Always. Reliable. Tight.

Installation Instructions

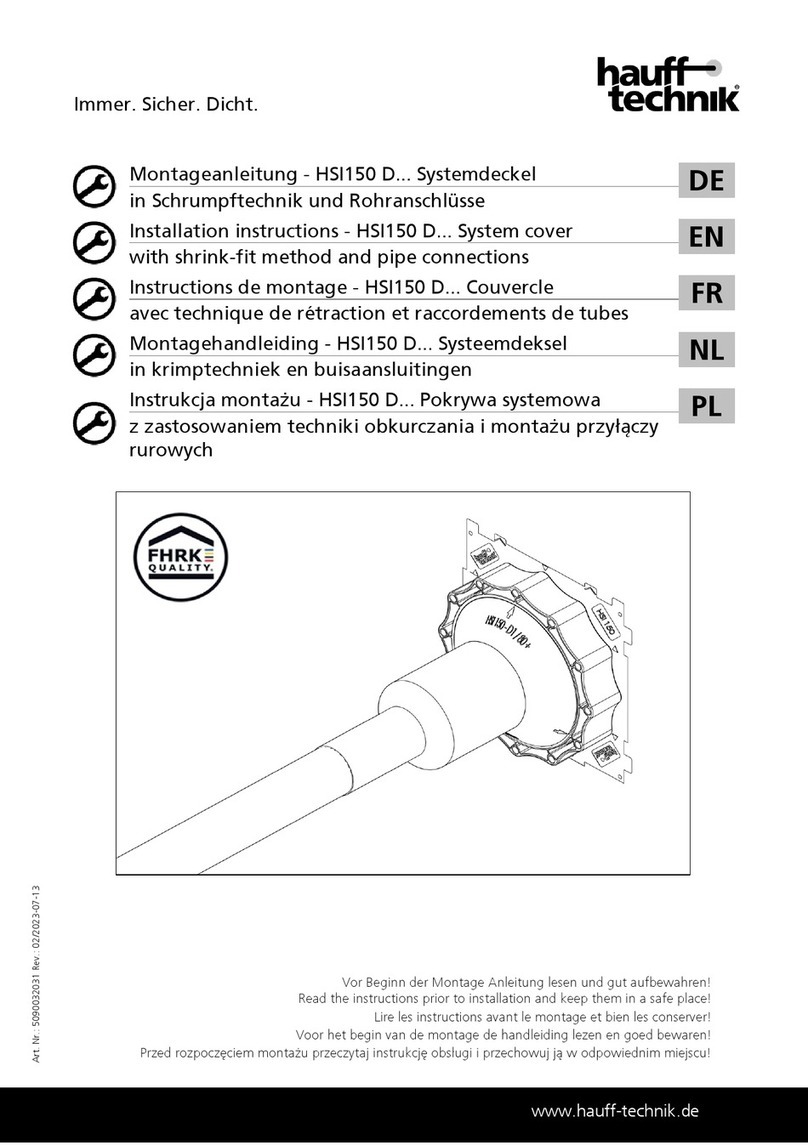

HSI 150 (cable entry system KES-M150)

Sleeve method KES-M150-D/ -KVB/ -HTV/ -D 3/58(-D 7/33).

EN

Detail

2.

1.

