RND lab 355-00010 User manual

www.rnd-electronics.com

True RMS

Autoranging

Digital Multimeter

User Manual

RND 355-00010

3

ENEN

2

Operating instruction for True RMS

Autoranging Digital Multimeter

1. Introducon

• Professional True RMS Industrial Digital Mulmeter and TFT color LCD display,

providing fast A/D converng sampling me, high accuracy , built-in

datalogging and Trend Capture feactures.

• It can trace any interrupted problems of the equipments and watch on

without person.

• It is easy to nd and solve the problems of the producon equipments,

providing Bluetooth technology and memory the datasheets.

• It is much more safe measurements.

• This meter measures AC/DC Voltage & Current, Resistance, Connuity,

Capacitance, Frequency (Electrical & Electronic), Duty Cycle, Diode Test and plus

Thermocouple Temperature.

• It can store and recall data.

• It features a waterproof, rugged design for heavy duty use.

• Proper use and care of this meter will provide many years of reliable service

2. Safety

2-1. Safety Symbols

This symbol adjacent to another symbol, terminal or operang device

indicates that the operator must refer to an explanaon in the

operang instrucons to avoid personal injury or damage to the meter.

WARNING This WARNING

symbol indicates a potenally hazardous situaon, which if not

avoided, could result in death or serious injury.

CAUTION This CAUTION symbol indicates a potenally hazardous situaon, which if not

avoided, may result damage to the product.

MAX This symbol advises the user that the terminal(s) so marked must not be

connect to a circuit point at which the voltage with respect to earth ground

exceeds (in this case) 1000 VAC or VDC.

This symbol adjacent to one or more terminals idenes them as being associat

with ranges that may, in normal use, be subjected to parcularly hazardous

voltages. For maximum safety, the meter and its test leads should not be handled

when these terminals are energized.

Please read this manual before switching the unit on.

Important safety information inside.

4 5

ENEN

This symbol indicates that a device is protected throughout by double insulaon or

reinforced insulaon.

2-2.Per IEC1010 Overvoltage Installaon Category Overvoltage Category I

Equipment of Overvoltage Category I is equipment for connecon to circuits in

which measures

are taken to limit the transient overvoltages to an appropriate low level.

Note: Examples include protected electronic circuits.

Overvoltage Category II

Equipment of Overvoltage Category II is energy-consuming equipment to be supplied

from the

xed installaon.

Note: Examples include household, oce, and laboratory appliances.

Overvoltage Category III

Equipment of Overvoltage Category III is equipment in xed installaons.

Note: Examples include switches in the xed installaon and some equipment for

industrial use with permanent connecon to the xed installaon.

Overvoltage Category IV

Equipment of Overvoltage Category IV is for use at the origin of the installaon.

Note: Examples include electricity meters and primary over-current protecon equipment.

2-3.Safety Instrucons

• This meter has been designed for safe use, but must be operated with cauon.

• The rules listed below must be carefully followed for safe operaon.

1.Never apply voltage or current to the meter that exceeds the specied maximum:

Input Protecon Limits

Funcon

V DC or V AC

mA AC/DC

A AC/DC

Frequency, Resistance, Capacitance,

Duty Cycle, Diode Test, Connuity

Temperature

Surge Protecon: 8kV peak per IEC 61010

Maximum Input

V DC or V AC

800mA 1000V fast acng fuse

10A 1000V fast acng fuse

(10A for 30 seconds max every 10 minutes)

1000VDC/AC rms

1000VDC/AC rms

2.Use extreme CAUTION when working with high voltages.

3.Do not measure voltage if the voltage on the “COM” input jack exceeds 1000V above

earth ground.

4.Never connect the meter leads across a voltage source while the funcon switch

is in the current, resistance, or diode mode, doing so can damage the meter.

5.Always discharge lter capacitors in power supplies and disconnect the power

when making resistance or diode tests.

6.Always turn o the power and disconnect the test leads before opening the covers

to replace the fuse or baeries.

7.Never operate the meter unless the back cover and the baery and fuse covers are in

place and fastened securely.

8.If the equipment is used in a manner not specied by the manufacturer, the

protecon provided by the equipment may be impaired.

