RoadHog RH48200 User manual

RH48200

RH60200

RH72200

RoadHog

For units

Built After May 2010

MANUAL

Operation

Maintenance

Service

Parts

Warranty

Serial number ___________________________

Date released for shipment _________________

RoadHog, Inc. 877-640-9975 www.roadhog-inc.com

PUBLICATION DATE: 09/10/13

2

INTRODUCTION

Thank you for your investment in Roadhog Inc. We are confident that you will find that

your Roadhog Inc is the easiest to operate, safest, most durable, and most efficient

attachment on the market.

Your Roadhog Inc is equipped with high performance, heavy duty components. To en-

sure that these components operate properly and effectively, this manual must be fol-

lowed. If any question regarding the operation or performance of this attachment ex-

ists, contact your Roadhog Inc dealer at once.

This manual contains safety instructions, guidelines for efficient operation, trouble-

shooting tips, and service maintenance procedures. When applicable, the terms “right”

and “left” are referenced from a sitting position and facing forward in the loader.

Throughout this manual, information is provided in boxes and highlighted by the word

IMPORTANT. This information should be read carefully. If complied with, it will

improve the operating efficiency of the unit and provide directives that will minimize

costly breakdowns and extend the life of the machine.

This warning symbol appears throughout this manual and

indicates that a safety hazard may exist if the information

given is not properly followed. When the warning signal is

encountered in the manual or on the unit, Be Alert! Your

personal safety is involved!

For more copies of this manual or the necessary safety decals, contact your Roadhog

Inc dealer.

