RMF Systems CMS 2 User manual

User Manual

CMS2

1

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

2

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Table of Contents

1 General Warnings and Information for the End User ...............................................................................................5

1.1 General Safety Warnings....................................................................................................................................5

1.3 Operator Position and Dangerous Areas............................................................................................................6

1.4 Dangers and Hazards that cannot be eliminated...............................................................................................6

1.5 Personal Protective Equipment..........................................................................................................................7

2 Transportation and Storage.......................................................................................................................................8

2.1 Transportation and Handling Conditions ...........................................................................................................8

2.2 Storage................................................................................................................................................................8

3 Warranty, Limitations and Disclaimers......................................................................................................................9

4 Product Presentation...............................................................................................................................................11

4.1 Benefits.............................................................................................................................................................11

4.2 Product features...............................................................................................................................................11

4.2.1 Moisture Sensor.........................................................................................................................................11

4.2.2 Data Logger................................................................................................................................................12

5 Technical Specification ............................................................................................................................................13

5.1 Performance .....................................................................................................................................................13

5.2 Electrical Interface............................................................................................................................................13

5.3 Physical Attributes............................................................................................................................................13

5.4 Fluid Characteristics..........................................................................................................................................15

5.5 Environment .....................................................................................................................................................16

6 Product Installation and General Operation ...........................................................................................................17

6.1 Installation........................................................................................................................................................17

6.1.1 Physical Procedure..............................................................................................................................17

6.1.2 Electrical Interface.....................................................................................................................................18

6.1.2 Hydraulic Connection ................................................................................................................................24

6.2 General Operation............................................................................................................................................27

6.2.1 Physical Checks..........................................................................................................................................27

6.2.2 Front Panel Operation ...............................................................................................................................28

3

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6.2.3 CMS removal and Product Maintenance...................................................................................................30

6.3 CMS Control......................................................................................................................................................31

6.3.1 Computer Connection ...............................................................................................................................31

6.3.2 PC Software Operation..............................................................................................................................32

6.3.3 Settings ......................................................................................................................................................33

6.4 Standard Communication Protocols.................................................................................................................42

6.4.1 Modbus......................................................................................................................................................42

6.4.2 CAN-bus .....................................................................................................................................................46

6.4.3 Analogue 4-20mA Modes..........................................................................................................................49

6.5 Disposal.............................................................................................................................................................51

7 Troubleshooting / FAQ ............................................................................................................................................52

7.1 Misuse of Product.............................................................................................................................................52

7.2 Fault Finding .....................................................................................................................................................52

7.2.1 LED Flashing / Fault Codes.........................................................................................................................52

7.2.2 Test Status .................................................................................................................................................53

7.2.3 Other Faults ...............................................................................................................................................53

7.3 Test Duration ....................................................................................................................................................54

8 How to Order...........................................................................................................................................................55

8.1 Common Features ............................................................................................................................................55

9 Related Products......................................................................................................................................................56

9.1 RDU 2.0.............................................................................................................................................................56

9.2 CMSUSBI ...........................................................................................................................................................56

10 Service and Recalibration ......................................................................................................................................57

11 Reference...............................................................................................................................................................58

11.1 Further Modbus Information..........................................................................................................................58

11.1.1 Modbus Registers ....................................................................................................................................58

11.1.2 Implementing Modbus ............................................................................................................................63

11.2 Further CAN-bus Information.........................................................................................................................65

11.2.1 Example Walk through ............................................................................................................................65

11.2.2 Messages .................................................................................................................................................70

11.3 Measuring Water in Hydraulic and Lubricating Fluids....................................................................................73

11.4 ISO4406:1999 Cleanliness Code System.........................................................................................................75

4

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

11.5 NAS1638 Cleanliness Code System (now defunct, replaced by SAE AS4059E Table 1) .................................76

11.6 SAE AS4059 REV E Cleanliness Classification for Hydraulic fluids ..................................................................76

11.7 Recommendations..........................................................................................................................................77

11.8 Hydraulic System Target Cleanliness Levels ...................................................................................................78

11.9 New ISO Medium Test Dust and its effect on ISO Contamination Control Standards ...................................79

11.10 Clean Working Practices...............................................................................................................................83

5

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

1 General Warnings and Information for the End User

1.1 General Safety Warnings

Do not operate, maintain or carry out any procedure before reading this manual. Any individual operating the

unit shall wear the following Personal Protective Equipment:

Protective eyewear

Safety shoes

Gloves

Overalls (or other suitable protective clothing)

Before carrying out any machine installation procedures and/or before use, one should scrupulously follow the

instructions listed in this manual. Moreover, it is necessary to comply with the current regulations related to

occupational accident prevention and safety in the workplace.

