www.rojaex.com 3

Important safety instructions!

For the safety of persons it is impor-

tant to follow these instructions!

Please keep the manual and hand it over

to the new owner in case of change of

ownership!

This device can be used by children 8

years of age and by persons with with

reduced physical, sensory or mental abili-

ties or lack of experience and experience

and knowledge if they are supervised or

instructed instructed in the safe use of

the use of the device, and understand

the hazards involved understand.

Children are not allowed to play with the

device.

Cleaning and maintenance by the user

must not be carried out by children wit-

hout supervision.

WARNING!

The motor must be disconnected from its

power source during cleaning, mainte-

nance and parts replacement.

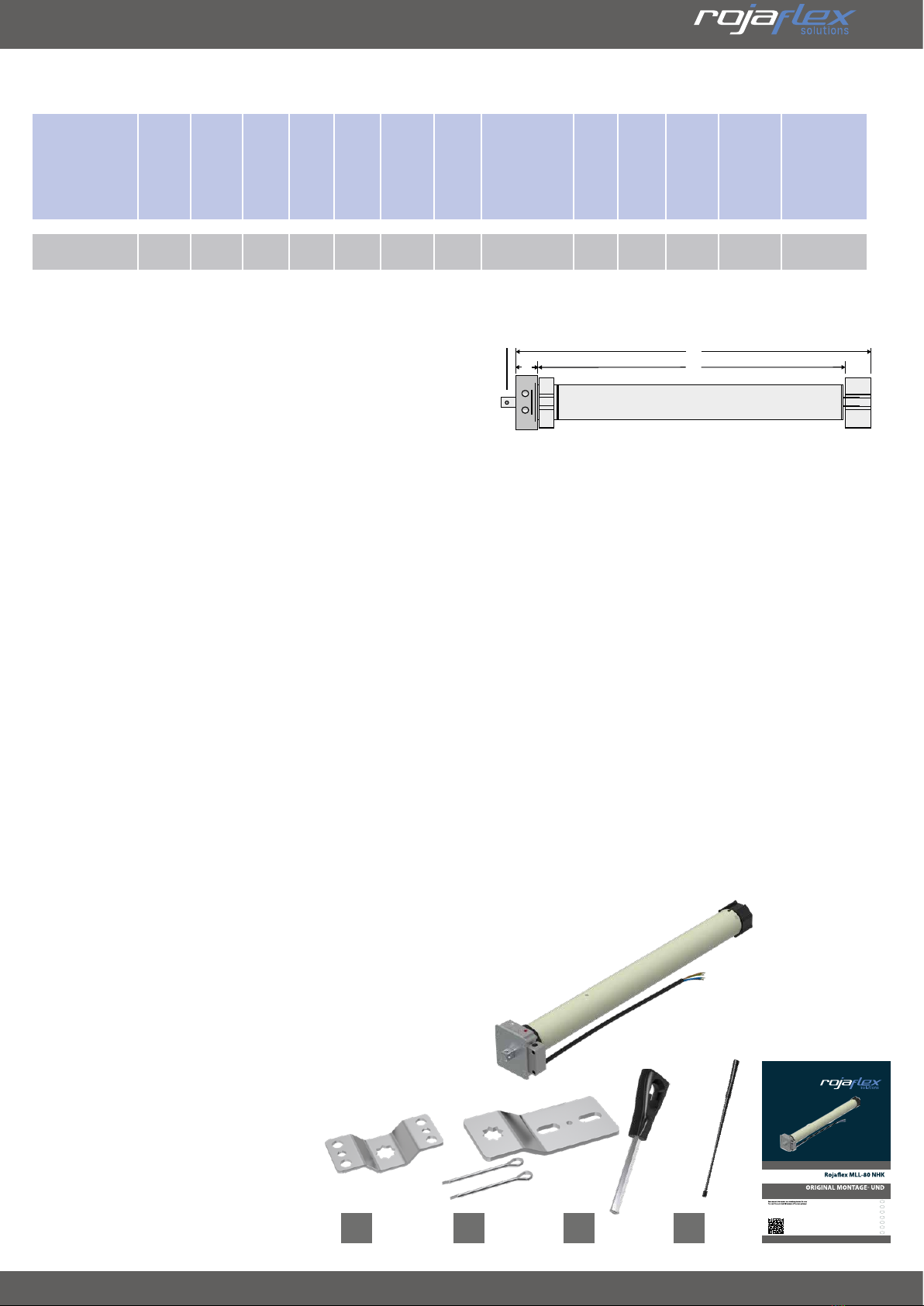

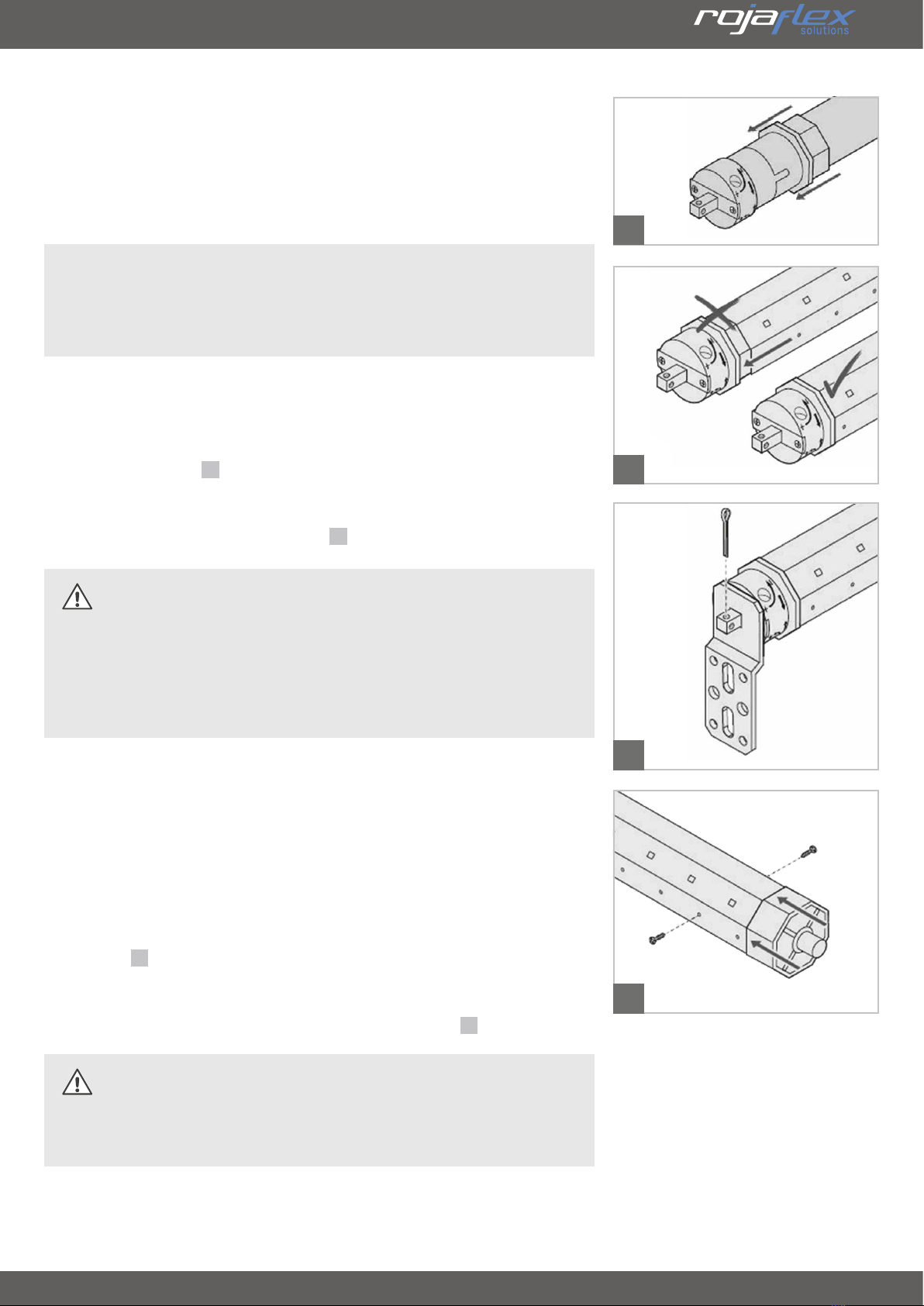

After unpacking, compare the motor

type with the corresponding information

on the nameplate.

Incomplete devices or devices that do

not comply with the specifications must

not be put into operation.

WARNING!

Non-observance may result in danger

to life!

There is a danger to life from electric

shock when working on electrical equip-

ment!

