The Getting Started Guide for HHT

T

able of Contents

i

Chapter 1

Controller Styles 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting

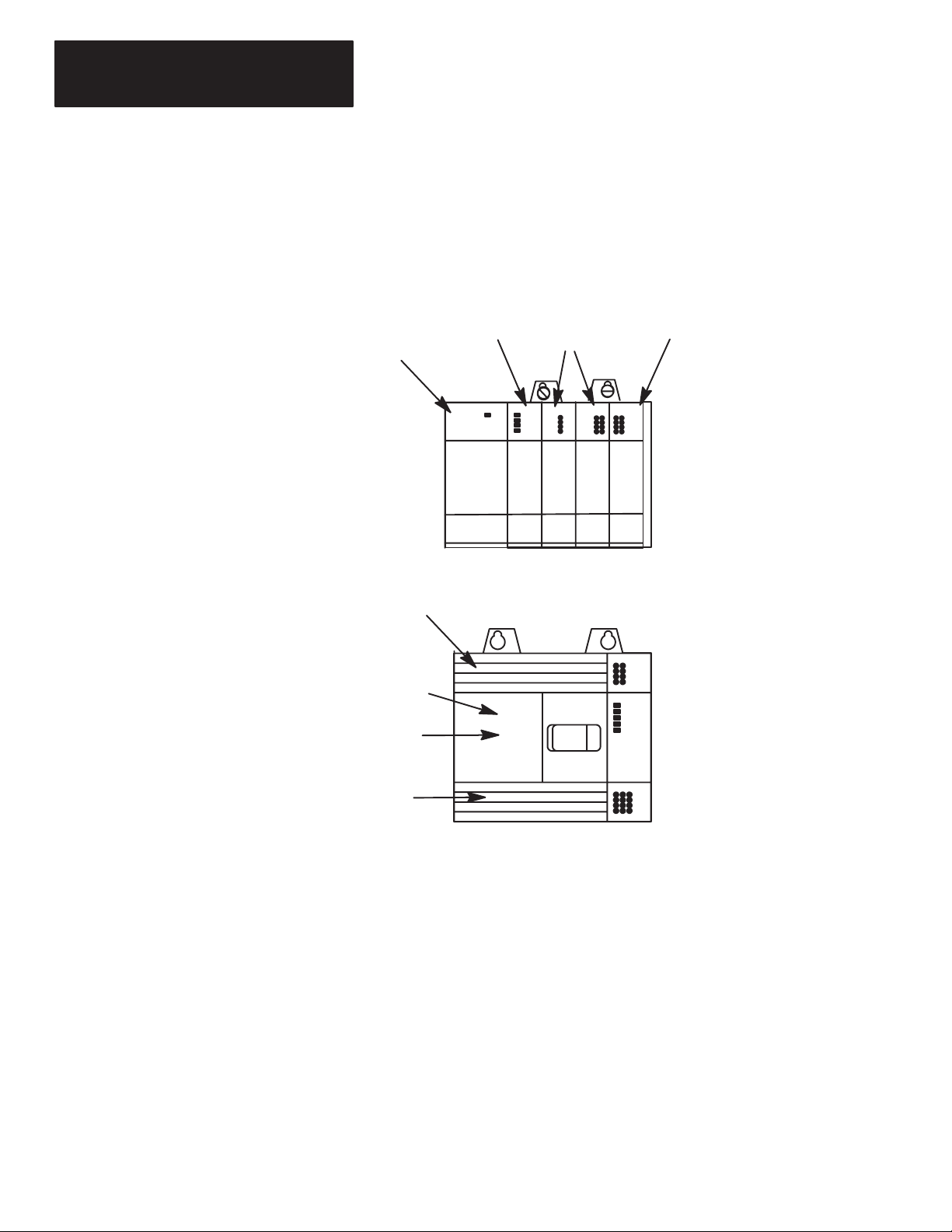

Up a Demo Unit

1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting

Up a Field–Wired Controller

1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Memory Pak, Battery

, and Communication Cable

1–4. . . . . . . . . . .

HHT

Features

1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHT

Powerup

1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHT Display Format 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The

Keyboard

1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu

Function Keys (F1, F2, F3, F4, F5)

1–9. . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Keys (A 7, B 8, C 9...) 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto

Shift

1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cursor Keys 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ZOOM and RUNG Keys 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

SLC

500 File Concepts

2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program

Files

2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

Files

2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How External I/O Devices Communicate with the Processor 2–3. . . . . . . . . . . . .

