Roadmaster 1139-143 User manual

Other Roadmaster Automobile Accessories manuals

Roadmaster

Roadmaster Hands-Free Bluetooth Car Kit VRBT330W Owner's manual

Roadmaster

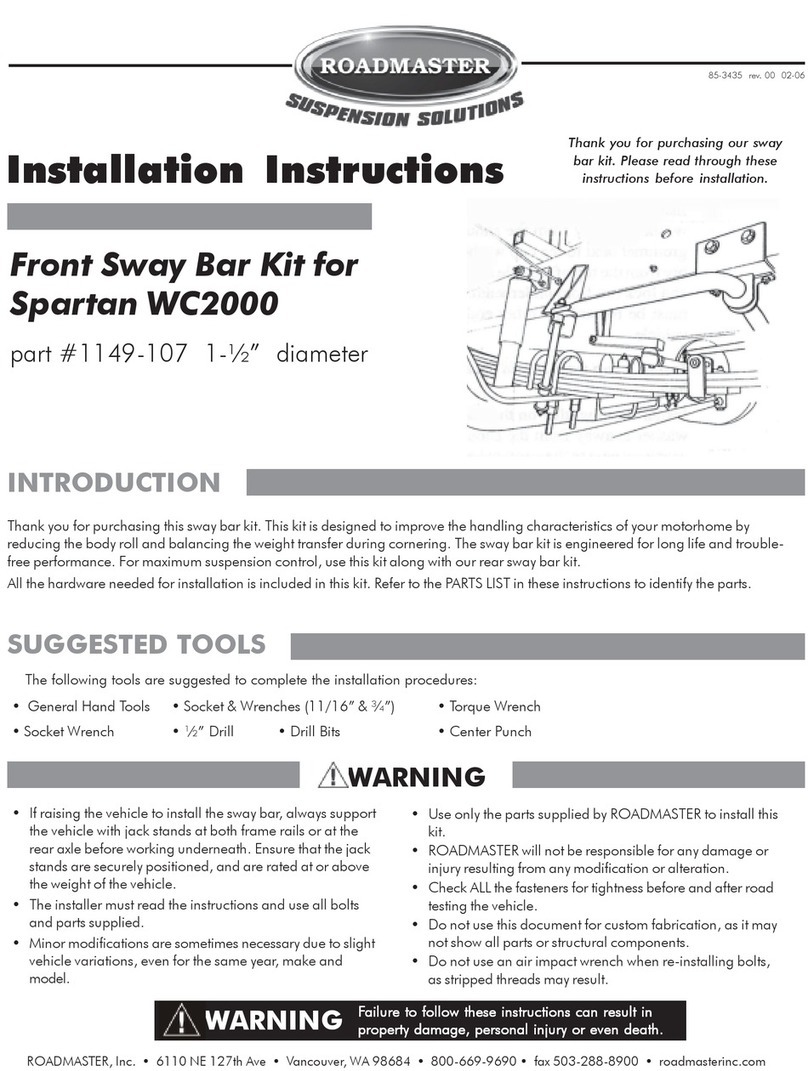

Roadmaster 1149-107 User manual

Roadmaster

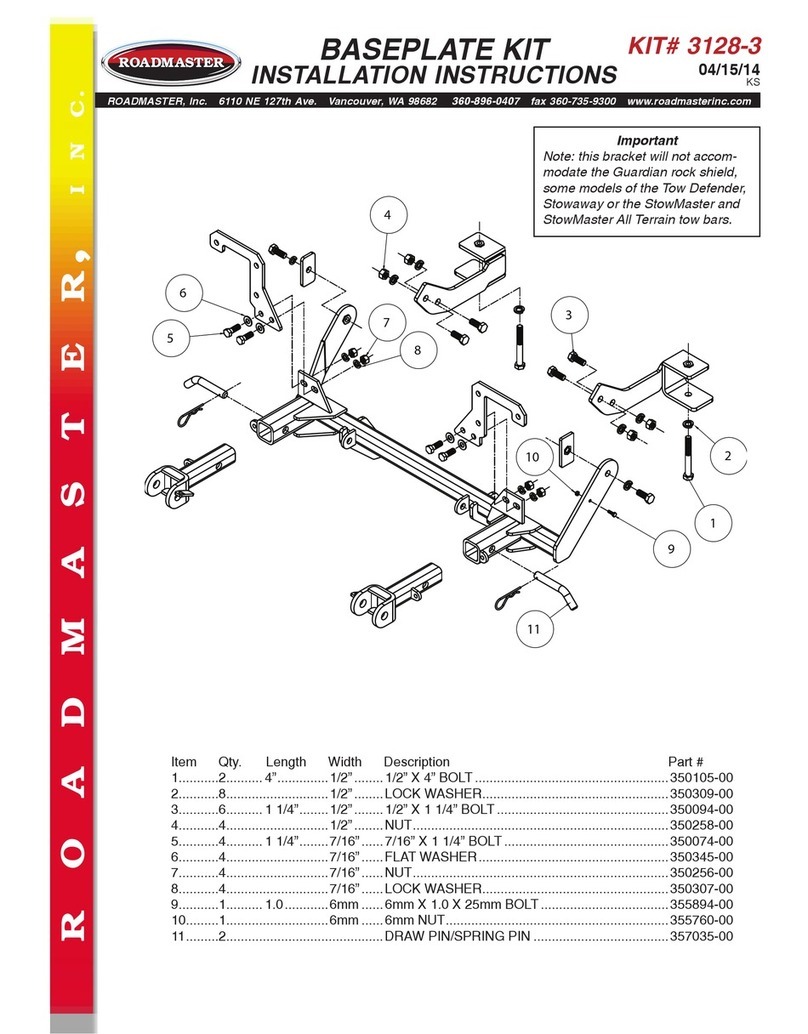

Roadmaster 3128-3 User manual

