2

INSTRUCTIONS AND USER MANUAL

Modellsport

GENERAL INFORMATION

• The model is designed for the components specied by us. Unless

otherwise stated, servos and other electronic components are

designed for standard supply voltage. Recommended cell count for

Lipo batteries also refers to standard Lipos voltage of 3.7V per cell.

If you use other servos, a different motor and controller, batteries, or

propellers, please make sure they t rst. In the event of deviations,

corrections and adjustments must be made by yourself.

• Before starting construction, always put the servos into neutral. To

do this, switch on the remote control and move the joysticks and

trim buttons (save the one for the throttle) to the middle position.

Connect the servos to the corresponding outputs of the receiver

and supply them with a suitable power source. Please observe the

connection diagram and the operating instructions of the remote

control system manufacturer.

• Do not leave your model in the blazing sun or in your vehicle for long

periods of time. Too high temperatures can lead to deformation/dis-

tortion of plastic parts or blistering of covering foils.

• Before the rst ight, check the wing symmetry, tail unit and fuselage.

All parts of the model should have the same spacing from the left

and right wing or tail plane to the centre of the fuselage or the same

angle.

• If necessary, rebalance the propellers if vibrations are noticeable

when the motor is running up.

• Bubble formation in the covering foils normal to a certain extent due

to temperature and humidity differences and can be easily elimina-

ted with a foil iron or hairdryer.

• For models in shell construction („full GFRP/CFRP“), burrs may occur

at the seams due to the production process. Carefully remove them

with ne sandpaper or a le.

GENERAL SAFETY INFORMATION

• Be sure to read the safety instructions carefully before operating your

model.

• Always follow the procedures and settings recommended in the

instructions.

• If you are using remote-controlled model aircraft, helicopters, cars or

ships for the rst time, we recommend that you ask an experienced

model pilot for help.

• Remote-controlled models are not toys in the usual sense and may

only be used and operated by young people under 14 years of age

under the supervision of adults.

• Their construction and operation requires technical understanding,

careful craftsmanship and safety-conscious behaviour.

• Mistakes or negligence during construction, ying or driving can result

in considerable damage to property or personal injury.

• Since the manufacturer and seller have no inuence on the proper

construction/assembly and operation of the models, these risks are

expressly pointed out and any liability is excluded.

• Propellers on aircraft and all moving parts in general pose a constant

risk of injury. Avoid touching such parts at all costs.

• Note that motors and controllers can reach high temperatures duri-

ng operation. Avoid touching such parts at all costs.

• Never stay in the danger area of rotating parts with electric motors

with connected drive battery.

• Overcharging or incorrect charging can cause the batteries to ex-

plode. Make sure the polarity is correct.

• Protect your equipment and Models from dust, dirt and moisture. Do

not expose the equipment to excessive heat, cold or vibration.

• Use only recommended chargers and charge your batteries only

up to the specied charging time. Always check your equipment for

damage and replace defects with original spare parts.

• Do not use equipment that has been damaged or got wet due to

a fall, even if it is dry again! Either have it checked by your specialist

dealer or in the Robbe Service or have it replaced. Hidden faults can

occur due to wetness or a crash, which lead to a functional failure

after a short operating time.

• Only the components and accessories recommended by us may be

used.

• Do not make any changes to the remote control which are not de-

scribed in these instructions.

SAFETY NOTE FOR MODEL OPERATION

Attention, danger of injury!

• Always keep a safe distance from your model aircraft.

• Never y over spectators, other pilots or yourself.

• Always perform ight gures in a direction away from the pilot or

spectators.

• Never endanger people or animals.

• Never y near power lines or residential areas.

• Do not operate your model near locks or public shipping.

• Do not operate your model on public roads, motorways, paths and

squares, etc., but only in approved locations.

• Do not operate the model in thunderstorms.

• Before each ight, check your remote control system for sufcient

function and range.

• After ying, remove all batteries from the model.

Do not „aim“ the transmitter antenna at the model during operation. In

this direction, the transmitter has the lowest radiation. The best position

of the antenna is to the side of the model.

Use of devices with image and/or sound recording function:

If you equip your model with a video or image recording device (e.g.

FPV cameras, action scams etc.) or the model is already equipped

with such a device at the factory, please note that you could violate

the privacy of one or more persons by using the recording function. An

overight or driving on private ground without the appropriate permissi-

on of the owner or approaching private ground can also be regarded

as an invasion of privacy. You, as the operator of the model, are solely

and fully responsible for your actions.

In particular, all applicable legal requirements must be observed,

which can be found in the roof associations or the relevant authorities.

Failure to comply can result in substantial penalties.