3

TABLE OF CONTENTS

Page

SAFETY DECALS …………………………………………………………………………….4

SAFETY PRECAUTIONS …………………………………………………………………..5

MANDATORY SAFETY SHUTDOWN PROCEDURE ……………………………………5

SAFETY ………………………………………………………………………………………..6

SETUP ………………………………………………………………………………………….7

OPERATION …………………………………………………………………………..…..8-17

MAINTENANCE AND SERVICE……………………………..………...…………...…18-26

CHASSIS GROUP PARTS DRAWING……….………………………...……………..27-28

ATTACH GROUP PARTS DRAWING……….………………………...….……...…...29-34

DRIVETRAIN AND DRUM GROUP PARTS DRAWING…...………...……….….....35-36

ENGINE GROUP ……………………..……….……………………………....………...37-38

CLUTCH GROUP ………………………………………………………………………..39-40

HYDRAULIC GROUP PARTS DRAWING……………………………………….…...42-43

HYDRAULIC VALVE ( DEPTH , TILT AND SIDE SHIFT )PARTS DRAWING……44-

45

HYDRAULIC VALVE ( CLUTCH ) PARTS DRAWINGS…………………….……...46-47

HYDRAULIC TANK PARTS DRAWINGS…………………………………………….48-49

HYDRAULIC SCHEMATIC...……………………………...….……………………..…….50

ELECTRICAL DISCONNECT POINTS PRIOR TO WELDING…………….…………..51

ELECTRICAL GROUP ( MASTER PANEL)………………………………………… 52-53

ELECTRICAL SCHEMATICS………….…………………...……………….…..……..54-56

DECAL GROUP PARTS LIST………...…….…………………………...…………….57-58

SPECIFICATIONS ……………………………………………...….………………………..59

WARRANTY ………………………………………………………...……………………….60

WARRANTY CLAIM FORM………………………………………..…………………...….61

NEW MACHINE DELIVERY REPORT…………………………………………………….62

OWNER INFORMATION CARD……………………………………………………………63

4

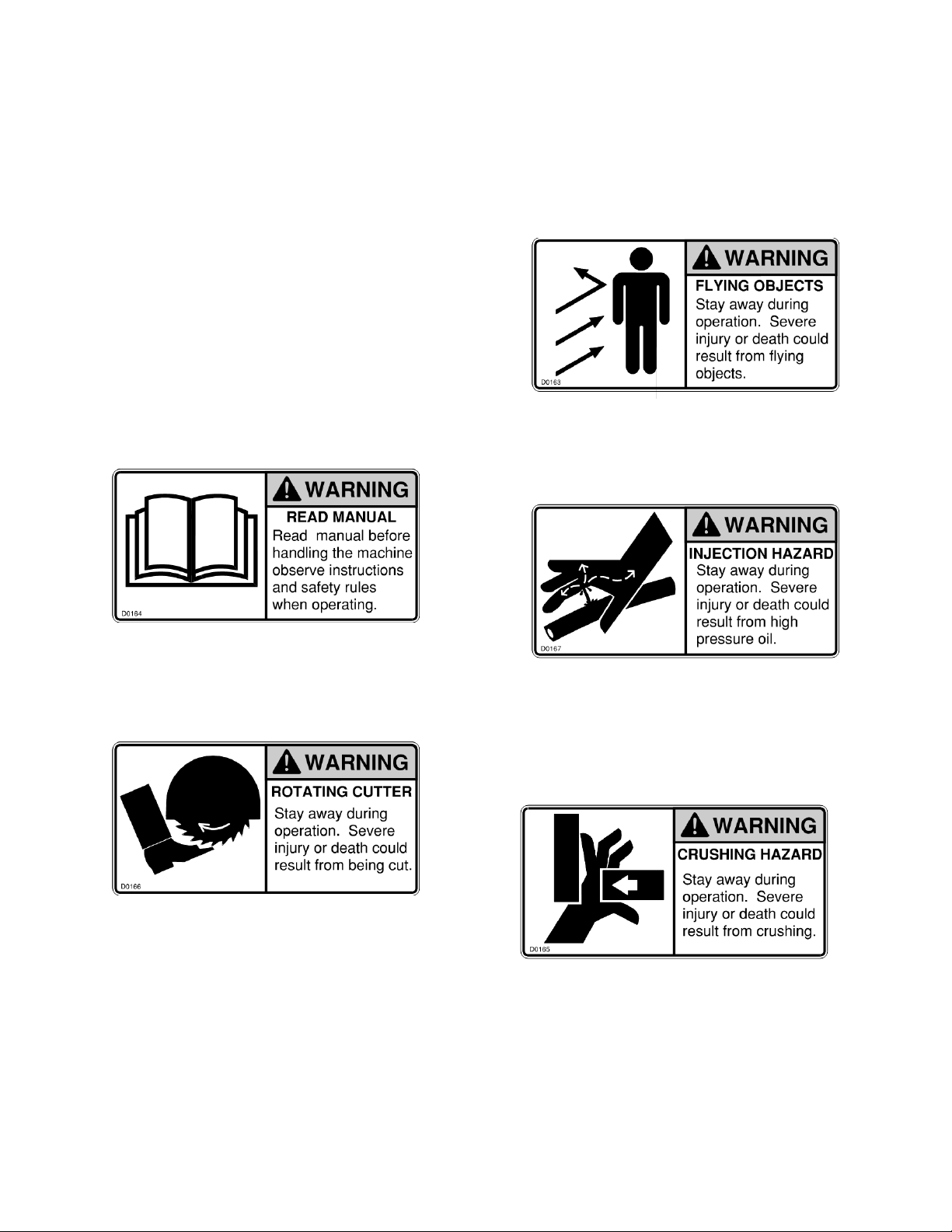

SAFETY DECALS

The safety decals existing on the

attachment should be clearly read-

able and always followed. The lo-

cation and description of the de-

cals is shown in the parts diagram.

The CRUSHING HAZARD decal

warns the operator and bystanders

to stay away during operation.

The ROTATING CUTTER decal

warns the operator and bystanders

to stay away during operation.

The READ MANUAL decal warns

the operator to read this manual

before operating the attachment. The INJECTION HAZARD decal

warns the operator and bystanders

to stay away during operation.

The FLYING OBJECTS decal

warns the operator the operator

and bystanders to stay away dur-

ing operation.

5

SAFETY

PRECAUTIONS

ACCIDENTS ARE

PREVENTABLE WITH YOUR HELP

Understand and comply with applicable

laws and regulations.

Call local utilities before you dig.

1-888-258-0808

Know the location of underground gas, water

and electrical lines.

Inspect area for holes, drop-offs, or unstable

ground.

Know the weight limitations of operating

surfaces and clearances.

Remember: Safe operation begins with the

operator.

BEFORE OPERATING THIS

EQUIPMENT, THE FOLLOWING

SAFETY INFORMATION SHOULD BE

READ AND UNDERSTOOD. IN

ADDITION, EACH INDIVIDUAL

WORKING WITH THE EQUIPMENT

SHOULD BE FAMILIAR WITH THE

SAFETY PRECAUTIONS

Exercise extreme caution when attaching and removing the attachment, operating with

other workers present, and servicing the unit.

Roadhog Inc makes operator safety a priority when designing machinery. Exposed

moving parts are guarded whenever possible for safety. However, not all moving parts

can be shielded in order to ensure proper operation. This operator’s manual and safety

decals on the machine provide important safety information when observed closely If

safety decals become difficult to read, replace them immediately. (see “Safety De-

cals”).

MANDATORY SAFETY

SHUTDOWN

PROCEDURE

BEFORE cleaning, adjusting, lubricat-

ing, or servicing this unit, ALWAYS fol-

low the MANDATORY SAFETY SHUT-

DOWN PROCEDURE:

1. Lower loader arms and roll attach-

ment forward until it is flat on the

ground.

2. Apply loader parking brake and stop

the loader engine.

3. Remove loader key and keep with

you while you are working on the at-

tachment.

4. Turn cold planer engine off and lock

control panel using the PIN security

feature.

FAILURE TO FOLLOW THE

PROCEDURES BEFORE CLEANING,

ADJUSTING, LUBRICATING, OR

SERVICING THIS UNIT COULD LEAD

TO SERIOUS INJURY OR DEATH.

WARNING

WARNING

6

SAFETY

A careful operator is the best protection

against accidents. Most accidents involv-

ing operators of industrial equipment are

caused by failure to observe basic safety

precautions. Know the equipment and

worksite before you operate. Familiarize

yourself with the safety precautions listed

below.

THE FOLLOWING PRECAUTIONS

MUST BE OBSERVED FOR THE

SAFETY OF THE OPERATOR

AND/OR SERVICE PERSONNEL.

1. Read and observe all safety infor-

mation and decals on the skid steer

loader and attachment BEFORE

operating the unit!

2. Refer to the SAFETY section of your

loaders operator’s manual and ob-

serve all safety recommendations set

forth in the manual.

3. When loading, keep attachment as

low to ramps & trailer as possible.

