SuperSigma2 QRM PMS –V01.02.02 17-1-2020 Page 3 (58) ©2019 DMC GmbH Herten Germany

CONTENTS

1DMC PHILOSOPHY –INTRODUCTION ..................................................................................................................... 5

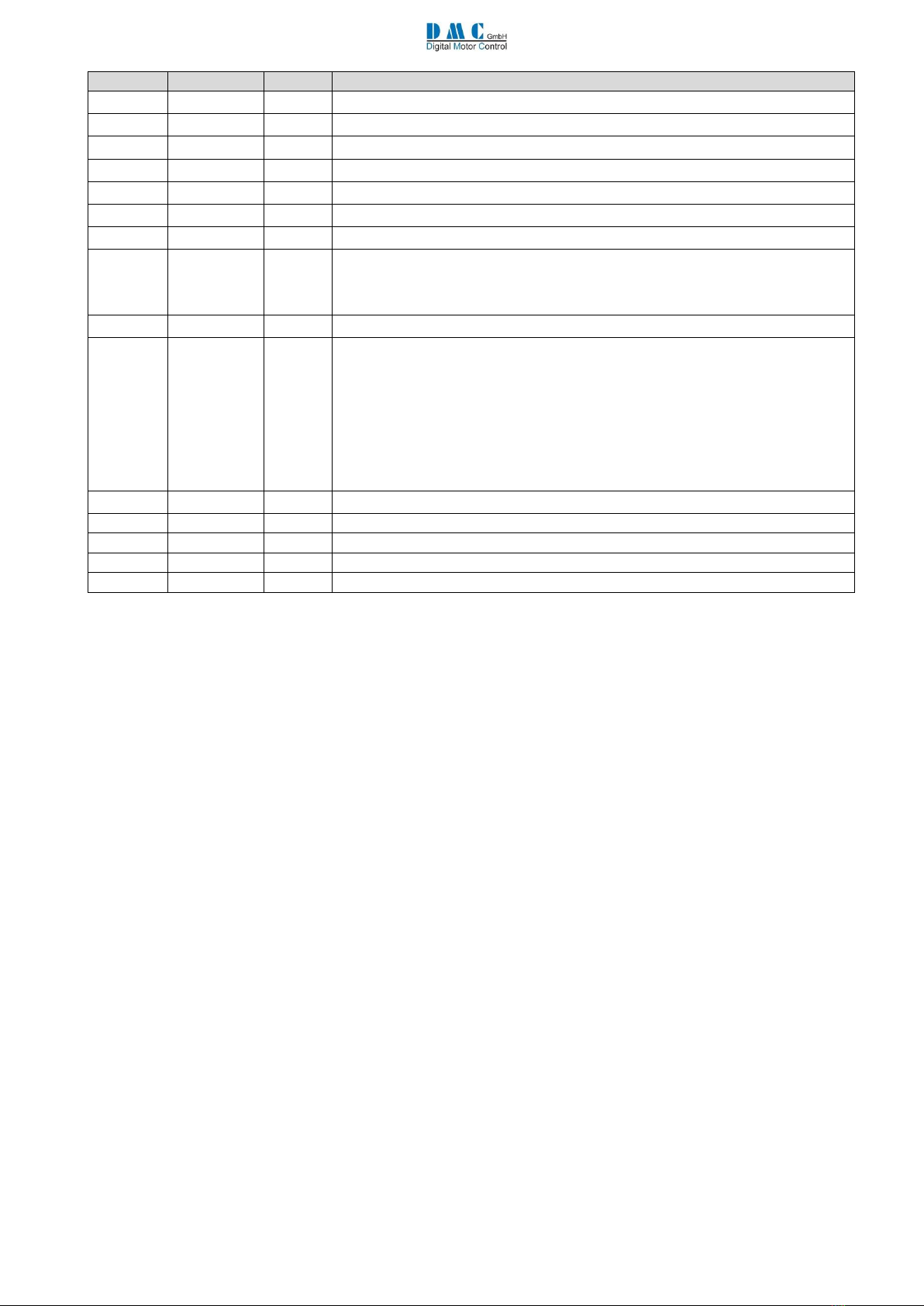

2SUPERSIGMA2 VARIANTS ...................................................................................................................................... 6

3CONTROLLER FEATURES......................................................................................................................................... 7

4TECHNICAL SPECIFICATIONS................................................................................................................................... 8

4.1 ELECTRICAL ..............................................................................................................................................................8

4.1.1 Voltage specifications: .....................................................................................................................................8

4.1.2 Current specifications: .....................................................................................................................................8

4.2 ENVIRONMENTAL ......................................................................................................................................................8

4.3 MECHANICAL ...........................................................................................................................................................9

5INSTALLATION INSTRUCTIONS ............................................................................................................................. 10