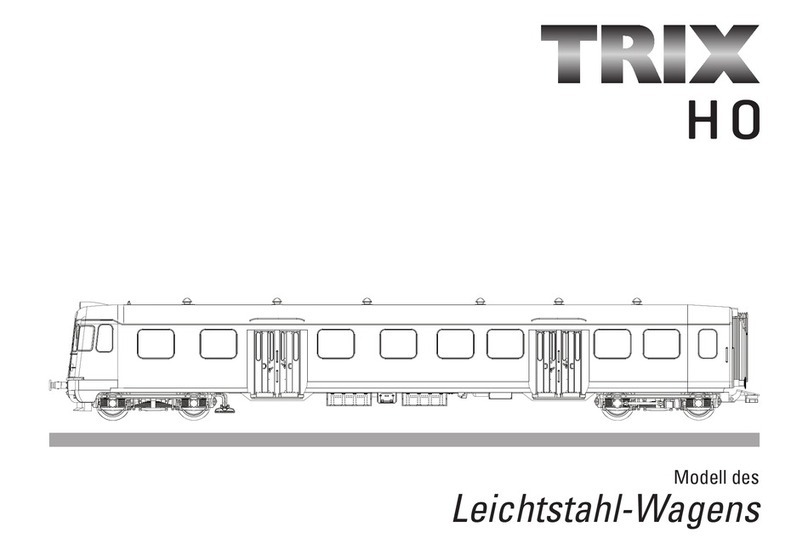

PREFACE

Dear model builder,

You have chosen the VAYU kit from our company. For this we would

like to thank you very much.

The VAYU is a ying wing with a wide range of use. The VAYU is deliver-

ed as a kit. The laser-cut wooden parts will be assembled and glued

with only a few steps in the plug-in box principle. Please read these

instructions carefully, even if you have already built many RC models.

We have given a lot of thought to detail solutions in order to keep the

construction effort as simple and low as possible without neglecting the

functionality.

The kit is manufactured with modern CNC technology. This gives you

the certainty that you will not experience any unpleasant surprises due

to mismatched components when building the VAYU.

Now we wish you a lot of fun building your new VAYU and especially

ying it afterwards.

PLEASE READ THIS MANUAL CAREFULLY BEFORE YOU START ASSEMBLING

THE MODEL.

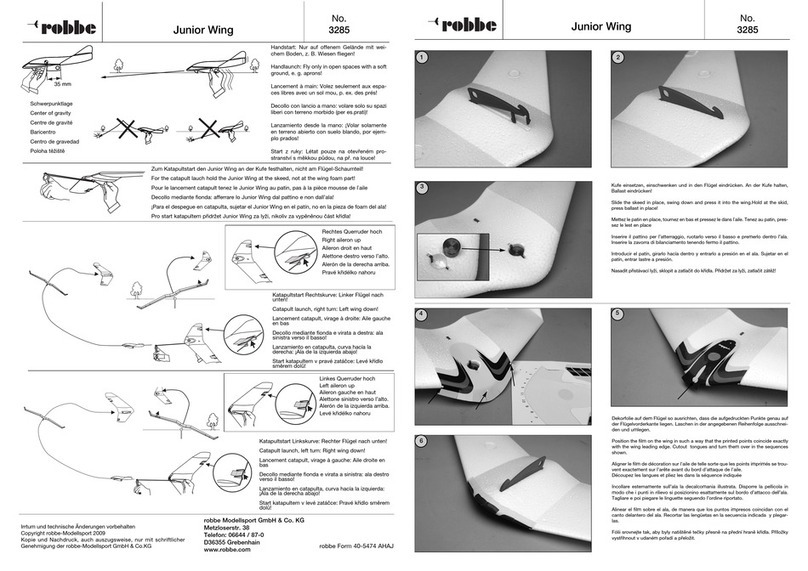

FLIGHT INSTRUCTIONS

• Before the rst ight, observe the instructions in the „Safety Instruc-

tions“ section.

• When ying the model, you should choose a day with as little wind as

possible

• A large, at area without obstacles (trees, fences power lines etc.) is

suitable for the rst ights.

• Please carry out a functional test of the drive train / power set and

remote control.

• After assembling the model on the aireld, check once again that

all model components such as wing, tail units, wing mounts, engine,

linkages, etc. are rmly and properly fastened.

• For a hand start a helper should be present, who can throw the mo-

del with enough thrust into the air.

• The start usually takes place against the wind.

• Do not stall the model near the ground

• Do not initiate tight turns in the immediate vicinity of the ground.

• Check the reactions of the model to the rudder deections. If ne-

cessary, adjust after landing to increase or decrease the deections

accordingly.

• The minimum ight speed must be at an adequate safety altitude.

• Initiate the landing with sufcient speed