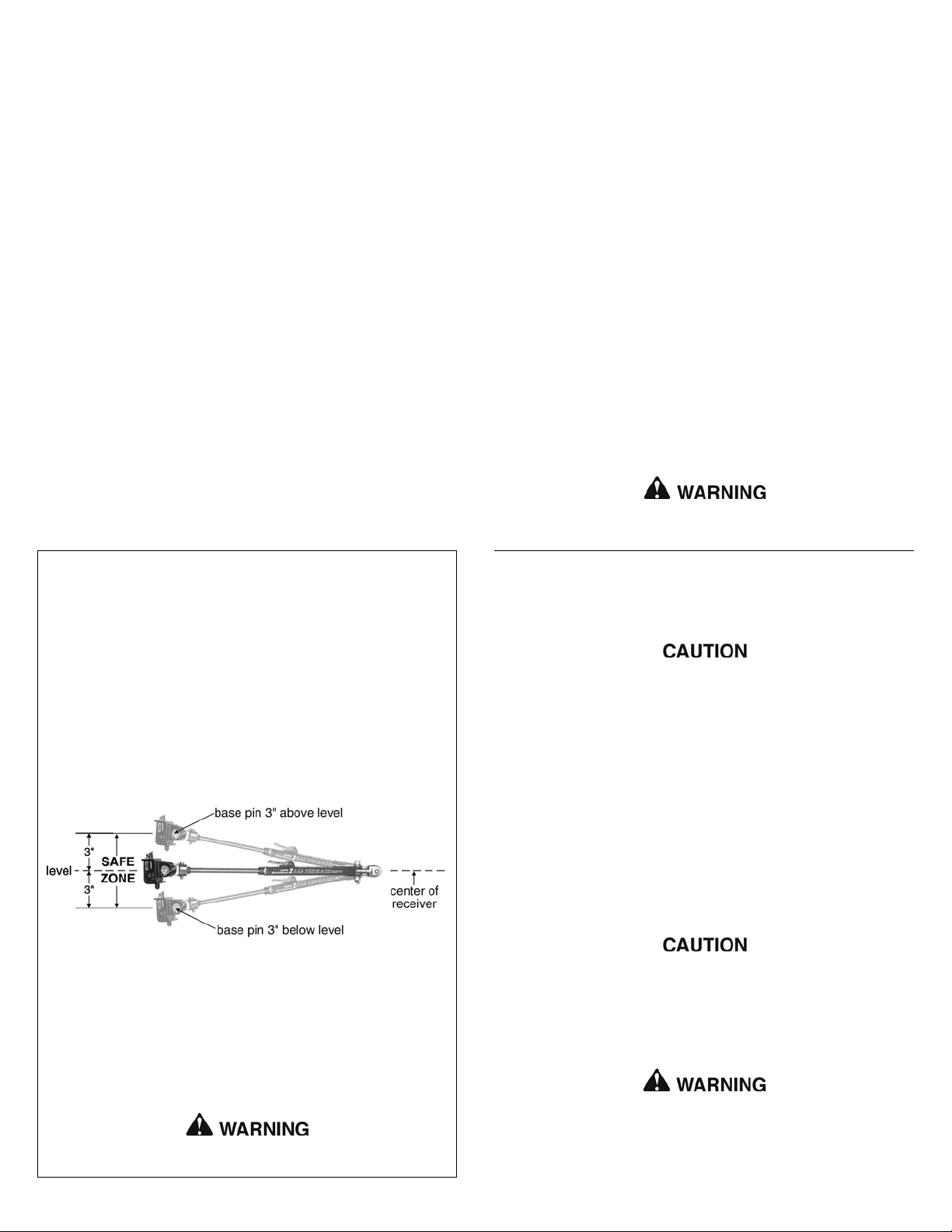

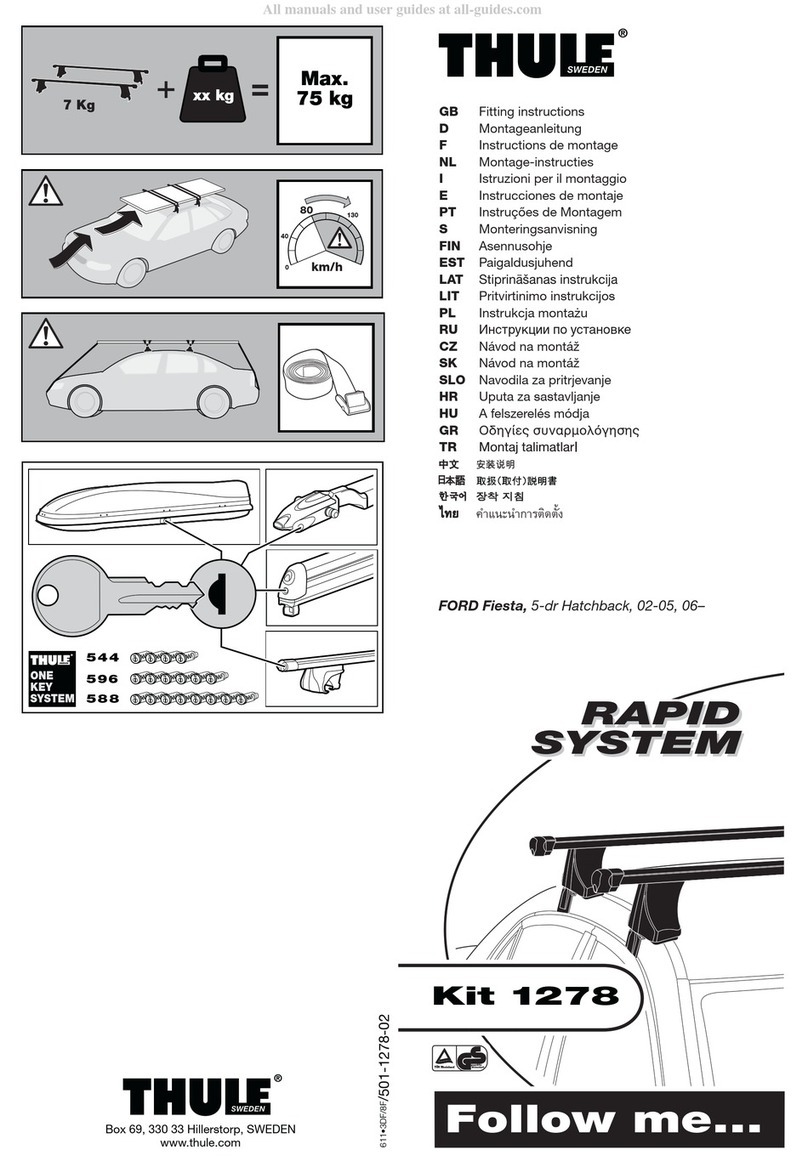

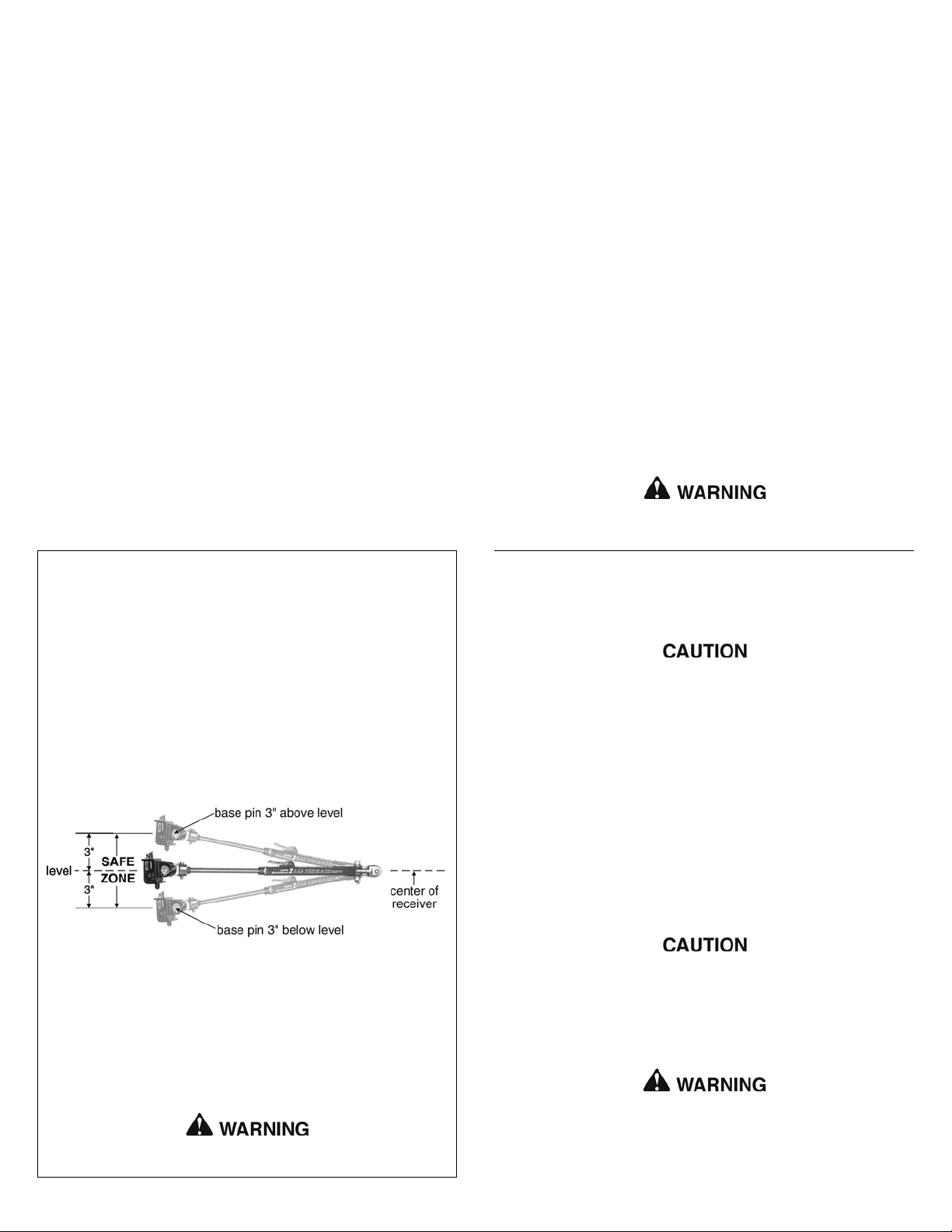

Towing with a motorhome-mounted tow bar which has an upward or

downward slope puts undue strain on the entire towing system. For that

reason, do not tow if the tow bar is not within the ‘Safe Zone’ — no

more than three inches above or below level.

Towing a vehicle with a tow bar that is not within the Safe Zone will

result in significant wear and tear on the tow bar and brackets, sig-

nificant wear and tear on the vehicle’s suspension and frame, and the

eventual failure of the towing system.

To determine if the tow bar is within the Safe Zone — first, con-

nect the motorhome and vehicle on level ground.

Next, measure the distance from the center of the motorhome receiver

