Wheels with carbon fiber rims will exhibit different braking characteristics than wheel with

aluminum rims. Please refer to our FAQ and carbon rim braking manual insert for more information.

Carbon rims do not dissipate the heat generated by braking as fast as aluminum rims. Managing rim

temperatures through proper brake application is important. If rims are allowed to overheat, damage

to the rim and/or tire can result. During long descents, it is very important that brakes are applied

with greater force, more frequently, and for the shortest possible time period. Just like in a car,

DO NOT DRAG YOUR BRAKES. The technique of frequent, hard braking and releasing, even if only

releasing for brief periods, significantly reduces rim temperatures.

Carbon rims can have a higher rate of brake pad wear, especially in wet conditions. Check your

brake pad thickness before each ride.

Carbon rims are different from aluminum rims in wet braking conditions. We recommend test riding

your carbon wheels in wet conditions.

Brakes and Tandem Wheels

Rolf Prima tandem wheels are compatible with industry standard tandem brakes. Both front and

rear alloy tandem wheels are compatible with rim or disc brakes. Carbon fiber tandem wheels

and Tandem Stealth are designed for disc brake only.

Follow the brake manufacturer’s instructions for installation and adjustment.

MTB, Road Disc, Cyclocross disc brakes

Rolf Prima mountain bike, cyclocross and road disc wheels are compatible with 6 bolt or Center

Lock disc brake rotors depending on the model. They are not rim brake compatible. Refer to

your bike and/or brake owner’s manual for proper installation and setup.

Cassette Compatibility

All road, cyclocross and tandem Rolf Prima wheels are Shimano/SRAM 11-speed compatible as are

most MTB wheels. To use a 10-speed cassette with 11-speed compatible wheels, use the 1.8mm Rolf

Prima supplied spacer behind the cassette in addition to any spacer included with your cassette. For

road 11-speed cassettes, do not use the Rolf Prima supplied spacer. For 11-speed MTB cassettes (not

XD) use the 11-speed spacer.

Rolf Prima Campagnolo wheels are 10/11-speed compatible. Contact your Rolf Prima dealer for

options to convert between Shimano and Campagnolo (road), or Shimano and SRAM XD (MTB).

Installation and Recommendations

There are many different drivetrain and tire systems. Before attempting any installation of compo-

nents onto this wheelset, make sure the parts are compatible. Tires, valves, gear clusters, brakes

and the frame and fork spacing must be correct. If you are unsure of the compatibility of any part,

consult your Rolf Prima dealer.

