Manual No. 4801-5156 Rev 4-08 Table of Contents RollSeal SC-325 & SC-650

Table of Contents

Section Title Page

1. Warnings (Avertissements) ............................................................................................................................3

2. Limited Warranty ...........................................................................................................................................7

3. Ratings and Specifications..............................................................................................................................8

4. Introduction ....................................................................................................................................................8

4.1 How the Smart Controllers Communicate with the RollSeal Automatic Doors.....................................9

5. Smart Controller User Interface......................................................................................................................9

5.1 The Power Switch...................................................................................................................................9

5.2 The Display Indicator ...........................................................................................................................10

5.3 Interpreting the Display Indicator.........................................................................................................10

5.4 Safety Beam..........................................................................................................................................12

5.5 Leading Edge Switch Option................................................................................................................12

5.6 Home and Safety Limit Switches .........................................................................................................12

6. SC-325 and SC-650 Initial Setup .................................................................................................................12

6.1 Program Mode ......................................................................................................................................12

6.2 Acceleration and Deceleration Range...................................................................................................15

6.3 Switch Settings .....................................................................................................................................16

6.4 Door Setup............................................................................................................................................16

7. Jog Mode ......................................................................................................................................................17

8. Door Activation Methods .............................................................................................................................17

8.1 Directional Switch Input.......................................................................................................................18

8.2 Manual (Single) Switch Input...............................................................................................................18

8.3 Timed Switch Input ..............................................................................................................................18

9. Troubleshooting Controller and/or Door......................................................................................................19

9.1 P12 – Input Status Indicators................................................................................................................19

9.2 Error Codes and Recommended Action ...............................................................................................20

10. Controller Installation and Setup..............................................................................................................21

10.1 Tools Required .....................................................................................................................................21

10.2 Installation Instructions ........................................................................................................................21

10.3 Typical Smart Controller Installation ...................................................................................................22

11. Accessories ...............................................................................................................................................23

11.1 Power BackUp for SC-325 Controller (Ordered Separately) ...............................................................23

11.2 Remote Transmitter and Receiver (Ordered Separately)......................................................................23

11.3 2-Button Close/Open Switch Module (Ordered Separately) ................................................................24

11.4 Ceiling/Wall Mount Pull Switch Assembly (Ordered Separately) .......................................................24

12. Wiring Diagrams, Schematics, etc............................................................................................................25

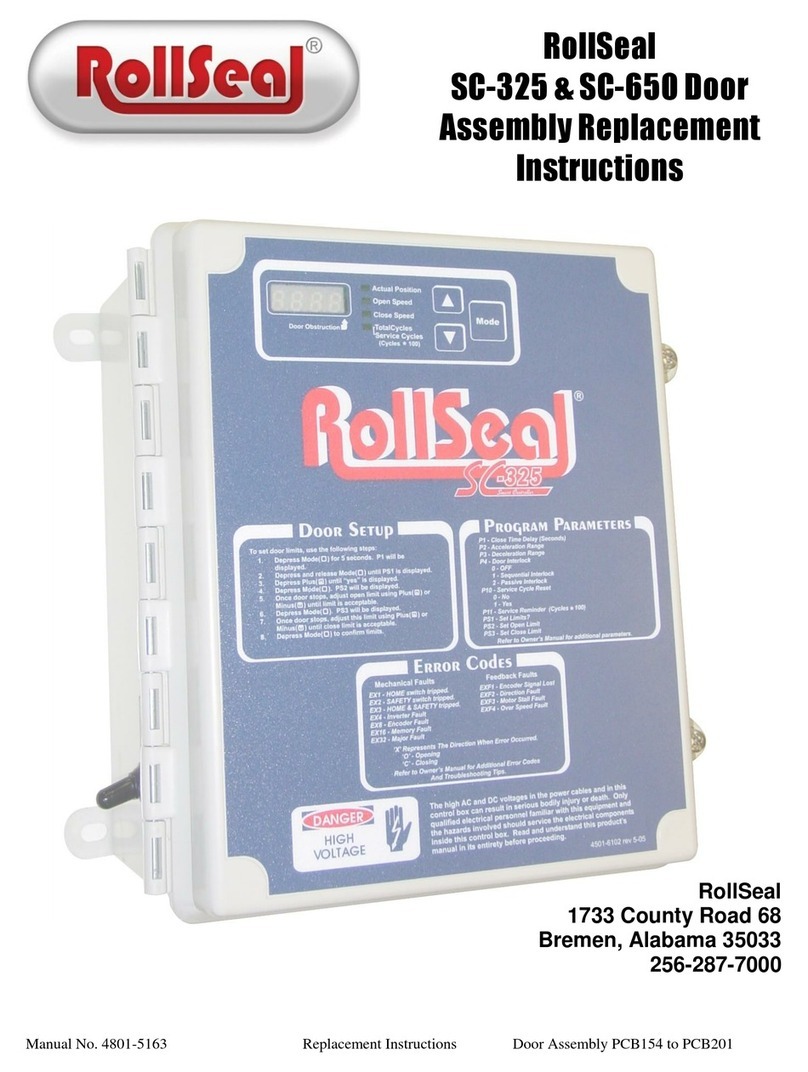

12.1 Smart Controller SC-325 V1 Layout....................................................................................................25

12.2 Smart Controller SC-325 V1 Connection Diagram (Internal Wiring)..................................................26

12.3 Smart Controller SC-325 V2, SC-650 V1 & V2 Layout......................................................................27

12.4 Smart Controller SC-325 V2, SC-650 V1 & V2 Connection Diagram (Internal Wiring)....................28

12.5 Connecting AC Power to the Smart Controller ....................................................................................29

12.6 RS-500/600 Motor Brake Rectifier Wiring Diagram ...........................................................................30

12.7 Connecting Power BackUp to the SC-325 Controller ..........................................................................31

12.8 Connecting to the Automatic Doors .....................................................................................................32

12.9 Interlocking Two Automatic Doors......................................................................................................33

12.10 Connecting the Operator Switches to the Smart Controller..............................................................34

12.11 Connecting Switches and Remote Receiver to the Smart Controller ...............................................35

12.12 Connecting Switches to the SC-325 Wiring Option “-W01” ...........................................................36

12.13 Connecting Moving Door Warning Light to the Smart Controller...................................................37

12.14 RollSeal Automatic Door Wiring Diagram ......................................................................................38

12.15 RollSeal Smart Controller Wiring Diagram .....................................................................................39

13. Replacement and Optional Parts...............................................................................................................40