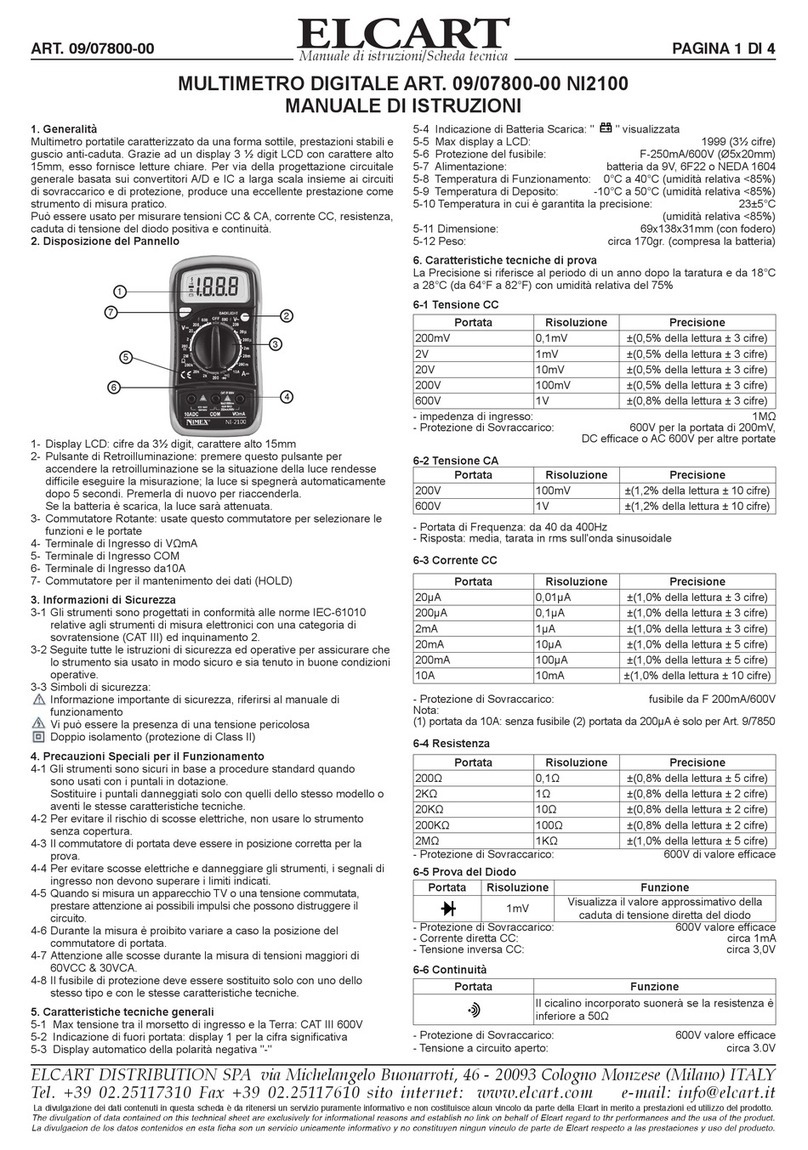

3.Descripon

3-1.Meter Descripon

1-50,000 Counts LCD Display

2-F1 Soware Key

3-F2 Soware Key

4-F3 Soware Key

5-F4 Soware Key

6-RANGE Buon

7-HOLD/REL Buon

8-Funcon Switch

9-10A Input Jack

10-μA mA Input Jack

11-Posive Input Jack

12-COM Input Jack

13-Tilt Stand

14-Baery Cover

OFF

Ω

CAP

mA

^rqO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

t^TERPROOF

V

V CAPΩ

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LP F

mA%

4~20 mV

_äìÉíççí Ü

RANGE HOLD

REL

F1

F2

F4

F3

1

2

6

4

5

7

8

9

10

11

12

3

13

14

6 7

ENEN

3-2.Understanding the Display

1.So key labels Indicates the funcon of the buon just below the displayed label.

2.Bar graph Analog display of the input signal.

3.Minus sign Indicates a negave reading.

4.Displays measurement informaon about the input signal.

5.Indicates the range the Meter is in and the ranging mode (auto or manual)

6.Time Indicates the me set in the internal clock.

7.Buetooth Indicate

8.Baery level Indicates the charge level baeries.

9.Beeper Indicates the Meter’s beeper is enabled (not associated with the

connuity beeper).

10.Units Indicates the units of measure.

-0.0 4

Auto range 06:32

GRAPH

-500 -300 -100 01 00 300 500mV

MODE SAVE MAX

mV

1

2

4

5 6 7

10

9

8

3

3-3.Understanding the Push Buons

The 6 push buons on the front of the Meter acvate features that augment the funcon

selected using the rotary switch, navigate menus or control power to Meter circuits.

F1 Soware Key: Default switch to Graph measure.

F2 Soware Key: Default modes related to the rotary switch funcon

F3 Soware Key: Default into save mode default Display. And wake up for APO.

F4 Soware Key: Default modes MIN/MAX starts and stops MIN/MAX recording.

RANGE Buon: Into manual range and select range of the measure, if pressing the Range

Buon for greater that 1 second will return Auto Range.

HOLD/REL Buon: Freezes the present reading in the display and allows the

display to be saved,

if pressing the HOLD/REL Buon for greater that 1 second will switch relave mode.

HOLD/REL Buon: Freezes the present reading in the display and allows the display to be

saved,if pressing the HOLD/REL Buon for greater that 1 second will switch relave mode.

3-4.Understanding the Rotary Switch

• Select a primary measurement funcon by posioning the rotary switch to one of the

icons around its perimeter.

• For each funcon, the Meter presents a standard display for that funcon

(range, measurement units and modiers).

• Buon choices made in one funcon do not carry over into another funcon.

AC/DC Amps Measurements.

mA : AC/DC Milliamps Measurements.

% 4-20mA Measurements.

AC/DC Microampere Measurements up to 5,000μA.

AC Voltage Measurements

DC and AC+DC Voltage Measurements.

AC/DC Milli-Volts Measurements.

Frequency and Duty Cycle Measurements.

Ω Resistance, Diode Test, Capacitance and Connuity Measurements.

Temperature Measurements.

10A :

mA :

4~20mA%:

µA :

V :

V AC+DC:

mV :

Hz%:

CAP:

Temp:

8 9

EN EN

3-5.Using the Input Terminals

• All funcons except current use the V/OHMS and COM input terminals.

• The two current input termin for 500mA and 10A current measurement.

10A: Input for 0A to 10.00A current (20A overload for 30 seconds on, 10 minutes o).

μAmA: Input for 0A to 500mA current measurements.

COM: Return terminal for all measurements.

VΩCAP Hz Temp: Input for Voltage, Connuity, Resistance, Diode Test, Conductance,

Capacitance.

4.Measure Funcon

4-1.AC Voltage Measurement

WARNING: Risk of Electrocuon. The probe ps may not be long enough to contact the live

parts inside some 240V outlets for appliances because the contacts are recessed deep in the

outlets. As a result, the reading may show 0 volts when the outlet actually has voltage on it.

Make sure the probe ps are touching the metal contacts inside the outlet before assuming

that no voltage is present.

CAUTION: Do not measure AC voltages if a motor on the circuit is being switched ON or OFF.

Large voltage surges may occur that can damage the meter.

1. Set the funcon switch to the VAC Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

3. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

4. Read the AC voltage in the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

5. 0000

Auto range 06:32

GRAPH

01 23 4 5V

MODE SAVE MAX

V

4-2.DC Voltage Measurement

CAUTION: Do not measure DC voltages if a motor on the circuit is being switched ON or

OFF. Largevoltage surges may occur that can damage the meter.