Roadmaster

Roadmaster Sterling ALL-TERRAIN 576 Original instructions

Roadmaster

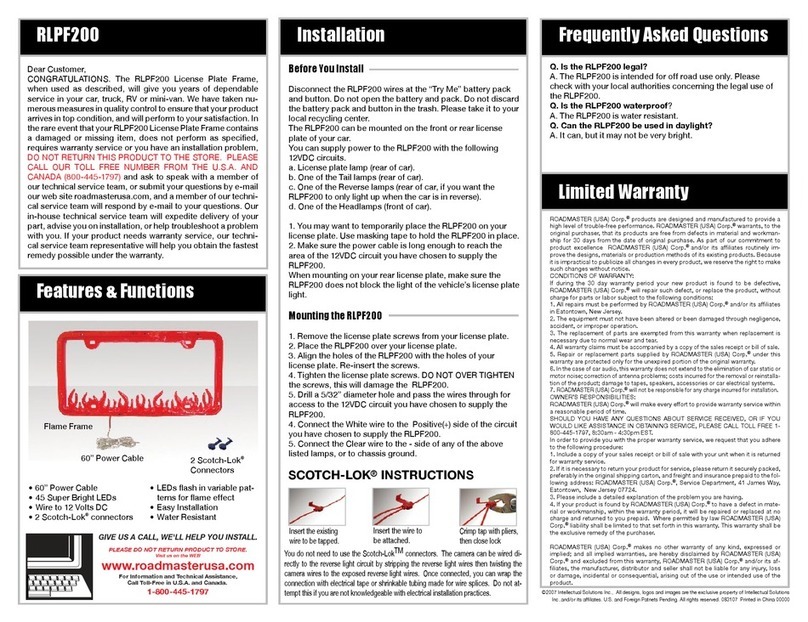

Roadmaster RLPF200 User manual

Roadmaster

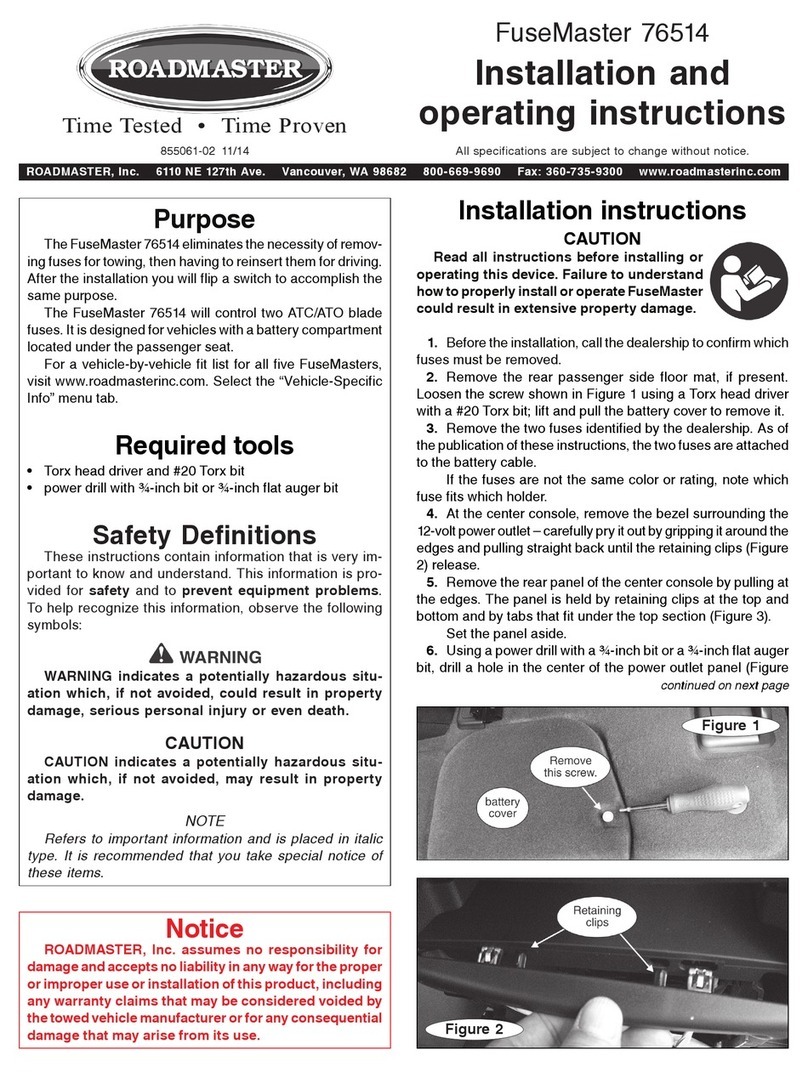

Roadmaster FuseMaster 76514 User manual

Roadmaster

Roadmaster FALCON 522 Original instructions