Limit stop

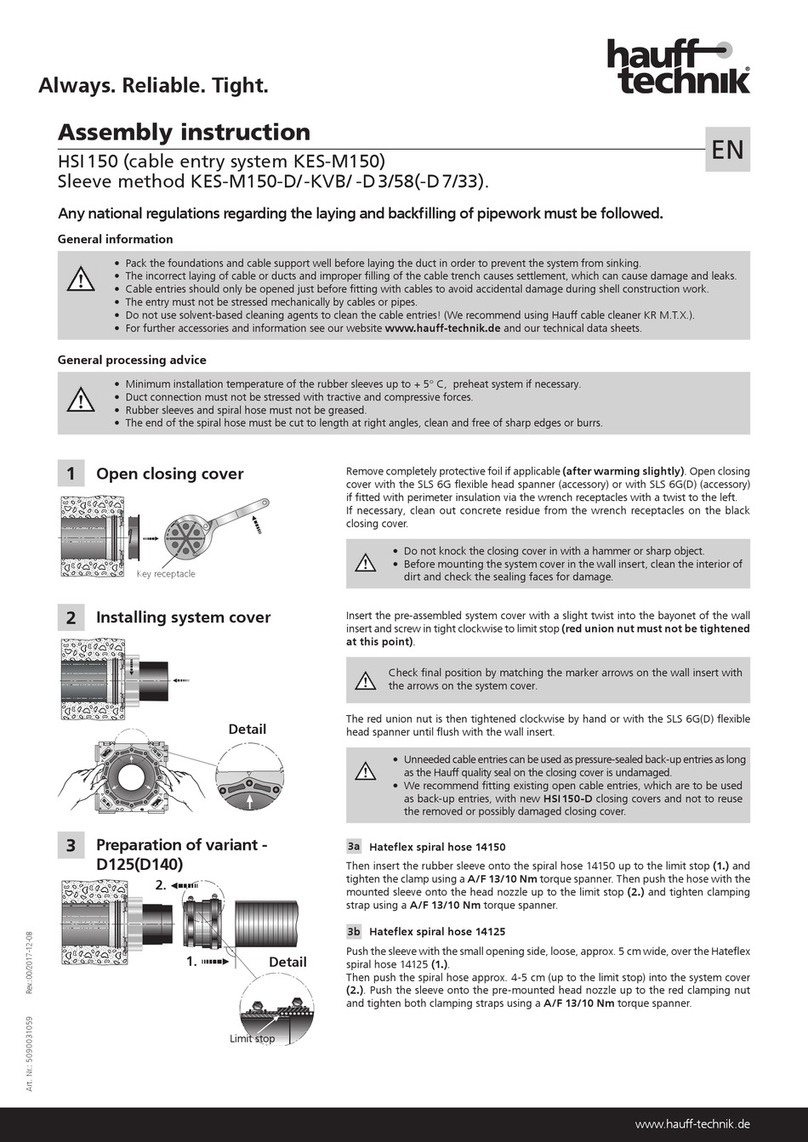

3

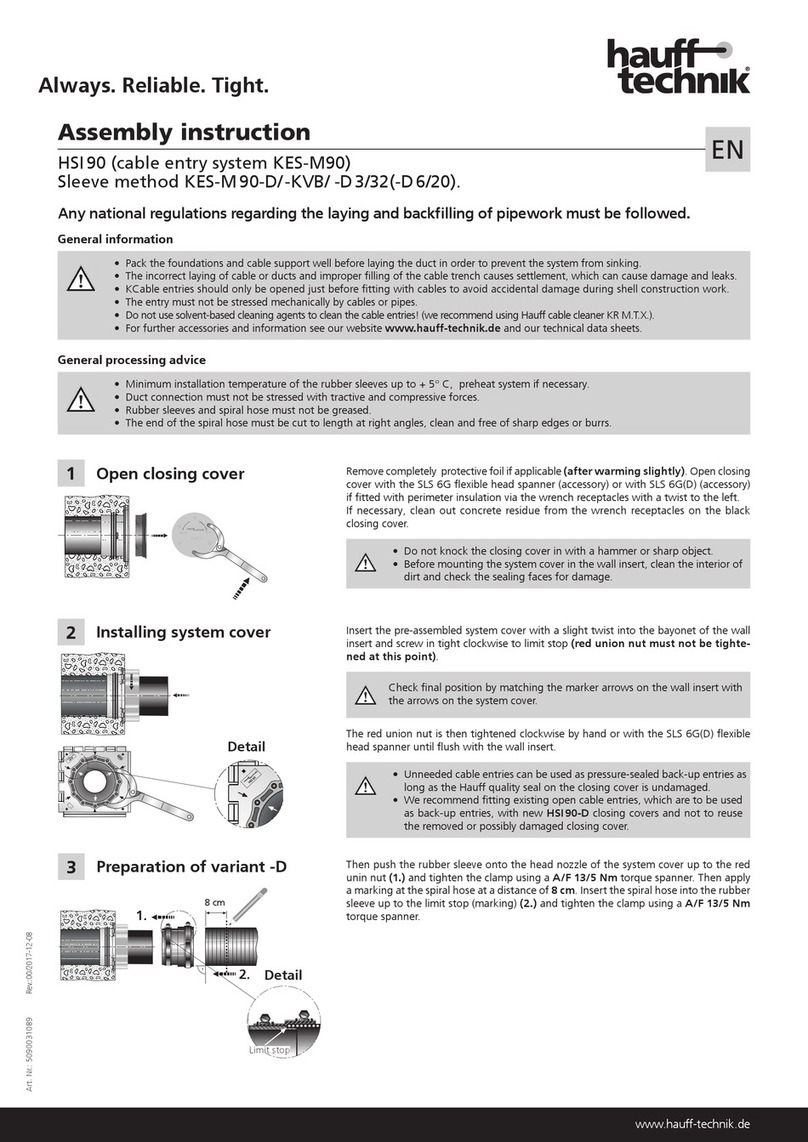

1

2

Remove protective foil if applicable (after warming slightly). Open closing

cover with the SLS 6G exible head spanner (accessory) or with SLS 6G(D)

(accessory) if tted with perimeter insulation via the wrench receptacles

with a twist to the left.

