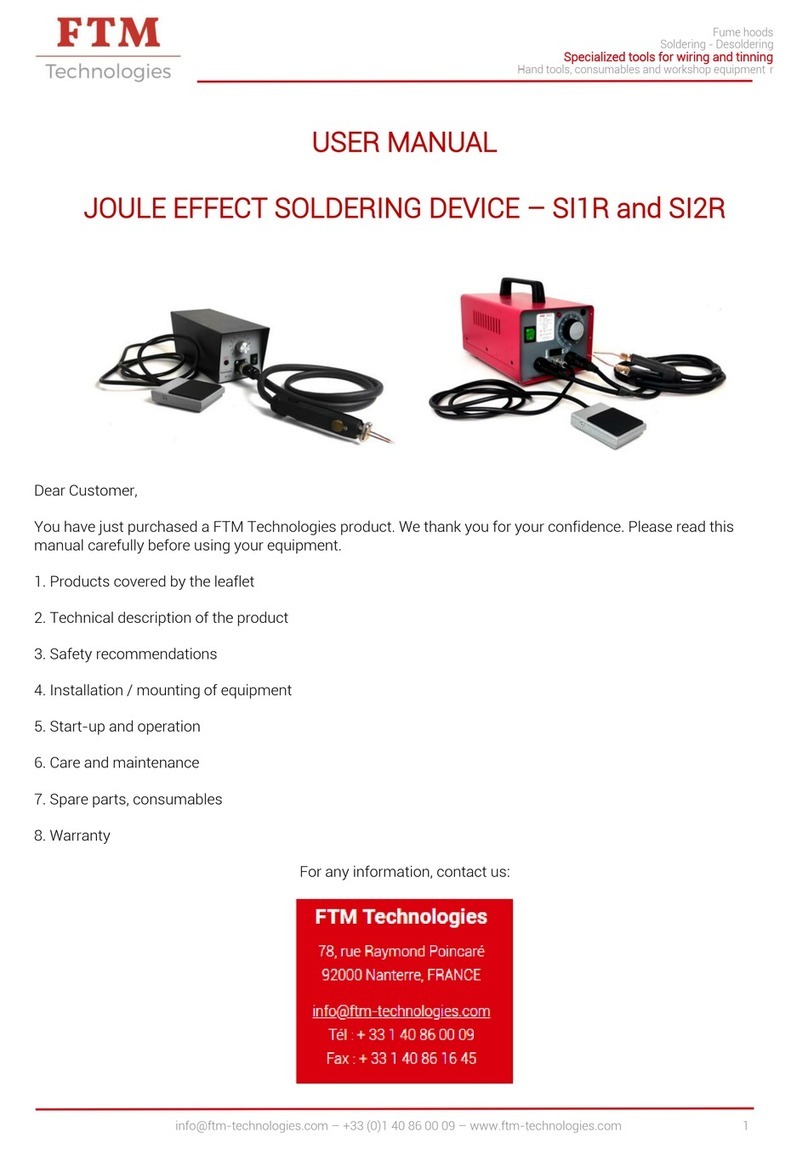

RND 560-00155 User manual

RND560‐00155SolderingStation

1

RND560‐00155

100WTemperatureControlledSolderingStation

InstructionManual

RND560‐00155SolderingStation

2

INTRODUCTION

Thank you for purchasing this intelligent high power RND lab soldering station – the best solution for your

solderingneedsespeciallyforleadfreeapplications!Webelievethatyouwillbemorethansatisfiedwithmany

features and the versatility of your new soldering station.Please carefully read the instruction manual prior to

operatetomaximizetheadvantagesofusingyournewsolderingstation.

WARNING:

This appliance is not intended for use by children or other persons without assistance or supervision if their

physical,sensoryormentalcapabilitiespreventthemfromusingitsafely.Childrenshouldbesupervisedtoensure

thattheydonotplaywiththeappliance.Failuretoobservethesafetyregulationwillresultinarisktolife.The

manufacturershallnotbeliablefordamageresultingfrommisuseoftheunitorunauthorizedalterations.

