2

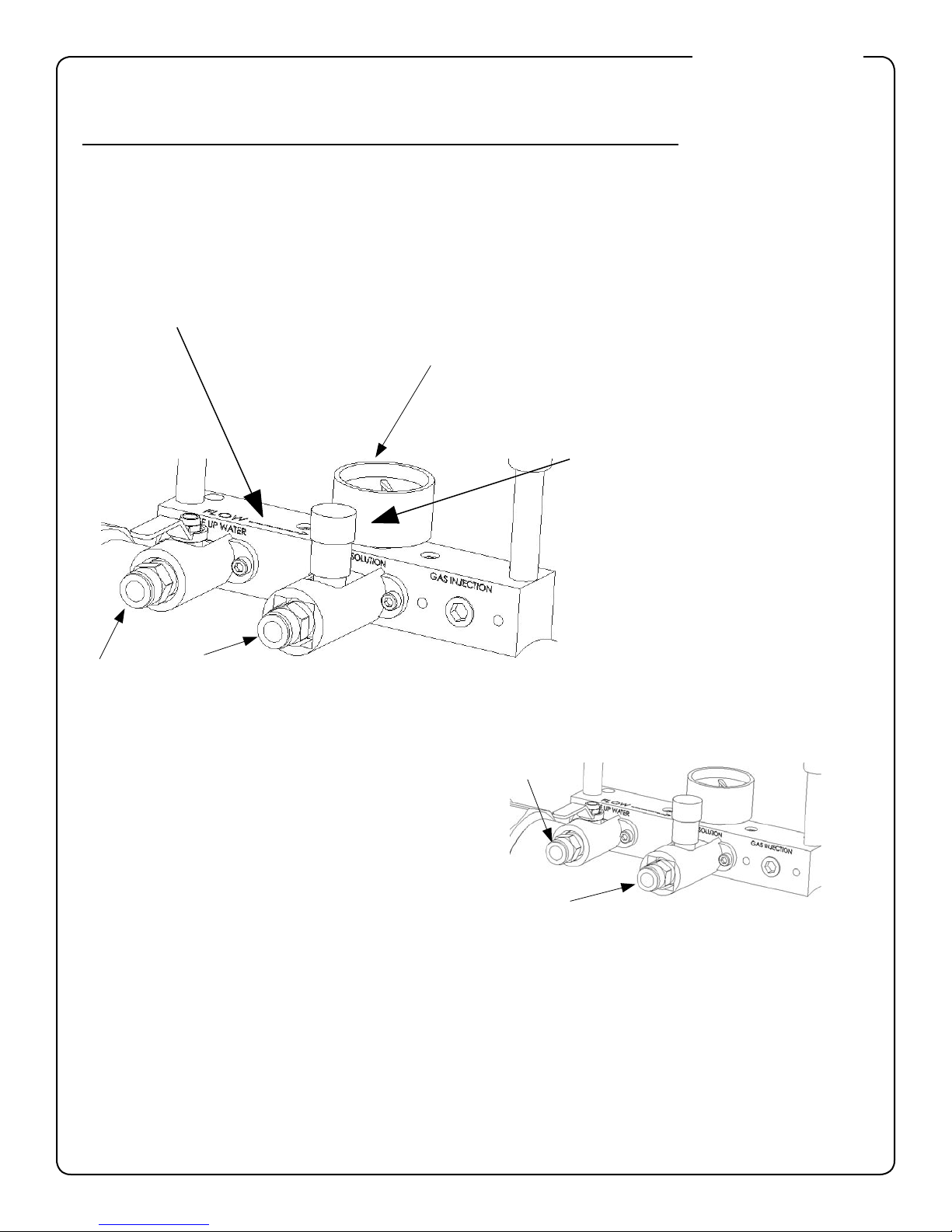

Solution Mixing

TM

Needle Valve Setting 150-200 GPM 200-300 GPM 300-400 GPM 400-600 GPM 600+ GPM

FULL OPEN 22 gph (14 min) 45 gph (7min) 64 gph (5 min) 90 gph (3 min) 110 gph (3 min)

3 turns 17 gph (18 min) 34 gph (9 min) 48 gph (6 min) 68 gph (4 min) 83 gph (4 min)

2 turns 6 gph (55 min) 12 gph (27 min) 16 gph (19 min) 23 gph (13 min) 28 gph (11 min)

