continued from preceding page

when the tow bar arm extends for towing, and the in-

ner arm will separate from the outer arm.

The towed vehicle will not be held in place if the

tow bar arm separates, which may cause a loss of ve-

hicular control, a traffic accident or loss of the towed

vehicle, resulting in property damage, personal injury

or even death.

12. With the safety bolt attached, test the operation of the

inner arm — press the Autowlok button down and slide the

inner arm forward and backward, to its fullest extent.

If the inner arm does not slide smoothly, trim the rear

bushing — remove the 3/8" safety bolt, press the Autowlok

button down and slide the inner arm out.

As before, trim an equal amount from each side of the

bushing. Then test the operation of the inner arm and trim

more, if necessary, until the inner arm slides forward and

backward smoothy.

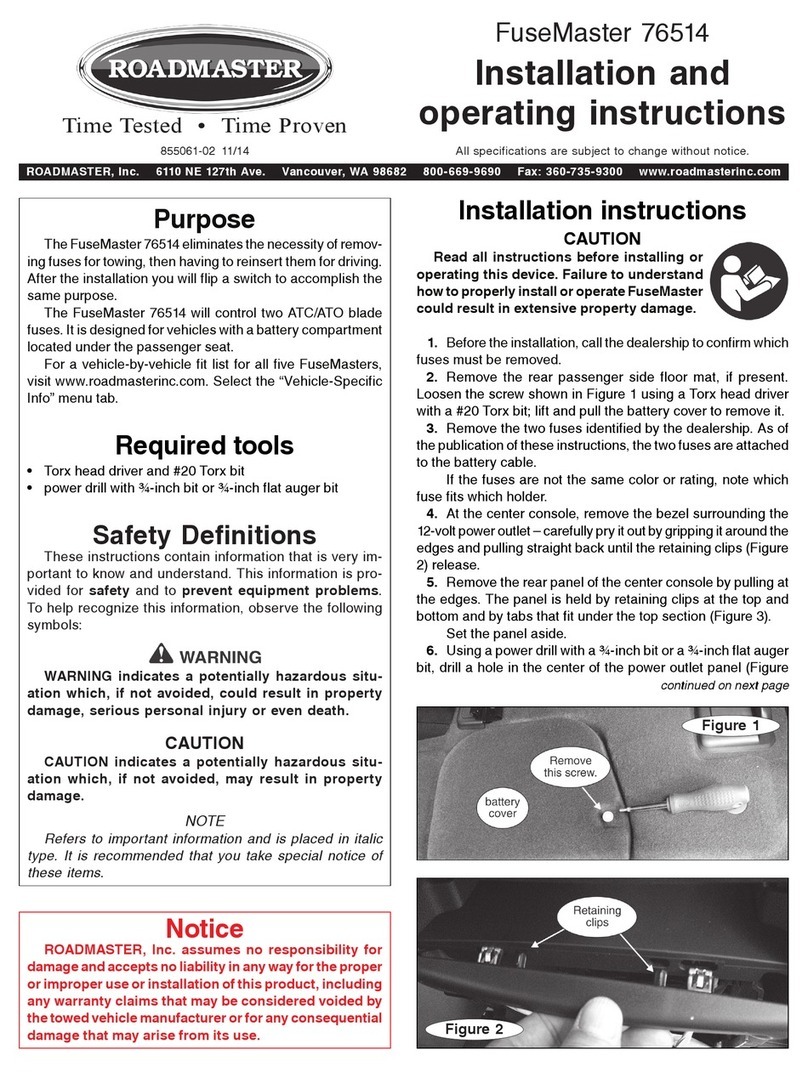

13. With the safety bolt attached, the Autowlock button in

the locked position (Figure 6) and the rear bushing flush

to the edge of the outer arm (Figure 6), drill two 1/8" pilot

holes for the pop rivets (Figure 6).

Secure the bushing in place with two 1/8" pop rivets

(one on each side).

14. If necessary, repeat steps 1 through 13 for the other

tow bar arm.

To replace an Autowlok button…

1. It is not necessary to disassemble the tow bar to replace

an Autowlok button.

First, open the tow bar and extend both arms until the

buttons on both arms snap into the locked position.

Note: if the button is missing, it will be necessary to lift

the button stem (Figure 2) up slightly as you extend the arm,

so that the button stem will clear the inner arm weldment and

inner arm bushing.

2. Set the coupler on any object that will allow the tow bar

arms to rest at a convenient height to work on the button.

3. With the arms fully extended and locked, draw a straight

line with a pencil across the top of the inner arm (Figure 4),

3/4" from the edge of the black outer arm (Figure 4).

4. Depress the button (or the button stem, if the button is

missing) and slowly close the arm until the edge of the black

outer arm is even with the pencil line you drew in the previous

step.

Quality Towing Systems since 1974

ROADMASTER, Inc. • 6110 NE 127th Ave. • Vancouver, WA 98682 • 800-669-9690 • www.roadmasterinc.com

This position will stabilize and support the button stem

so that the new button can be properly attached.

5. Remove the old button (if present) with pliers or channel

locks, being careful not to scratch the button stem.

6. Clean any residue that may be on the exposed surface

of the button stem.

Note: for easier attachment to the button stem (step 7,

below), drop the button in boiling water for five minutes. The

heat will make the button more flexible.

If you choose this method, dry the button completely

before applying the glue.

7. Follow the instructions on the supplied package of epoxy

glue to mix and activate the glue, then apply enough to lightly

cover the inside of the button. Next, apply enough glue to

completely fill the grooves at the top of the button stem.

Within 30 seconds, position the button over the top of

the button stem, and tap the button down over the stem, as

far as it can go, with a rubber mallet.

CAUTION

Ensure that the button is tapped completely down,

as far as it can go. If the button is not completely down,

it will not depress the pin and spring far enough to lock

or unlock the tow bar arm.

8. Allow 24 hours for the epoxy glue to set. The button can

be depressed and released after approximately 10 minutes,

but do not pull on the button for 24 hours.