down to the ground. Then, measure the distance from the center of one

of the base pins down to the ground.

Compare these two measurements. To be within the Safe Zone, they

cannot be more than three inches apart if the base pin is above or

below the motorhome hitch receiver.

If the tow bar is not within the Safe Zone, you must purchase a hitch

accessory to raise or lower the hitch receiver. ROADMASTER has three

accessories available — Hi-Low Hitches, Hi-Low Drops and Dual Hitch

Receivers — which will raise or lower the hitch receiver from two to 10

inches, depending on the model.

Towing with the tow bar more than three inches above or below level

will void the ROADMASTER warranty.

Failure to follow these instructions may cause property damage,

personal injury or even death.

2

• Stress to the owner that the tow bar must be within the ‘Safe Zone’

— no more than three inches above level or three inches below level.

Towing with an out-of-level tow bar will cause significant wear and tear

on the tow bar and mounting brackets, and on the towed vehicle’s sus-

pension and frame. (See the section titled “Stay within the ‘Safe Zone’”

for further information.)

• Show the owner how to properly operate the tow bar. Familiarize

yourself with the features of the tow bar. Demonstrate them to the owner,

and ask the owner to connect and disconnect the tow bar and other

components of the towing system, until the owner is comfortable with its

operation.

• Advise the owner to always use safety cables when towing. The

safety cables must connect the towed vehicle to the towing vehicle, frame

to frame.

• Caution the owner to choose safety cables based on the weight of

the towed vehicle.