CAUTION:

Alwaysplacethesolderingironinitsoriginalholderwhennotbeingused.

Keepthesolderingtipandheatingelementawayfromthebody,clothesandflammablematerialwhenin

operation.

Thesolderingtipandtheheatingelementarestillremaininghotafterbeingswitchedoff.Ensurethatyoudo

nottouchthesolderingtipandtheheatingelement.

Foryourhealth,donotinhalesolderfumes.

Youmustnotundertakeworkonliveparts.Onlythetechnicianispermittedtoundertakerepairs.Usethe

originalreplacementpartsonly.

KEYFEATURES

Safetycutoff

Whenthesensorisbrokenorifthereisaninternalcircuitproblemthedisplaywillshow“S‐E”andthepoweron

thesolderingironwillbecutoff.

ImportantNotice:

Thefollowingoperationisthenormaloperatingmode

1.Undernormaloperatingmode:Pressingupkey“▲”ordownkey“▼”willchangethe

temperatureofthesolderingiron。

2.DisplayPanelTemperaturechangeadjustmentby“Tap“thewhitebuttonBesidetheLCD

displaywithPre‐settingfunctionfor 3 ChannelCH1、CH2、CH3 temperaturesetting

RND560‐00155SolderingStation

3

LOW VOLTAGE OUTPUT WITH SAFETY OPERATION: The power unit is isolatedfromtheA.C.linebya

transformer and allows 32VAC to drive the heating element. Solderwandrunsfrom32 Volts forsafety

andwith100Whighpowerceramicheaterforasuper‐fastheat‐upandquicktemperaturerecovery.The

solderwandisattachedwithaheatresistant,non‐burning,flexible6‐wirecord.

ISOLATEDIRONHOLDERWITHTIPCLEANER:Madeoflowabrasivebrassshavingsinsteadofconventional

spongestomeetRoHSrequirement.Cleansbetterandnowaterisnecessary.

ESDSAFEANDSPIKEFREECIRCUITRY:The“ZeroVoltage”electronicswitchingdesignalsoprotectsvoltage

and current sensitive components (CMOS devices, etc.) againstdamaging currentand transient voltage

spikescommonlyproducedbylessefficient,mechanicallyswitchedstations.

DETACHABLEACPOWERCORDWITHPLUG:EngineeredACoutletforalternatingACpowercordwithplug

andconnectorspeciallydesignedforindividualCEcountriesrequirements.

EARTH JACK: With a grounding connector, there is the possibility for a grounding of the wire strap if

required.

PRODUCTDESCRIPTION

The high power electronically temperature controlled soldering station with microchip controllers was

developedtomeetthepresentandfuturelead‐freesolderingneedsoftheelectronicproductionindustryand

suitable for work on professional SMD electronics. An ergonomic handle with shorter distance between

heatingelementandtipgetsveryfastheatuptimeandquickheatcompensation.Ahigh‐qualitysensorand

RND560‐00155SolderingStation

4

heat transfer technology ensure precise temperature regulation, which is essential for making consistent,

reliablesolderedconnections.Thealuminumalloyhousinghastheadvantagesofastrongstructure,goodheat

dissipationandefficientshieldingofelectro‐magneticinterference.Itprovidesallthebenefitsoftemperature

regulationandconnectsviaahighlyflexibleburn‐resistantlead,anditcanbeeasilyadjustedintemperature.

This soldering station incorporates electronic circuitry which enables the user to alter tip temperature from

150to500Ԩwithoutchangingtipsorheatingelements.Italsofeaturesabigdigitaldisplaykeysonthefront

panelgettogetaclearvisionandforcomfortablesetting.Thetemperatureismaintainedwithin+/‐3Ԩ(+/‐

6Ԭ) of its operating temperature by a thermocouple sensor placed in the head of the heating element,

allowingthetiptorestagainstthesensor.The100Whighpowerresultsinbotharapidheat‐upandasuper

fastrecovery.