5.1 SAFETY..................................................................................................................................................................10

5.2 MECHANICAL INSTALLATION AND COOLING ..................................................................................................................10

5.3 POWER WIRING ......................................................................................................................................................10

5.4 LIGHT WIRING.........................................................................................................................................................10

5.5 SPEED SENSOR CABLING............................................................................................................................................10

5.6 CONTACTORS .........................................................................................................................................................11

5.7 FLASHING NEW SOFTWARE........................................................................................................................................11

5.8 POWER UP DELAY ...................................................................................................................................................11

6EMC GUIDELINES.................................................................................................................................................. 12

6.1 POWER CABLES.......................................................................................................................................................12

6.2 SIGNAL CABLES.......................................................................................................................................................12

6.3 CONTROLLER..........................................................................................................................................................12

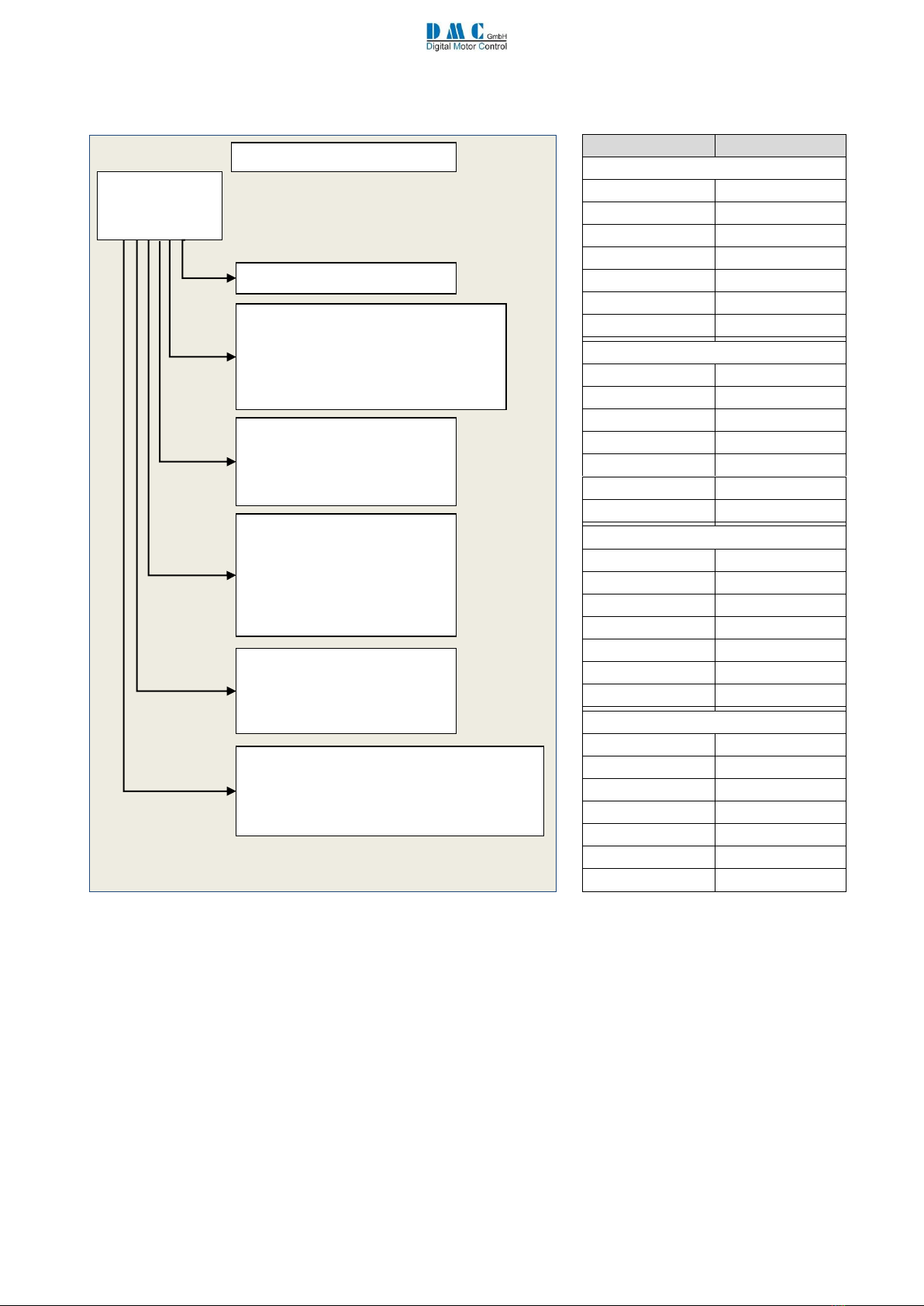

7CALIBRATOR ........................................................................................................................................................ 13