The mains connection of the motor and

all work on electrical installations may

only be carried out by an authorized

electrician in accordance with the con-

nection diagrams in this manual.

Carry out all assembly and connection

work in a de-energized state.

When using the device in damp rooms,

observe the regulations for installation

in damp rooms, especially DIN VDE 0100,

Parts 701 and 702.

Observe the protective measures

protective measures contained in these

regulations.

The use of defective devices can endan-

germent of persons and damage to

damage to property (electric shock, short

circuit).

Never use defective or damaged dama-

ged devices.

Check the motor and power cord for

intactness.

Please contact our Service (see last

page for contact) if you notice any da-

mage to the device.

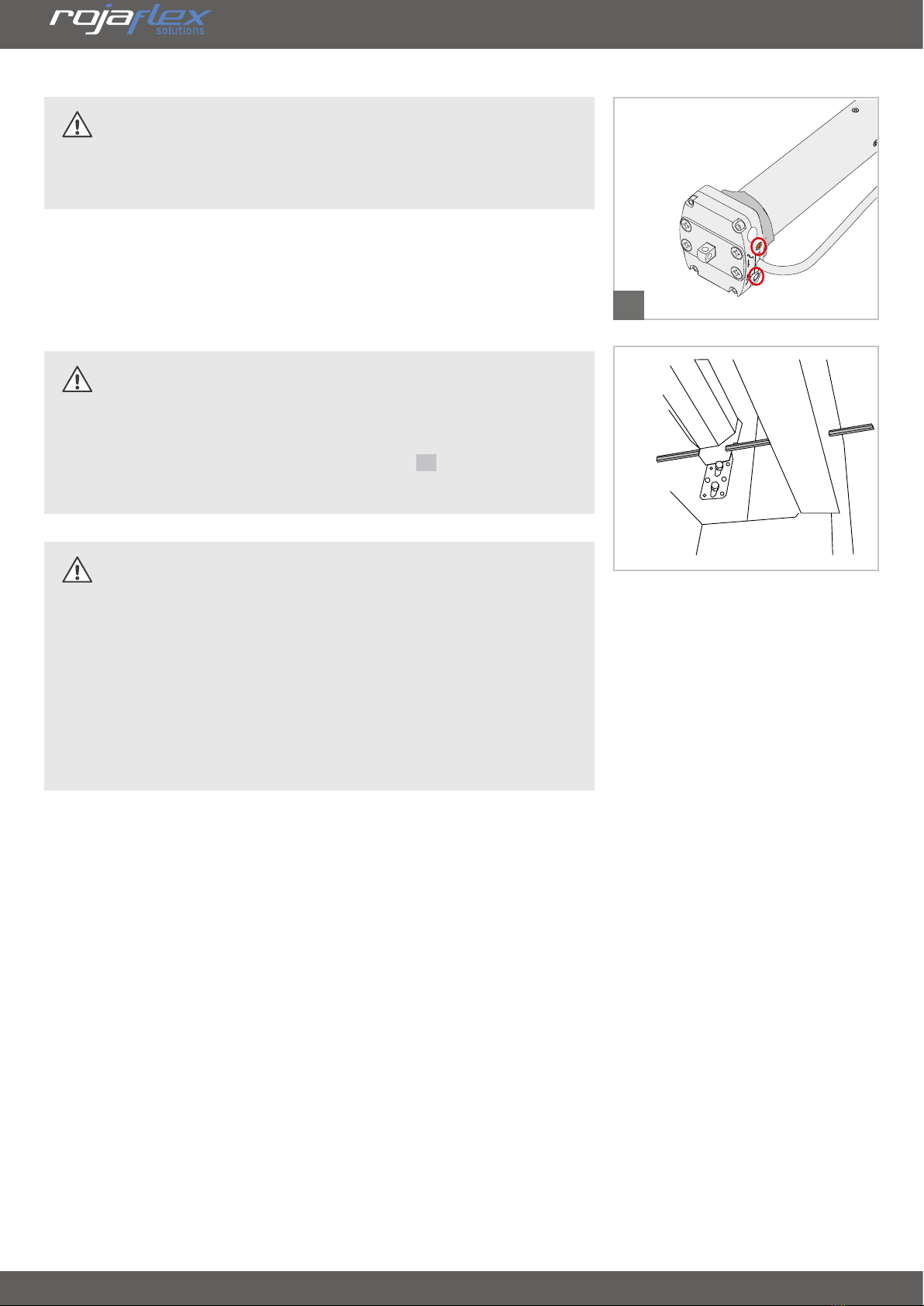

ATTENTION!

