Congratulations on the purchase of your Perrin & Rowe bathroom tapware. Correctly installed and with sensible

care, this product will give you many years of trouble free service.

The Transitional Bathroom Collection

Installation & User Guide

IMPORTANT INFORMATION

Beforeyou proceed... Werecommend you engage theservices of a registered plumber to install this

product.

In addition to theguidebelow it is essential that thewritten information overleaf is carefully read and

understood.

PreparationCheck Box for Installer

Please check that the contents of your Perrin & Rowe Shower Trim set are complete. Please check before you

install the product that there is no damage to the contents as we cannot accept any responsibility after

installation.

1

PreparationCheck Box for Installer - Wall Mounted

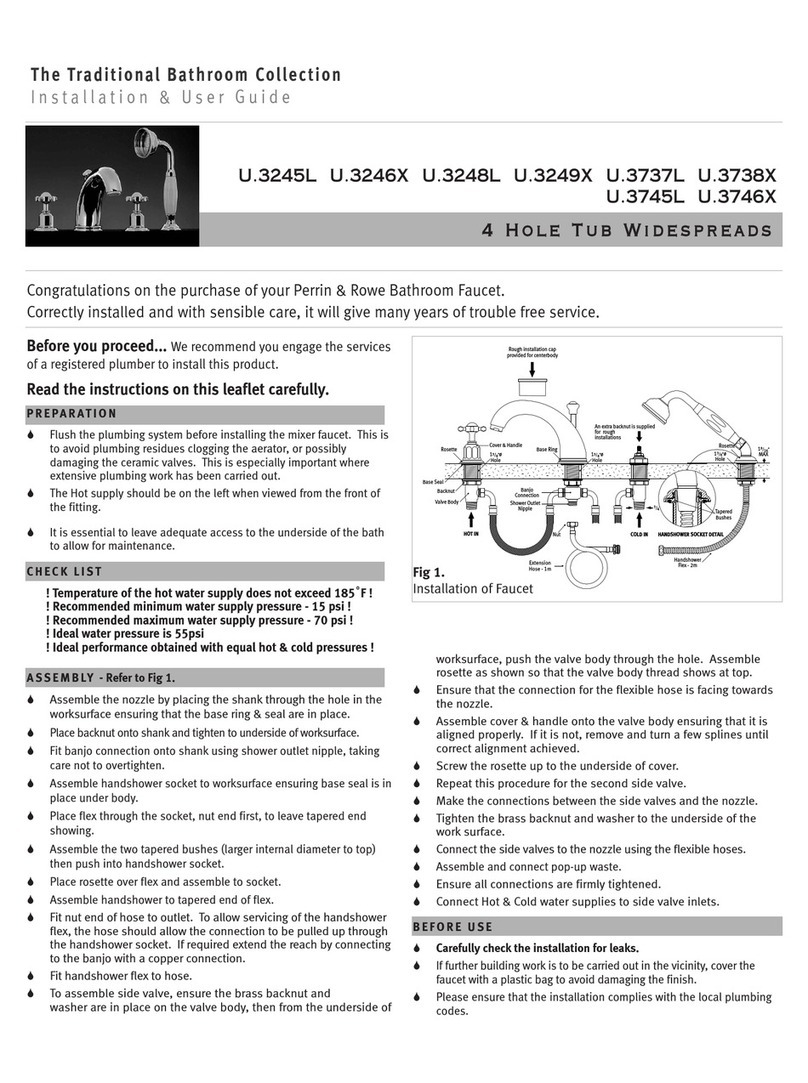

Flush the plumbing system before

installing the bathroom product.

Wall Plate

Lever Assembly

2.5AF Wall Plate

Fixing Screws

Prepare cavity to

sizes shown below.

We recommend that the hot and cold supplies

should have conveniently placed isolating

valves to accomodate any servicing

requirements.

2

Trim

Front view of

cavity with

plaster

guard

removed

Side view of

cavity

Fixing Plate

U.5886TX

O

165mm

O

(6 . 1/2")

3.1

2" MIN

4.1

8" MAX

67mm MIN

90mm MAX

3

CAUTION: Protect finish on

TRIM, PLATE & LEVER or X-TOP

• When finished tiling the wall, remove the plaster guard

(A) by removing x2 screws, and turn off water supply.

• Fit fixing plate onto in-wall rough.

• Ensure the 2 alignment ID marks on both Splined

Spindle and Valve Cartridge are aligned with

each other before you attempt to place the Trim in

position(see diagram B).

• Align holes on face plate with rough in-wall plate and

push on Trim assembly (C), ensuring the fit is secure by

rotating the Lever against the override stop.

• Once the Trim assembly is mounted into correct

aligned position, use Face Plate fixing screws (D) to

secure face plate to tiled wall. Use a 2.5AF Allen Key,

taking care not to damage finish.

At this stage ENSURE the ROUGH is

correctly installed (In-Wall) - Valve

Body: U.5585R (pictured above &

left), before attempting this Trim

installation.

IN-WALL

U.5585R

D

OPERATION

• The temperature is adjusted by rotating the Lever/X-Top either left or right.

• Rotate the seperate flow control lever anti-clockwise a quarter turn to

activate the shower flow.

• The thermostatic cartridge has been set to give a temperature of 100ºF

(38ºC), this is when the temperature control lever is in the vertical position.

• A hotter shower can be achieved by pulling out the temperature override

mechanism (see diagram) and rotating the lever anti-clockwise, up to

118ºF (48ºC).

•Anti-Scald: The Thermo cartridge will automatically shut down

completely on failure of either the hot or cold supply. This is to safe guard

children or the elderly. Cartridge will reactivate when failure has been

corrected.

INSTALLTRIM

A

B

SPINDLE ID

MARK

VALVE ID

MARK

C

ROUGH IN-WALL

PLATE

FIXING PLATE