1 turn 4 gph (1.5 hour) 7 gph (44 min) 10 gph (31 min) 14 gph (22 min) 17 gph (18 min)

FEED SOLUTION CONSUMPTION CHART

Consumption in gallons per (how many minutes to empty a 5 gallon bucket) hour

FLOW RATE in gallons per minute (GPM)

Vita-D-Chlor FEED SOLUTION MIXING AND

FEED SOLUTION VALVE SETTING CHARTS

This chart is good for water ow between 175 - 900 gpm

0 - .5 1/4 cup 2

.5 - 1 1/2 cup 2

1 - 1.5 1/2 cup 3

1.5 - 10 5 cups 2

10 - 30 15 cups 2

30 - 50 15 cups 3

50 - 150 25 cups Full open

150 - 200 34 cups Full open

If... Then add... Set Control Valve on...

Cl.(ppm, mg/l) Vita-D-Chlor cups for maximum Cl.

value per 5 gal water

NOTE: Mixed solution cannot be stored overnight. It will decrease in potency and will not dechlorinate.

If you

Turn control valve

toward 0

Turn control valve

toward full open

Increase the V-D-C mix

amount

Decrease the V-D-C mix

amount

You will

Decrease the ow of feed

solution

Increase the ow of feed

solution

Be able to decrease the

feed solution ow

Have to increase the feed

solution ow

And

Increase the amount of time

between solution batch mixing.

Decrease the amount of time

between solution batch mixing.

Increase the amount of time

between solution batch mixing.

Decrease the amount of time

between solution batch mixing.

Keep in mind

You might not be adding enough feed

solution to dechlorinate the water.

You might be using too much V-D-C mix

and overdosing the discharge water.

More V-D-C will be used and less time

spent making solution batches.

Less V-D-C used. More time spent

making solution batches.