4. Always lower the loader arms fully

before leaving the operator’s seat.

NEVER CRAWL UNDER RAISED

LOADER ARMS.

5. BE SURE to raise the attachment

totally off the ground BEFORE side

shifting.

6. CAREFULLY inspect ALL hydraulic

hoses and connections on a routine

basis; Always use a piece of card-

board when searching for leaks.

7. BE SURE to exercise the above

MANDATORY SAFETY SHUTDOWN

procedure, BEFORE proceeding with

any work on the attachment.

NEVER USE YOUR HANDS AS

ESCAPING FLUID UNDER PRESSURE

CAN PENETRATE THE SKIN CAUSING

SERIOUS INJURY. IF HYDRAULIC

FLUID DOES PENETRATE THE SKIN,

SEEK IMMEDIATE MEDICAL

ATTENTION BY A DOCTOR FAMILIAR

WITH THIS TYPE OF INJURY OR

GANGRENE MAY RESULT.

NEVER ALLOW HANDS OR FEET

NEAR ANY WORKING PART OF THE

ATTACHMENT UNLESS THE

MANDATORY SAFETY SHUTDOWN

PROCEDURE HAS BEEN

COMPLETED.

WARNING WARNING

WARNING

WARNING

7

READ THIS ENTIRE MANUAL AS

WELL AS THE DECALS ON THE

ATTACHMENT BEFORE ATTEMPT-

ING ANY MAINTENANCE, SERVICE

OR SETUP OF THE UNIT.

SETUP

Hoses / Fittings

Hydraulic fittings are used to connect

all hoses. All fittings should be tight

and free of hydraulic leaks. Hoses

must be free of crimps or cuts that

might result in leakage. Check your

attachment before operation to make

sure all hose routings are kink-free and

allow for maximum movement of all

depth and side shift functions required

during normal operation.

Drum Assembly

For proper operation, teeth must be

installed in every holder on the drum.

Welds on holder and blocks should

be inspected weekly for cracks. Any

cracks should be fixed as soon as pos-

sible. Teeth should be inspected daily

for wear. Tooth should be allowed to

freely rotate within their holders.

Holders should be inspected daily for

wear. Holder wear is not typically cov-

ered under warranty. Holders may be

hard-faced to replace worn holder ma-

terial.

WARNING

Although the Roadhog Inc is supplied

fully assembled, some simple checks

should be performed before operation

begins.

Safety Decals

The safety decals existing on the attach-

ment should be clearly readable and al-

ways followed. The location and descrip-

tion of the decals is shown in the explod-

ed diagram. Copies of the decals are

shown in “Safety Decals” section.

Lubrication

The dead shaft bearing, supporting the

left hand side of the drum, should be lu-

bricated at least once a week. Daily

lubrication may be required during heavy

use or in extremely dusty conditions.

The planetary oil should be changed af-

ter the first 50 hours of operation, and

then once a year after that.

8

OPERATION

The cold planer is an engine powered attachment intended for cutting asphalt or con-

crete surfaces. The performance of the attachment can vary greatly depending upon

how it is used and operated. Therefore, the recommended operating procedures con-

tained within this manual should be followed at all times for maximum productivity.

Prior to operating the attachment, read this entire manual. Follow all safety guidelines

in this manual and safety decals on the unit. Make sure that all guards, shields, and

decals are in place and in good condition prior to operation.

Attaching to Loader

Pin on style mounting

To attach the unit to the loader, start the loader and rotate the coupler out. Move

the machine forward and align the male bosses on the male portion of the loader

attach with the female bosses on the Roadhog. Insert pins and secure pins to boss-

es per the manufacturers recommended procedure.

Attaching to Loader

quick attach style mounting

To attach the unit to the loader, start the loader and rotate the quick coupler out.

Move the machine forward and align the

male portion of the quick attach on the loader with the female portion of the quick

attach on the Roadhog. Secure the quick attach per the manufacturers recom-

mended procedure.

WARNING

ALWAYS follow the loader manufacturers recommended procedures for mounting

attachments to the loader. Refer to attachment mounting instructions in the loaders

operating manual. Severe injury or death could result from crushing.

GENERAL CONTROL SYSTEM

Units can be operated from either the panel or using the radio controller. The

master panel has illuminated push buttons that change colors during operation which

indicate the following and provide visual feedback to the operator.

RED—indicates that a function cannot be operated.

GREEN—means it can be operated

Flashing GREEN—tells the operator which mode or function is currently active.

Amber—used to tell the operator the water kit is in auto mode and slave to the clutch.

9

Loader operation

1. Clear all bystanders.

2. Enter loaders operator platform.

3. Engage parking brake.

4. Start loader.

5. Start Roadhog ( see instructions on pages

10 thru 13 of this manual )

4. Roll out the loader bucket function so that the Roadhog

depth skis are level and in full contact with the pavement.

5. Lower the Roadhog cutting drum to the desired depth per

instructions on pages 10 thru 13 of this manual.

6. Apply the foot brake.

7. Place the loaders transmission in 1st gear.

Loader engine should be at idle.

8. Release parking brake and foot brake. This step will start

the cutting operation.

NOTE: Cutting drum feed rate and loader ground speed)

is dependent upon depth of cut, age of pavement,

size and type of aggregate in pavement, density of

pavement and ambient temperature.

