2

ORDERING INFORMATION

AND MODEL NUMBERS

Order by model number in Table 1.

Table 1 - Measurement

MODEL NO. DESCRIPTION

571A-A Acceleration, 0 - 5 G peak

571A-B Acceleration, 0 - 10 G peak

571A-C Acceleration, 0 - 20 G peak

571A-D Velocity, 0 - 0.5 IPS peak

571A-E Velocity, 0 - 1 IPS peak

571A-F Velocity, 0 - 2 IPS peak

Accessory Items

PART NO. DESCRIPTION

086568A0016* Standard IP66 Cable - 16 foot,

2 conductor shielded cable,

MIL-C-5015 2 socket connector with

splash-proof boot.

086568A0032 Standard IP66 Cable - same as above

except 32 foot

086568A0064 Standard IP66 Cable - same as above

except 64 foot

086568A0112 Standard IP66 Cable - same as above

except 112 foot

086568B0016** IP68 Cable - 16 foot, 2 conductor

shielded cable, MIL-C-5015 2 socket

connector with splash-proof boot

086568B0032 IP68 Cable - same as above except 32

foot

086568B0064 IP68 Cable - same as above except 64

foot

086568B0112 IP68 Cable - same as above except

112 foot

435KB311 Mounting stud for 1/4-28 tapped hole

(supplied with transmitter)

435KB311-01 Mounting stud for 3/8-24 tapped hole

435KB311-02 Mounting stud for M8 X 1.25-6G

tapped hole

435KB311-03 Mounting stud for M6 X 1.00-6G

tapped hole

* 16 foot standard cable is a stock item.

For other cables allow 6-8 weeks delivery.

Cable accessory must be ordered separately.

** For submersible applications use IP68 cable.

SPECIFICATIONS

DYNAMIC

Output (±5% of span) ……………..……....… 4 – 20 mADC

Vibration Range ………………………..…..…… See Table 1

Frequency Response:

- 3 dB …..………………….….…... 2 Hz – 2 kHz

Repeatability ………………………………..………..... ±2%

Resonant Frequency, mounted, nominal ………..…… 28 kHz

Transverse Sensitivity, max. …………..…………..…….. 5%

ELECTRICAL

Power Requirements (Two wire loop power):

Voltage Source …………….....14 VDC – 30 VDC

Loop Resistance …….…………………….……….see page 4

Grounding …………………………………….. case isolated,

internally shielded

Protection ………………….……… reverse wiring, overload,

ESD & EMI

ENVIRONMENTAL

Temperature Range …….…..…-40°to 85°C (-40°to 185°F)