•If the towed vehicle and all its contents weigh 6,000 pounds or less, use

6,000-pound rated safety cables. There are several choices in this range

— call ROADMASTER (800-669-9690) or visit www.roadmasterinc.com.

•If the towed weight is between 6,000 and 8,000 pounds, use 8,000-pound

capacity safety cables (double- or single-hook, part numbers 648 or

649).

•If the towed weight is between 8,000 and 10,000 pounds, you must

use 10,000-pound rated safety cables or chains.

The weight capacity of the safety cables must meet or exceed the

towed weight, or the safety cables will fail.

•The BlackHawk 2 All Terrain tow bar is rated at a maximum of 10,000

pounds carrying capacity; therefore the weight of the towed vehicle and

all its contents cannot exceed 10,000 pounds. Above 8,000 pounds,

10,000-pound capacity safety cables or chains must be used. In addition,

the receiver hitch and all supplementary towing equipment must be rated

at no less than the weight of the towed vehicle and all its contents.

Installer’s safety checklist

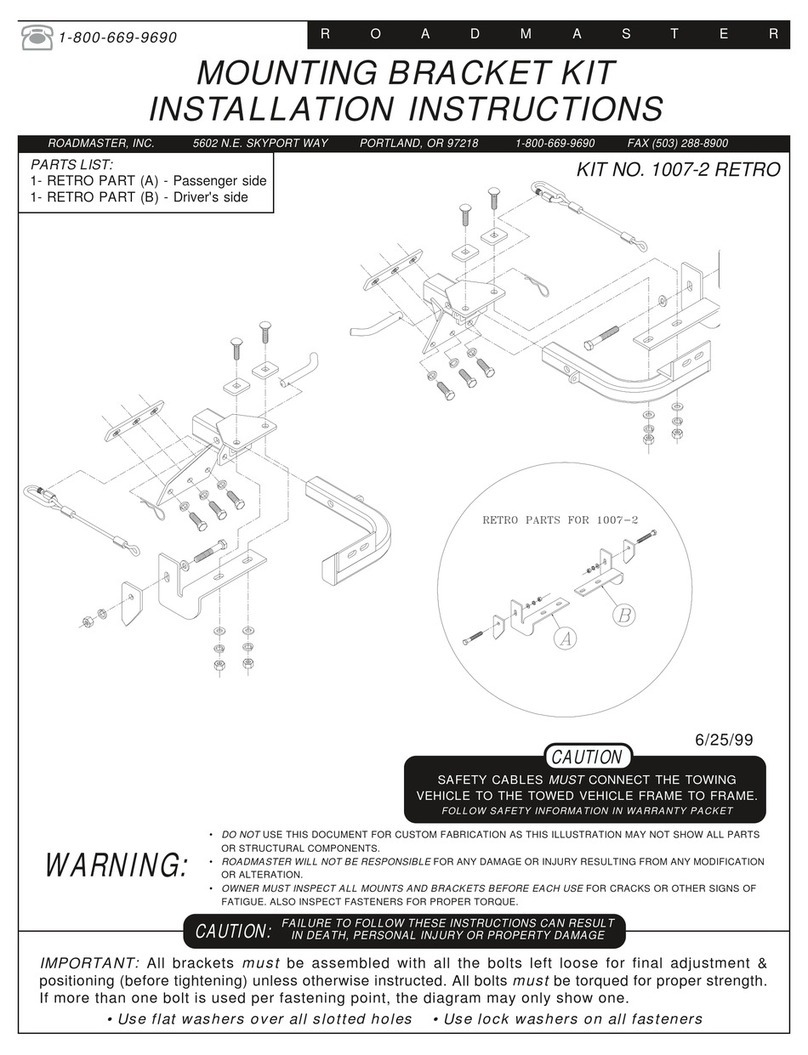

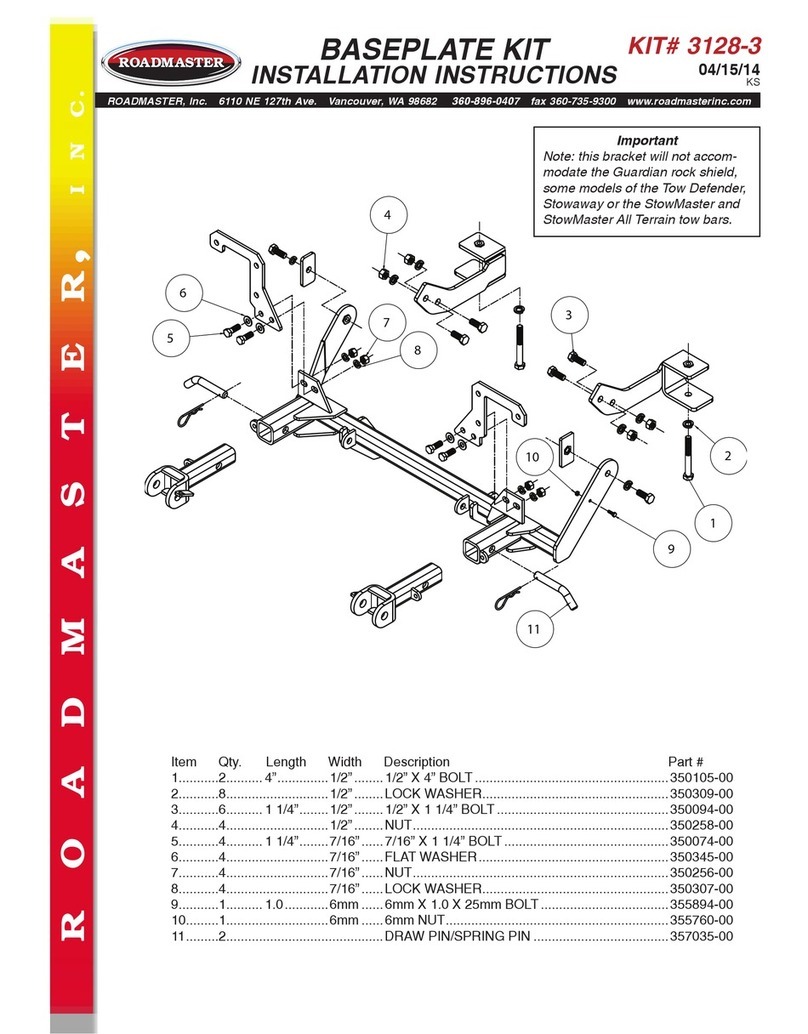

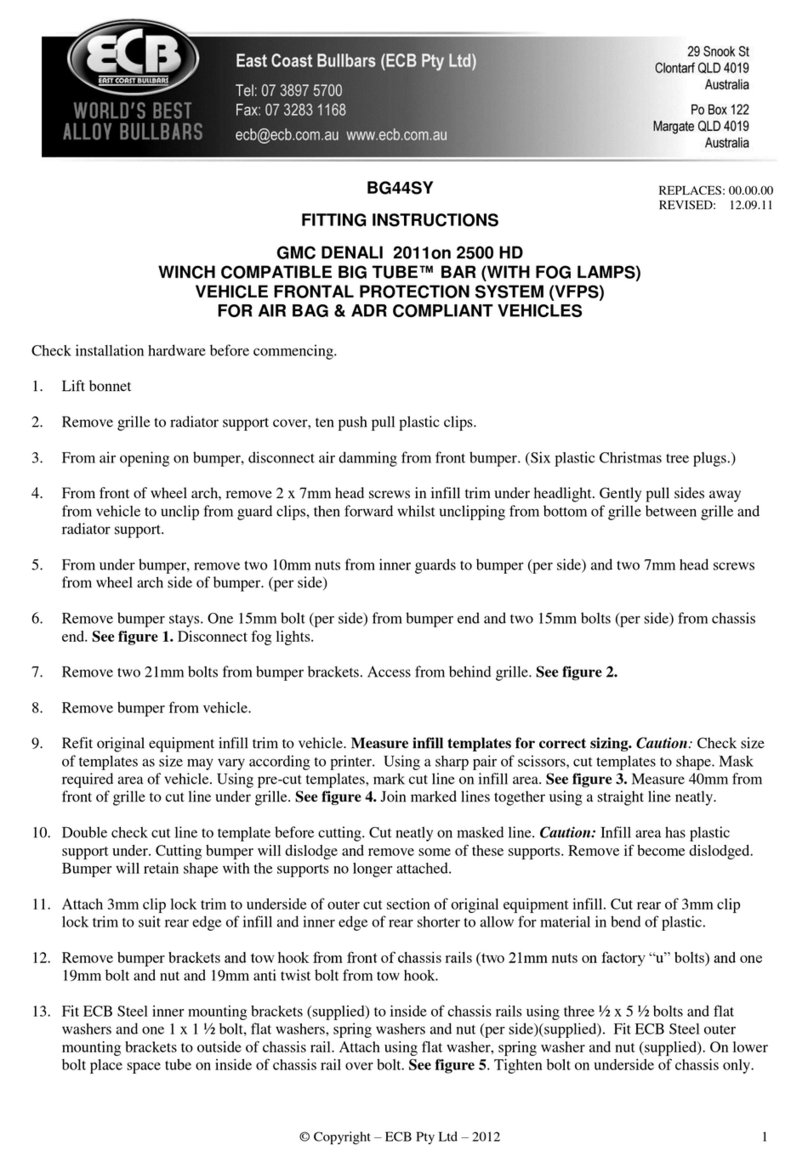

• The tow bar must be attached to a bracket which is bolted to the

towed vehicle’s frame or unibody. In order to be towed, virtually all

vehicles require a tow bar mounting bracket that is connected to the

frame, unibody or chassis and extends beyond the bumper.

• Caution the owner to secure the tow bar with linch pins (or optional

padlocks) before towing. Unless the tow bar is secured to both vehicles