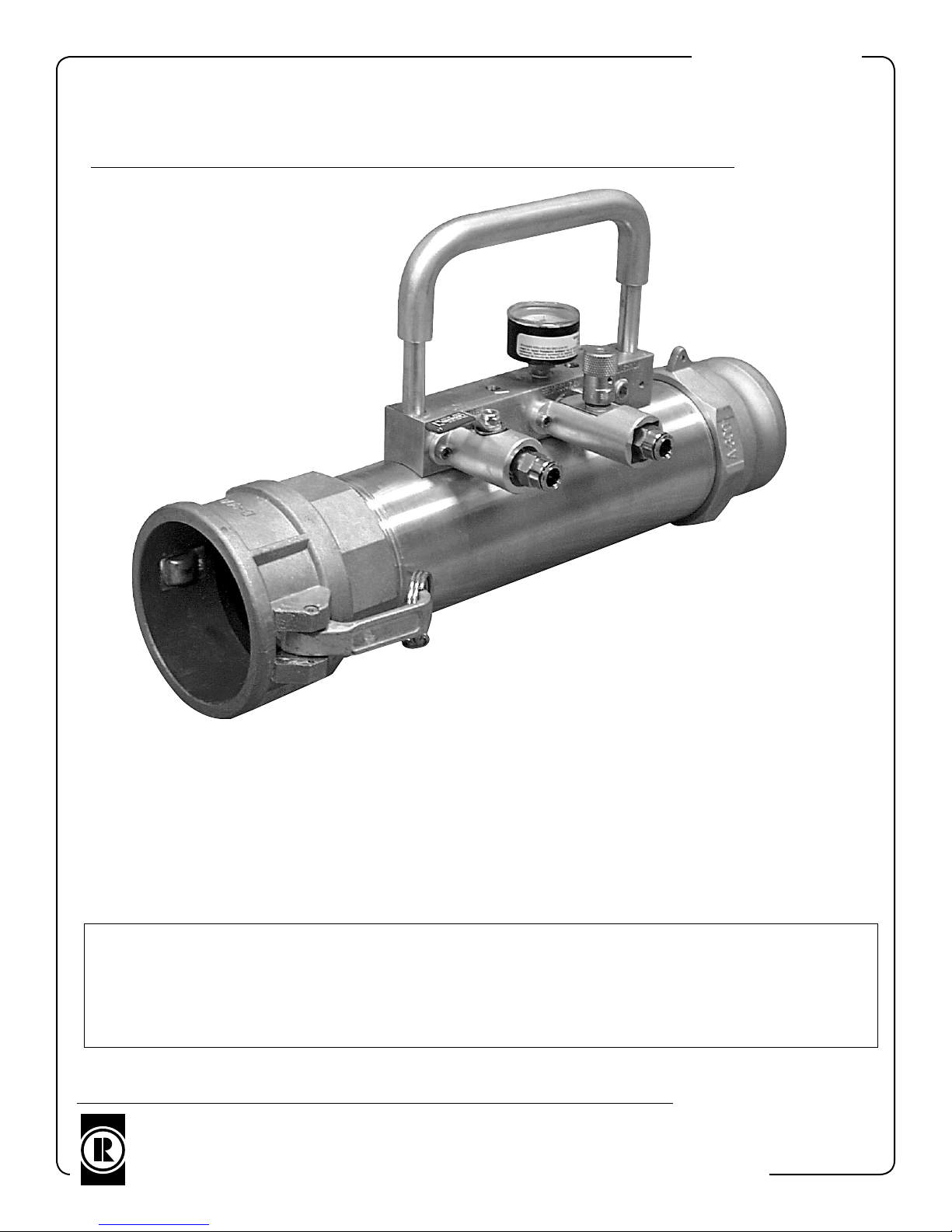

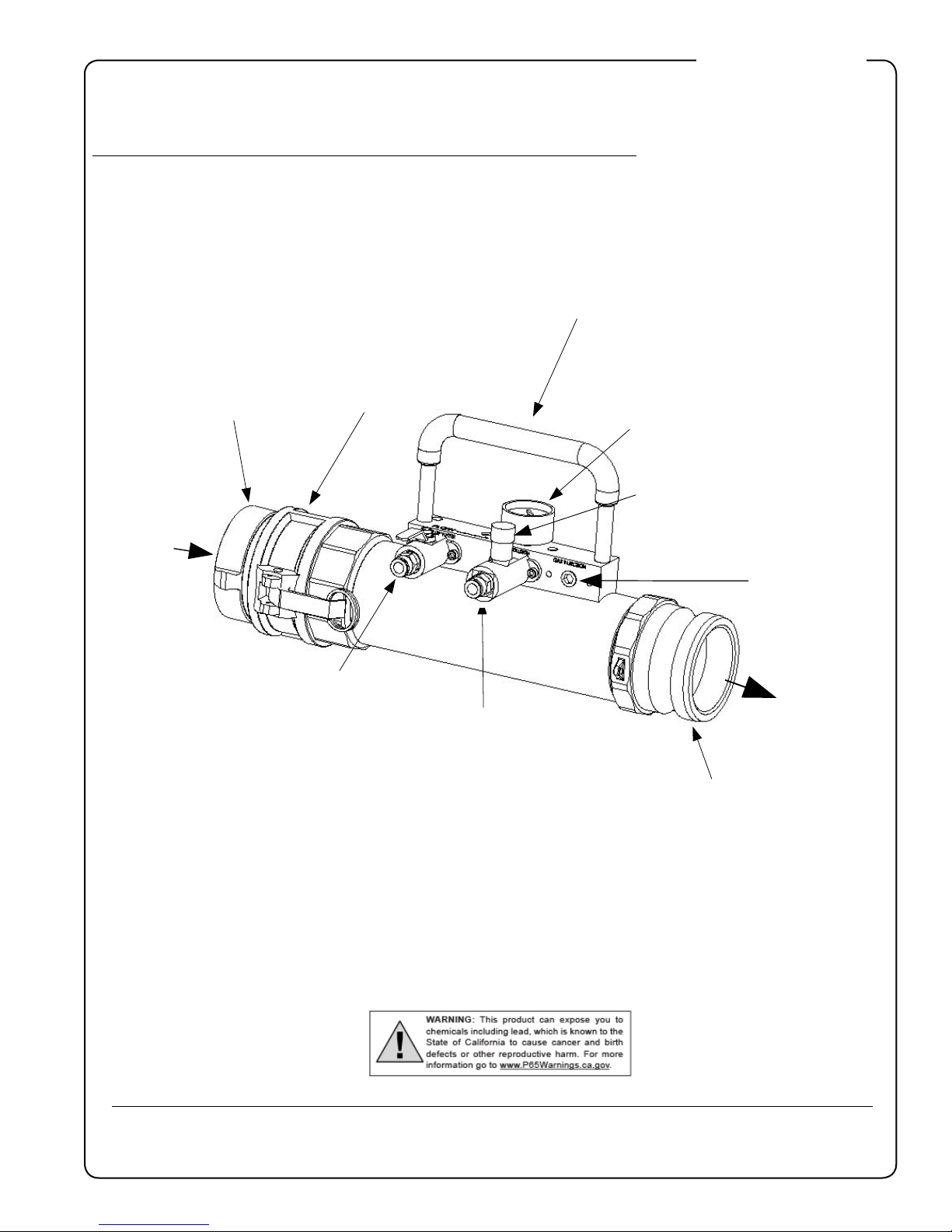

