16

EN

16

1 GENERAL SAFETY PRECAUTIONS

Failure to respect the informaon given in this manual may cause personal injury or damage to

the device.

This installaon manual is intended for qualied personnel only.

ROGER TECHNOLOGY cannot be held responsible for any damage or injury due to improper use or any use other the intended usage indicated in this

manual.

Installaon, electrical connecons and adjustments must be performed by qualied personnel, in accordance with best pracces and in compliance

with applicable regulaons.

Read the instrucons carefully before installing the product. Bad installaon could be dangerous.

Before installing the product, make sure it is in perfect condion: if in doubt, do not use the equipment and contact qualied personnel only.

Do not install the product in explosive areas and atmospheres: the presence of inammable gas or fumes represents a serious safety hazard.

Before installing the motorisaon device, make all the necessary structural modicaons to create safety clearance and to guard or isolate all the

crushing, shearing, trapping and general hazardous areas.

Make sure the exisng structure is up to standard in terms of strength and stability.

ROGER TECHNOLOGY is not responsible for failure to observe Good Working Methods when building the frames to be motorised, or for any

deformaon during use.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking into account: applicable laws and direcves, Good

Working Methods, installaon premises, system operang logic and the forces developed by the motorised door or gate.

The safety devices must protect against crushing, cung, trapping and general danger areas of the motorised door or gate.

The European standards EN 12453 and EN 12445 dene the minimum safety requirements for the operaon of automac doors and gates. In

parcular, these standards require the use of force liming and safety devices (sensing ground plates, photocell barriers, operator detecon funcon

etc.) intended to detect persons or objects in the operang area and prevent collisions in all circumstances.

Where the safety of the installaon is based on an impact force liming system, it is necessary to verify that the characteriscs and performance of

the automaon system are compliant with the requisites of applicable standards and legislaon.

The installer is required to measure impact forces and programme the control unit with appropriate speed and torque values to ensure that the door

or gate remains within the limits dened by the standards EN 12453 and EN 12445.

ROGER TECHNOLOGY declines all responsibility if component parts not compable with safe and correct operaon are ed.

Display the signs required by law to idenfy hazardous areas.

Each installaon must bear a visible indicaon of the data idenfying the motorised door or gate.

An omnipolar disconnecon switch with a contact opening distance of at least 3mm must be ed on the mains supply.

Make sure that upline from the mains power supply there is a residual current circuit breaker that trips at no more than 0.03A and overcurrent cutout

upstream of the electrical system in accordance with best pracces and in compliance with applicable regulaons.

When requested, connect the automaon to an eecve earthing system that complies with current safety standards.

During installaon, maintenance and repair operaons, cut o the power supply before opening the cover to access the electrical parts.

The electronic parts must be handled using earthed anstac conducve arms.

Only use original spare parts for repairing or replacing products.

The installer must supply all informaon concerning the automac, manual and emergency operaon of the motorised door or gate, and must

provide the user with the operang instrucons.

The packaging materials (plasc, polystyrene, etc.) should not be discarded in the environment or le within reach of children, as they are a potenal

source of danger.

Dispose of and recycle the packing components in accordance with the standards in force.

These instrucon must be kept and forwarded to all possible future user of the system.

2 DECLARATION OF CONFORMITY

I the undersigned, as acng legal representave of the manufacturer:

Roger Technology - Via Bocelli 8, 31021 Bonisiolo di Mogliano V.to (TV)

hereby DECLARE that the appliance described hereaer:

