Condensing Gas Fired Unit Heaters – G Series: Manual of installation, use and maintenance

Ed. 09/2018 1

TABLE OF CONTENTS

Section1: GENERAL INFORMATION AND TECHNICAL CHARACTERISTICS..............2

1.1 GENERAL WARNINGS.....................................................................................................................2

1.2 OPERATION OF THE UNIT ..............................................................................................................3

1.3 CONSTRUCTIVE CHARACTERISTICS............................................................................................5

1.4 TECHNICAL DATA ............................................................................................................................6

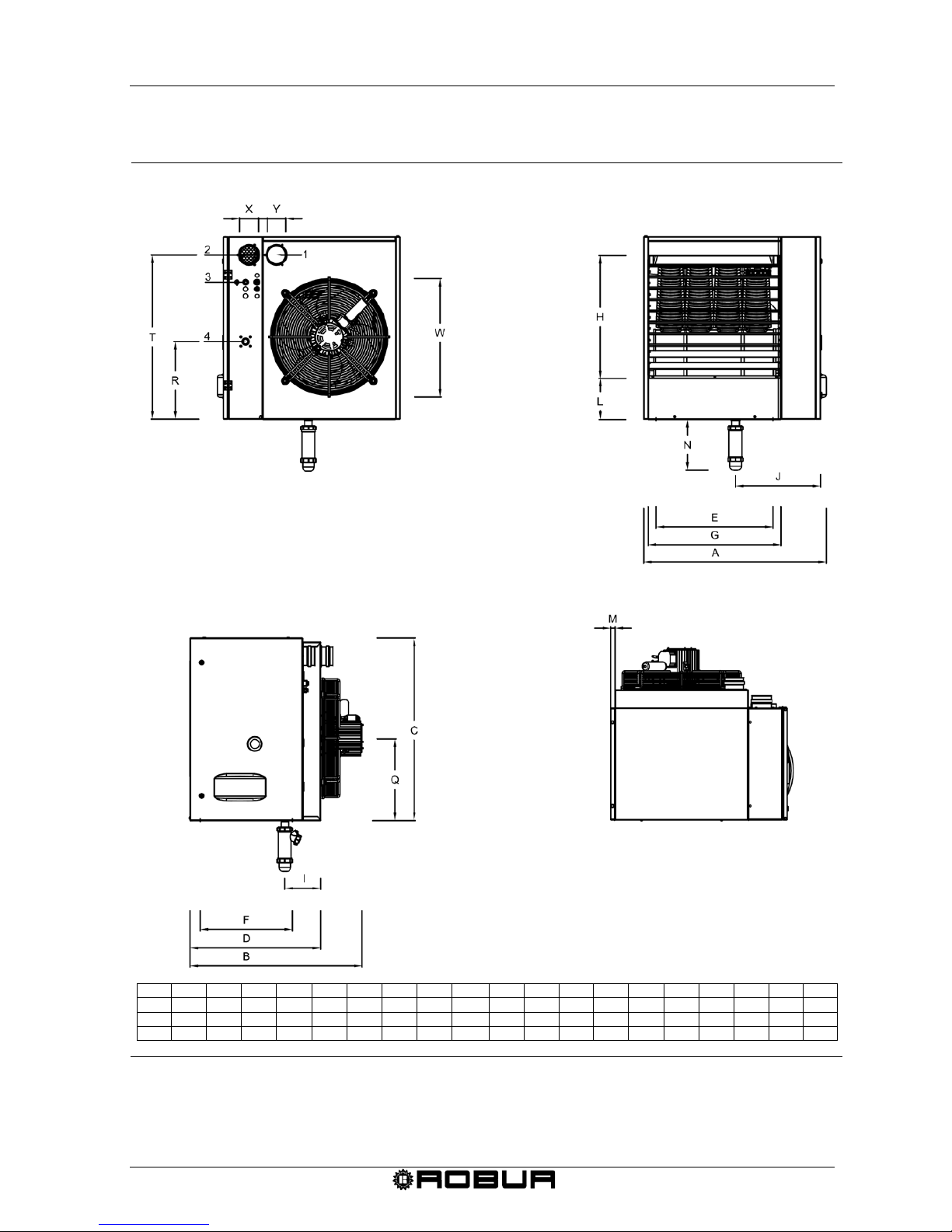

1.5 DIMENSIONS OF G SERIES GAS FIRED UNIT HEATER...............................................................7

section 2: END USER........................................................................................................9

2.1 FUNCTIONS OF CHRONOTHERMOSTAT......................................................................................9

2.2 SETTING THE TIME AND DAY ON THE CHRONOTHERMOSTAT............................................. 10

2.3 SETTING THE COMFORT, ECONOMY AND ANTI- FREEZING TEMPERATURES ON THE

CHRONOTHERMOSTAT ............................................................................................................... 10

2.4 PROGRAMMING OF THE DAILY SET POINT ON THE CHRONOTHERMOSTAT...................... 11

2.5 SELECTING A PRESET DAILY PROFILE ON THE CHRONOTHERMOSTAT ............................ 13

2.6 SELECTING A PRESET WEEKLY PROFILE ON THE CHRONOTHERMOSTAT........................ 13

2.7 TIMED FUNCTIONS OF THE CHRONOTHERMOSTAT............................................................... 15

2.8 KEYBOARD BLOCK....................................................................................................................... 17

2.9 INFORMATION SCREEN OF THE CHRONOTHERMOSTAT....................................................... 18

2.10 SELECTION MENU WINDOW ....................................................................................................... 19

2.11 MALFUNCTION WARNINGS ......................................................................................................... 20

2.12 TABLE OF ICON MEANINGS ON CHRONOTHERMOSTAT DISPLAY........................................ 22

2.13 HOW TO USE THE UNIT HEATER................................................................................................ 23

2.14 HOW TO USE THE UNIT WITH THE CHRONOTHERMOSTAT.................................................. 25

2.15 HOW TO USE THE UNIT WITHOUT A CHRONOTHERMOSTAT................................................ 30

2.16 SETTING FIELD.............................................................................................................................. 31

2.17 END OF SEASON........................................................................................................................... 32

section 3: PLUMBER INSTALLER..................................................................................33

3.1 GENERAL RULES FOR INSTALLATION OF THE APPLIANCE................................................... 33

3.2 INSTALLATION SEQUENCE ......................................................................................................... 33

3.3 SIZE AND INSTALLATION OF THE AIR INLET / EXHAUST FLUE.............................................. 35

3.4 CONDENSATE DRAINAGE ........................................................................................................... 44

section 4: ELECTRICAL INSTALLER.............................................................................46

4.1 HOW TO CONNECT THE HEATER TO THE ELECTRICAL SYSTEM......................................... 46

4.2 HOW TO CONNECT THE CHRONOTHERMOSTAT TO THE HEATER ...................................... 46

4.3 UNIT OPERATION WITH EXTERNAL CONSENT......................................................................... 47

4.4 REMOTE SIGNALLING OF THE ANOMALIES.............................................................................. 48

4.5 INSTALLATION WIRING DIAGRAM .............................................................................................. 49

4.6 WIRING DIAGRAM FOR MULTIPLE HEATER WITH ONE PROGRAMMER............................... 50

section 5: ASSISTANCE AND MAINTENANCE.............................................................52

5.1 START UP OF THE UNIT............................................................................................................... 52

5.2 HOW TO REGULATE THE GAS VALVE ....................................................................................... 52

5.3 CONVERSION TO ANOTHER TYPE OF GAS.............................................................................. 54

5.4 MAINTENANCE.............................................................................................................................. 55