Roadmaster

Roadmaster 156-75 User manual

Roadmaster

Roadmaster FuseMaster 76512 User manual

Roadmaster

Roadmaster 195125 User manual

Roadmaster

Roadmaster REJ2000 User manual

Roadmaster

Roadmaster Blackhawk 2 All Terrain User manual

Roadmaster

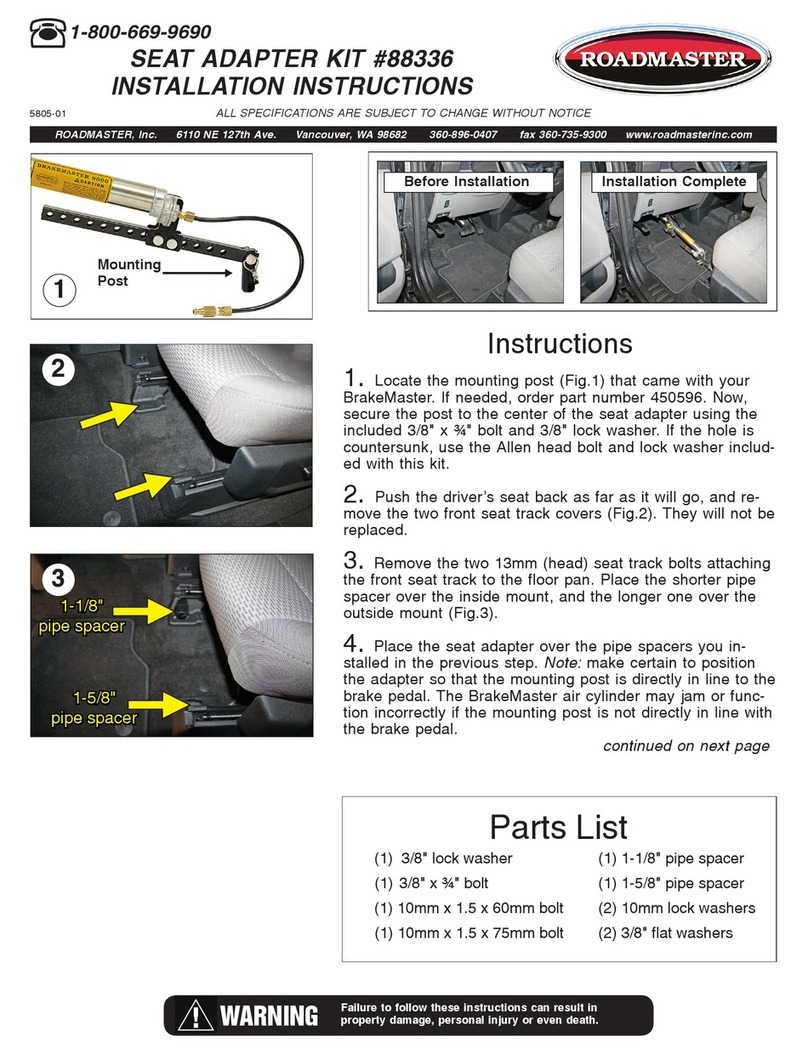

Roadmaster 88336 User manual