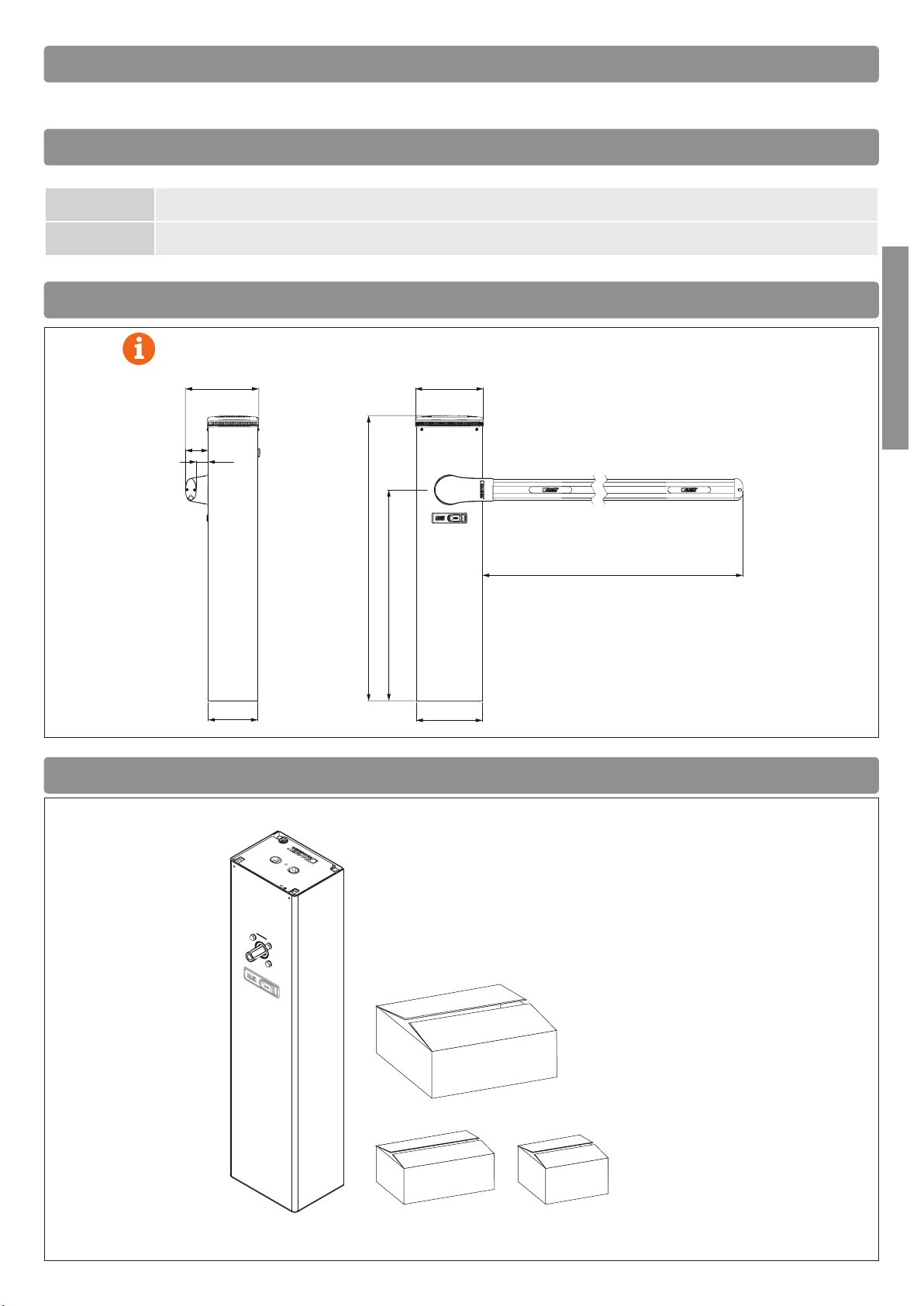

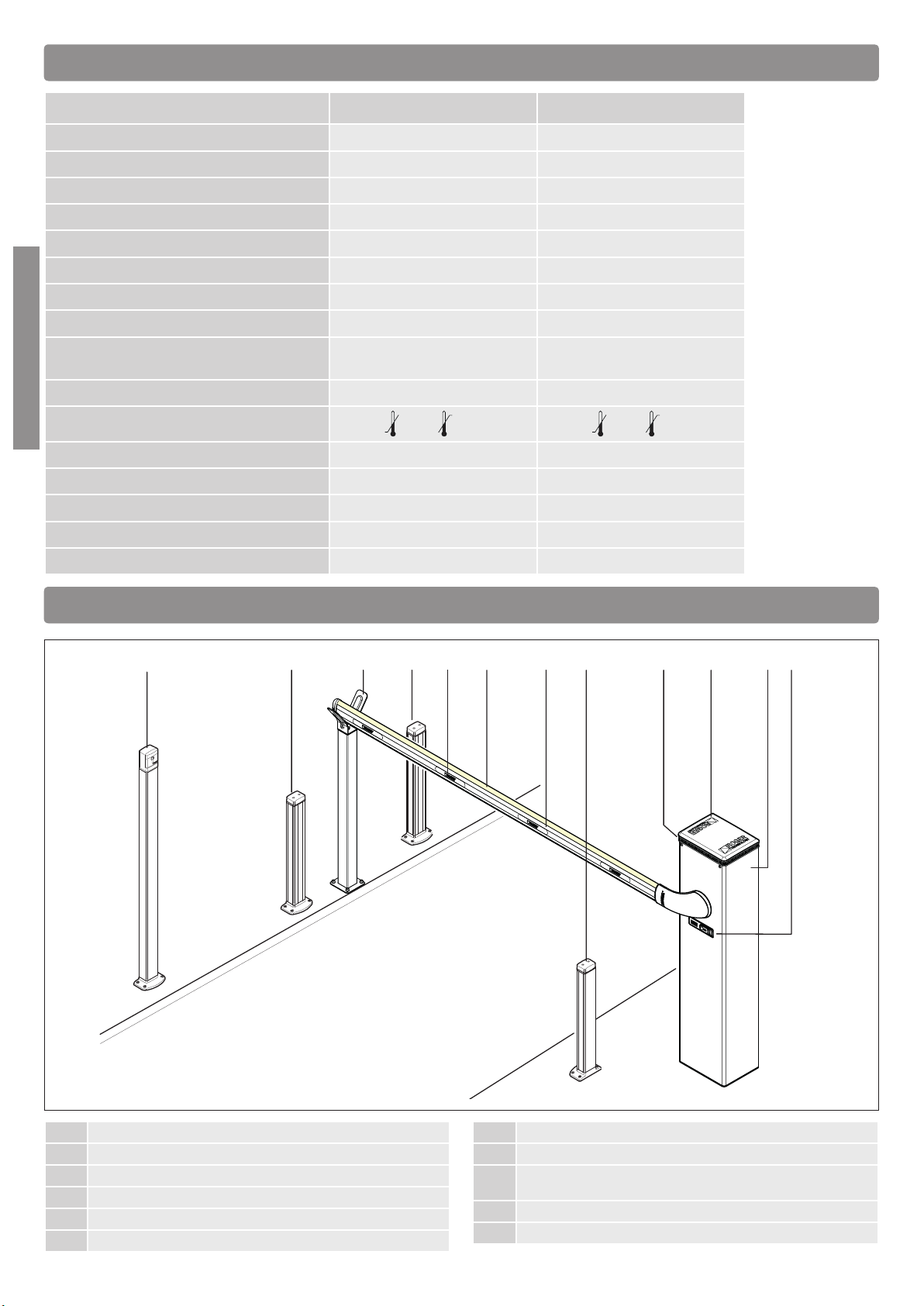

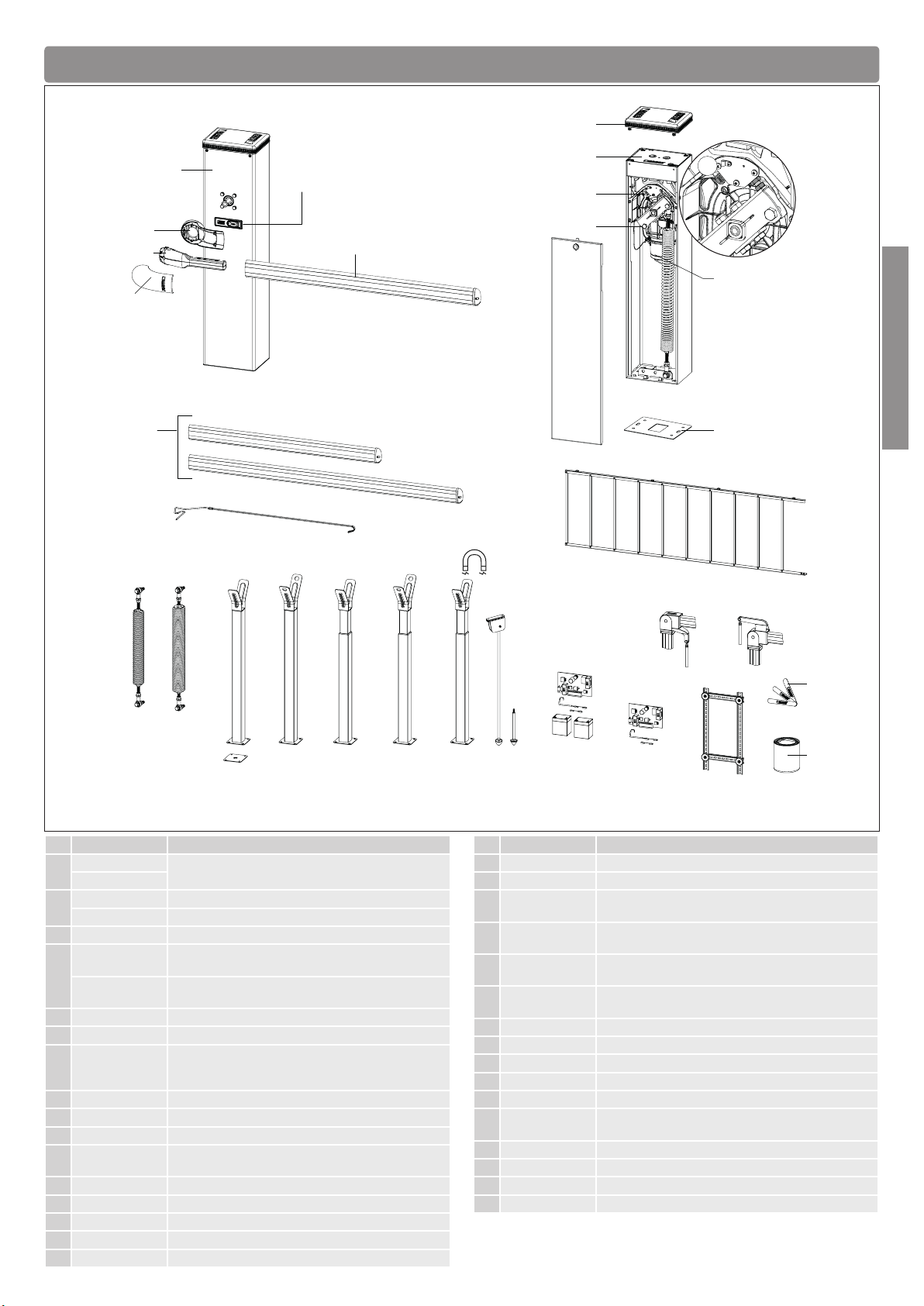

Descripon: Automac barrier

Model: BIONIK serie

Is conformant with the legal requisites of the following direcves:

• Direcve 2006/42/EC (Machinery Direcve) and subsequent amendments;

• Direcve 2014/35/EU (Low Voltage Direcve) and subsequent amendments;

• Direcve 2011/65/EC (RoHS Direcve) and subsequent amendments;

• Direcve 89/106/CEE CPD Direcve) and subsequent amendments;

and that all the standards and/or technical requirements indicated as follows have been applied:

EN 61000-6-3

EN 61000-6-2

EN 13241-1

Last two gures of year in which marking was applied | 17.

Place: Mogliano V.to Date: 21-04-2017 Signature

3 INTENDED USE

The BIONIK automated barrier is specically conceived for installaons in private or public car parks, in residenal, commercial or industrial areas or

in high trac zones.

This product may only be used for its expressly intended purpose. Any other usage is prohibited.

ROGER TECHNOLOGY cannot be held directly or indirectly responsible for any damage resulng from incorrect, inappropriate or unreasonable usage

of this product.