Vibration Limit ……………………………………250 g peak

Shock Limit ………………………………….….2,500 g peak

Electromagnetic Sensitivity, equiv. g …………... 10 µg/gauss

Sealing ………………………….. hermetic, NEMA 4X, IP68

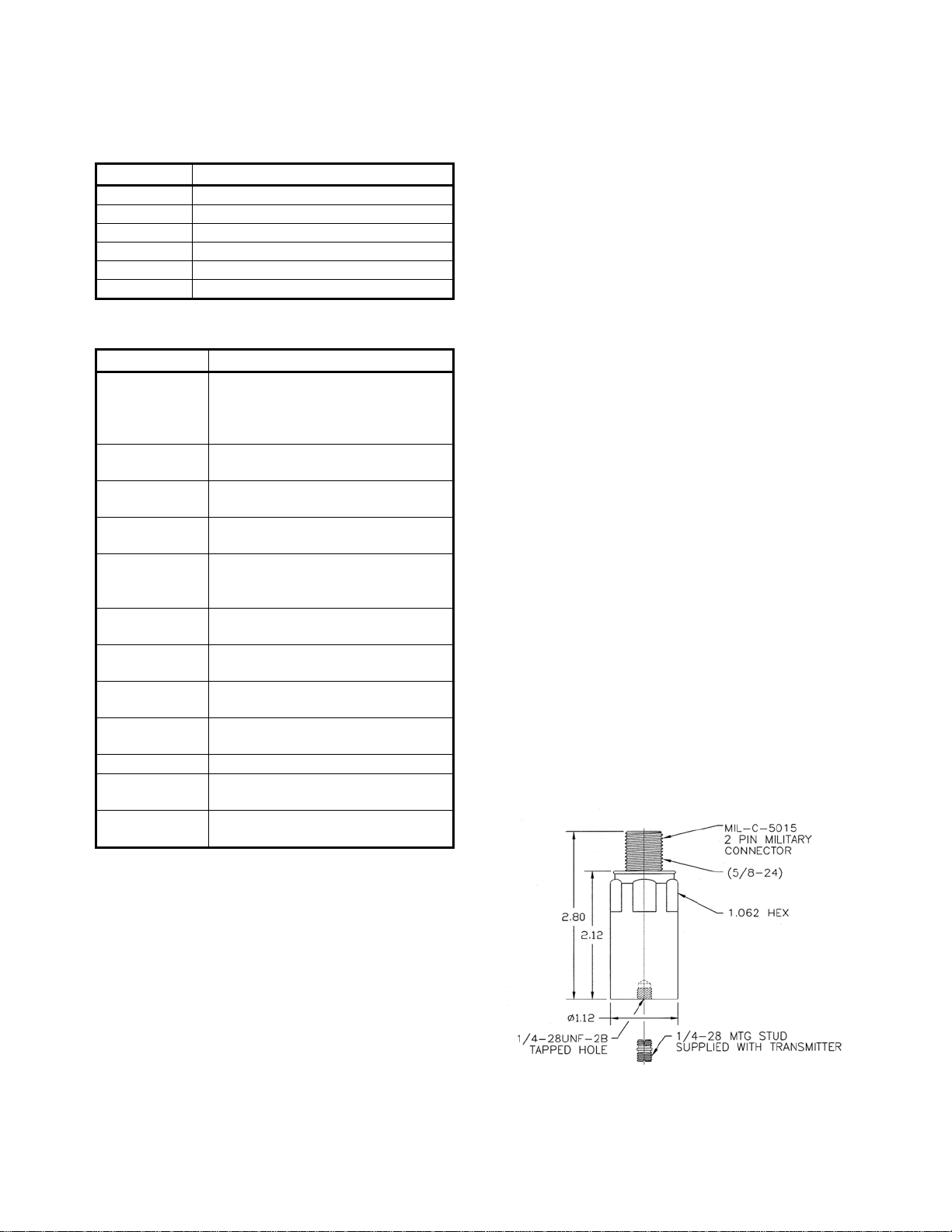

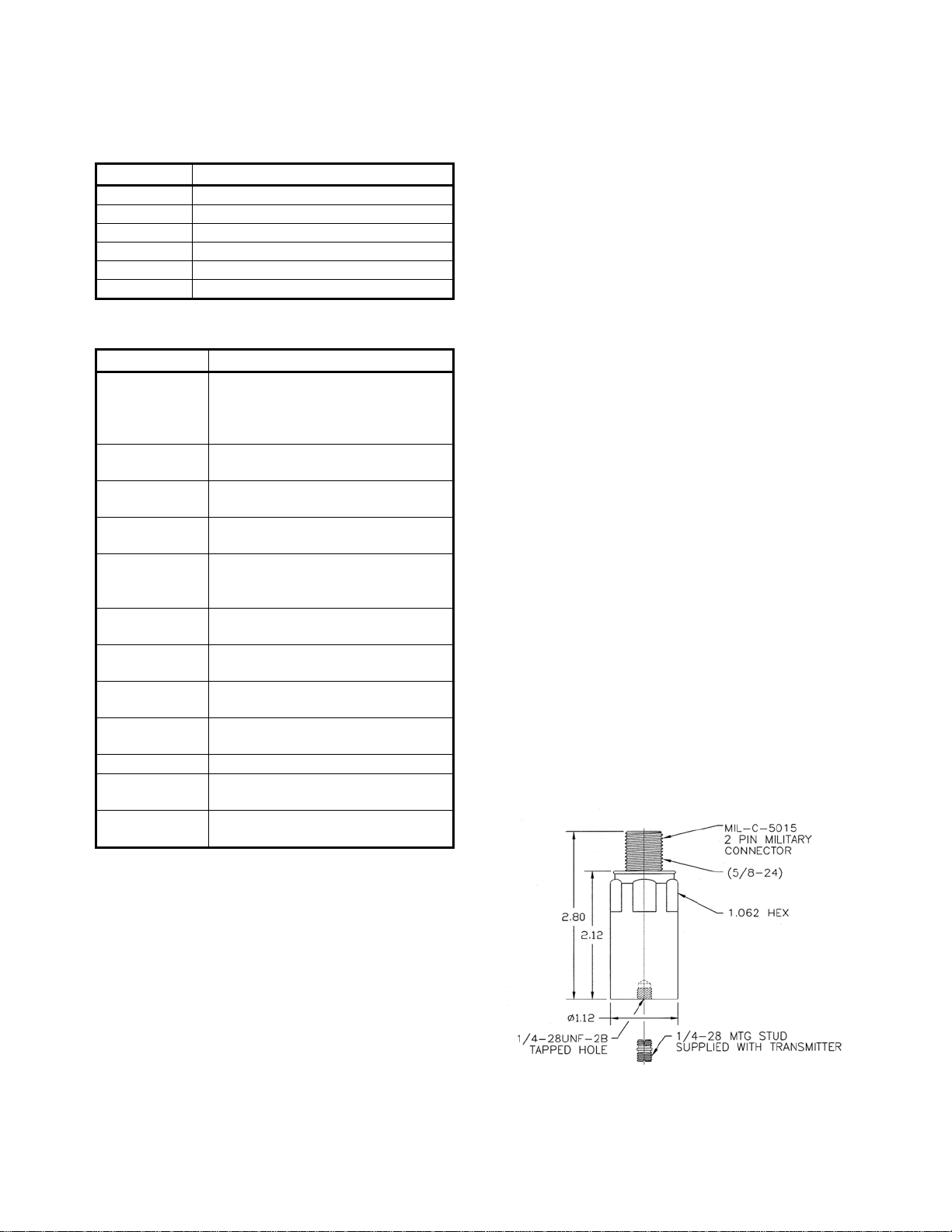

PHYSICAL

Sensing Element Design ………………….PZT ceramic/shear

Weight ……………………………………………..162 grams

Case Material ………………………….... 316L stainless steel

Case Rating ………………………………... IP68, NEMA 4X