1. Set the funcon switch to the VDC AC+DC Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the

Posive Input Jacks.

3. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

4. Read the DC voltage in the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

5. 0000

Auto range 06:32

GRAPH

-5 5V

MODE SAVE MAX

V

-4 -3 -2 -1 01 23 4

10 11

EN EN

4-3.AC+DC Voltage Measurement

1. Set the funcon switch to the VDC AC+DC Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

3. Press the MODE Buon (F2) to indicate “AC+DC” on the display.

4. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

5. Read the AC+DC voltage in the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

5. 0000

Auto range 06:32

GRAPH MODE SAVE MAX

V

AC+DC

0. 0000 V

5. 0000 V

4-4.mV Voltage Measurement

CAUTION: Do not measure mV voltages if a motor on the circuit is being switched ON or

OFF. Large voltage surges may occur that can damage the meter.

1. Set the funcon switch to the mVAC/DC Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

3. Press the MODE Buon (F2) to indicate “AC” or “DC” on the display.

4. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

5. Read the mV voltage in the display.

500. 00

Auto range 06:32

GRAPH

-500 -300 -100 01 00 300 500mV

MODE SAVE MAX

mV

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

4-5.DC Current Measurement

CAUTION: Do not make 10A current measurements for longer than 30 seconds, Exceeding

30

seconds may cause damage to the meter and/or the test leads.

1. Insert the black test lead banana plug into the COM Input Jack.

2. For current measurements up to 5000μA DC, set the funcon switch to the μA AC/DC

Posion and insert the red test lead banana plug into the μA/mA Input Jack.

3. For current measurements up to 500mA DC, set the funcon switch to the mA AC/DC

Posion and insert the red test lead banana plug into the μA/mA Input Jack.

4. For current measurements up to 10A DC, set the funcon switch to the 10A AC/DC

Posion and insert the red test lead banana plug into the 10A Input Jack.

5. Press the MODE Buon (F2) to indicate “DC” on the display.

6. Remove power from the circuit under test, then open up the circuit at the point where

you wish to measure current.

7. Touch the black test probe p to the negave side of the circuit; Touch the red test probe

p to the posive side of the circuit.

8. Apply power to the circuit.

9. Read the current in the display.

12 13

EN EN

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

500. 00

Auto range 06:32

GRAPH

-500 -300 -100 01 00 300 500µA

MODE SAVE MAX

µA

4-6.AC Current Measurement

CAUTION: Do not make 10A current measurements for longer than 30 seconds, Exceeding

30 seconds may cause damage to the meter and/or the test leads.

1. Insert the black test lead banana plug into the COM Input Jack.

2. For current measurements up to 5000μA AC, set the funcon switch to the μA AC/DC

Posion and insert the red test lead banana plug into the μA/mA Input Jack.

3. For current measurements up to 500mA AC, set the funcon switch to the mA AC/DC

Posion and insert the red test lead banana plug into the μA/mA Input Jack.

4. For current measurements up to 10A AC, set the funcon switch to the 10A AC/DC

Posion and insert the red test lead banana plug into the 10A Input Jack.

5. Press the MODE Buon (F2) to indicate “AC” on the display.

6. Remove power from the circuit under test, then open up the circuit at the point where

you wish to measure current.

7. Touch the black test probe p to the negave side of the circuit; Touch the red test probe

p to the posive side of the circuit.

8. Apply power to the circuit.

9. Read the current in the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

500. 00

Auto range 06:32

GRAPH

-500 -300 -100 01 00 300 500µA

MODE SAVE MAX

µA

4-7.% 4~20mA Measurement

1. Set up and connect as described for DC mA measurements.

2. Set the funcon switch to the 4~20mA% Posion.

3. The meter will display loop current as a % with 0mA=-25%, 4mA=0%, 20mA=100%

and 24mA=125%.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

25. 00

Auto range 06:32

MODE SAVE MAX

%

14 15

EN EN

4-8.Frequency/Duty Cycle(%) Measurement

1. Set the funcon switch to the Hz% Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

4. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

5. Read the Frequency in the display.

6. Press the MODE Buon (F2) again to indicate “%” on the display.

7. Read the % of duty cycle on the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

50. 000

Auto range 06:32

MODE SAVE MAX

Hz

4-9.Resistance Measurement

WARNING: To avoid electric shock, disconnect power to the unit under test and discharge

all capacitors before taking any resistance measurements, Remove the baeries and unplug

the line cords.

1. Set the funcon switch to the Ω CAP Posion.

2 .Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

4. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

5. Read the Resistance in the display.

4-10.Connuity Check

WARNING: To avoid electric shock, disconnect power to the unit under test and discharge

all capacitors before taking any capacitance measurements. Remove the baeries and

unplug the line cords.

1. Set the funcon switch to the Ω CAP Posion.

2. Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input Jacks.

4. Press the MODE Buon (F2) again to indicate “Ω” and “ ” on the display.

5. Posion the black test probe p and red test probe p respecvely in the spots of the

circuit to be measured.

6. If the resistance is less than approximately 25Ω, the audible signal will sound. If the circuit

is open, the display will indicate “OL”.

50. 000

Auto range 06:32

GRAPH

01 02 03 0 40 50M

MODE SAVE MAX

M

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

16 17

EN EN

25. 000

Auto range 06:32

01 00 2003 00 400 500

MODE SAVE MAX

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

4-11.Diode Test

1. Set the funcon switch to the Ω CAP Posion.

2.Insert the black test lead into the COM Input Jack and the red test lead into the Posive

Input

Jacks.

4.Press the MODE Buon (F2) again to indicate “V” and “ ” on the display.

5.Forward voltage will typically indicate 0.400 to 3.200V, Reverse voltage will indicate “OL”;

Shorted devices will indicate near 0V and an open device will indicate “OL” in

both polaries.

