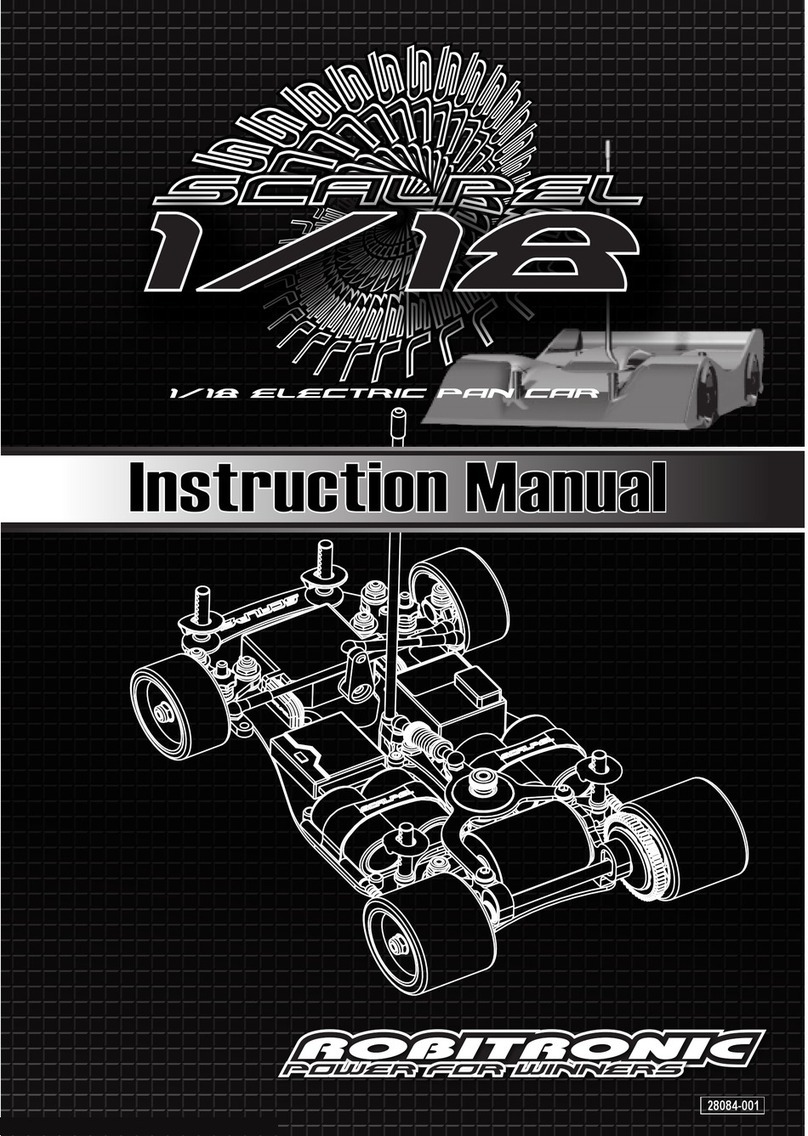

10. Optimal Installation of a Brushless system

If you would like use a brushless system in your SCALPEL, you need the special brushless motor mount (RA2069)to use

a brushless system from MAMBA or TEKIN. In the picture you can see a TEKIN RAGE brushless system installed in the

SCALPEL. This System fits better in the vehicle, if you remove the housing from the Speedo and enclose it in heat shrink.

In order to achieve cleaner wiring, the switch was removed from the Speedo and replaced by a short bridge. Likewise you

can remove the plugs between the engine and Speedo and solder them directly.

11. Vehicle settings

Here are some important fundamental tips to help set up your new Scalpel.

TWEAK

Follow the sequence of steps in order to adjust the tweak of the Scalpel correctly. This will ensure that you set up your kit

so that it is easier to handle and will drive straight forward.

a. Front axle: Adjust the wheel camber to approximately 0° with the help of the suspension rebound movement

set-screws.

b. Adjust the pressure of the spring to be equal on the left and right site.

c. Set the chassis on a surface that allows the front axles to extend down as far as possible. Use the set screws

on the arms to adjust the ride height so that both front arms travel down the same amount.

d. Check the camber of both front wheels again, readjust to 0° if necessary.

e. Next check the toe-in of the front axle. Optimal is 0°.

f. Ride Height: Set the vehicle on a level surface with the wheels on and check the ride height. The ride height

should be approximately 3-4mm. If necessary you can change the ride height by using the washers at the

knuckle. To adjust the rear ride height you can change out the transmission plates.

g. Rear axle: Loosen the nut on the friction disk absorption system, in order to allow friction free movement of

the power pod. Raise the chassis off the ground so that the wheels are touching. (During this procedure the

front wheels should be touching the ground at all times.) If the rear wheels touch at the same time, the power

pod is perfectly adjusted. If one rear wheel touches first, you have to correct it with the adjusting screws at the

t-bar, until both rear wheels touch the ground at the same time.