If necessary, clean out concrete residue from the wrench receptacles on

the black closing cover.

Installing system cover

Preparation of variant -D

Detail

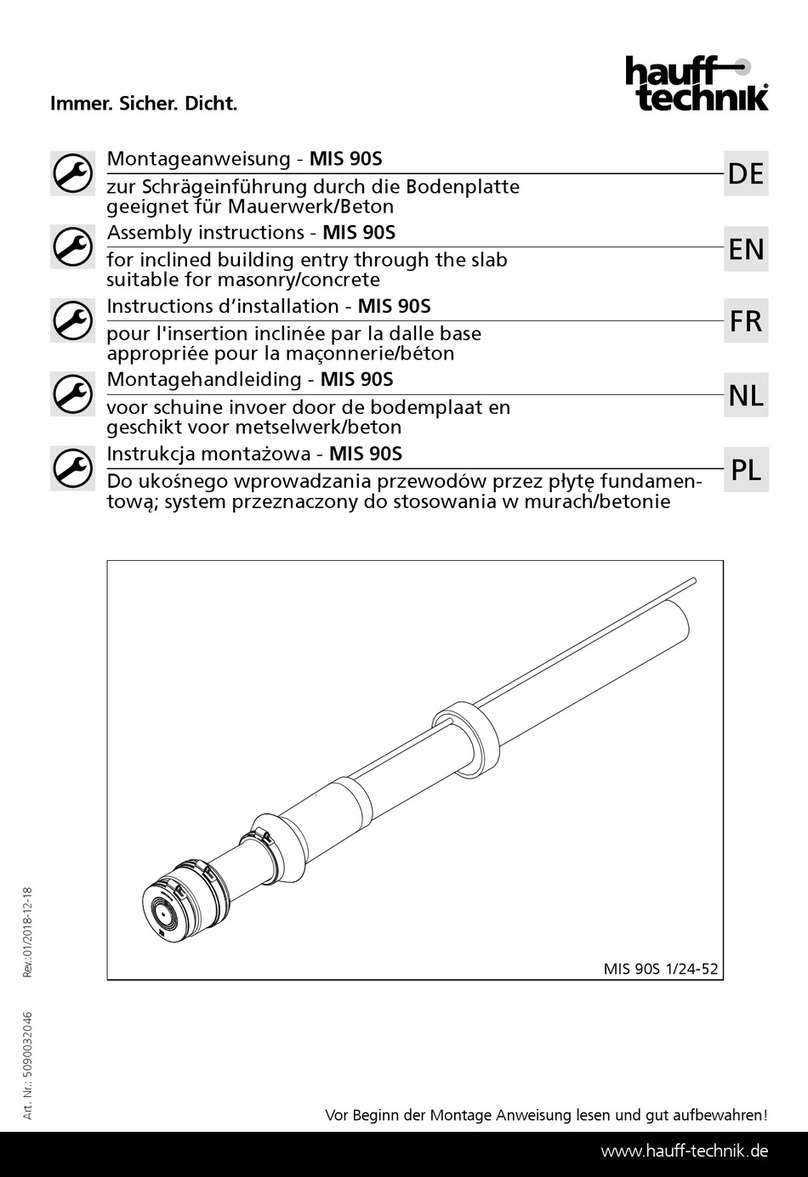

Any national regulations regarding the laying and backfilling of pipework must be followed.

Open closing cover

Key receptacle

Insert the pre-assembled system cover with a slight twist into the ba-

yonet of the wall insert and screw in tight clockwise to limit stop (red

union nut must not be tightened at this point).

The red union nut is then tightened clockwise by hand or with the

SLS 6G(D) exible head spanner until ush with the wall insert.

• Do not knock the closing cover in with a hammer or sharp object!

• Before mounting the system cover in the wall insert, clean the

interior of dirt and check the sealing faces for damage.

• Unneeded cable entries can be used as pressure-sealed back-up entries

as long as the Hauff quality seal on the closing cover is undamaged.

• We recommend tting existing open cable entries, which are to

be used as back-up entries, with new H S I 1 5 0 - D closing covers

and not to reuse the removed or possibly damaged closing cover.

Check nal position by matching the marker arrows on the wall in-

sert with the arrows on the system cover.

• Pack the foundations and cable support well before laying the duct in order to prevent the system from sinking.