Addressing

External I/O

2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External I/O Addressing Formats 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HHT Display of Instructions/Addresses 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Ladder

Logic Concepts

2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

True/False

Status

2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical

Continuity

2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processor Operating Cycle 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Configuration

of SLC 500 Controllers

3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

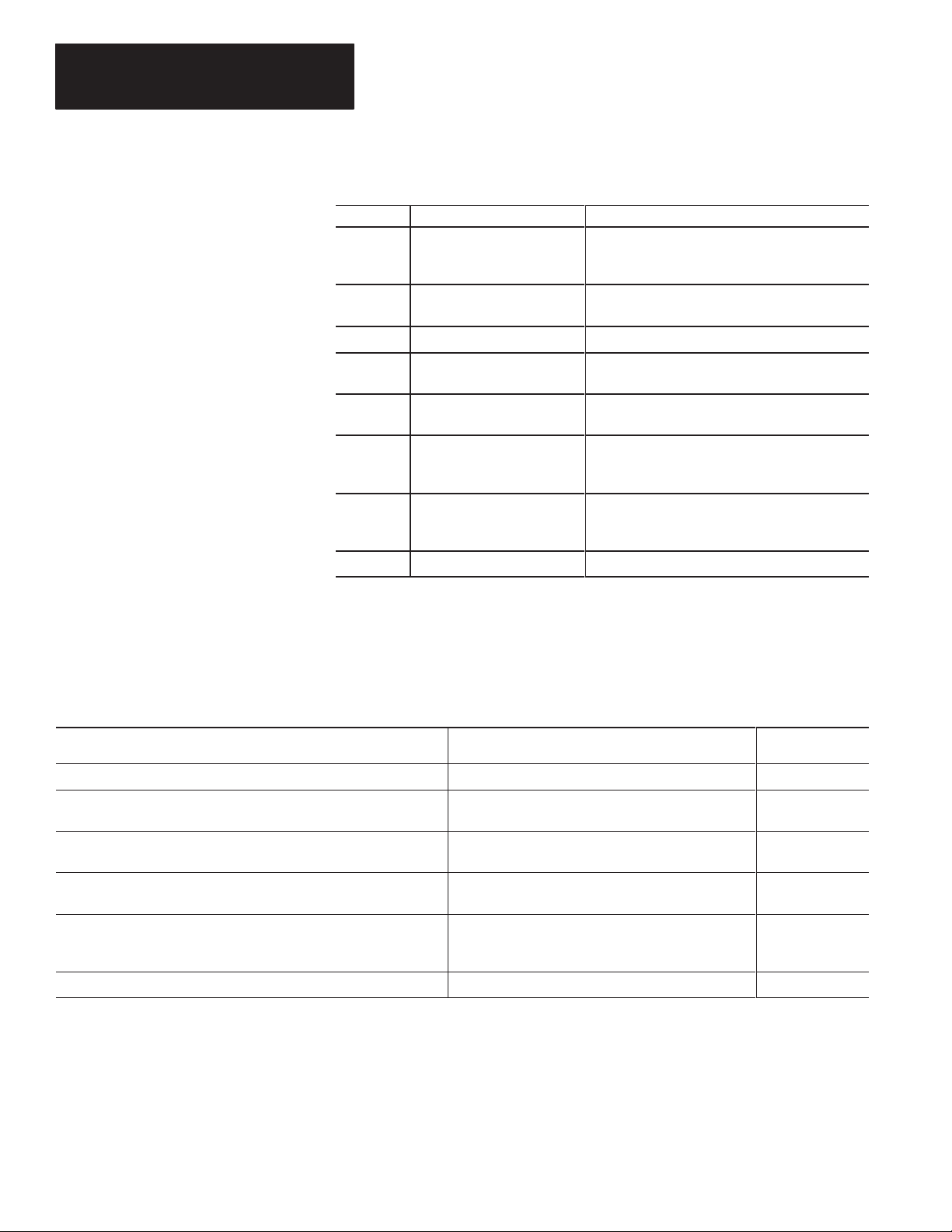

Controller Styles 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Numbers 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Arbitrary

Controller Used in this Guide

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating

a Program

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing the Memory of the HHT 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Naming

the Program and Configuring the Controller

3–6. . . . . . . . . . . . . . . . .

Naming Your Program 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Processor 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ConfiguringY

our I/O

3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring Y

our Data File

3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

a Simple Ladder Rung

3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering

a Rung

3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up Your Equipment

Control Basics

Creating a Program

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com