with all appropriate pins (or padlocks), the towed vehicle will detach.

• Read the instructions thoroughly before installing the ‘quick-dis-

connect’ (‘QD’) system and its components.

The tow bar will be attached to the QD system. If the QD system is not

properly aligned, centered and positioned on the towed vehicle, the tow

bar will not be centered on the towed vehicle, which may cause exces-

sive tire wear and other consequential, non-warranty damage.

• The installer must be sure that the vehicle is suitable or adaptable

for towing. Some vehicles must be equipped with a transmission lube

pump, an axle disconnect, driveline disconnect or free-wheeling hubs

before they can be towed. Failure to properly equip the vehicle will cause

severe damage to the transmission.

Check the manufacturer’s instructions for the proper procedure(s) to

prepare the vehicle for towing.

• The installer must NOT use the tow bar as a ground for welding.

Connecting a ground to the ‘A-frame’ of the tow bar will cause current

to flow through the locking spring, which will detemper the spring and

destroy the locking mechanism.

• Under no circumstances should the tow bar be welded to the vehicle,

nor should any of the pre-punched mounting holes be altered. Any weld-

ing or altering of the tow bar will void the owner’s warranty.

Failure to follow these instructions may cause property damage,

personal injury or even death.

Stay within

the ‘Safe Zone’

Connecting and

disconnecting

Use caution when handling the tow bar — if your hands, fingers or

