bipolar switch.

1.4 Connection to the drain

On the back of the extractor there is

aexiblehosewhichmustbeinserted

in the oven condensate discharge

pipe; when the extractor is on, it is

always under slight depression so it

conveys the exhausted fumes through

the condensator as shown in g.3�

Fig. 1

Fig. 2

Fig. 3

Obr. 3

Obr. 4

Obr. 2

Obr. 1

18

Umístění

• Nový odsavač kondenzátu pro trouby Steambox

a Kompatto se snadno instaluje: vyžaduje pouze

elektrické připojení a připojení k odtoku „bílé vody“.

• Odsavač musí být umístěn na víko trouby a musí

být připevněn dvěma držáky k zadní straně samotné

trouby (vyvrtáním otvoru v zadní části a vložením

dvou samořezných šroubů), jak je uvedeno na obr. 1.

• Odsavač je vhodné připojit k externímu potrubí

pro odvod kouře.

Elektrické připojení

• Elektrické připojení zajišťuje připojení kabelu

3 x 1,5 mm² ke svorkovnici umístěné uvnitř rozvodné

skříňky (obr. 2) (dosažitelné z horní části odsavače).

Kabel musí být připojen do zásuvky.

• VAROVÁNÍ: uživatel musí chránit zásuvku

bipolárním vypínačem.

Připojení k odsávání

• Na zadní straně odsavače je ohebná hadice, kterou

je třeba zasunout do potrubí pro odvod kondenzátu

z trouby; když je odsavač zapnutý, je vždy pod

mírným poklesem, takže odvádí odsávané výpary

přes kondenzátor, jak je znázorněno na obr. 3.

• Spotřebič není nutné připojovat k přívodu vody,

protože princip činnosti tohoto zařízení je založen na

hliníkovém kondenzátoru (obr. 4), kterým procházejí

výpary zachycené odsáváním. Rozdíl teplot mezi

výpary (horkými) a hliníkovým plechem (studeným)

vytváří kondenzát, který se zachycuje ve vaničce

umístěné pod kondenzátorem a odvádí se trubkou,

která musí být připojena k odtoku (obr. 1 - strana 9).

INSTALACE

Obr. 6

Obr. 5

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

9

It is not necessary to connect the

appliance to the water supply since

the operating principle of this unit is

based on an aluminium condensator

(g. 4) through which the fumes

captured by the suction pass�The

difference in temperature between the

fumes (hot) and the aluminium sheet

(cold) produces condensation, which

is collected by the tray placed under

the condensator and drained through

a pipe which must be connected to

the drain (g. 1 - page 9)

2. OPERATION

The user can turn the extractor on when required (by means of the

switch as shown above): the extractor will be activated at the minimum

speed: in this condition, the removal of the rear fumes�In the presence

of moisture (for example when the door is opened), the extractor will

increase the suction force to capture the most fumes possible�

Therstremovalofthevapours

that come out of the door is

performed by the labyrinth

lterlocatedonthefrontofthe

extractor� (g.5)

The unit features an automatic

moisture detection system

which adjusts the rotation speed

of the motor and therefore the

suction force� (g. 6)

Fig. 4

Fig. 5

Fig. 6

19

Uživatel může odsavač zapnout v případě potřeby

(pomocí přepínače, jak je uvedeno výše): odsavač se

aktivuje při minimální rychlosti: v tomto stavu dochází

k odstranění zadních výparů. V přítomnosti vlhkosti

(například při otevření dveří) odsavač zvýší sací sílu,

aby zachytil co nejvíce výparů.

První odstranění výparů, které vycházejí ze dveří,

provádí labyrintový ltr umístěný na přední straně

odsavače. (obr. 5)

Přístroj je vybaven automatickým systémem detekce

vlhkosti, který upravuje rychlost otáčení motoru,

a tím i sací sílu. (obr. 6)

NÁVOD K POUŽITÍ

20

Před jakýmkoli čištěním nebo údržbou odpojte spotřebič

od elektrické sítě.

Spotřebič se nikdy nesmí čistit přímým nebo

vysokotlakým proudem vody. Spotřebič se dále nesmí

čistit drátěnými houbičkami, běžnými ocelovými kartáči

nebo škrabkami; případně můžete použít nerezovou vlnu,

kterou spotřebič otřete ve směru vláken plechu. K čištění

používejte teplou mýdlovou vodu.

Snímač je vhodné pravidelně čistit (obr. 6). Chcete-li čidlo

vyčistit, vyjměte jej, jemně vyčistěte štěrbiny, přičemž

dávejte pozor, abyste nezničili vnitřní čidlo, a vnější čidlo

vložte zpět na místo.

Pravidelně čistěte také kondenzátor (obr. 4),

a to odšroubováním 4 šroubů. Omyjte jej jemným čisticím

prostředkem a poté odmašťovacím prostředkem vyčistěte

umyvadlo pod ním. Zbytky kapaliny vypusťte.

ČIŠTĚNÍ A ÚDRŽBA

This manual suits for next models

1

Table of contents

Languages:

Other RM Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Rühle

Rühle MPR 900 Turbo Translation of the original instructions

Bartscher

Bartscher Deli 306053 Translation of the original instruction manual

Silver King

Silver King SKPZ92-EDUS2 Technical manual and replacement parts list

EPTA

EPTA MELO HOT Series user manual

Arctic Air

Arctic Air ACP40 Installation, operation & maintenance manual

CARTER-HOFFMANN

CARTER-HOFFMANN LOGIX7 Series Owner's and operator's manual