continued from preceding page

blue wire to the terminal block screw labeled “blue wire”

in Figure 2.

Note: due to manufacturing variances, the preattached

blue wire may be mounted to a different terminal block

screw than the one shown in Figure 2. If this is the case,

match color to color — blue wire opposite blue wire.

Step Two

Attach the air line and compressor

Before connecting the air line, make certain that it

is clean. If dirt or debris is not removed, air pressure

will carry it through the system, which may prevent

proper operation of the braking system or damage

system components.

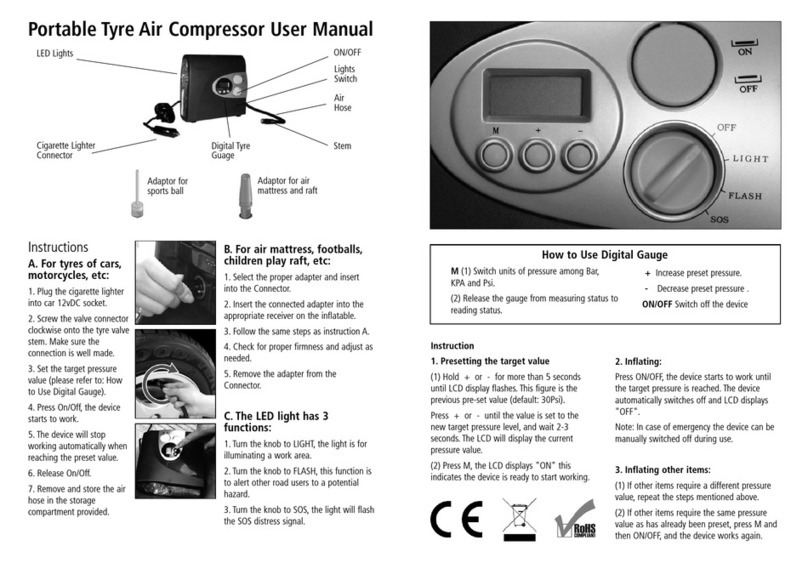

1. Connect the air line to the “out” compression fitting

on the air compressor (Figure 1). Before doing so, make

certain that the brass insert (Figure 3) is still inside the

line, and that the ferrule (Figure 3) is positioned ¼" from

the end of the line.

Note: if the brass inserts are omitted, the fittings will

not be airtight.

Next, push the air line into the compression fitting, as

far as it can go. Then push the ferrule into the compres-

sion fitting, and tighten the compression nut onto the

fitting.

Note: if the compression nut is overtightened, the fit-

ting will not be airtight. After completing the installation,

check the fittings for air leaks (Step Three, below).

2. With the air line attached, position the air compressor

over the four pilot holes, and use the provided screws to

secure the compressor in place.

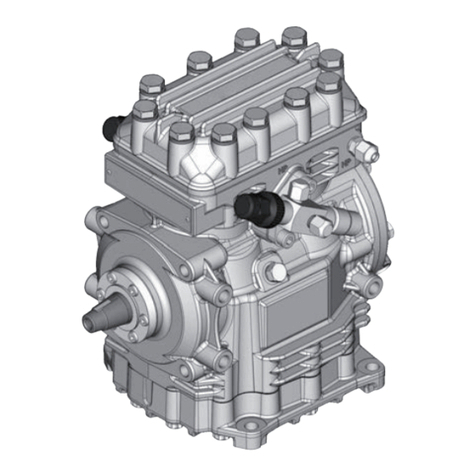

2. Check to make certain that the handle on the air tank

drain valve (Figure 4) is closed.

The handle on the air tank drain valve should only

be opened to drain the air tank. If the handle is open

during towing, the air compressor will run constantly,

which may damage the compressor.

Figure 3

Figure 4

Step Three

Check for proper function

1. Start the motorhome engine and allow the air com-

pressor to run until it shuts off (about 45 seconds). Then,

hold the brake pedal down until the air compressor shuts

off again.

If the air compressor does not function as described

above, check the wiring. Make certain that all connections

have been made as described in Step One — “Wire the

air compressor.”

2. Check for leaks in the air line — first, cover the fittings

at the air compressor with a leak check solution.

The air system now contains pressurized air, which

may cause severe eye or ear injury if it is inadver-

tently released. Wear appropriate eye and ear protec-

tion before adjusting the air system fittings.

Tighten any fittings, if necessary, and repeat until all

connections are airtight.

Towing and Suspension Solutions

ROADMASTER, Inc. • 6110 NE 127th Ave. • Vancouver, WA 98682 • 800-669-9690 • Fax 360-735-9300 • roadmasterinc.com