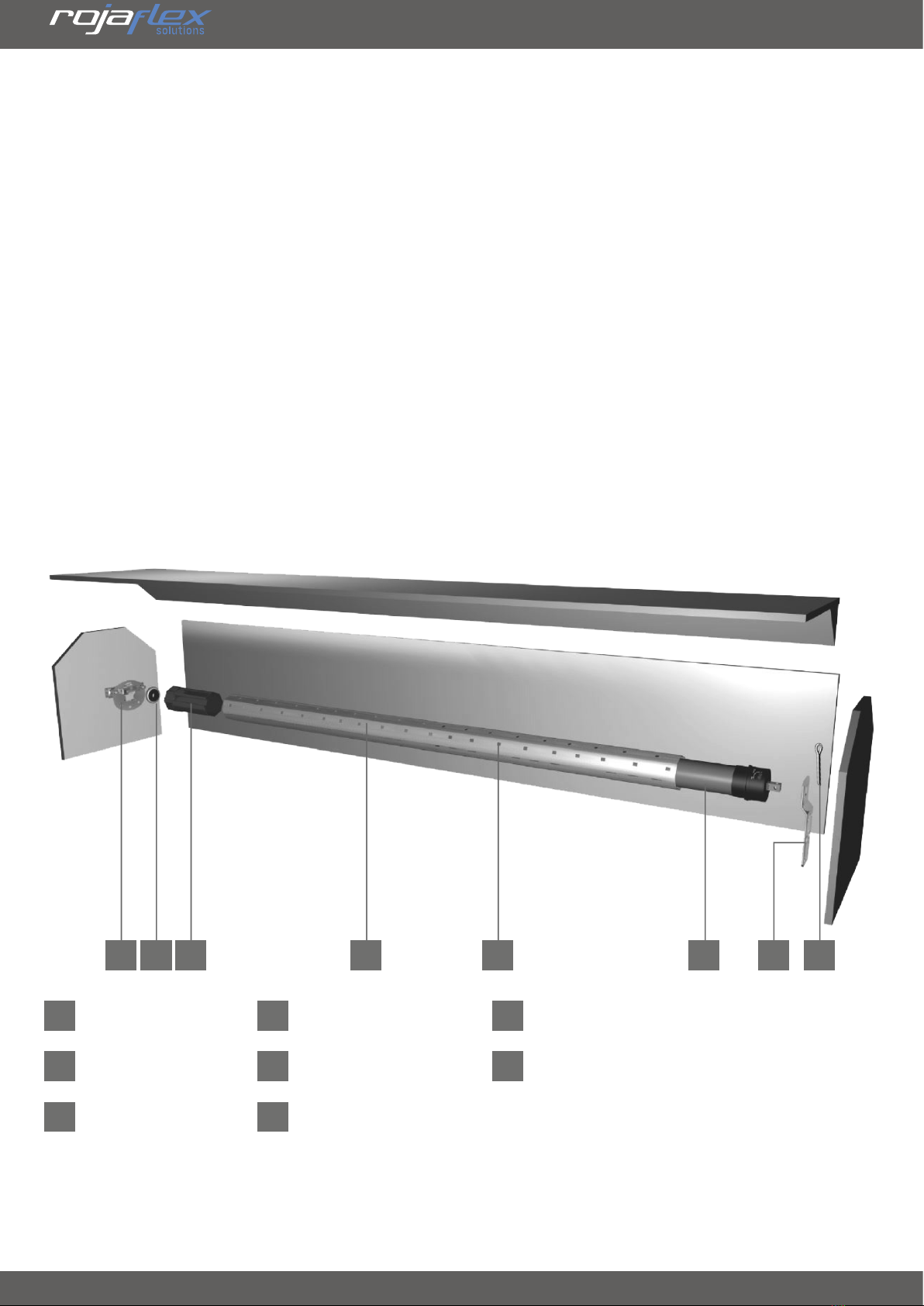

Notes on installation and connection

must be observed!

Improper installation and assembly

can lead to serious injuries!

Lay the power cable of the motor in-

ternally in the empty conduit up to the

junction box, observing the local electri-

cal regulations.

Mains cables must not be laid in the

winding space of the plant. Make sure

that the power cable does not come into

contact with moving parts of the plant.

General safety instructions