3

TOOL SAFETY

1. The POWER DRIVE is made to thread pipe. Follow instruc-

tionsinthisOperator’sManualontooluse.Otherusesmay

increasetheriskofinjury.

2. Secure POWER DRIVE using the 700V optional safety arm

(#05275). Do not use this POWER DRIVE without the safety

arm. Thesafetyarmresiststorquedevelopedduringthreading

andpreventslosingcontrolofthetool.

3. Do not use dull or damaged dies.Sharpcuttingtoolsare

lesslikelytobindandtooliseasiertocontrol

FUNCTIONAL DESCRIPTION

TheREED700APDPowerDriveisanpneumatic-motor-driven,

heavy-dutypowerdrivewhichprovidespowerforthreadingpipe

andconduitupto2”indiameter.The700APDisabletodrive

gearedthreaders,tappingmachines,orotherequipment.

SPECIFICATIONS / STANDARD EQUIPMENT

Threading Capacity

PipeandConduit:1/8”through2”righthandthreadsonly.

Motor, Gears, Speed

• Pneumatic, 4 HP motor. 28 RPM, up to 400 lb-ft torque

• Deadmanswitch,springreturntoOFFposition.

• Forward,neutralandreversedirectionalvalve.

• Spurgearreduction,bearingmountedshafts,gearspacked

ingrease.

• Spring-loadedadapterpawls.

• Gearcaseiscastaluminum.Handleiscastaluminum.

• Machineweight:46lbs(20.9kg).

• The700Vsafetyarm(standard)ishighlyrecommendedfor

operationtoabsorbpowerdrivetorque.

• SafetyArmweight:7lbs(3.2kg).SafetyArmisductileiron

andsteel

Auxilary Equipment Required:

Aircompressorcapableofsustaining80SCFM@90psi.,2.4cu.

m/min@6.2Bar.

Hosesequippedwithcompatiblettings.Fittingsshouldbeafull

boretypetomaximizemotorspeed.

USE A FILTER-REGULATOR-LUBRICATOR (FRL) UNIT not

included.ReedrecommendsFRL#97591.

NOTE:Itisimperativethatalter,regulator,lubricatorbeem-

ployedwhenrunningthe700APDPneumaticPowerDrive.The

airshouldbeclean,dry,andlubricatedtomaximizemotorlifeand

performance.

USE NONFLUID OIL® AIR LUBRICANT.

Thisproductmixeswithwaterinsidethelineandviathelubrica-

torisintroducedasamistintheairstreamtoprovidelubrication

fairlyquickly.SettheOilerdriponthelubricatorto3-4dropsper

minute.NonuidlubricatingoilissoldbythequartfromReedas

UPOIL#97583.

Reed Manufacturing700APD Power Drive

OPERATION

For threading with drophead die heads only, such as Reed

R12+ Dropheads with R12+ Segmental Dies.

WARNING: OPERATOR SHOULD BE THOROUGHLY

FAMILIAR WITH SAFETY INFORMATION BEFORE

ATTEMPTING TO OPERATE THIS EQUIPMENT.