any part of your body are caught between moving components, they

can be pinched, cut or otherwise injured.

Connecting the tow bar

1. First, attach the tow bar quick-disconnects — refer to “Installing the ‘quick-

disconnect’ system” on page one.

Note: the quick-disconnect system is not used with ROADMASTER ‘MS’

or ‘MX’ series mounting brackets. Instead, the tow bar is connected directly

to the mounting bracket with the base pins and linch pins.

With this exception, the instructions below apply.

2. Drive the vehicle within three or three-and-a-half feet of the motorhome

hitch receiver. The vehicle does not have to be perfectly centered to the

hitch receiver, just close. Then, put the vehicle in gear (park), set the

emergency brake and chock one of the wheels.

3. With the tow bar in the folded position, insert the stinger into the motor-

home hitch receiver, and attach the stinger to the hitch receiver with the

hitch pin and clip.

Attach the tow bar so that the locking mechanisms and the release

latch are pointing up. Components of the tow bar may be damaged if

the tow bar is attached with the release latch and the locking mecha-

nisms pointing down.

4. Hold both tow bar arms firmly, and rotate them up, so that they are

vertical.

Never release the tow bar arms when they are in the vertical posi-

tion. The arms can fall and cause severe personal injury.

5. Push the release latch forward, to bring both arms down to a horizontal

position.

Standing to one side, swing both arms away from you. Then, align

continued on page three