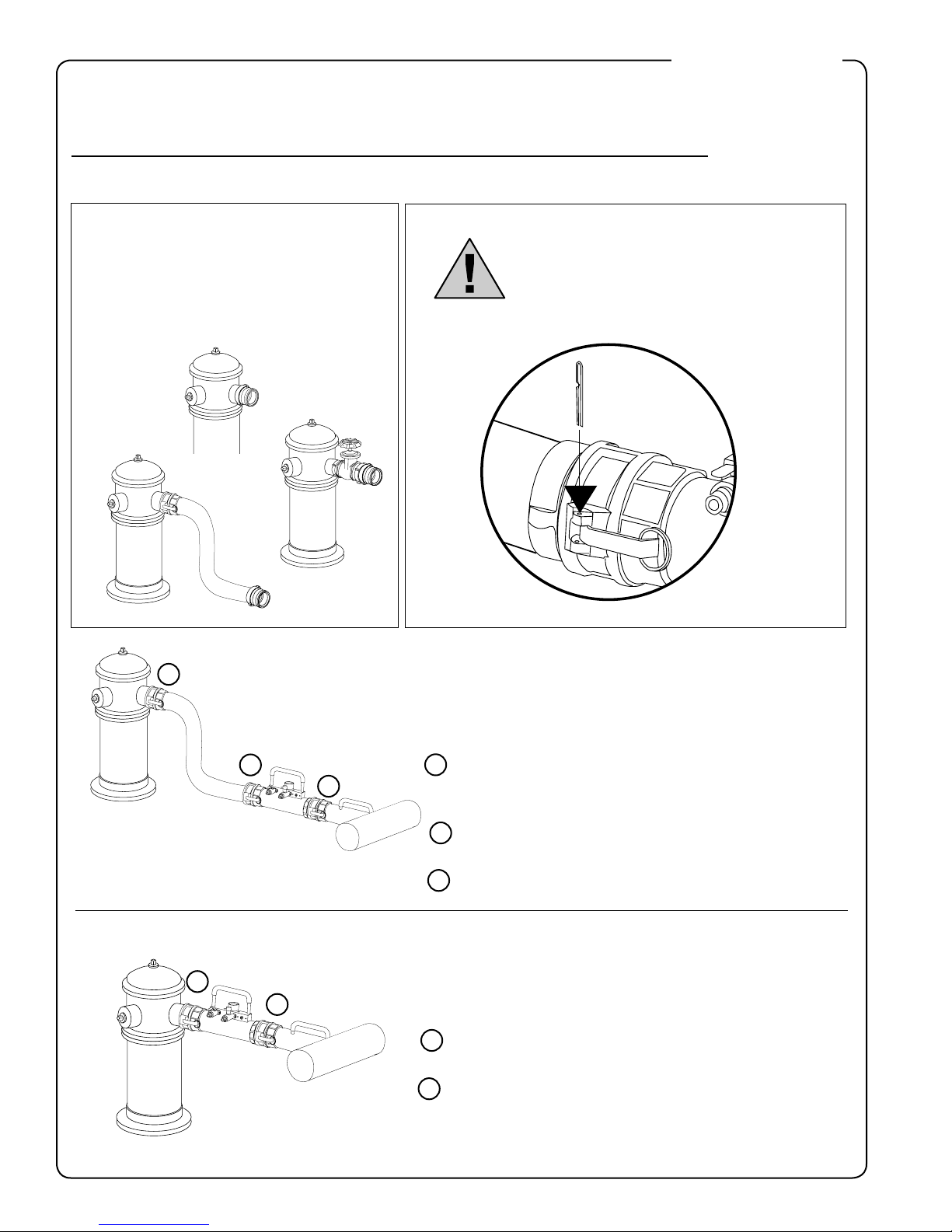

Transmate

deChlorinator