Mounting ……………………………..…1/4 – 28 tapped hole

Supplied Accessories …………………..1/4-28 mounting stud

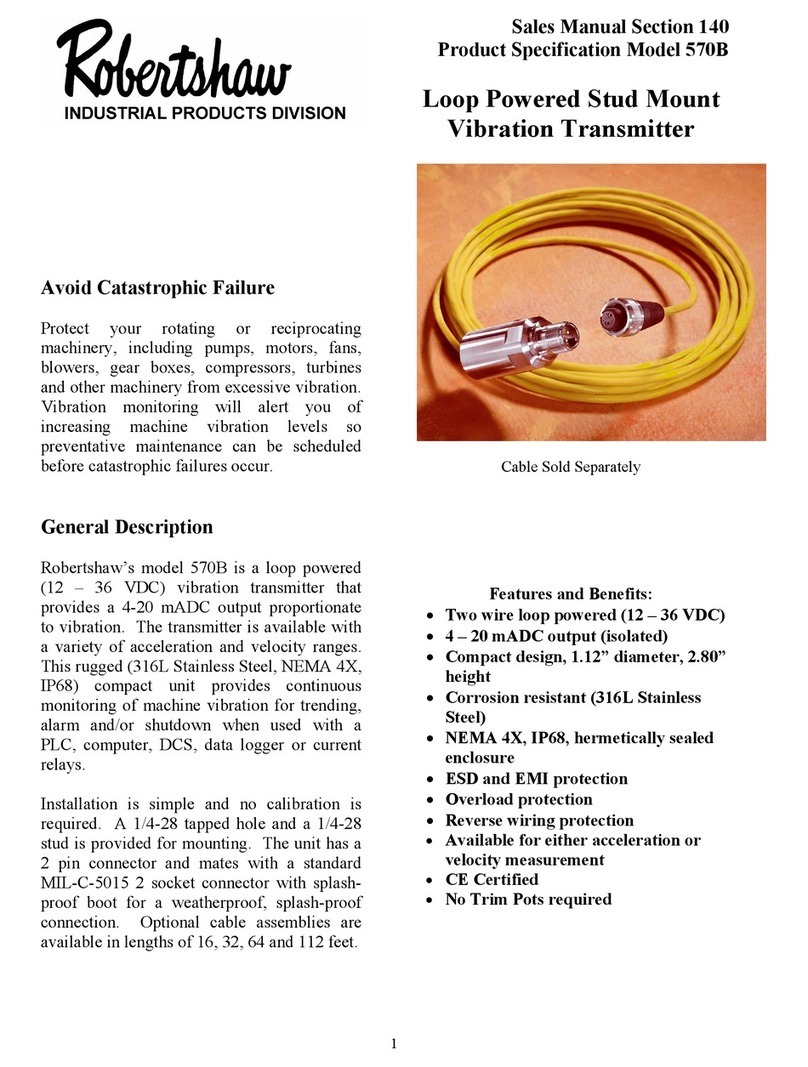

Output Connector ………………….….... MIL-C-5015, 2-pin

Pin A (white lead) ………………………. plus (+)

Pin B (black lead) ……………………….minus (-)

Cabling ……………………………… two conductor shielded

(see Accessory Items Table)

Torque Limit ………………………………... 30 in. lbs. Max.

Warranty ………………………………………………. 1 year