0. 5000

Auto range 06:32

01 23 4 5V

MODE SAVE MAX

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

V

4-12.Capacitance Measurement

WARNING: To avoid electric shock, disconnect power to the unit under test and discharge all

capacitors before taking any capacitance measurements. Remove the baeries and unplug the line

cords.

1. Set the funcon switch to the Ω CAP Posion.

2.Insert the black test lead into the COM Input Jack and the red test lead into the Posive Input

Jacks.

3.Press the MODE Buon (F2) again to indicate “nF” on the display.

4. Posion the black test probe p and red test probe p respecvely in the spots of the circuit to

be measured.

5. Read the Capacitance in the display.

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

50. 00

Auto range 06:32

nF

MODE SAVE MAX

18 19

EN EN

OFF

CAP

mA

AUTO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

WATERPROOF

V

V CAP

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LPF

mA%

4~20 mV

Bluetooth

RANGE HOLD

REL

F1

F2

F4

F3

250. 0

Auto range 06:32

°C

MODE SAVE MAX

4-13.Temperature Measurement

1. Set the funcon switch to the Temp Posion.

2. Insert the Temperature Probe into the input jacks, making sure to observe the

correct polarity.

3. Press the MODE Buon (F2) to indicate °C or °F.

4. Touch the Temperature Probe head to the part whose temperature you wish to measure,

Keep the probe touching the part under test unl the reading stabilizes

(About 30 seconds).

5. Read the temperature in the display.

0. 0000

Auto range 06:32

GRAPH

01 23 4 5V

MODE SAVE MAX

V

Auto range 06:32

START FASTS LOWC ANCEL

0

0.0000 V

Rate: 0.2 s

Range: 0.01

5.Default Display

5-1.Graph Measure

• Press the GRAPH Buon (F1), Meter will switch to Graph measure.

• Press the START Buon (F1).

• Press the FAST Buon (F2) or the SLOW Buon (F3) to adjust sampling rate.

• Press the CANCEL Buon (F1) to exit Graph and return to normal measurement mode.

Press the STOP Buon (F4).

START FAST SLOW CANCEL

20 21

EN EN

• Press the SAVE Buon (F1) to save graph.

• Press the BACK Buon (F4) to return.

5-2.Capturing Minimum and Maximum Values

• To acvate the MAX/MIN mode, Press MAX Buon (F4) at measure mode.

• As shown in Figure, the Meter displays eat the top of the measurement page, and the

MAX/MIN start date and me along the boom of the page.

• In addion, the recorded maximum, average, and minimum values appear in the

secondary display with their respecve elapsed mes.

• To stop a MAX/MIN recording session, press the STOP Buon (F2).

• Thesummary informaon in the display freezes, and the sokeys change funcon to allow

saving the collected data.

• Pressing the CLOSE Buon (F4) exits the MAX/MIN record session without saving the

collected data.

• To save the MAX/MIN screen data, the MAX/MIN session must be ended by pressing the

STOP Buon (F2), Next, press the SAVE Buon (F3).

Auto range 06:32

SAVE BACK

0

0.0000 V

Rate: 0.2 s

Range: 0.01

5-3.Capturing Peak Values

To acvate the peak mode, at AC measure MAX/MIN mode , Press the PMAX Buon (F4).

5-4.Relave Values

To acvate the relave mode, Press the HOLD/REL Buon for greater that 1 second.

-0 . 0430

Auto range 06:32

GRAPH MODE SAVE MAX

V

REL

Reference0 .3079 V

0.2649 V

5-5.Hold Mode

• To freeze the display for any funcon, Press the HOLD/REL Buon.

• Press the SAVE Buon (F3) to memory and the CLOSE Buon (F4) return measure.

STOP

22 23

EN EN

5-6.Save Funcon

Press the SAVE Buon (F3), into save menu.

Auto range 06:32

ENTER UP DOWN CANCEL

5-7.Storing Individual Measurement Data

• For common measurement funcons, a snapshot of the screen data is saved by pressing

the SAVE Buon (F3).

• Then pressing the DOWN Buon (F3) to the save select item, pressing the

ENTER Buon (F1).

5-8.Viewing Memory Data

• Viewing data stored in the Meter’s memory is performed through the save menu.

• Press the DOWN Buon (F3), posion the menu selector next to the menu item labeled

ViewM, and pressing the ENTER Buon (F1).

Auto range 06:32

ENTER UP DOWN CANCEL

5-9.Viewing Graph Data

• Viewing data stored in the Meter’s memory is performed through the save menu.

• Press the DOWN Buon (F3), posion the menu selector next to the menu item labeled

ViewG, and pressing the ENTER Buon (F1).

• Press the << Buon (F2) and the >> Buon (F3) to move cursor.

5-10.Recording Measurement Data

• Press the SAVE Buon (F3), then pressing the DOWN Buon (F3) to the Record select

Item, pressing the ENTER Buon (F1), Press the sokey labeled Start to start records.

• The recording session will connue unl the allocated memory is used, the baeries

expire, the rotary switch is moved, or the session is terminated by pressing the CLOSE

Buon (F4) labeled stop.

Auto range 06:32

ENTER UP DOWN CANCEL

366. 55

Auto range 06:32

DOWN CLOSE

mV

UPENTER

Set Duration: 00Days 00Hrs 01Min

Set Sample Interval: 00Min 01Sec

Start Record

Battery: partly empty

ENTER UP DOWN CANCEL

DOWN

Set Duraon: 00Days 00Hrs 01Mins

Set Sample Interval: 00Min 01Sec

Start Record

Baery: partly empty

DOWN DOWN

24 25

EN EN

5-12.Info

• Viewing data stored in the Meter’s memory is performed through the save menu.

• Press the DOWN Buon (F3), posion the menu selector next to the menu item labeled

Info and pressing the the ENTER Buon (F1).