The revolutionary “Zero Voltage” electronic switching design also protects voltage and current sensitive

components(CMOSdevices.etc.)againstdamagingcurrentandtransientvoltagespikescommonlyproduced

bylessefficient,mechanicallyswitchedstations.ThepowerunitisisolatedfromtheAClinebyatransformer

andallowsonly32VACtodrivetheheatingelement.Themanyfeaturesoftheproductmakeittheidealtool

for service and repair technicians as well as production line soldering operations. This unit is developed to

meetthepresentandfuturelead‐freesolderingneedsoftheelectronicproductionindustryand isidealfor

useatanyACoutlet.

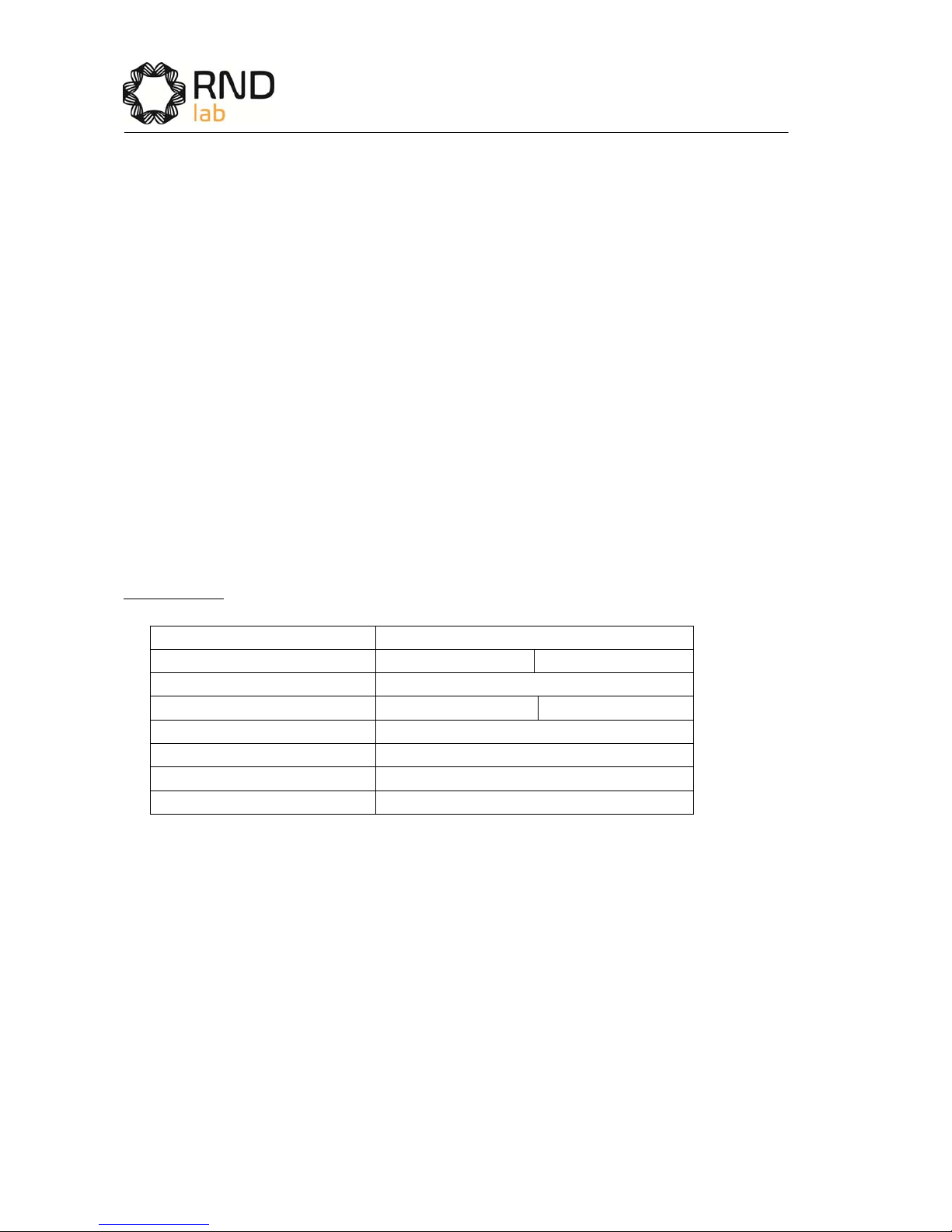

SPECIFICATIONS:

Model RND560‐00155

Input 220‐240VAC 50Hz 100‐120Vac 60Hz

Output 32VAC/100W

Fuse(Slowtype) T1A T2A

TemperatureRange 150Ԩ‐500Ԩ

Solderingiron 306K

FigureDimension 150x145x102mm(WxHxD)

Weight(Unitonly) 2.5kg

WORKINGTEMPERATURE

TomeetRoHSrequirements,the60/40solderalloysarenotallowed in the production process. The lead free

solderalloysrequireaworkingtemperatureof30Ԩ(54Ԭ)higherthanpreviousgenerationelectricalsolder.The

workingtemperatureofsolderisdetailedbelowandcanvaryfrommanufacturertomanufacturer.

Meltingpoint220Ԩ(428Ԭ)

Normaloperation300‐360Ԩ(572‐680Ԭ)

Productionlineoperation360‐410Ԩ(680‐770Ԭ)

Whenthe iron’s workingtemperatureis setwithin theparameterssuitableforthetypeofsolderbeingused,a

goodjointisassured.Toolowofatemperaturewillslowtherateofsolderflowwhileahightemperaturesetting

mightburnthefluxinthesolderandemitaheavy,whitesmokeresultinginadryjointorpermanentdamageto