9. Loader ground speed should be adjusted up or down

after the above factors in step 8 have been evaluated.

10. Adjust loader’s engine rpm and the loader’s ground speed to

maximize the load on the Roadhog’s cutting drum.

11. If the cutting drum on the Roadhog stalls, back up the

loader or lift or curl the Roadhog out of the pavement using the

loader’s bucket function.

WARNING

ALWAYS follow the loader’s manufacturers recommended operating procedures found in

the loader manufacturer’s operating manual for proper operation of the wheel loader.

Severe injury or death could result from improper operation of the wheel loader.

WARNING

If an emergency arises, immediately apply the wheel loader’s brakes and

Stop the wheel loader’s engine and the Roadhog’s engine.

The Roadhog’s engine may be stopped by pushing the red shutdown

button on the master panel or by pushing the red emergency stop button

on the remote transmitter.

10

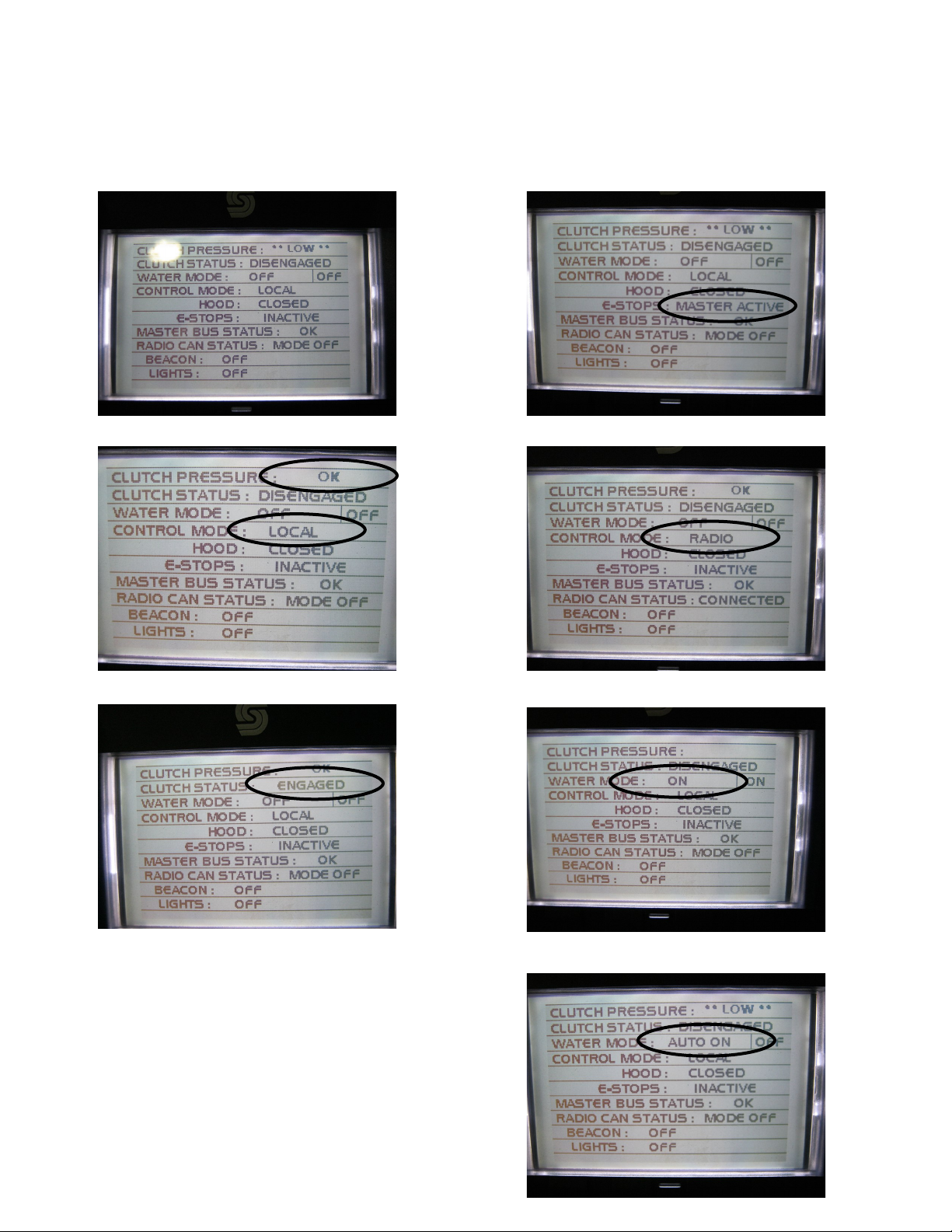

LCD Display Screens

Home Page Home Page w/ menu button

Contrast Page Up/Down Setup Menu

Home Page - Sub-Screens

Note: After activation the buttons, to move between sub screens just pr ess the page up/down button.

Note: Scr een 2 displays; hour meter , tor que

percentage, fuel efficiency, and voltage options.

Note: Scr een 3 displays; RPM, oil pr ess, and

engine temperature.

Setup Main Menu and Sub-Screens

Note: To enter setup menus, press the setup

button on the home page.

Note: The display is not a touch scr een. Ther e ar e buttons just below each image on the screen. To pull up

the function buttons press the left button once. That will activate the screen options. Push the button to activate the

function.

