Transport and positioning

10

2

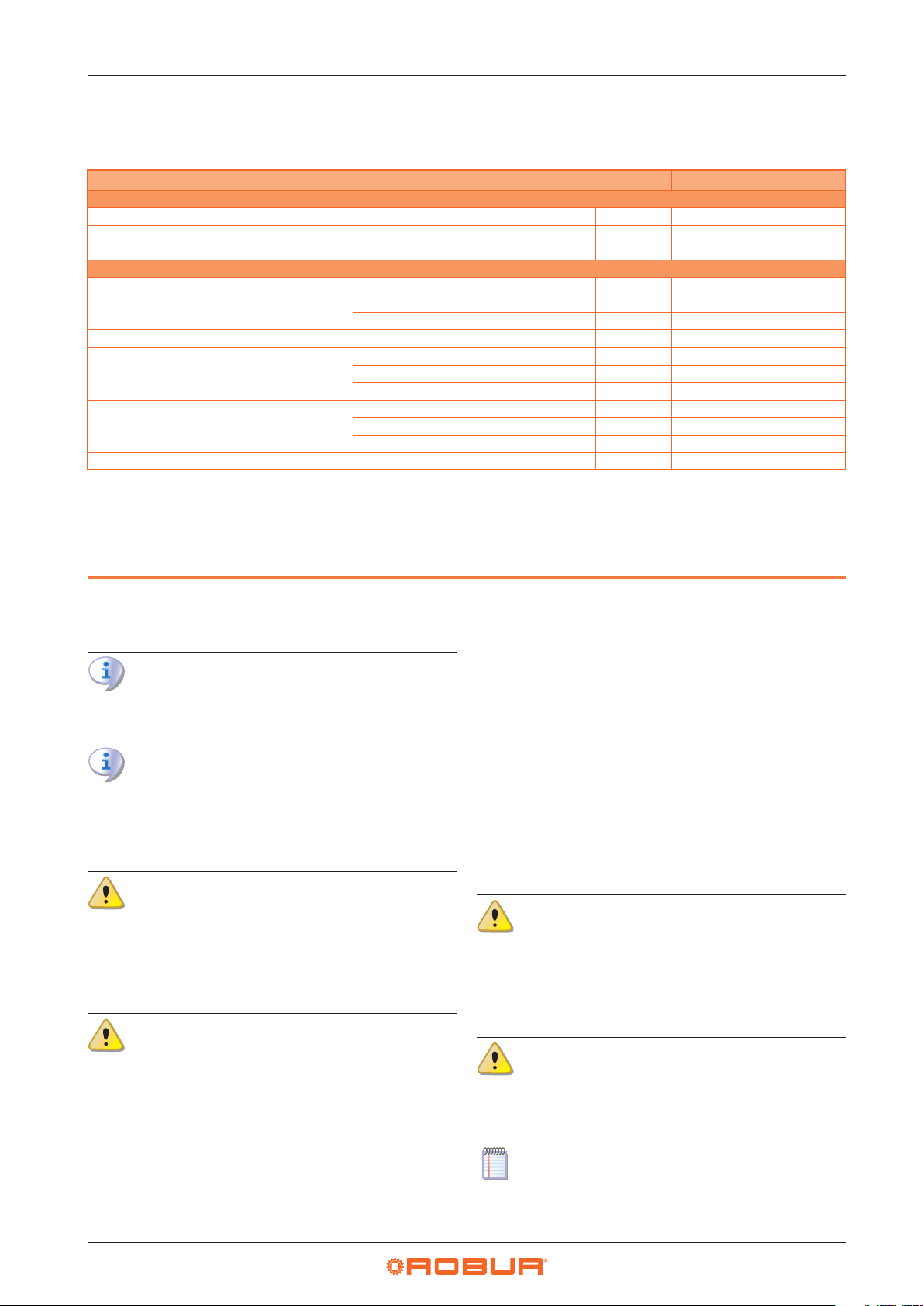

Table3.1Network gas pressure

Gas supply pressure [mbar]

Product category Countries of destination G20 G30 G31 G30 G31

II2H3B/P CH, CZ, DK, EE, FI, GR, IT, LT, NO, RO, SE, SI, SK 20 30

AT 20 50

II2H3P CH, CZ, ES, GR, HR, IE, IT, LT, PT, SI, SK 20 37

II2H3+ CH, CY, CZ, ES, GB, GR, IE, IT, LT, PT, SI, SK, TR 20 28-30 37

The appliance gas supply pressure, both static and dynamic, must comply with the values in theTable, with a tolerance of ± 15%.

3.3.5 Vertical pipes and condensate

▶

Vertical gas pipes must be tted with siphon and dis-

charge of the condensate that may form inside the

pipe.

▶

If needed, insulate the piping.

3.3.6 LPG pressure reducers

With LPG the following must be installed:

▶

A rst stage pressure reducer, close to the liquid gas

tank.

▶

A second stage pressure reducer, close to the appli-

ance.

Pressure reducers must always be installed outside

the building.

3.4 COMBUSTION PRODUCTS EXHAUST

Compliance with standards

The appliance is approved for connection to a

combustion products exhaust duct for the types

shown in Table 1.1

p.8

.

3.4.1 Flue gas exhaust and combustion air

intake connection

▶

Ø 60/100 mm on the rear (Figure 1.1

p.8

)

3.4.2 Installation types

The ue gas exhaust/air intake of the TS 2000 gas-red

convectors must be carried out, using the supplied coax-

ial pipes, on the installation wall (maximum pipe length

50 cm).

Warnings

The installation of coaxial pipes with a vertical

downward outlet is prohibited (leads to recircula-

tion of ue gas with lock-out of the appliance).