Notices aimed at the prevention of health hazards for personnel operating the machine are highlighted in this

document with signs having the following meaning:

WARNING

It relates to important information concerning the product, its use or part of this

documentation to which special attention must be paid

DANGER

It means that failure to comply with the relevant safety regulations may result in death,

serious injury or serious property damage.

In order to quickly identify the professionals concerned with reading this manual, the following definitions were

used:

OPERATOR

This is any individual whose task is to use the machine for production purposes. The

operator is aware of all the measures taken by the machine manufacturer in order to

eliminate any source of injury risk in the workplace and takes into account the

operational constraints.

PERSONNEL

INVOLVED IN

SLINGING AND

HOISTING

OPERATIONS

This is any individual whose task is to handle the machine or parts of it. Personnel

involved in slinging and hoisting operations are aware of the issues regarding the safe

transfer of machinery or parts of it and, therefore, uses appropriate lifting equipment,

following the instructions provided by the product manufacturer.

CAUTION

It means that failure to comply with the relevant safety regulations may result in mild

injury or property damage.

6

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

MACHINE SETTER

This is any individual whose task is to set up the machine for its operation. The

machine setter is aware of the measures taken to eliminate all sources of injury risks in

the workplace and takes into account the operational constraints. The machine setter

takes all the appropriate precautions in order to operate in utmost safety conditions.

MAINTENANCE

TECHNICIAN

This is any individual whose task is to carry out maintenance activities on the machine.

The maintenance technician is aware of the possible danger situations that may arise

and takes the appropriate precautions in order to eliminate the risks of accidents in the

workplace.

ELECTRICIAN

This is any individual whose task is to carry out maintenance activities on the electrical

wiring of the machine. The electrician is aware of the possible danger situations that

may arise and takes the appropriate precautions in order to eliminate the risks of

accidents in the workplace.

1.3 Operator Position and Dangerous Areas

No operator is required for operating the unit. However, the following areas are to be considered dangerous: The

ones close to the electric motor because of live equipment with potentially hot surfaces.

WARNING

The unit shall be taken out of service and/or dismantled in accordance with the

current regulations in force in the country where the machinery is installed

WARNING

The machinery is not suitable for outdoor use and all the electrical devices have a

protection class starting from IP 55 upwards.

1.4 Dangers and Hazards that cannot be eliminated

-Electric shock risk on the electric motor; in case of motor malfunction

-Burn risk because of high temperatures

-Accidental oil leaks with consequent risk of slipping

-Hose breakage and resulting lubricant loss

With oil temperatures exceeding 40/45 °C, it is vital to be extremely careful when handling the metal lances/the

hoses and when moving the unit. Avoid direct contact with hot oil and with the filter body.

ALL EQUIPMENT SHOULD BE ALLOWED TO COOL PRIOR TO HANDLING, AFTER IT HAS BEEN IN USE

7

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

1.5 Personal Protective Equipment

When operating the unit, personnel must be wearing safety shoes, gloves and goggles. In general, the PPEs to be

used according to the activities on the machinery are listed in the following table:

Activity

PPEs

Ordinary operation

Shoes, gloves, goggles, overall

Planned maintenance

Shoes, gloves, goggles, overall

8

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

2 Transportation and Storage

2.1 Transportation and Handling Conditions

The unit is shipped in a cardboard box, encased in polyurethane foam.

The packed weight of the CMS and accessories is 2.5kg.

2.2 Storage

The unit should be stored in a suitable location away from the production area when not in use. The unit should

be stored with the caps provided on the ports. This location should not impede any other production or

personnel.

9

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

3 Warranty, Limitations and Disclaimers

RMF Systems warrants that the products that it manufactures and sells will be free from defects in material,

workmanship & performance for a period of 12 months from the date of shipment.