Auto range 06:32

ENTER UP DOWN CANCEL

Auto range 06:32

DOWN CLOSEUP

g

r

6.Setup Opons

• Viewing data stored in the Meter’s memory is performed through the save menu.

• Press the DOWN Buon (F3), posion the menu selector next to the menu item label

Setup and pressing the ENTER Buon (F1).

Auto range 06:32

ENTER UP DOWN CANCEL

Auto range 06:32

ENTER UP DOWN CANCEL

Reset

Format

Display

Meter Inf

Bluetooth

Calibration

Temperature

6-1.Reseng Meter

• The Meter’s setup opons can be reset to default values through the setup menu.

• Open the setup menu, posion the menu selector next to the menu item labeled Reset

and press the ENTER Buon (F1).

• Then a message will appear asking to conrm the reset acon.

• Press the OK Buon (F2) to perform the reset.

6-2.Meter Info

• The Meter Info selecon lists the serial number, rmware version, are displayed.

• Open the setup menu, posion the menu selector next to the menu item labeled Meter

Info and press the ENTER Buon (F1).

DOWN DOWN

Fno. Graph- According to graphically display

measurement informaon

Fno. Mode-Related to the rotary switch funcon

Fno. Save-Accesses the memory management

menu for saving measuremnt, seng up recording

sessions, or viewing and deleng stored

measurements from memory

CLOSE

DOWN DOWN

5-11.Viewing Trend Data

• Viewing data stored in the Meter’s memory is performed through the save menu.

• Press the DOWN Buon (F3), Posion the menu selector next to the menu item labeled

ViewR and pressing the ENTER Buon (F1).

• Press the the TREND Buon (F1).

• Press the + Buon (F2) to increase graph resoluon, press the >> Buon (F3) to

move cursor.

26 27

EN EN

Auto range 06:32

ENTER UP DOWN CANCEL

Reset

Format

Display

Meter Inf

Bluetooth

Calibration

Temperature

Auto range 06:32

CLOSE

6-3.Seng Format

• Open the setup menu, posion the menu selector next to the menu item labeled Format

and press the ENTER Buon (F1).

• Using the cursor buons, move the menu selector next to the menu item labeled

Numeric(Date\Time) format, press the EDIT Buon (F1) to edit, select 0.0000(0,0000) and

MM/DD/YY(DD/MM/YY) and 24 HOUR(12 HOUR) format.

Auto range 06:32

ENTER UP DOWN CANCEL

Reset

Format

Display

Meter Info

Bluetooth

Calibration

Temperature

Auto range 06:32

CLOSE

Format

DOWNUPEDIT

Beeper

Numeric Format

Date Format

Time Format

Auto range 06:32

CANCEL

Format

Beeper

Numeric Format

Date Format

Time Format

6-4.Seng Display

• Open the setup menu.

• Posion the menu selector next to the menu item labeled Display and press the ENTER

Buon (F1).

O

Meter Info

Fireware Version: V1.10

DOWN

DOWN

DOWN MM/DD/YY MM/DD/YY

6-5.Seng Date and Time

• Open the setup menu, posion the menu selector next to the menu item labeled Display

and press the ENTER Buon (F1).

• Next posion the menu selector next to either the Set Date item or Set Time item and

press the EDIT Buon (F1).

28 29

EN EN

6-6.Auto Power O

• Open the setup menu, posion the menu selector next to the menu item labeled Display

and press the ENTER Buon (F1).

• Then Posion the menu selector next to the menu item labeled Auto Power O and press

the EDIT Buon (F1).

• To set Auto Power O, use UP (F2) and DOWN (F3) to adjust the me to one of

the preset values.

• 0 is disable the meout feature.

• Press the OK Buon (F1) to set the selected me, press the CANCEL Buon (F4) to return.

6-7.Foreground and Background

• Open the setup menu, posion the menu selector next to the menu item labeled Display

and press the ENTER Buon (F1).

• Then posion the menu selector next to the menu item labeled Foreground and

Background and press the OK Buon (F1).

• Use UP (F2) and DOWN (F3) to adjust.

6-8.Set Font

• Open the setup menu, posion the menu selector next to the menu item labeled Display

and press the ENTER Buon (F1).

• Then Posion the menu selector next to the menu item labeled Select Font and press the

EDIT Buon (F1)

• Use UP (F2) and DOWN (F3) to adjust.

Auto range 06:32

ENTER UP DOWN CANCEL

Reset

Format

Display

Meter Info

Bluetooth

Calibration

Temperature

Auto range 06:32

CANCELOK

Turn on Bluetooth?

6-9.Bluetooth

•You can use the Bluetooth communication link and transfer the contents of a meter’s

memory to a PC.

• Open the setup menu, position the menu selector next to the menu item labeled

Bluetooth and press the the ENTER Button (F1).

• Turn on Bluetooth” and press the OK Button (F1) , “Turn off Bluetooth” and press the OK

Button (F1).

•The Bluetooth app can be installed on mobile phones. The recommended

communication distance between mobile device and multimeter should not exceed

5.5m, and it will need to be re-connected manually if disconnected.

30 31

EN EN

7.Replacing the Baeries

WARNING: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the baery cover.

WARNING: To avoid electric shock, do not operate the meter unl the baery cover is in

place and fastened securely.

Refer to Figure and replace the baeries as follows:

1. Turn the Meter o and remove the test leads from the terminals.

2. Remove the baery door assembly by using a standard blade screwdriver to turn

the baery door screw one-half turn counterclockwise.

3. Replace the baeries with 7.4 volt charge baeries Observe proper polarity.

4. Reinstall the baery door assembly and secure it by turning the screw one-half

turn clockwise.

8.Replacing the Fuses

WARNING: To avoid electric shock, disconnect the test leads from any source of voltage

before removing the meter cover.

WARNING: To avoid electric shock, do not operate your meter unl the fuse cover is in place

and fastened securely.