7.1 THE CALIBRATOR.....................................................................................................................................................13

7.2 CALIBRATOR MAP....................................................................................................................................................14

7.3 DMC PC PROGRAMMER..........................................................................................................................................14

8DASHBOARD DISPLAY .......................................................................................................................................... 15

8.1 GENERAL INFORMATION ...........................................................................................................................................15

8.2 DISPLAY SETUP MENU ..............................................................................................................................................15

8.3 DISPLAY FEATURES SETUP.........................................................................................................................................16

8.4 DISPLAY ICONS .......................................................................................................................................................17

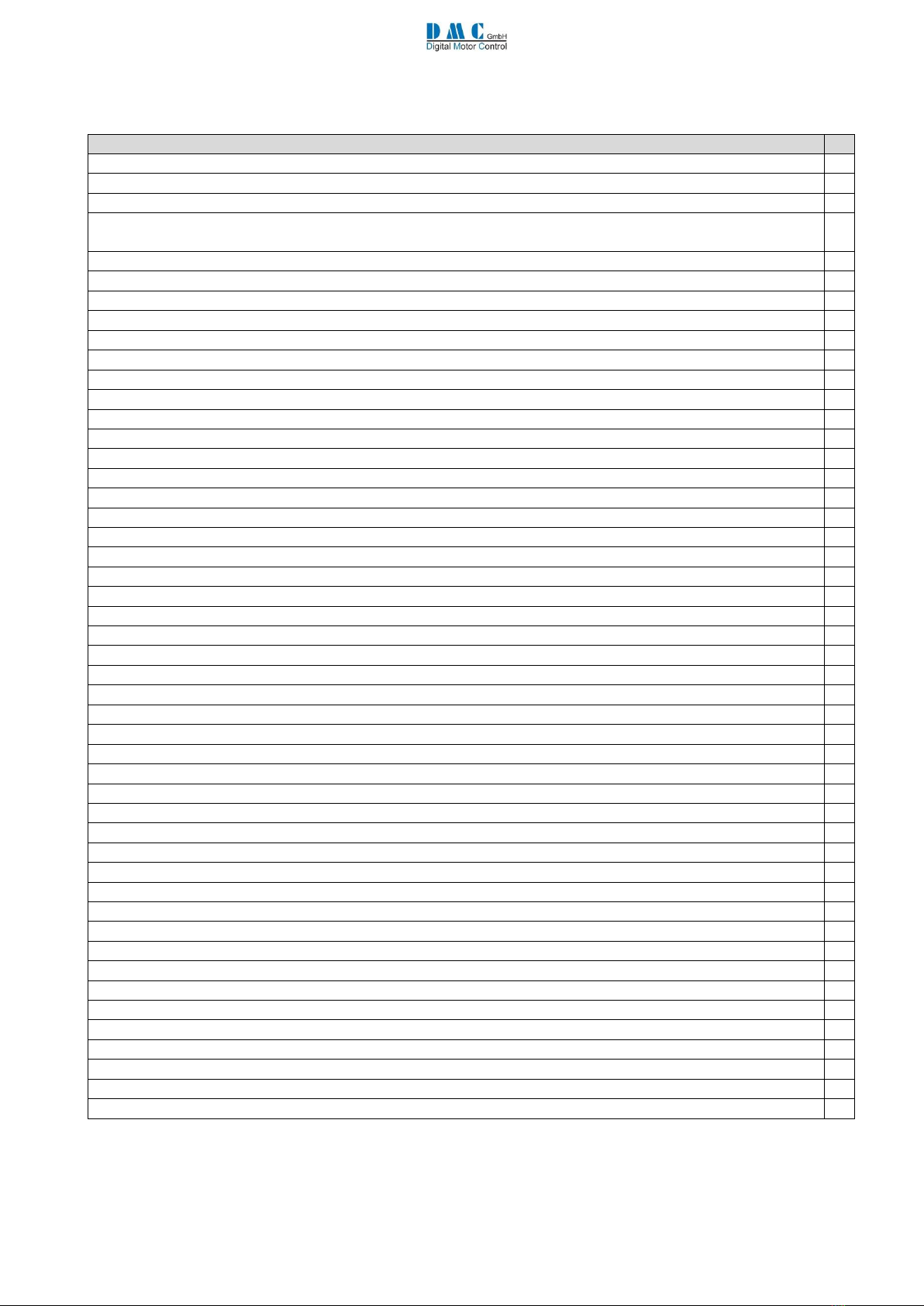

9PARAMETERS....................................................................................................................................................... 18

9.1 MENU 1“ADJUSTMENT”..........................................................................................................................................18

9.2 MENU 1“TRACTION ADJUSTMENTS”..........................................................................................................................18