theprintedcircuitboard(PCB)andmayalsoshortenthetiplife.

RND560‐00155SolderingStation

5

IMPORTANT:

Thetemperatureabove410Ԩ(770Ԭ)isnotrecommendedfornormalsolderingfunctions,butcanbeusedfor

shortperiodsoftimewhenhightemperaturesarerequired.Pleasenotethattheleadfreesolderalloysrequirea

highersolderingtemperaturewhichshortenstiplife.

OPERATINGINSTRUCTIONS

Ensurethattheworkingvoltagematchesyourpowersupplybeforebeginninguse.

Checkcarefullyforanydamageduringtransportation.

Thisunitcontains:

1. Solderwand.

2. Ironholderwithbrasstipcleaner.

3. ACpowercordwithplug.

OPERATINGPROCEDURES:

1. Ensurethatthebaseunitpowerswitchisinthe“OFF”position.

2. PluginSolderwandandconnectACpowercordtomains“In‐let”.

3. Turn“Mainspowerswitch”to“ON”position.

4. Pressthe“▲”keyupuntilthetemperatureto250Ԩ(482Ԭ).Thentinthesurfaceofthetipbyapplyinga

newcoveringofsolderafterbeingwarmedtoprotecttipandextenditslife.

5. Whenthetemperaturereachestothedesiredtemperaturethattheheatingindicatorlightwillbeflashedon

andofftomaintainthesettemperature.Theunitnowisreadyforuse.

TEMPERATURECHANNELSSTORAGE

Thistouchscreenmodelhasamemorychannelsforthreepre‐settemperaturelevels–CH1,CH2,CH3.These

channelsareaccessedbypressingthewhitebuttonontherightsideofthescreen.Eachtimeyoupressthis

button,thescreenwithscrolltothenextCHnumberinsequence,andeventuallyloopsbacktoCH1.Ifyouleave

thechannelmemoryonacertainnumber,thesettemperaturewillchangetothatlevel,andthedisplay

temperaturewillbegintoadjusttomatchthesettemperature.