Referring to Figure, examine or replace the Meter’s fuses as follows:

1. Turn the Meter o and remove the test leads from the terminals.

2. Remove the baery door assembly by using a standard blade screwdriver to turn

the baery door screw one-half turn counterclockwise.

3. Remove the fuse by gently prying one end loose, then sliding the fuse out of its bracket.

4. Install only specied replacement fuses.

5. Reinstall the baery door assembly and secure it by turning the screw one-half

turn clockwise.

6. Remove the six screws securing the rear cover.

7. Gently remove the old fuse and install the new fuse into the holder.

8. Replace and secure the rear cover, baery and baery cover.

32 33

EN EN

9. Li-ion Baery Charge

1. Turn the Meter o and remove the test leads from the terminals.

2. Remove the baery door assembly by using a standard blade screwdriver to turn

the baery door.

3. Install the baery to the external charging stand, plug in the special adapter and

plug the adapter into a live socket. (Specic charging instrucons are shown in the

charging stand instrucons).

10.Specicaons

10-1.Specicaons

500mV

5V

50V

500V

1000V

0.01mV

0.0001V

0.001V

0.01V

0.1V

±(0.5% +

5 digits)

50/60Hz <1kHz

±(3.0% +

5 digits)

±(1.5% +

10 digits)

<5kHz

±(3.0% +

5 digits)

<20kHz (1)

±(5.5% +

20 digits)

±(3.5% +

10 digits)

Unspecied

Unspecied Unspecied

500mV (2)

5V

50V

500V

1000V

0.01mV

0.0001V

0.001V

0.01V

0.1V

±(0.1% + 5 digits)

±(0.05% + 5 digits)

±(0.1% + 5 digits)

(2): When using the relave mode (REL Q) to compensate for osets.

(1): Upper 10 % of range.

5V

50V

500V

1000V

0.0001V

0.001V

0.01V

0.1V

<1kHz

±(1.2% + 20 digits)

<5kHz

±(3.5% + 20 digits)

Unspecied

500 Ω (3)

5K Ω (3)

50KΩ (3)

500K Ω (3)

5M Ω (3)

50M Ω (3)

0.01(3)

0.0001(3)

0.001k(3)

0.1k(3)

0.0001M(3)

0.001M(3)

±(0.20% + 10 digits)

±(0.20% + 5 digits)

±(0.50% + 5 digits)

±(2.0% + 20 digits)

(3): When using the relave mode (REL Q) to compensate for osets.

500μA

5000μA

50mA

500mA

10A

0.01μA

0.1μA

0.001mA

0.01mA

0.001A

±(0.5% + 5 digits)

±(0.3% + 8 digits)

±(0.5% + 8 digits)

34 35

EN EN

500μA

5000μA

50mA

500mA

10A

0.01μA

0.1μA

0.001mA

0.01mA

0.001A

50/60Hz

±(0.8% + 5 digits)

<5kHz

±(3% + 5 digits)

10A: 30 sec max with reduced accuracy.

All AC current ranges are specied from 5% of range to 100% of range.

5nF (3) 0.001nF

50nF 0.01nF

500nF 0.1nF

5μF 0.001μF

50μF 0.01μF

500μF 0.1μF

10mF 0.01mF

±(1.5% + 20 digits)

±(1.5% + 8 digits)

±(1.0% + 8 digits)

±(1.5% + 15 digits)

±(1.0% + 8 digits)

±(1.5% + 8 digits)

±(2.5% + 20 digits)

(3): With a lm capacitor or beer, using relave mode (REL ) to zero residual.

50Hz

500Hz

5kHz

50kHz

500kHz

5MHz

10MHz

0.001Hz

0.01Hz

0.0001kHz

0.001kHz

0.01kHz

0.0001MHz

0.001MHz

±(0.01% + 5 digits)

Unspecied

Sensivity: 2V rms min. at 20% to 80% duty cycle and <100kHz; 5Vrms min at 20% to 80% duty

cycle and >100kHz.

10.00-10kHz 0.01-0.001kHz ±(0.5% reading)

Sensivity: 2Vrms.

0.1 to 99.90% 0.01% ±(1.2% + 5 digits)

Pulse width: 100μs-100ms, Frequency: 5Hz to 150kHz.

-200 to 1350°C

-328 to 2462°F

0.1°C

0.1°F

±(1.0% + 3.0°C)

±(1.0% + 5.4°C)

Does not include error of the thermocouple probe.

Accuracy specicaon assumes ambient temperature stable to ±1°C.

Use a long me, reading will increase 2°C.

<-50°C Temp Rang accuracy ±(3%+5°C).

10-2.General Specicaons

Enclosures Double molded

Shock 6.5 feet (2 meters)

Waterproof IP67

Diode Test Test current of 1.5mA maximum, open circuit voltage 3.2V

DC typical.

Connuity Check Audible signal will sound if the resistance is less than 25Ω(ap

prox.), test current <0.35mA.

PEAK Captures peaks >1ms

Temperature Sensor Requires type K thermocouple

Input Impendance >10MΩ VDC & >9MΩ VAC

AC Response True rms

AC Response The term stands for “Root-Mean-Square,” which represents the

method of calculaon of the voltage or current value.

Average responding mulmeters are calibrated to read correctly

only on sine waves and they will read inaccurately on non-sine

wave or distorted signals. True rms meters read accurately

on either type of signal.

ACV Bandwidth 50Hz to 20000Hz

Display 50,000 Counts TFT LCD

Overrange Indicaon “OL” is displayed

Auto Power O 5-30minutes (approximately) with disable feature

Polarity Automac (no indicaon for posive); Minus (-) sign for negave

Measurement Rate 20 mes per second, nominal

Low Baery Indicaon “ ” is displayed if baery voltage drops below operang voltage

Baery One 7.4 volt (NEDA 1604) baery

Fuses mA/μA ranges: 0.8A/1000V ceramic fast blow A range; 10A/1000V

ceramic fast blow.