11

LCD Display Screens (continued)

Home Page with just power on

Changes to screen during operations of Road Hog

Home Page with e-stop on panel

Home Page engine on in panel mode Home Page engine on in radio mode

Home Page clutch engaged Home Page water kit on

Home Page water kit slave to clutch

12

STARTING PROCEDURE- USING MASTER PANEL ON ROADHOG

This procedure requires another operator at ground level.

Engine start

1. Follow all safety procedures.

2. Turn power switch until the control panel lights up.

3. Ensure radio button is in “panel” mode (PANEL will display on LCD screen & button will

be constantly green).

4. Turn and pull red shutdown button out on master panel.

5. Press “engine start” button on master panel until engine starts.

Drum drive engagement

1. Follow all safety procedures.

2. Allow engine to run for 2 to 3 minutes.

3. Push “engine throttle” button on master panel for 2 seconds to engage high idle.

4. Hold “clutch engage” button on master panel for 4 to 8 seconds (Button will flash green)

NOTE: momentary delay of engagement is normal

This engagement may take longer in cooler temperatures.

Drum depth engagement

1. Press and hold “depth down” button on master panel down lower the cutting drum

until the desired cutting depth is reached. Press the “depth up” button on master

panel up to raise the cutting drum. Release button once desired depth is reached.

Side shift engagement

1. Press and hold “side shift” button on master panel. Hold until desired position is

reached. Release button

Tilt engagement IMPORTANT: Always preset the desired angle and depth of cut prior to

making

the cut.

1. Press and hold the “tilt” button until the desired angle is reached.

2. Press and hold the “ depth down” button until the desired depth of cut is reached.

3. Lower the drum into the cut by lowering the loader arms. Only one ski will contact the ground.

Normal shutdown proce- dure using master panel ( non-emergency only )

1. Press “ clutch disen- gage” button to disengage clutch and drum

2. Press “ engine throttle” button on master panel to engage low idle

3. Press red “shutdown” button on master panel to stop engine

13

STARTING PROCEDURE- USING MASTER PANEL ON ROADHOG

(continued)

This procedure requires another operator at ground level.

Water Kit Control

1. Once the engine is started.

2. Press “water kit button” button on master panel once to start the pump. (Button will flash

green when on)

3. Press “water kit button” button on master panel twice to activate slave to clutch.

(Button will be solid amber when in auto)

4. Press “water kit button” button on master panel three times to stop the pump. (Button will

be solid green when off)

Fully lower the loader arms and then roll out the bucket function until the planer skis are level with

the pavement.

Move the throttle to the full rpm position. and keep it there during the milling operations. Begin the

operation by setting the depth cylinders to zero depth at the depth gauge. Lower the drum into the

cut to the desired depth. Move forward at a speed that will allow the drum to mill or cut efficiently

without stalling.

NOTE. Milling speed will depend on tooth condition, age and density of the material, aggregate

size and ambient temperature.