Hardware/Firmware

Should the hardware prove defective during the warranty period, RMF Systems, at its discretion, will either repair

the defective product or replace it with an equivalent product in exchange for the defective unit without charge

for parts, labour, carriage and insurance.

Software

RMF Systems warrants that software will operate substantially in accordance with its functional specification for

12 months from date of shipment provided that the integrity of the operating environment has not been

compromised through misuse, inappropriate handling, abnormal operating conditions, neglect or damage

(unintentional or otherwise) or the introduction of third party product (software or hardware) that in any way

conflicts with the RMF Systems product.

Eligibility

This warranty extends to the original purchaser only or to the end-user client of an RMF Systems authorised

affiliate.

How to obtain service?

To obtain service under the terms of this warranty, the customer is required to notify RMF Systems before the

expiration of the warranty period and to return the item in accordance with RMF Systems product return policy.

Any product returned for warranty repair must be accompanied by a full fault report specifying the symptoms and

the conditions under which the fault occurs. Should RMF Systems incur additional cost as a result of a failure to

complete the appropriate paperwork, an administrative charge may be levied.

Exclusions

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

care. RMF Systems shall not be obligated to provide service under this warranty if:

a) Damage has been caused by a failure to make a full and proper inspection of the product (as described by the

documentation enclosed with the product at the time of shipment) on initial receipt of the product following

shipment;

b) Damage has been caused by the attempts of individuals, other than RMF Systems staff to repair or service the

product;

c) Damage has been caused by the improper use or a connection with incompatible equipment or product

including software applications.

Charges

Under cover of this warranty, RMF Systems will pay the carriage and insurance charges for the shipment of

defective product back to site of manufacture and for its return to the client’s original site of despatch except

when:

a) RMF Systems product return policy has not been followed.

b) Product failure is caused by any of the exclusions described above, when the customer will be liable for the full

cost of the repair (parts and labour) plus all carriage and insurance costs to and from RMF Systems premises.

c) The product is damaged in transit and a contributory cause is inadequate packaging. It is the customer’s

responsibility to ensure that the packaging used to return equipment to RMF Systems is the same, or has

10

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

equivalent protective qualities, to that used to ship the product to the customer in the first instance. Any damage

resulting from the use of inadequate packaging will nullify RMF Systems obligations under this

warranty. Should the customer’s product be damaged in transit following a repair at RMF Systems site, a full

photographic record of the damage must be obtained (packaging and the product) to support any claim for

recompense. Failure to present this evidence may limit RMF Systems obligations under this warranty.

THIS WARRANTY IS GIVEN BY RMF SYSTEMS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, NON INFRINGEMENT OR

FITNESS FOR A PARTICULAR PURPOSE. RMF SYSTEMS LTD SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES ( INCLUDING LOSS OF DATA), WE

SPECIFICALLY DISCLAIM ANY AND ALL WARRANTIES TO CUSTOMERS OF THE CUSTOMER. THE CUSTOMER’S

SOLE REMEDY FOR ANY BREACH OF WARRANTY IS THE REPAIR OR REPLACEMENT, AT RMF SYSTEMS

DISCRETION, OF THE FAILED PRODUCT.

RMF Systems BV maintains a policy of product improvement and reserves the right to modify the specifications

without prior notice.

11

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

4 Product Presentation

The CMS measures and quantifies the numbers of solid contaminants in Hydraulic, Lubrication and Transmission

applications. The CMS-M is designed to be an accurate instrument for permanently installed applications utilising

mineral oil as the operating fluid. Other fluid media versions are available for offshore [N] and aerospace

phosphate ester [S] applications.

The unit can operate using any of the international standard formats ISO 4406:1999, NAS 1638, AS 4059E/F and

ISO 11218.

The CMS incorporates a machine connector for power and PLC connection, capable of RS485, CANBUS or 4-20mA

signaling. A separate connector is also provided for simultaneous computer remote monitoring or settings access

using RS485 or a USB:RS485 interface.

The integrated data logger records up to 4000 test results internally, for use where a computer cannot be

permanently connected.

Simple switched inputs and alarm outputs are provided as alternative means of controlling the testing and

signaling the results. The "full colour’’ front panel led provides a basic indication of the cleanliness level.

The instrument uses the light extinction principle whereby a specially collimated precision LED light source shines

through the fluid and lands on a photodiode. When a particle passes through the beam it reduces the amount of

light received by the diode, and from this change in condition, the size of the particle can be deduced.