36

37

EN

DE

Operang Temperature 5 to 40°C (41 to 104°F)

Storage Temperature -20 to 60°C (-4 to 140°F)

Operang Humidity Max 80% up to 31°C (87°F) decreasing linearly to 50% at

40°C (104°F)

Storage Humidity 50% at 40°C (104°F)

Operang Altude <80% 7000. (2000meters) maximum.

This meter is intended for origin of installaon use and

protected, against the users, by double insulaon per

EN61010-1 and IEC61010-1 2nd Edion (2001) to Category

IV 600V and Category III 1000V; Polluon Degree 2. The

meter also meets UL 61010-1, 2nd Edion (2004), CAN/CSA

C22.2 No. 61010-1 2nd Edion (2004), and UL 61010-2-033,

1st Edion (2012).

www.rnd-electronics.com

True RMS-Digitalmultimeter

mit automatischer

Bereichswahl

Benutzerhandbuch

RND 355-00010

38

39

DE

DE

Bedienungsanleitung für das True

RMS-Digitalmultimeter mit automatischer

Bereichswahl

1. Einleitung

• Professionelles True RMS-Digitalmulmeter für Industrieanwendungen und

TFT-LCD-Farbdisplay für schnelle A/D-Umwandlung, hohe Präzision, integrierte

Datenprotokollierung und Funkonen zur Trendaufzeichnung.

• Es kann alle Störungen durch Unterbrechung in den Geräten aufspüren und ohne Einsatz

von Personal weiterverfolgen.

• Die Probleme der Produkonsausrüstung können dank Bluetooth-Technologie und

Speicherung der Datenbläer einfach aufgespürt und gelöst werden.

• Die Messungen bieten erheblich mehr Sicherheit.

• Dieses Messgerät misst AC/DC-Spannung und -Strom, Widerstand, Durchgang, Kapazität,

Frequenz (elektrisch und elektronisch), Tastverhältnis, Diodentest und zusätzlich die

Temperatur des Thermoelements.

• Es können Daten gespeichert und abgerufen werden.

• Es verfügt über ein wasserdichtes, robustes Design für hohe Beanspruchung.

• Bei ordnungsgemässer Verwendung und Pege dieses Messgeräts arbeitet es viele Jahre

zuverlässig

2. Sicherheit

2-1. Sicherheitssymbole

Dieses Symbol neben einem anderen Symbol, einer Klemme oder einem Bediengerät

weist darauf hin, dass der Bediener eine Erläuterung in der Bedienungsanleitung

beachten muss, um Verletzungen oder Schäden am Messgerät zu vermeiden.

WARNUNG Dieses Symbol WARNUNG weist auf eine potenziell gefährliche Situaon hin, die zu

schweren oder tödlichen Verletzungen führen kann, wenn sie nicht vermieden wird.

ACHTUNG Dieses Symbol ACHTUNG weist auf eine potenziell gefährliche Situaon hin, die zu

einer Beschädigung des Produkts führen kann, wenn sie nicht vermieden wird.

MAX Dieses Symbol weist den Benutzer darauf hin, dass die hiermit gekennzeichnete(n)

Klemme(n) nicht mit einem Anschluss verbunden werden darf/dürfen, an dem die

Spannung in Bezug auf die Schutzerde (in diesem Fall) 1000 V AC oder V DC übersteigt.

Dieses Symbol neben einer oder mehreren Klemmen kennzeichnet diese als

mit Bereichen verbunden, die bei normalem Gebrauch besonders gefährlichen

Spannungen ausgesetzt sein können. Um maximale Sicherheit zu gewährleisten,

dürfen das Messgerät und seine Messleitungen nicht angefasst werden, wenn diese

Anschlüsse unter Spannung stehen.

Bie lesen Sie dieses Handbuch, bevor Sie das Gerät

einschalten.

Wichtige Sicherheitsinformationen im Lieferumfang

enthalten.

37

38

39

DE

DE

Bedienungsanleitung für das True

RMS-Digitalmultimeter mit automatischer

Bereichswahl

1. Einleitung

• Professionelles True RMS-Digitalmulmeter für Industrieanwendungen und

TFT-LCD-Farbdisplay für schnelle A/D-Umwandlung, hohe Präzision, integrierte

Datenprotokollierung und Funkonen zur Trendaufzeichnung.

• Es kann alle Störungen durch Unterbrechung in den Geräten aufspüren und ohne Einsatz

von Personal weiterverfolgen.

• Die Probleme der Produkonsausrüstung können dank Bluetooth-Technologie und

Speicherung der Datenbläer einfach aufgespürt und gelöst werden.

• Die Messungen bieten erheblich mehr Sicherheit.

• Dieses Messgerät misst AC/DC-Spannung und -Strom, Widerstand, Durchgang, Kapazität,

Frequenz (elektrisch und elektronisch), Tastverhältnis, Diodentest und zusätzlich die

Temperatur des Thermoelements.

• Es können Daten gespeichert und abgerufen werden.

• Es verfügt über ein wasserdichtes, robustes Design für hohe Beanspruchung.

• Bei ordnungsgemässer Verwendung und Pege dieses Messgeräts arbeitet es viele Jahre

zuverlässig

2. Sicherheit

2-1. Sicherheitssymbole

Dieses Symbol neben einem anderen Symbol, einer Klemme oder einem Bediengerät

weist darauf hin, dass der Bediener eine Erläuterung in der Bedienungsanleitung

beachten muss, um Verletzungen oder Schäden am Messgerät zu vermeiden.

WARNUNG Dieses Symbol WARNUNG weist auf eine potenziell gefährliche Situaon hin, die zu

schweren oder tödlichen Verletzungen führen kann, wenn sie nicht vermieden wird.