14

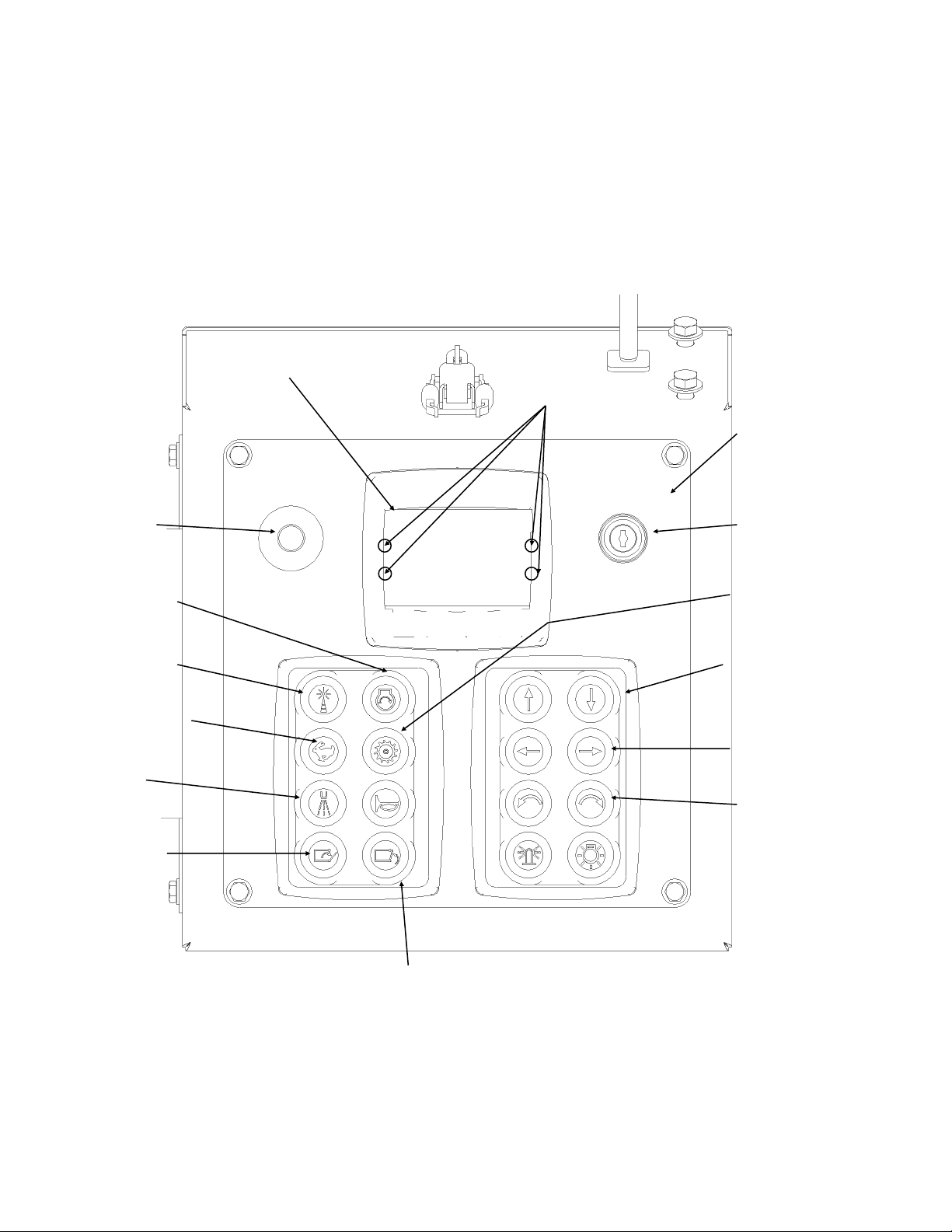

Diagram of master panel

Power key switch

Master panel

Shutdown

button

Radio/panel

Engine start

Engine throttle button

Clutch engage/

disengage switch

Depth buttons

Side shift buttons

LCD display

Tilt buttons

Water kit button

Hood open button

Hood close button

Warning/Error

Lights

15

STARTING AND OPERATING PROCEDURE - USING REMOTE TRANSMITTER

This procedure may be done at ground level using an additional operator, or may

be done by a single operator from the wheel loader’s operator seat.

Engine start

1. Follow all safety procedures

2. Turn power key until the master panel lights up.

3. Press ON button.

4. Ensure master panel button is in “ radio” mode (RADIO will display on LCD screen and

button will flash green).

5. Check for green power indicator light on remote transmitter

6. Turn and pull red stop button “out” on master panel

7. Press “fuel run/stop” button on remote transmitter once

1. Press “engine start” button on remote transmitter until engine starts

Drum drive engagement

1. Follow all safety procedures

2. Allow engine to run for 2 to 3 minutes.

3. Press “throttle high/low” button on remote transmitter once to engage high idle

4. Press “ clutch engage” button on remote transmitter for 4 to 8 seconds to engage drum

NOTE: Momentary delay of engagement is normal

This engagement may take longer in cooler temperatures.

Drum depth engagement

1. Press and hold “drum down” button on remote transmitter to lower the cutting drum until the

desired cutting depth is reached. Use the drum up arrow button

on remote transmitter to raise the cutting drum.

Side shift engagement

1. Press and hold “side shift” button on remote transmitter. Hold

until desired position is reached. Release button

Tilt engagement IMPORTANT: Always preset the desired angle and depth of cut prior to mak-

ing

the cut.

1. Press and hold the “tilt” button until the desired angle is reached.

2. Press and hold the “ depth” button until the desired depth of cut is reached.

3. Lower the drum into the cut by lowering the loader arms. Only one ski will contact the ground.

16

STARTING AND OPERATING PROCEDURE - USING REMOTE TRANSMITTER

This procedure may be done at ground level using an additional operator, or may

be done by a single operator from the wheel loader’s operator seat.

Normal shutdown procedure using remote ( non- emergency only )