Roadmaster

Roadmaster 2120 Quick start guide

Roadmaster

Roadmaster Sterling All Terrain User manual

Roadmaster

Roadmaster BrakeMaster 9000 User manual

Roadmaster

Roadmaster StowMaster ALL TERRAIN User manual

Roadmaster

Roadmaster FuseMaster 76511 User manual

Roadmaster

Roadmaster Sterling Operating instructions

Roadmaster

Roadmaster 031-5 User manual

Popular Automobile Accessories manuals by other brands

Subaru

Subaru J1010FN800 installation manual

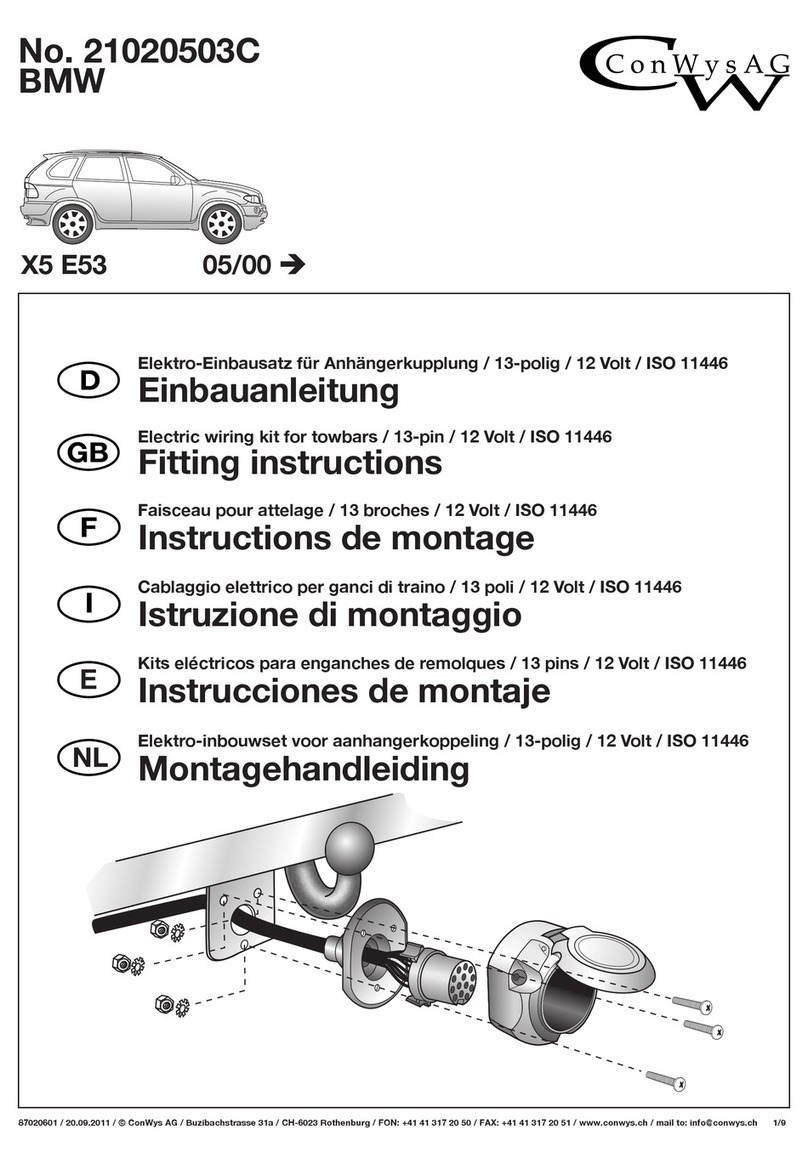

ConWys AG

ConWys AG 21020503C Fitting instructions

Alpine

Alpine HCE-C117D owner's manual

Hama

Hama 00200015 operating instructions