It is forbidden to install coaxial pipes with a vertical

outlet upwards (due to rain, water, objects inltra-

tion, with consequent lock-out of the appliance).

3.5 INSTALLATION PROCEDURE

In accordance with the installation project, prepare the

gas supply line and make the holes for the ue and com-

bustion air intake pipes.

3.5.1 Install the gas-red convector on the wall

1. Check the packaging for visible signs of damage, oth-

erwise, notify the carrier immediately.

2. Remove the gas-red convector from its packaging

by rst removing the air intake and ue gas exhaust

pipes. Do not damage or discard the cardboard jig

with the drilling template required for installing the

gas-red convector.

3. Fix the jig to the wall where the gas-red convector is

to be installed, making sure it is perpendicular to the

oor.

4. Mark on the wall the holes for the air intake and ue

gas exhaust duct and for the two wall plugs that will

hold the support bracket.

5. Drill the hole (Ø 100 mm) to house the coaxial pipe

and holes to x the support bracket (drill 6 mm holes

to insert the provided wall plugs). The Ø 100 mm hole

for the duct can be made with a suitable core drill or

by means of a succession of smaller holes made with a

simple drill on the perimeter to be removed.

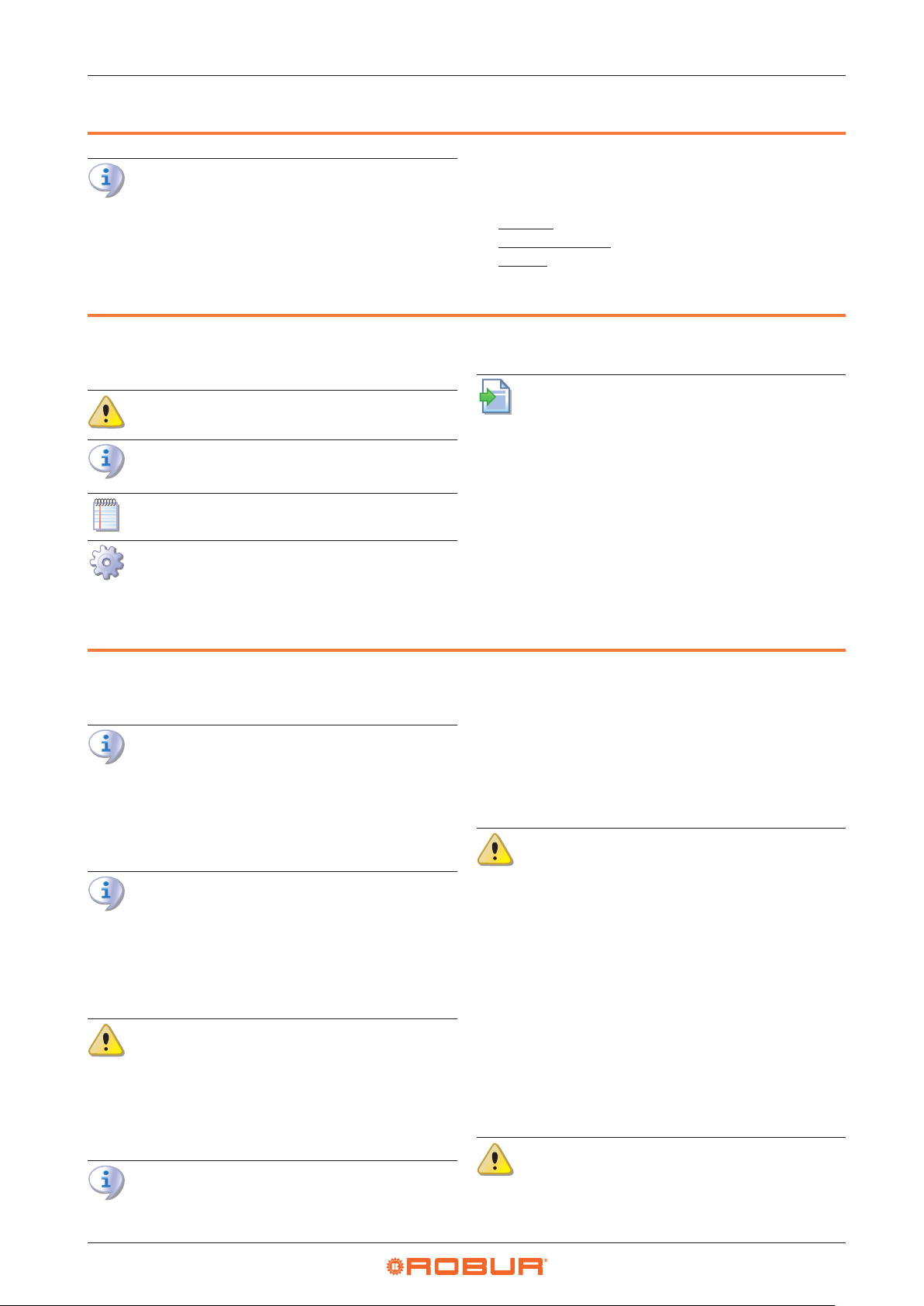

If the appliance is to be installed on a wall cov-

ered with ammable material, such as wallpaper,

matchboarding, etc., part of this must be removed

to a Ø 130 mm around the ue outlet hole to reach

the bare wall. If it is not possible to remove only

the ammable layer (e.g. all-wood walls) it will be

necessary to drill a hole 30 mm deep around the

pipe (see Figure 3.1

p.10

).

Figure3.1Ø 130 hole drilling

130 mm

30 mm

6. Use the supplied plugs to x the support bracket to

the wall, making sure that the holes at the ends of the

bracket are at the bottom (see Figure 3.2

p. 11

). It

is recommended, even at this stage, to check that the

bracket is parallel to the oor.