1. Press “ clutch disengage” button to disengage clutch and drum

2. Press “ throttle high/low” button to engage low idle

3. Press “ fuel run/stop” button to shut off fuel flow

17

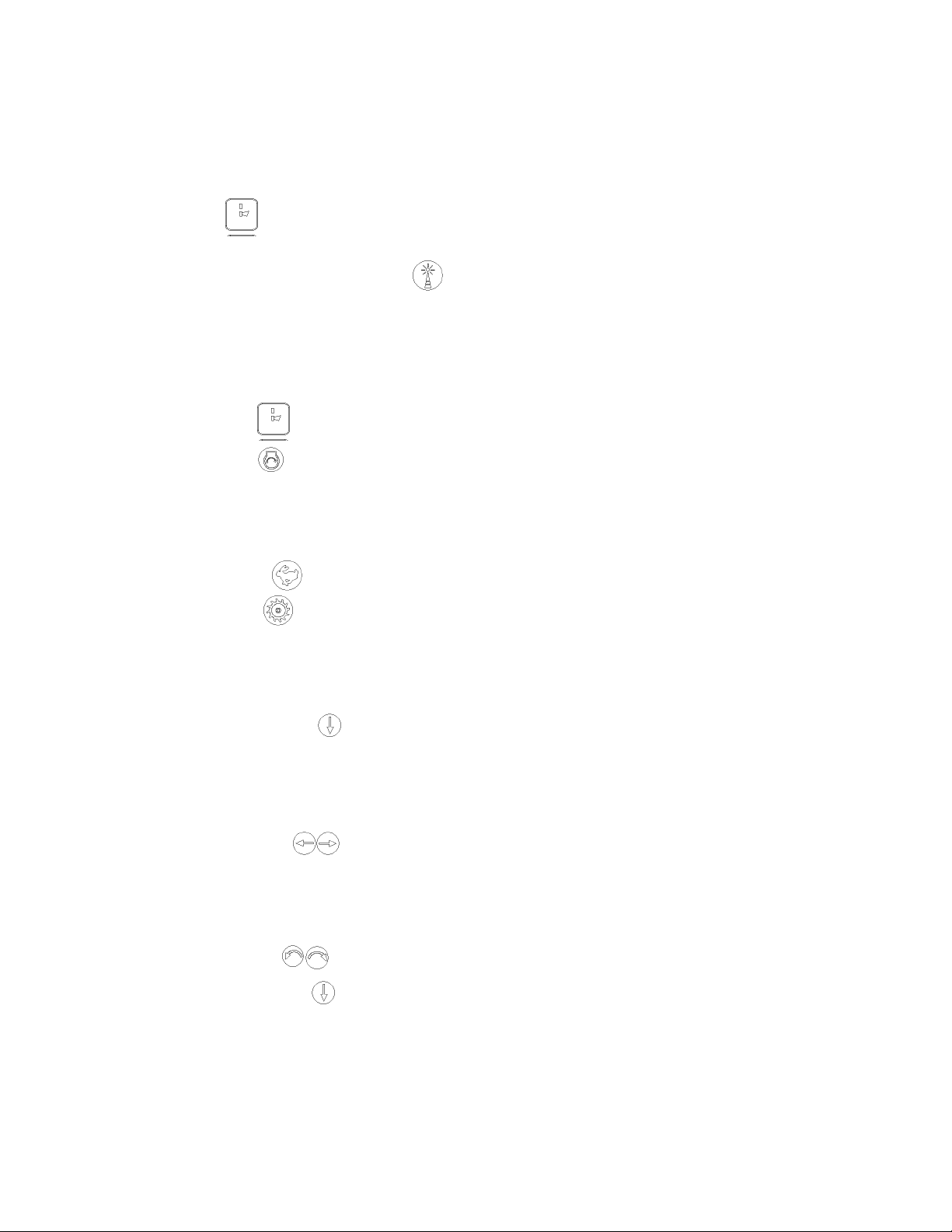

Emergency stop button/Key

Drum side shift right

Drum side shift left

Drum up

Drum down

Power indicator

Throttle button Clutch engage/disengage button

Tilt left button

Engine start button

ON/Fuel button

Diagram of Radio

Tilt left button

Display

18

MAINTENANCE

Proper maintenance of the attachment will

result in longer life and the more produc-

tive and cost effective operation. There are

two basic categories of maintenance re-

quired, pick/holder replacement and

component lubrication. For proper opera-

tion, the picks should be checked each four

(4) hours and lubricated daily with a water

based emulsifying agent to ensure that they

can freely rotate in their holders.

BEFORE PERFORMING ANY

MAINTENANCE ON THE UNIT, PER-

FORM THE MANDATORY SAFETY

SHUTDOWN PROCEDURE.

WARNING

Pick/Holder Replacement

As regular use takes place, normal wear of

the carbide picks will occur with the outer

most picks wearing first. The pick tool in-

cluded with the cold planer should be use

to remove the picks from the cast holders.

In the event the pick tool is not available,

any hardened punch or tool allowing ac-

cess to the bottom of the holders can be

used.

IMPORTANT

Welder must be grounded directly to drum

during pick holder replacement or SEVERE

BEARING DAMAGE WILL RESULT.

A length of pipe with a 3/4 to 1 inch inside

diameter can be placed over the pick to pro-

tect it from a direct hit. Striking a small piece

of wood placed on the pick to absorb the

shock will prevent damage.

NEVER DRIVE THE PICK BY STRIK-

ING DIRECTLY ON THE END OF THE

PICK AS THIS CAN CAUSE THE PICK

TO CHIP AND CAUSE INJURY OR

CREATE SMALL STRESS FRAC-

TURES IN THE PICK, RESULTING IN

PREMATURE WEAR.

WARNING

ALWAYS WEAR SAFETY GLASSES

WHEN PERFORMING THIS OPERA-

TION. HARDENED TOOLS AND PICKS

CAN SHATTER CAUSING INJURY.

WARNING

The factory installed carbide pick chosen

for use is a general purpose pick as the

cold planer is designed for both asphalt

and concrete applications. Picks de-

signed for extended periods of concrete

cutting are available from the factory or

your dealer.

To prevent the picks from seizing in the

holders, the picks should be sprayed

with a lubricate at the end of each day.

This will break down the asphalt build up

in the holders and prevent premature

wear by allowing the picks to rotate in

the holders. Excess lubricant should be

caught in a collection pan and properly

disposed of.

If the pick remains in the holder beyond

its intended replacement point, it reduces

the cutting performance and will not pro-

tect the holder. Inspect the cutting drum

every 30 minutes of operation. Check

the picks and holders for wear. If the

picks are worn enough to indicate slight

holder wear, replace the picks.

NOTE: always disconnect the ECU, radio

receiver and master panel prior to any

welding.

See page 39 for these 3 locations.