ACHTUNG Dieses Symbol ACHTUNG weist auf eine potenziell gefährliche Situaon hin, die zu

einer Beschädigung des Produkts führen kann, wenn sie nicht vermieden wird.

MAX Dieses Symbol weist den Benutzer darauf hin, dass die hiermit gekennzeichnete(n)

Klemme(n) nicht mit einem Anschluss verbunden werden darf/dürfen, an dem die

Spannung in Bezug auf die Schutzerde (in diesem Fall) 1000 V AC oder V DC übersteigt.

Dieses Symbol neben einer oder mehreren Klemmen kennzeichnet diese als

mit Bereichen verbunden, die bei normalem Gebrauch besonders gefährlichen

Spannungen ausgesetzt sein können. Um maximale Sicherheit zu gewährleisten,

dürfen das Messgerät und seine Messleitungen nicht angefasst werden, wenn diese

Anschlüsse unter Spannung stehen.

Bie lesen Sie dieses Handbuch, bevor Sie das Gerät

einschalten.

Wichtige Sicherheitsinformationen im Lieferumfang

enthalten.

40

41

DE

DE

Dieses Symbol weist darauf hin, dass ein Gerät durchgehend durch doppelte oder verstärkte

Isolierung geschützt ist.

2-2.Gemäss IEC1010 Überspannungskategorie Überspannungskategorie I

Bei Geräten der Überspannungskategorie I handelt es sich um Geräte für den Anschluss an

Stromkreise, in denen Massnahmen ergrien werden, um die transienten Überspannungen

auf ein angemessenes, niedriges Niveau zu begrenzen.

Hinweis: Beispiele sind geschützte elektronische Schaltungen.

Überspannungskategorie II

Geräte der Überspannungskategorie II sind Geräte, die Energie verbrauchen und von der

Fesnstallaon versorgt werden müssen.

Hinweis: Beispiele hierfür sind Haushalts-, Büro- und Laborgeräte.

Überspannungskategorie III

Bei Geräten der Überspannungskategorie III handelt es sich um Anlagen in Fesnstallaonen.

Hinweis: Beispiele sind Schalter in der Fesnstallaon und einige Geräte für den

industriellen Einsatz mit permanentem Anschluss an die Fesnstallaon.

Überspannungskategorie IV

Geräte der Überspannungskategorie IV sind für den Einsatz am Installaonsort vorgesehen.

Hinweis: Beispiele hierfür sind Stromzähler und primäre Überstromschutzeinrichtungen.

2-3. Sicherheitsvorschrien

• Dieses Messgerät wurde für den sicheren Gebrauch entwickelt, muss jedoch mit Vorsicht

betrieben werden.

• Die unten aufgeführten Regeln müssen für einen sicheren Betrieb sorgfälg befolgt werden.

1.Legen Sie niemals den angegebenen Höchstwert überschreitende(n) Spannung oder

Strom an das Messgerät an:

Eingangsschutzgrenzwerte

Funkon

V DC oder V AC

mA AC/DC

A AC/DC

Frequenz, Widerstand, Kapazität,

Tastverhältnis, Diodentest, Durchgang

Temperatur

Überspannungsschutz: 8 kV Spitze nach IEC 61010

Maximale Eingangsleistung

V DC oder V AC

800 mA 1000 V inke Sicherung

10A 1000 V inke Sicherung

(Max. 10 A für 30 Sekunden alle 10 Minuten)

1000 V DC/AC rms

1000 V DC/AC rms

2. Bei Arbeiten mit hohen Spannungen ist äusserste VORSICHT geboten.

3.Messen Sie die Spannung nicht, wenn die Spannung an der COM-Eingangsbuchse 1000 V

über der Schutzerde überschreitet.

4.Schliessen Sie die Messgerätekabel niemals an eine Spannungsquelle an, während sich der

Funkonsschalter im Strom-, Widerstands- oder Diodenmodus bendet. Andernfalls kann

das Messgerät beschädigt werden.

5.Entladen Sie Filterkondensatoren immer in Netzteilen und trennen Sie die

Stromversorgung, wenn Sie Widerstands- oder Diodenprüfungen durchführen.

6.Vor dem Önen der Abdeckungen zum Austauschen der Sicherung oder Baerien stets die

Stromversorgung ausschalten und die Messleitungen abklemmen.

7.Betreiben Sie das Messgerät nur, wenn die hintere Abdeckung und die Akku- und

Sicherungsabdeckungen richg angebracht und gut befesgt sind.

8.Wenn das Gerät auf eine andere Weise verwendet wird als vom Hersteller angegeben, ist

der Schutz, den das Gerät bietet, nicht gewährleistet.

3.Beschreibung

3-1.Beschreibung des Zählers

LCD-Anzeige mit 1-50'000 Zählwerten

2-F1 Sowareschlüssel

3-F2 Sowareschlüssel

4-F3 Sowareschlüssel

5-F4 Sowareschlüssel

6-Taste RANGE (Bereich)

7-Taste HOLD/REL (Halt/relav)

8-Funkonsschalter

9-10 A Eingangsbuchse

10-μA-mA-Eingangsbuchse

11-Posiver Eingangsbuchse

12-COM-Eingangsbuchse

13-Kippständer

14-Akkufachabdeckung

OFF

Ω

CAP

mA

^rqO POWER OFF

10A

mA

A

10A V

10A

800mA

FUSED COM

CAT IV 600V

CAT III 1000V

True RMS Autoranging Digital Multimeter

30 sec MAX

every 15 min

IP67

t^TERPROOF

V

V CAPΩ

Hz

%

Temp

µA

AC+DC

Hz

%

Temp

°C °F

LP F

mA%

4~20 mV

_äìÉíççí Ü

RANGE HOLD

REL

F1

F2

F4

F3

1

2

6

4

5

7

8

9

10

11

12

3

13

14

39

38

Table of contents

Languages:

Other RND lab Multimeter manuals