4.1 Benefits

−Live real time monitoring

−Manual, automatic and remote control flexibility

−Moisture and temperature sensing

−Multicolour LCD and LED for clear visual indication of any faults and alarms

−Instant result download on USB versions

4.2 Product features

4.2.1 Moisture Sensor

CMS-W models measure water content using a capacitive RH (relative humidity) sensor. The result is expressed as

percentage saturation. 100% RH corresponds to the point at which free water exists in the fluid, i.e. the fluid is no

longer able to hold the water in a dissolved solution. This is also normally the point at which damage occurs in a

hydraulic system, so is an ideal measurement scale that is independent of the fluid characteristics.

The water saturation point (100% RH) is temperature dependent, so the temperature is measured at the same

time. This enables results to be compared meaningfully.

The temperature measured is that of the fluid passing through the unit. Note this may differ from that of the

hydraulic system, depending on flow rate, pipe length and ambient temperature. It is not intended to be an

accurate indication of system temperature, but to provide a reference for the RH measurement. Nevertheless

experience has shown the temperature measured is within a few degrees of that of the hydraulic system, in most

applications.

12

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

4.2.2 Data Logger

The CMS includes a built-in data logger, which adds the facility to log and timestamp test results locally within an

internal memory, even when not connected to a computer.

−Test logging is determined by the log settings (see section 6.3.3).

−Each log entry is time-stamped and contains the CMS serial number, so that it can be identified later.

−The CMS memory has space for around 4000 log entries. When full, the oldest log entry is overwritten.

See section 6.3.1 + 6.3.2 for details of how to download the test log via bespoke windows based software.

4.2.2.1 Data Transfer via USB Stick

The U version of the CMS allows direct download via a USB memory stick. With the CMS powered up, plug the

USB stick into the USB connector at the top of the unit.

The screen / indicator will turn yellow briefly as it writes the test records to the USB stick. When complete, it will

turn green and the stick can be removed. If there is a problem with the data transfer (stick full or corrupt or not

recognised) then the screen / indicator will turn red. If this happens the operator can remove the stick and try

again with an alternative.

The USB stick provided with the unit is pre-formatted for the transfer. Other USB sticks may need to be re-

formatted (FAT32).

PLEASE NOTE: The USB option is not to be used for anything other than a memory stick

for results download. Any subsequent use other than that intended may cause damage

to the device

13

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

5 Technical Specification

5.1 Performance

Technology LED Based Light Extinction Automatic Optical Contamination Monitor

Particle Sizing >4, 6, 14, 21, 25, 38, 50, 70μm

Analysis range ISO 4406: Code 0 to 25

NAS 1638 Class 00 to 12

AS4059 Rev E Table 1 & 2 Sizes A-F: 000

Please Note: (Lower Limits are Test Time dependent)

If system cleanliness is expected to be above 22/21/18 or approx. NAS 12

Calibration Each unit individually calibrated with ISO Medium Test Dust (MTD) based on ISO 11171,

on equipment certified by I.F.T.S. ISO 11943

Moisture & Temperature Measurement % saturation (RH) and fluid temperature (°C) –Mineral Oil /

Diesel version only

Accuracy ±½ ISO code for 4, 6, 14μm

±1 code for 21, 25, 38, 50, 70μm

±3°C

±3%RH

5.2 Electrical Interface

Supply Voltage 9-36V DC

Supply Current 12V 24V 36V

150mA 80mA 60mA K version

70mA 40mA 30mA NON- K version

Power Consumption 2.2W max

Test Time Adjustable 10 - 3600 seconds (factory set to 120s)