• The incorrect laying of cable or ducts and improper lling of the cable trench causes settlement, which can cause damage and leaks.

• Cable entries should only be opened just before tting with cables to avoid accidental damage during shell construction work.

• The entry must not be stressed mechanically by cables or pipes.

• Do not use solvent-based cleaning agents to clean the cable entries! (we recommend using Hauff cable cleaner KR M.T.X.).

• For further accessories and information see our website www.hauff-technik.de and our technical data sheets.

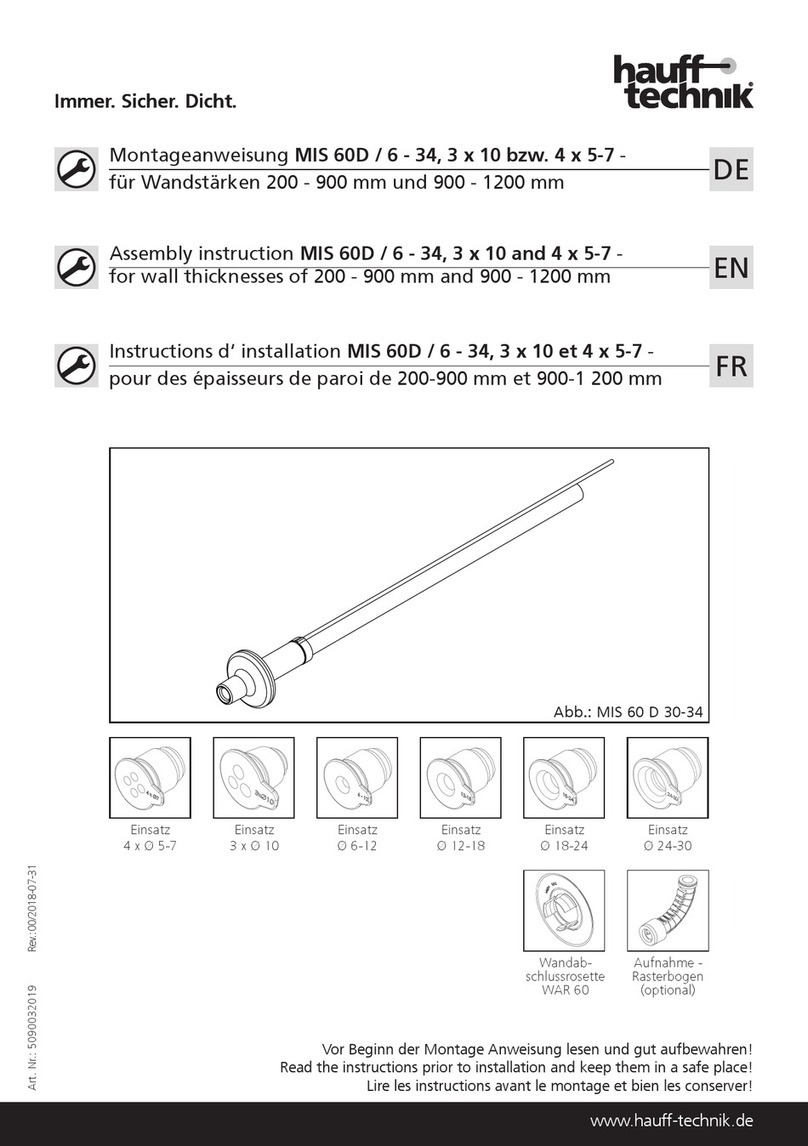

General processing advice:

• Minimum installation temperature of the rubber sleeves up to + 5° C, preheat system if necessary.

• Duct connection must not be stressed with tractive and compressive forces.

• Rubber sleeves and spiral hose must not be greased.

• The end of the spiral hose must be cut to length at right angles, clean and free of sharp edges or burrs.

Then insert the rubber sleeve onto the spiral hose 14150 up to the limit

stop (1.) and tighten the clamp using a A/F 13/10 Nm torque spanner.

Then push the hose with the mounted sleeve onto the head nozzle up

to the limit stop (2.) and tighten clamping strap using a A/F 13/10 Nm

torque spanner.

Push the sleeve with the small opening side, loose, approx. 50 cm wide,

over the Hateex spiral hose 14125 (1.).

Then push the spiral hose approx. 4-5 cm (up to the limit stop) into the

system cover (2.). Push the sleeve onto the pre-mounted head nozzle

up to the red clamping nut and tighten both clamping straps using a

A/F 13/10 Nm torque spanner.

3a

3b

Hateflex spiral hose 14150

Hateflex spiral hose 14125