Brakes and Brake Pads

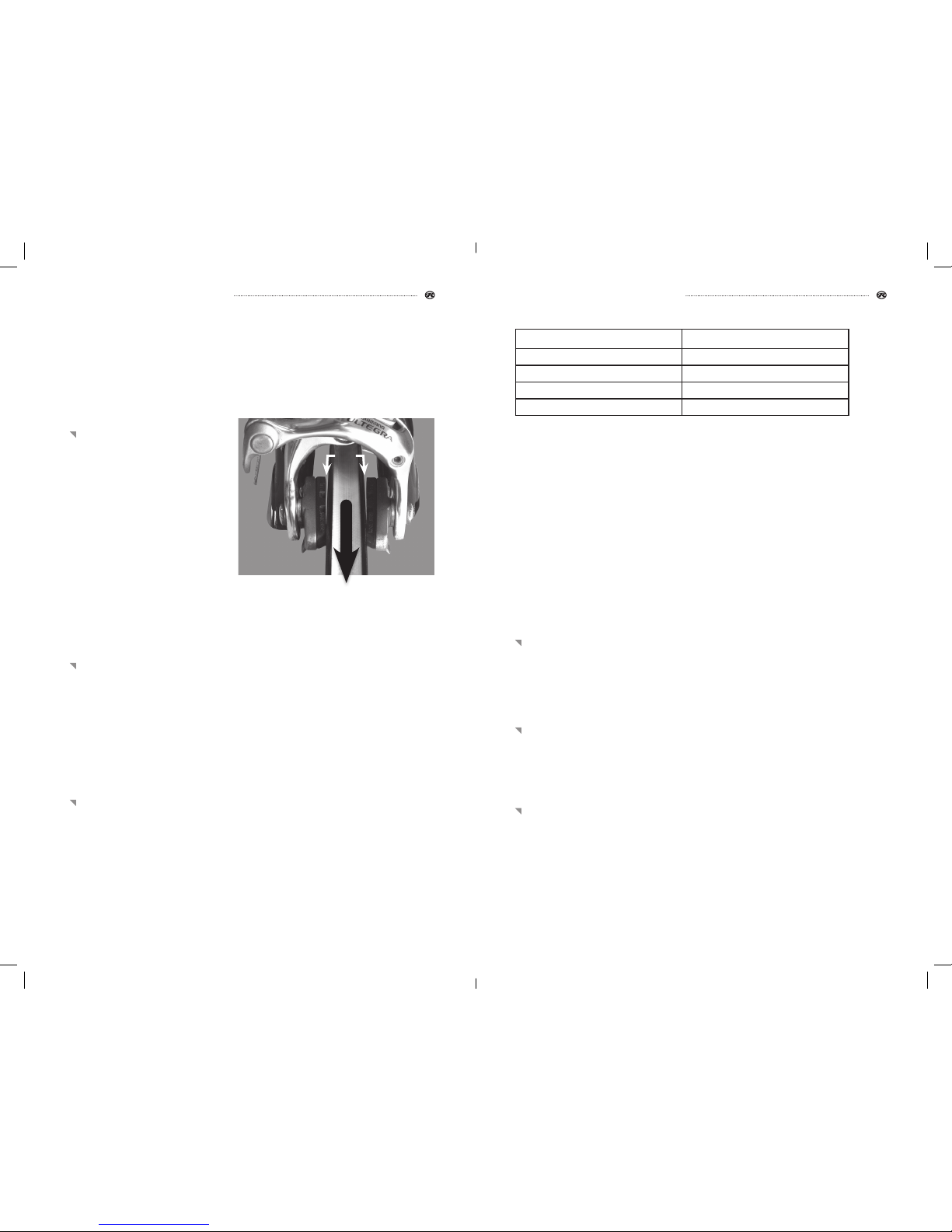

Proper brake pad adjustment

Rim brake pads should be adjusted so

that they sit 1mm to 2mm away from the

rim when the brakes are released. Toe-in

brake pads 1mm. When the forward most

tip of the pad first contacts the rim, there

should be 1mm space at the back of the

pad. Brakes should be properly centered

over the rim so that each pad is the same

distance from the rim when the brakes

are released.

Rim brake pads should be aligned properly with the braking surface of the rim and should contact

only the machined or designated brake surface of your rim. Ensure there is adequate clearance

between the top of the brake pad and the tire. Improper or misaligned pads can cause premature rim

wear or a sudden tire blowout.

Rims with aluminum braking surface: Brake pad selection and maintenance

While your Rolf Prima alloy wheels do not require special brake pads, for best braking perfor-

mance use Rolf Prima RED brake pads. Brake pads from many manufacturers are available in

different compounds. It is important that medium compound pads designed for aluminum rims

are used with your Rolf Prima wheels. Soft pads may cause brake stutter or be too “grabby”.

Hard compound pads are abrasive and may decrease the life of your wheels.

Inspect and clean your brake pads frequently. Road grit, small rocks and other items can

become embedded in brake pads and cause accelerated wear of the braking surface. If you hear

scratching noises when you brake that is a hint. Check and clean your pads.

Rims with carbon braking surface: Brake pad selection and maintenance

Rolf Prima Carbon wheels with carbon brakewalls feature a specially prepared braking surface,

but can still be susceptible to heat build-up issues and abrasion. These carbon wheels come

with Rolf Prima brake pads. We strongly recommend the use of the supplied Rolf Prima pads as

the use of other pads may void the warranty and decrease the braking function.

FWD

FIGURE 5.1

TOE-IN

GAP

1MM