Data Storage Approximately 4000 timestamped tests in the integral CMS memory

Keypad & LCD 6 keys, 128x64 pixels, back-lit graphical display

Communication RS485

Options MODBUS

CANBUS

4-20mA

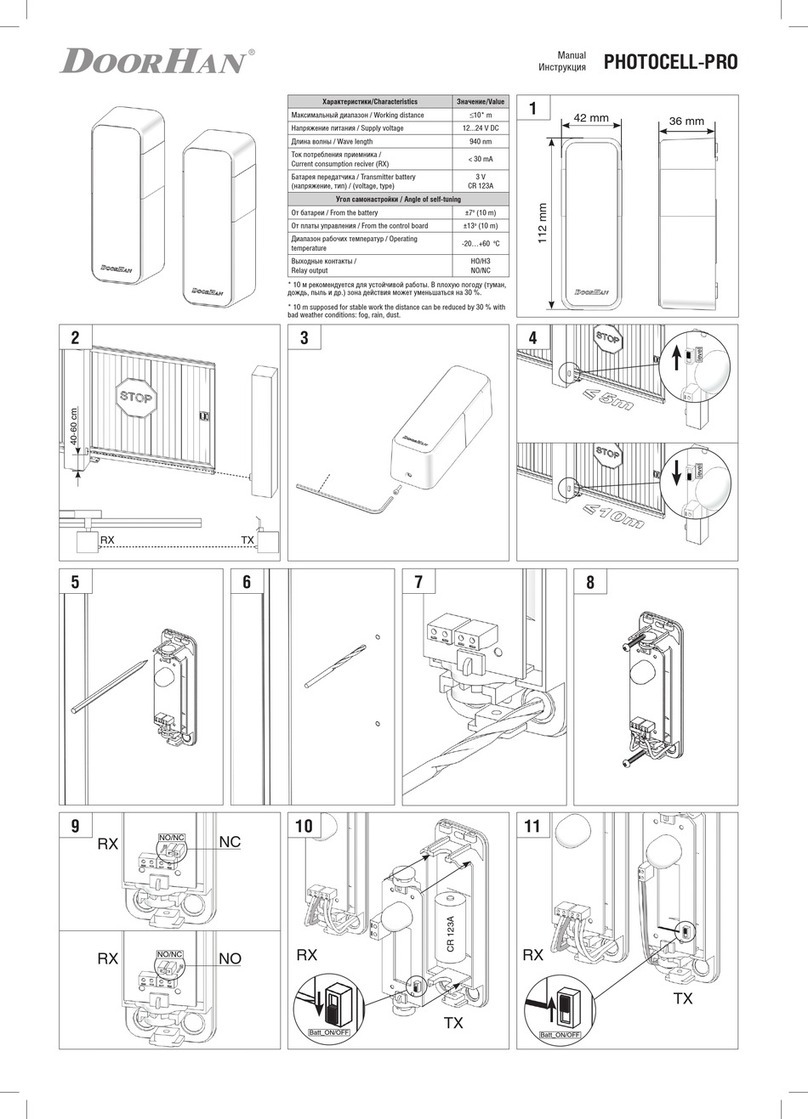

5.3 Physical Attributes

Dimensions 123mm (H) x 142mm (W) x 65mm (D)

14

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Mounting 2 holes Ø7mm 126mm apart

Weight 1.6kg

Connections G1 M16x2 hydraulic connection

G3 ¼” BSPP Female Port

G4 7/16 UNF Female Port

Seal Material M/N Version –Viton (contact RMF Systems for any fluids that are incompatible with Viton

seals

S Version - Perfluoroelastomer

15

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

5.4 Fluid Characteristics

Fluid compatibility M version - mineral oils, synthetic fluids and diesels

N version –water based/ subsea fluids & M version fluids

S version –Aerospace phosphate esters, Skydrols® and N & M version fluids.

Viscosity ≤ 1000 cSt

Fluid temperature -25°C to +80°C

Operating Flow Rate 20-400ml/min

16

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Maximum Pressure 420barg static (For high frequency pressure pulse applications contact RMF Systems)

Differential Pressure Typically 0.5bar

5.5 Environment

Ambient working temperature -25°C to 80°C non K version / -25°C to 55°C K version

IP Rating IP66

IK Rating IK04

5.6 Wetted Parts List

M version

N Version

S Version

Copper Alloy C46400

Stainless Steel

Stainless Steel

Stainless Steel

Sapphire (Al2O3)

Sapphire (Al2O3)

Sapphire (Al2O3)

Viton

Perfluoroelastomer

Viton

PTFE

PTFE

PTFE

EPDM

FR4

17

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

6 Product Installation and General Operation

6.1 Installation

Each CMS supplied consists of the following:

−CMS

−Calibration certificate

−USB Stick which includes: Product User Guides, RMF-View software, accessory product drivers and product

brochures

−Pre-wired 3m cable

−Quick Start Guides

Optional Equipment:

−Circular connector pre-wired with 3m cable

−CMSRDU2 Remote display unit

−500μm coarse screen filter

−CMSUSBi USB adaptor with pre-wired CMS cable

−CMSETHi RJ-45 adaptor with pre-wired CMS cable

6.1.1 Physical Procedure

−Decide on tapping points in hydraulic circuit

−Locate the unit mechanically and bolt to desired location using fixing holes provided. The CMS must be in a

vertical orientation, with the oil flowing upwards through it

−Wire back to junction box

−Check flow in acceptable range. There needs to be a differential pressure of more than approximately 0.5bar

placed across the CMS, such that a flow of fluid is generated within the range of the unit.

−If there is no suitable differential pressure available, then a flow controller will be needed. One solution is the

pressure compensated flow control valve. This limits the flow to around 200ml/minute for differential

pressures up to 400bar. This should be fitted to the drain side of the CMS (the top fitting).

−Fix mechanically

−Connect hoses or hard pipe from the system

−There must be no extra restriction placed in the drain hose. Do not have a pipe going to a restrictor to

control flow. Any such restrictor must be mounted directly to the CMS drain fitting. (A)

−Fluid flow must be from the bottom fitting to the top, following the direction of flow arrow on the product

labelling i.e. the bottom fitting is the inlet and the top fitting is the outlet.

−Fit electrical connector, wire back to a junction box.

(A) This is because any length of pipe between the CMS and a downstream restrictor can act as an accumulator.

Any pressure pulsations (for example from a pump) in the feed to the CMS are then translated into pulsations in

18

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

flow rate, sometimes leading to flow reversals in time with the pulsations. If the flow is very low this can sweep

the same particle backwards and forwards through the sensing volume multiple times, confusing the results.

6.1.2 Electrical Interface

RMF Systems’separate CMS-USBi product is available for those wishing to have a simple plug and play solution

providing connection of the CMS to a computer. This section is for those wishing to do their own wiring to the

product.