Tosetthevalueforanychannelmemory,followthesestepsinorder:

1.Pressandholdthe‘SET’buttononthetouchscreenfor3second,regardlessofwhichCHiscurrentlyallocated.

WhentheSETbuttonisreleased,theCH0numberwillbeflashing.

2.PresstheSETbuttonagain.TheCALiconwillbeflashing.(TemperatureadjustbuttonstosetCALtemperature

correctionvalue!^)

3.PressSETagaintomovetoCH1,andagainforCH2,CH3.Chooseanyoneyouwishtoset.(TheSETorder

progressionthroughthechannelsis:CH0>CAL>CH1>CH2>CH3>…inaloop.)

4.Adjustthetemperatureusingthearrowbuttonsonthetouchscreentoadesiredvalue.

5.PressENTERtoconfirmthetemperatureforthatCHnumber.TheCHnumberwillstopflashingtoindicatethat

ithasbeenstoredinmemory.

6.Repeattheprocessfortheotherchannelsasrequired.

7.Ifyoupressanytemperatureadjustbuttonwhileusingapresetchannelmemory,theunitwillcancelthat

pre‐setandreverttothedefaultCH0.Toreturntoachannelmemoryofyourpreference,justpressthewhite

buttonandscrolltothatCHnumber.

RND560‐00155SolderingStation

6

^NOTE:TosettheCALtemperaturecorrectionvalue,followsteps1and2first,andthenstep4toadjustthevalue

indegreesCelsius,endingwithstep5toENTERthedeterminedvalue,whetheritbepositiveornegative.TheCAL

rangeis‐99tozeroto+99andoncesetforacorrectvalue,itappliestoallpresetchannelsandCH0i.e.alwayson.

NB:Thisfunctionrequiresaspecialsolderingironthermometertoworkcorrectly.Thisthermometerisnot

currentlyoneoftheoptionalaccessoriesforthismodel.

TEMPORARYPOWERDOWNMODE

Pressthewhitebuttonontherightsideofthetouchscreenforatleast3seconds.

Inthisstate,theheatingelementismanuallydisengagedandcoolingbegins,asindicatedbythepresenceofthe

‘snowflake’ontheleftofthescreen.

Astheironcoolsdown,onceitreachesbelow100°C,theiconwillchangetoahalfmooniconforsleepandthe

stationwillbeidling.Itwillremaininthistemporarypowerdownstateindefinitely,untiltheuserpressesthe

whitebuttonoranyotherarrowbutton,atwhichpointtheheaterwillreactivateandreturntotheprevious

temperaturesetting.

CAUTIONS:

REMEMBER,THETIPISHOT!

- Thetipandbarrelofthesolderwandwillcauseseriousburnsiftheyareallowedtocontactskin.Always

returnthesolderwandtothesafetyholderaftereachuse.

DONOTWORKONLIVECIRCUITS

- Beforeworkingonanymainspoweredequipment,makesurethatitisturnedoff,andthemainsplugis

removedfromthepowerpoint.

DONOTUSEIFDAMAGED

- Ifthepowerleadbecomesdamagedorthesolderingstationbecomesfaulty,discontinueuseimmediately.To

complywithsafetystandards,thepowerleadmustonlybereplacedbyauthorizedtechniciansasspecial

purposetoolsarerequired.

Caution:

Solderingironsoperateathightemperaturesandcaneasilyburnpeopleorobjects.Donottouchthetipandheater

atanytimeandkeepitasafedistancefromflammablematerials whiletheunitisonorwhileit’scooling.Please

allowasufficienttimeforittocoolbeforechangingtipsorservicingtheunit!

COMMONCAUSESOFTIPUNWETTING

1. Tiptemperaturehigherthan410Ԩ(770Ԭ).

2. Thetipworkingsurfacesarenottinnedwhiletheironidling.

3. Lackoffluxinsoldering,wicking,repairing,andtouch‐upoperations.

4. Wipingthetiponahighsulfurcontent,dirtyordryspongesandrags.

5.Touchingwithorganicsubstancessuchasplastic,resin,silicone,greaseorotherchemicals.