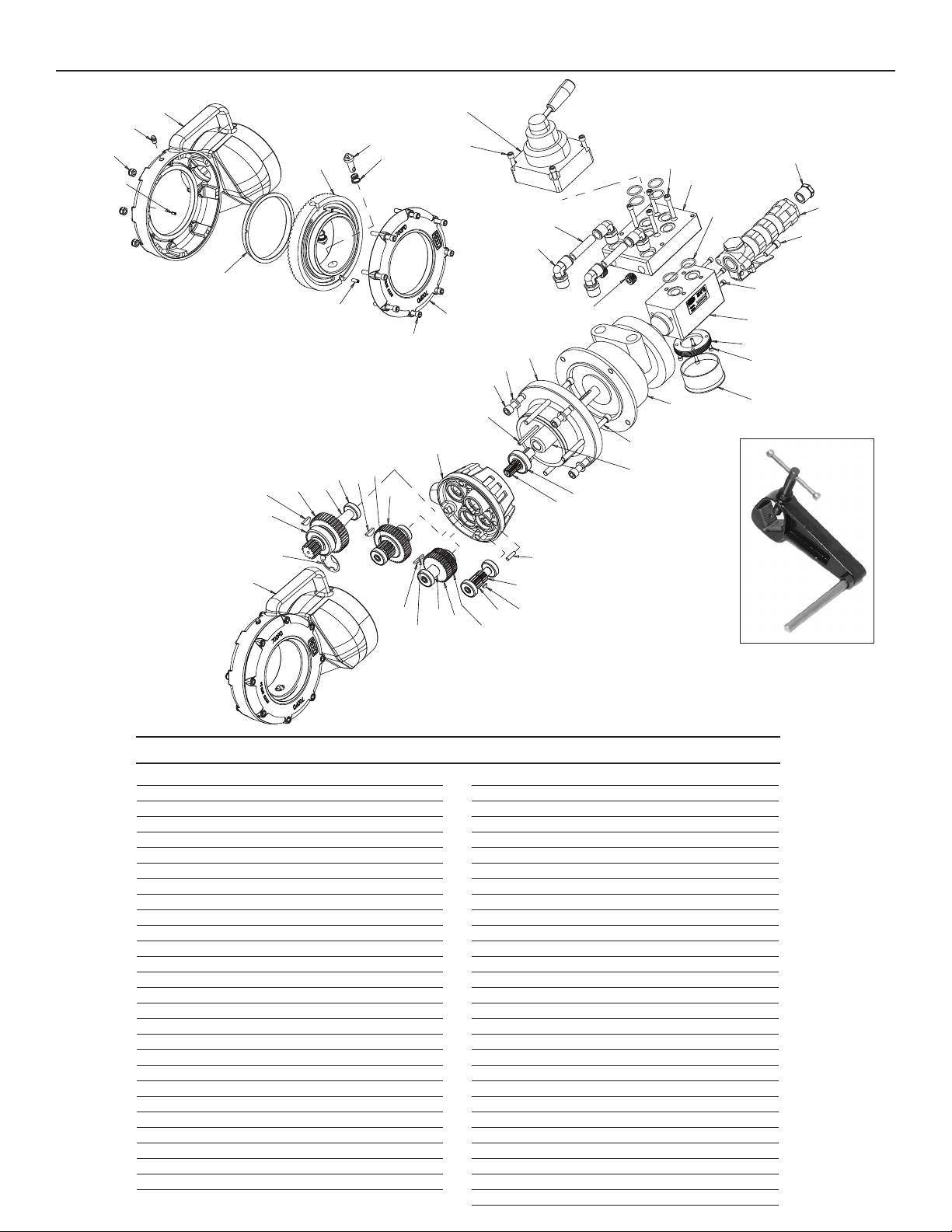

See Figures 1-5.

1.Pushdieheads,smallendrst,squarelyintopowerdrive

openinguntilspring-loadedadapterpawlscatchsecurely.

NOTE:Installationcanbeoneithersideoffacegear.

2.Securepipeinportabletripodorbenchvise,ifavailable.

WARNING: WHEN THREADING ANY SIZE PIPE, THE 700V

OPTIONAL SAFETY ARM SHOULD ALWAYS BE USED AND

SECURELY LOCKED ON PIPE BECAUSE OF TORQUE DE-

VELOPED DURING THREADING.

3.Ensureatleast6”(150mm)ofexposedpipeend.Position

700Vsafetyarmbetween4”(100mm)and7”(180mm)from

theendofthepipesotheendoftheguidebaris1”(25mm)to

4”(100mm)beyondtheendofthepipe.Clampthesafetyarm

securelyontothepipe.Whenthreading11/2”and2”pipe,itis

besttoplacethesafetyarmjust4”(100mm)fromtheendof

thepipeforrmestcontrolofhighertorque.

4.Placedieheadoverendofpipe.Makesurepowerdriveis

correctlypositionedonsupportarm.Forrighthandthreads,die

headshouldrotateclockwise(lookingatfaceofdiehead).

NOTE:Duringthreading,applyplentyofREEDThreadguardcut-

tingoiltodies.

5.Simultaneouslyactuatedeadmanswitchandexertpressure

againstdieheadwithpalmoffreehandtomakesurethreadis

started.

6.Keepdeadmanswitchdepresseduntilendofpipeisevenwith

edgeofchaser,thenreleasedeadmanswitch.

WARNING: HOLD ON TO POWER DRIVE HANDLE FIRMLY

TO RESIST INITIAL TORQUE WHILE BACKING OFF DIE

HEAD.

7.Aftercompletionofthethread,andafterthemotorhas

stopped,actuatethedirectionalvalveinthereversedirection.

8.Whendiescleartheendofthepipe,griphandleontopofthe

powerdriveandremovethepowerdrivefromthepipe.Re-

leasethesafetyarmandremoveitaswell.

MAINTENANCE

WARNING: ALWAYS DISCONNECT AIR SUPPLY BEFORE

SERVICING POWER DRIVE.

NOTE: Ifanymaintenanceisrequired,takepowerdrivetoan

authorizedREEDwarrantyrepaircenterorreturntofactory.

Lubrication

Gearinghasbeengreasedatthefactoryanddoesnotrequire

additionalgrease.Itisbesttoblowdustoffthemachineafter

workisover.