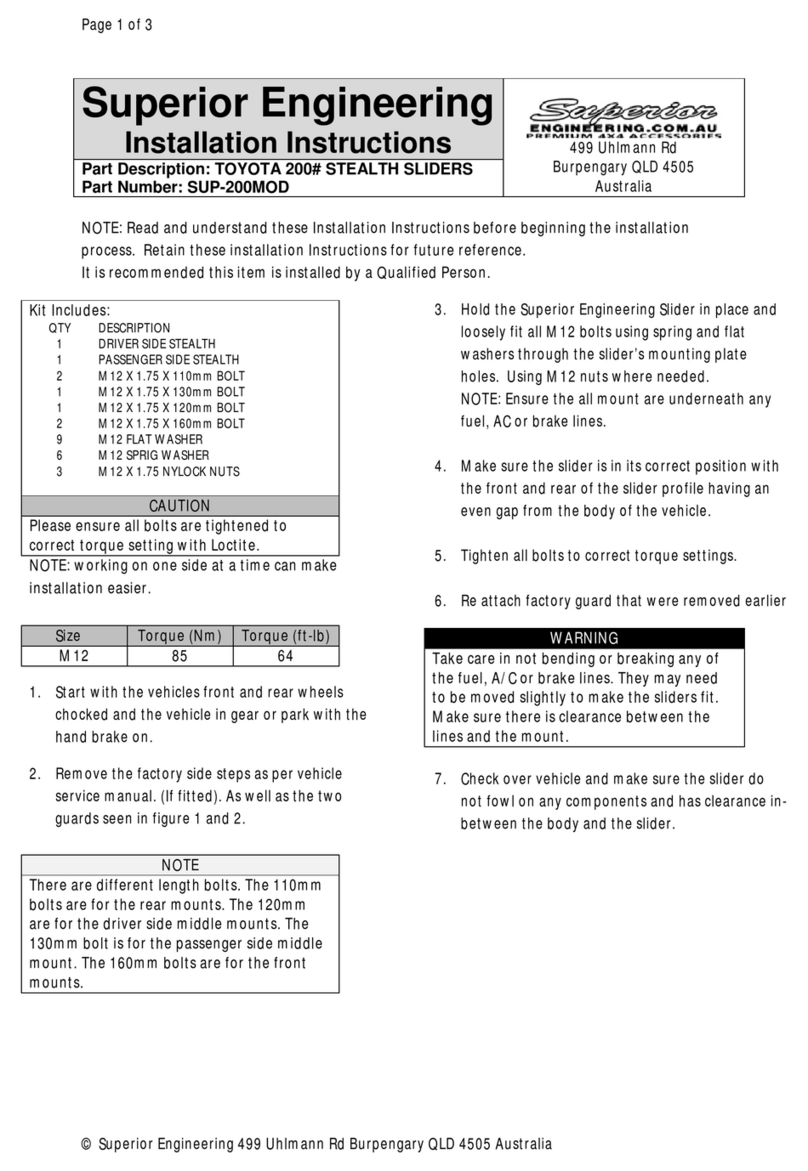

Superior Engineering

Superior Engineering SUP-200MOD installation instructions

SCHROTH

SCHROTH Interior Net Installation and use guideline

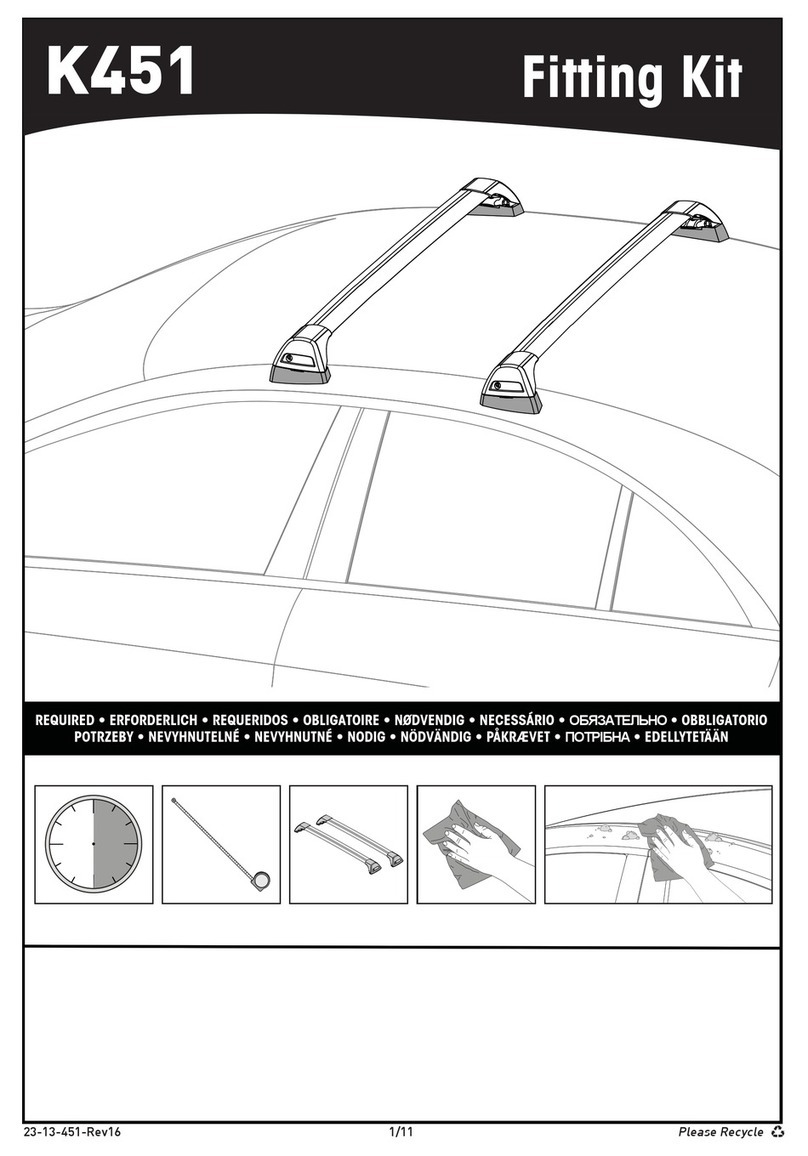

Yakima

Yakima K451 manual

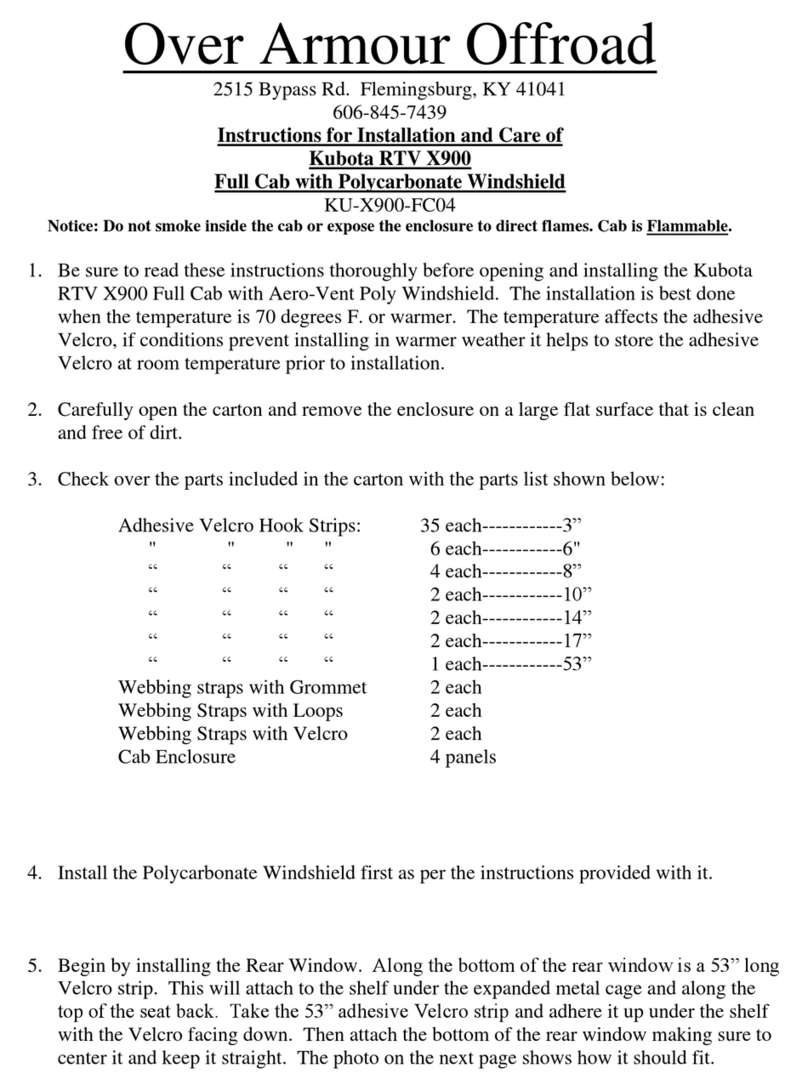

Over Armour Offroad

Over Armour Offroad KU-X900-FC04 Instructions for Installation and Care

Metra Electronics

Metra Electronics 98-5999 installation instructions

Circutor

Circutor Wallbox eNext Series installation guide

CrimeStopper

CrimeStopper SecurView SV-6713 Insruction manual

Parrot

Parrot Minikit+ quick start guide