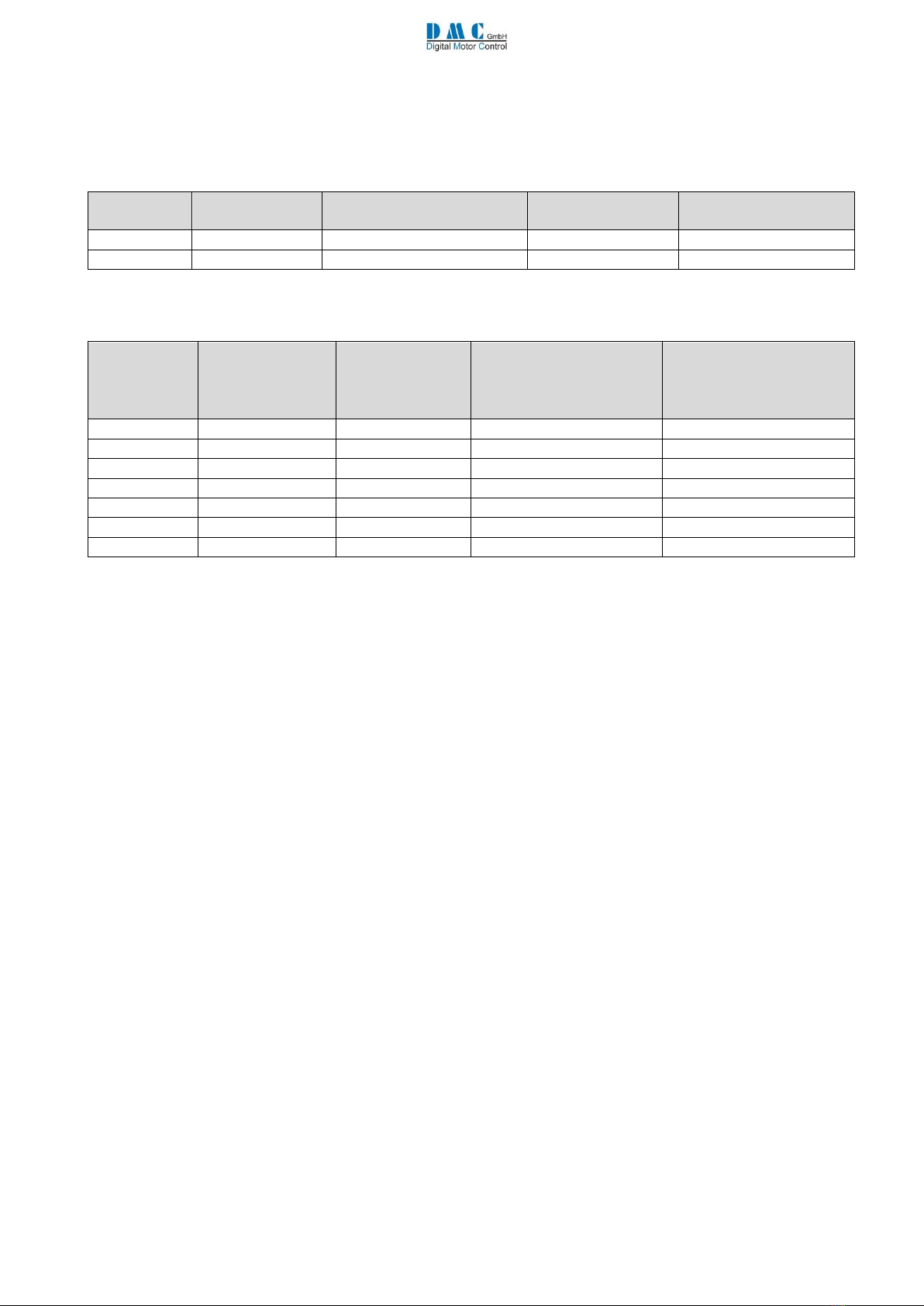

9.2.1 Neutral braking setup options .......................................................................................................................20

9.2.2 Neutral braking setup in speed control mode (control mode 0) ....................................................................20

9.2.3 Neutral braking setup in torque control mode (control mode 1) ...................................................................20

9.2.4 Neutral braking setup in torque control mode (control mode 2) ...................................................................20

9.2.5 Hill Hold..........................................................................................................................................................20

9.3 MENU 1“PUMP ADJUSTMENTS”...............................................................................................................................21

9.4 MENU 2“STATUS”..................................................................................................................................................22

9.4.1 Status tables...................................................................................................................................................23

M2-3 BDI States table..............................................................................................................................................23

M2-6 Drive and brake status table ..........................................................................................................................23

M2-7 Speed limits table...........................................................................................................................................23

M2-8 Torque limits table .........................................................................................................................................23

M2-9 Motor limits table ..........................................................................................................................................23

9.5 MENU 3“CONTROLLER SETUP”.................................................................................................................................24