19

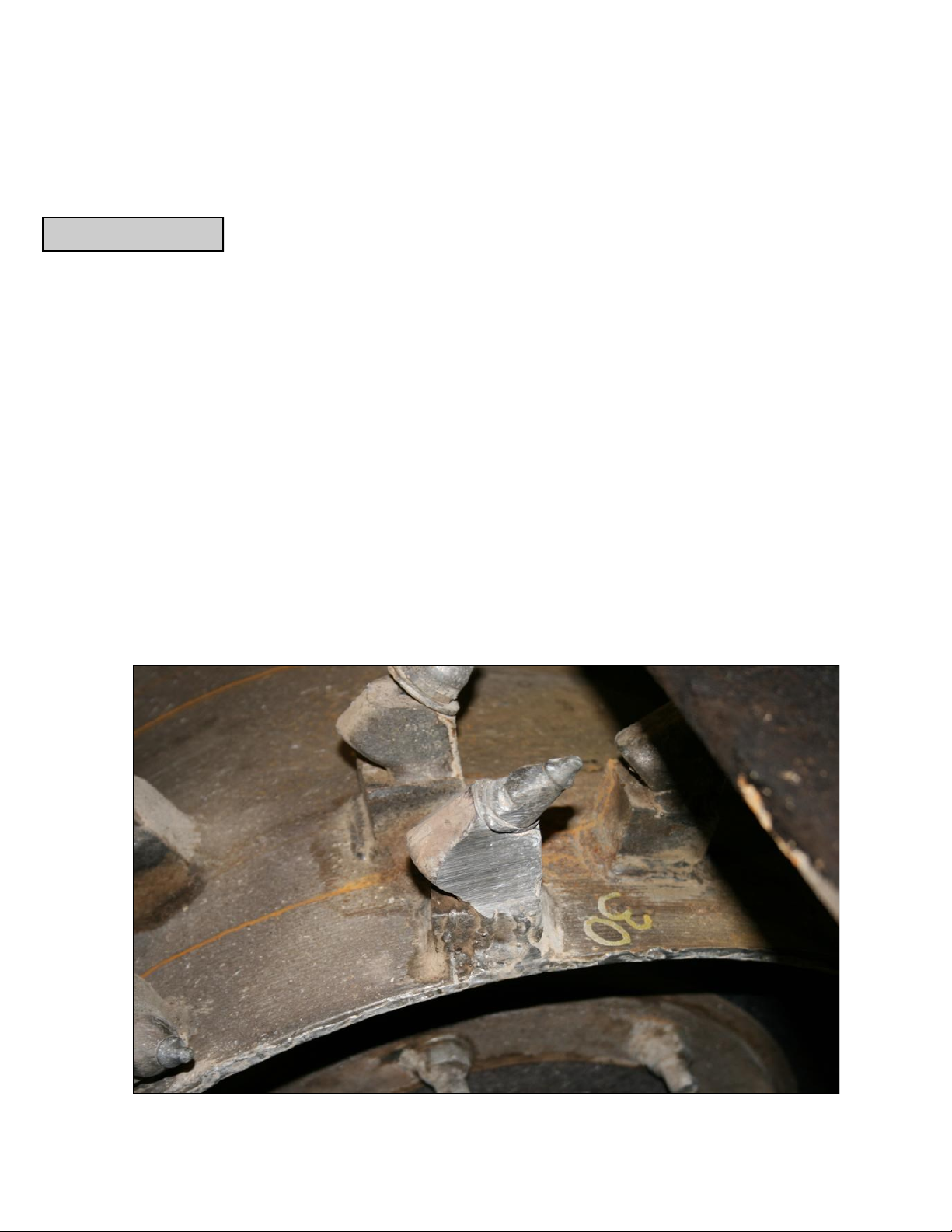

Tooth is no longer rotating in the holder, causing premature tooth and holder wear.

Tooth maintenance ( and rotation ) is critical to extending the life of the tooth and tooth holder and overall production of

the RoadHog.

Check the condition of the teeth every 30 minutes, until wear patterns are determined under current conditions.

Tooth life varies with depth, density, material, aggregate and maintenance, which includes allowing the tooth to rotate.

Various tooth styles are available to match material and aggregate variables, which may increase tooth life and production.

Consult the factory for further assistance.

The tooth has two functions: serves as the consumable cutting tool and it protects the holder.

The tooth must be allowed to rotate in its’ holder. If it locks up, then tooth and holder wear is greatly accelerated

If the tooth is allowed to remain past its’ usable life, the holder will exhibit premature wear characteristics. ( see photo below ).

To promote rotation, spray the teeth daily with a water based asphalt emulsifier to break down asphalt emulsion.

Example: Zep’s Orange Response ( part number 0750 ).

Water should always be used, as it may increase tooth life by 20 to 40% and suppresses the milling dust.

Edge teeth will always wear faster than center teeth, due to side loading of the drum during the loader’s steering corrections.

Edge holders and drum edges are hard-faced at the factory and will be required throughout the machines life.

Tooth Maintenance

IMPORTANT

20

Warranty will not be allowed for failure due to the following: normal wear and tear, abuse or accident, excessive

flow or pressure, modification of original equipment, improper service or maintenance.

Roadhog does not warrant ANY ground engaging parts ( drums, teeth, holders or bases )

against wear, unless the wear is determined by Roadhog to have been caused by an engi-

neering or manufacturing defect.

Teeth may last twice as long if they are free to rotate in their holder

Rotating teeth Non-rotating teeth

Examples of remaining tooth life ( % )

100 95 90 75 40 20 0 -5

This manual suits for next models

2

Table of contents

Other RoadHog Construction Equipment manuals