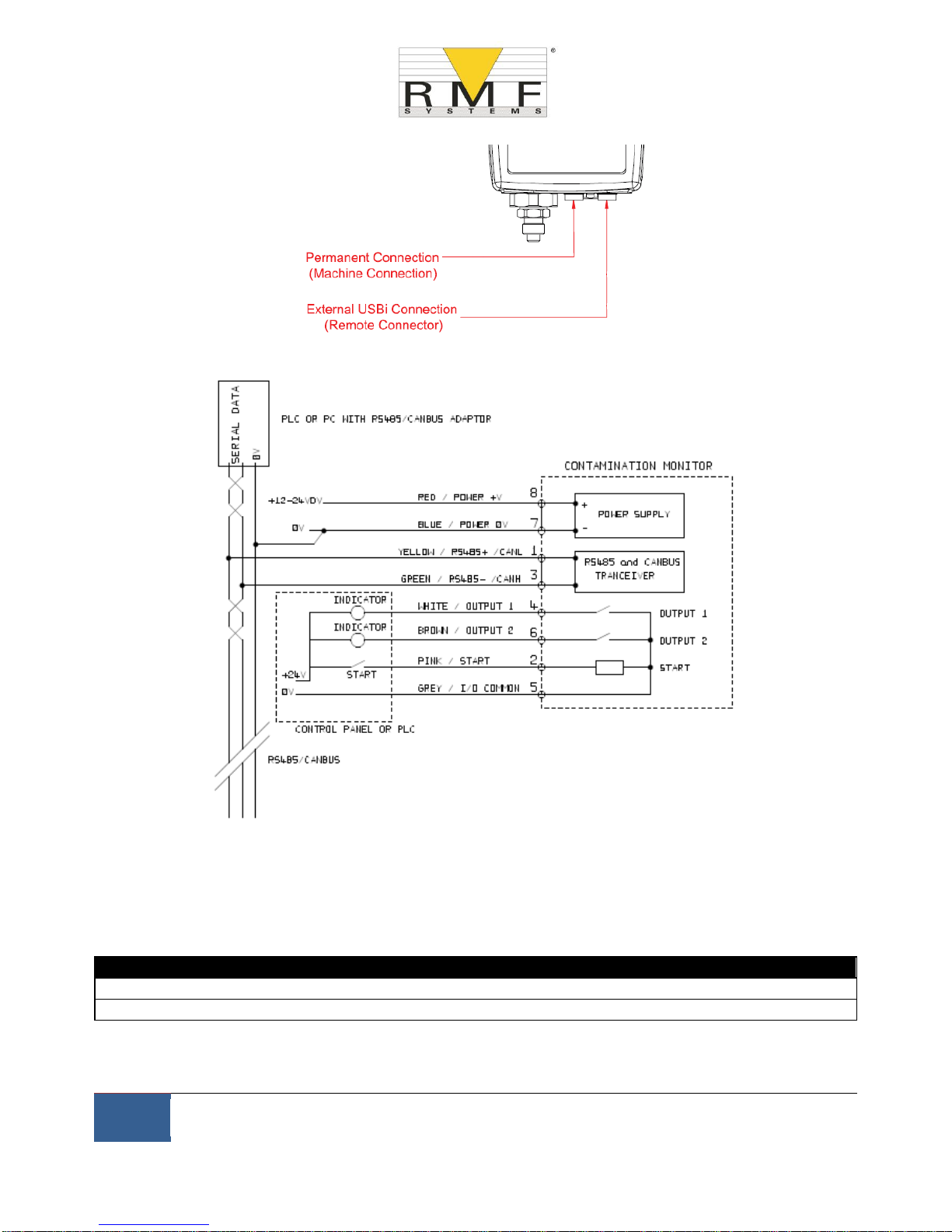

6.1.2.1 Electrical Connectors

The CMS has two circular connectors located on the lower face of the unit. The USBi product can be connected to

either one depending on the installation configuration, see figure 6.1.

Pin

Colour

“Machine” Connector

“Remote” Connector

1

Yellow

RS485+/CANL/4-20mA(A)

RS485+

2

Pink

START INPUT

3

Green

RS485-/CANH/4-20mA(B)

RS485-

4

White

OUTPUT 1

5

Grey

I/O COMMON

6

Brown

OUTPUT 2

7

Blue

DC 0V

DC 0V

8

Red

DC +POWER

DC +POWER

6.1.2.1.1 Remote Connector

The ``remote connector’’ is intended for temporary connection of an external communication device e.g.

CMSUSBi so as to allow data download, remote control or diagnostics using the RMF-View software.

This is the circular connector furthest from the hydraulic connection, see figure 6.1.

This carries RS485 data and can also be used to power the unit temporarily in the event of a system being shut

down, thus no longer providing power to the unit.

This connector doesn’t send alarm signals as shown in the wiring diagram 6.7. If you require a USBI to send alarm

signals it has to be connected to the machine connector.

6.1.2.1.2 Machine Connector

The ``machine connector’’ is intended for permanent connection to the PLC / machine that powers the CMS

during normal operation. It has power connections, a start signal input, two relay outputs, and a data pair that

can be set to RS485, CANbus or 4-20mA signaling modes.

This is the circular connector closest to the hydraulic connection, see figure 6.1.

NOTE: If CANBUS or 4-20mA option has been selected, standard communication with an RS485 adapter (e.g.

USBI) on this port is no longer available.

The right hand port (remote connector) should be used if temporary connection is required.

NOTE: Start signal and relay outputs only apply to this connector.

19

As a policy of continual improvement, RMF reserves the right to alter the specification without prior notice.

201.028 REV 1 Date of Issue: 18 June 2018

Figure 6.1 Connector Orientation

Figure 6.2 Machine Connector External Wiring Example

6.1.2.2 DC Power

DC power is connected to pins 7 and 8 of either circular connector (Red and Blue if using the pre-wired cable). All

the other signals are optional.

Item

Minimum

Maximum

Voltage

9V DC

36V DC

Current

200mA

Table of contents

Popular Accessories manuals by other brands

SIKA

SIKA VVX operating manual

Barbarian Basketball Systems

Barbarian Basketball Systems Titanium Series Assembly instructions and owner's manual

Orno

Orno SOUL DC Operating and instalation instructions

Digital reasures

Digital reasures PowerNow! 10000+ user guide

Clevertouch

Clevertouch WL10A-G user manual

Pil Sensoren

Pil Sensoren P41-350-I-CM12 manual