6.Impuritiesinsolderand/orlowtincontent.

RND560‐00155SolderingStation

7

CAREOFTIPS

Caution:

The soldering iron can reach very high temperatures. Be sure to turn the unit off prior to carrying out any

maintenanceortroubleshootingstepslistedbelow.

IMPORTANT

Removethetipandcleanaftermoderatetoheavyuseoratleastdailyforlightusage.Removeanyloosebuildup

inthetipretainingassemblytopreventtipfreezing.

Thesoldertipssuppliedareironcladcooperandifusedproperly,theyshouldmaintainoptimumlife.

1. Alwaystinthetipbeforereturningittotheholder,turningoffthestation,orstoringitforlongperiodsoftime.

Wipethetiponabrasscleanerpriortouse.

2. Keepingtheironsetathightemperatures(morethan400Ԩwillshortentiplife.

3. Donotuseexcessivepressuretothetiporrubthejointwiththetipwhilesoldering;itdoesnotimprovethe

heattransferandmaydamagethetip.

4. Applysoldertothejoint,notthetipwhensoldering.Thefluxisnaturallycausticandthuswilleatawaythetip.

5. Nevercleanthetipwithafileorabrasivematerials.

6. Donotusefluxeswhichcontainchlorideoracid.Useonlyrosinorresinactivatedfluxes.

7. Ifanoxidefilmformsonthetip,itcanberemovedbycarefulbuffingwitha600‐800gritemerycloth,

isopropylalcoholorequivalentandthenwrappingrosincoresolderaroundthenewlyexposedsurfaces.Coat

thetinnedareaswithrosin‐coresolderaftertheresin‐corehasmelted.

NEWTIPS

Applyingthefollowingstepswillleadtooptimumlife.

1. Settemperaturetomin.thenturnthemainpowerswitchtothe“ON”position.

2. Settemperatureto250Ԩ(482Ԭ).

3. Coatthetinnedsurfaceswithrosin‐coresolderafterreaching250Ԩ(482Ԭ).

4. Settodesiredtemperatureafterallowingtheunittoidleat250Ԩfor3minutes.

5. Theironwillbereadyforuseonceitreachesthepresettemperature.

IMPORTANT:

Removeandcleanthetipdaily.Ifanewtipisinstalled,remove any loose build up in the barrel assembly,

otherwisethetipmayfusetotheheatingelementorretainingbarrel.

MAINTENANCE

TIPMAINTENANCEANDDRESSING

Tips can be changed or replaced simply by unscrewing the knurled nut barrel assembly. The station must be

switchedoffandallowedtocoolbeforethisoperationasdamagemayresultifthesystemisleftonwithoutthetip

inplace!

Afterremovingthetip,blowoutanyoxidedustthatmayhaveformedinthetipretainingareaofthebarrel.Be

careful to avoid getting this dust in your eyes. Replace the tip and screw back the knurled nut barrel assembly

using only firm hand pressure to tighten. Pliers should only be used to tighten the nut to avoid burning your

fingers,butcareshouldbetakennottoover‐tightenasthiscoulddamagetheelement.

RND560‐00155SolderingStation

8

GENERALCLEANING

Theoutercoveroftheironandstationmaybecleanedwithadampclothusingsmallamountsofliquiddetergent.

Neversubmerse theunitin liquidor allowanyliquidtoenterthecaseofthestation.Neveruseanysolventto

cleanthecase.

SERVICE

If the iron or station should become faulty or, for some reasonnotoperatenormally,thesystemshouldbe

returnedtotheservicedepartmentofyourauthorizeddealerorserviceagent.Orasimilarlyqualifiedpersonin

ordertoavoidahazard.

INTERCHANGEABLETIPS

Table of contents

Other RND Soldering Gun manuals