3

Yasui K2 NEXT Instruction Manual SKU: SKU: 79-300-K2-8KW

6-4-1. CLEANING ...............................................................................................................25

6-4-2. DISASSEMBLING FILTER UNIT .............................................................................25

6-4-3. CLEANING FILTER ..................................................................................................25

6-4-4. REASSEMBLING .....................................................................................................26

6-4-5. HIGH-DENSITY FILTER ELEMENT 5 micron (option) ............................................. 26

6-5. FILTERS FOR SENSORS .............................................................................................. 27

6-6. SCRAPER ...................................................................................................................... 27

6-7. LUBRICATION ................................................................................................................ 28

6-8. THERMOCOUPLE ......................................................................................................... 28

7. ADVANCED OPERATION .................................................................................................... 29

7-1. WINDOWS ..................................................................................................................... 29

7-1-1. ALL LIST tab ............................................................................................................29

7-1-2. TEMP tab .................................................................................................................31

7-1-3. SUC tab ...................................................................................................................33

7-1-4. PRESS tab ...............................................................................................................33

7-1-5. OPEN tab .................................................................................................................34

7-1-6. UPPER PART on CAST window ..............................................................................34

7-1-7. MEMORY REGISTRATION ......................................................................................38

7-2. SHOT tab ........................................................................................................................ 39

7-3. CONFIG tab .................................................................................................................... 40

7-3-1. MACHINE ................................................................................................................42

7-3-2. COPY/CLEAR ..........................................................................................................42

7-3-3. COUNTER ...............................................................................................................45

7-3-4. LANGUAGE .............................................................................................................45

7-3-5. SECURITY ...............................................................................................................46

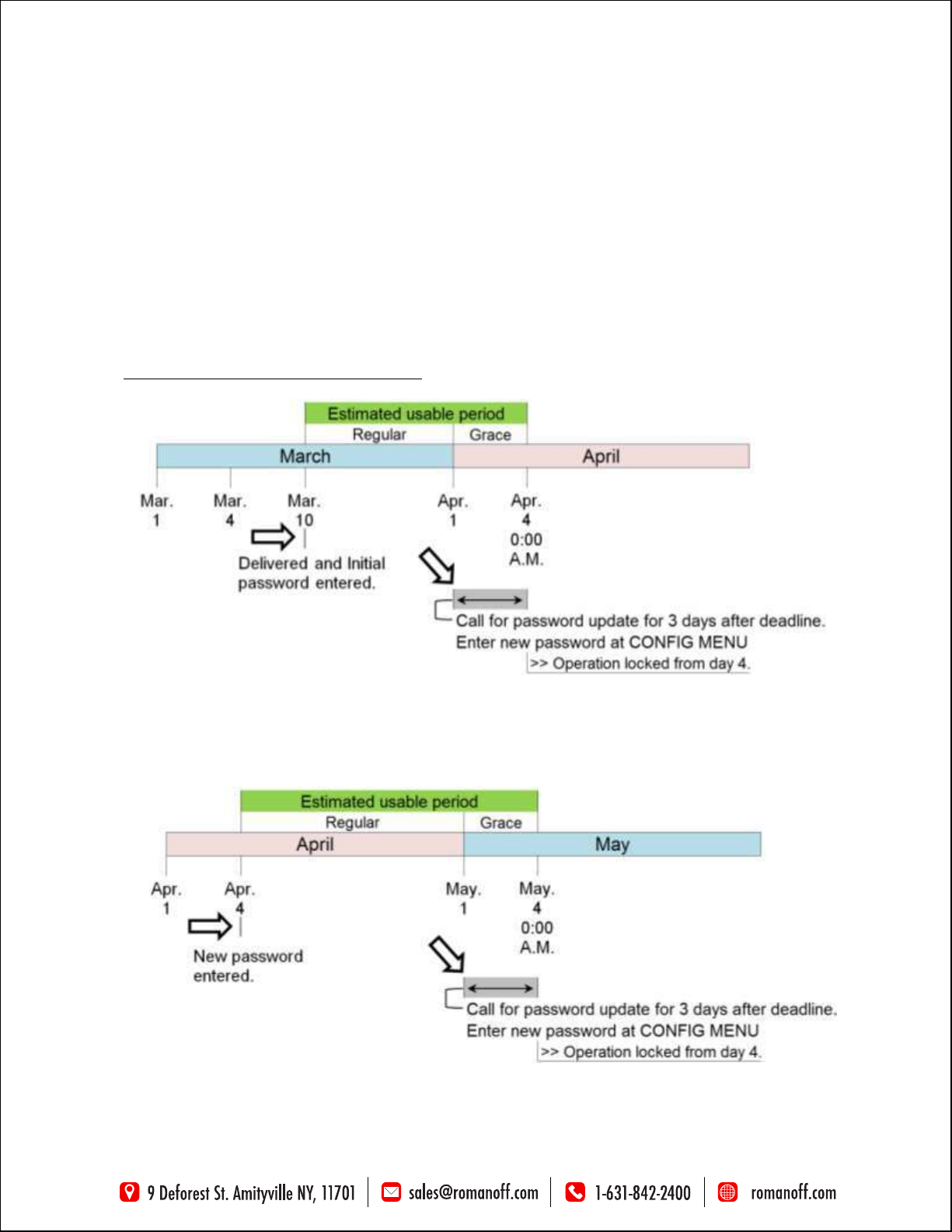

7-3-6. PAYMENT PASSWORD ...........................................................................................48

7-3-7. DISPLAY ..................................................................................................................48

7-3-8. DATE & TIME ..........................................................................................................49

7-3-9. MAINTENANCE .......................................................................................................50

7-3-10. LOG & HISTORY ...................................................................................................51

8. TROUBLE SHOOTINGS ...................................................................................................... 52

8-1. ERROR MESSAGES ...................................................................................................... 52

8-2. ERROR CODE ............................................................................................................... 53

9. INSTALLATION ................................................................................................................... 55

9-1. PLACE ............................................................................................................................ 55

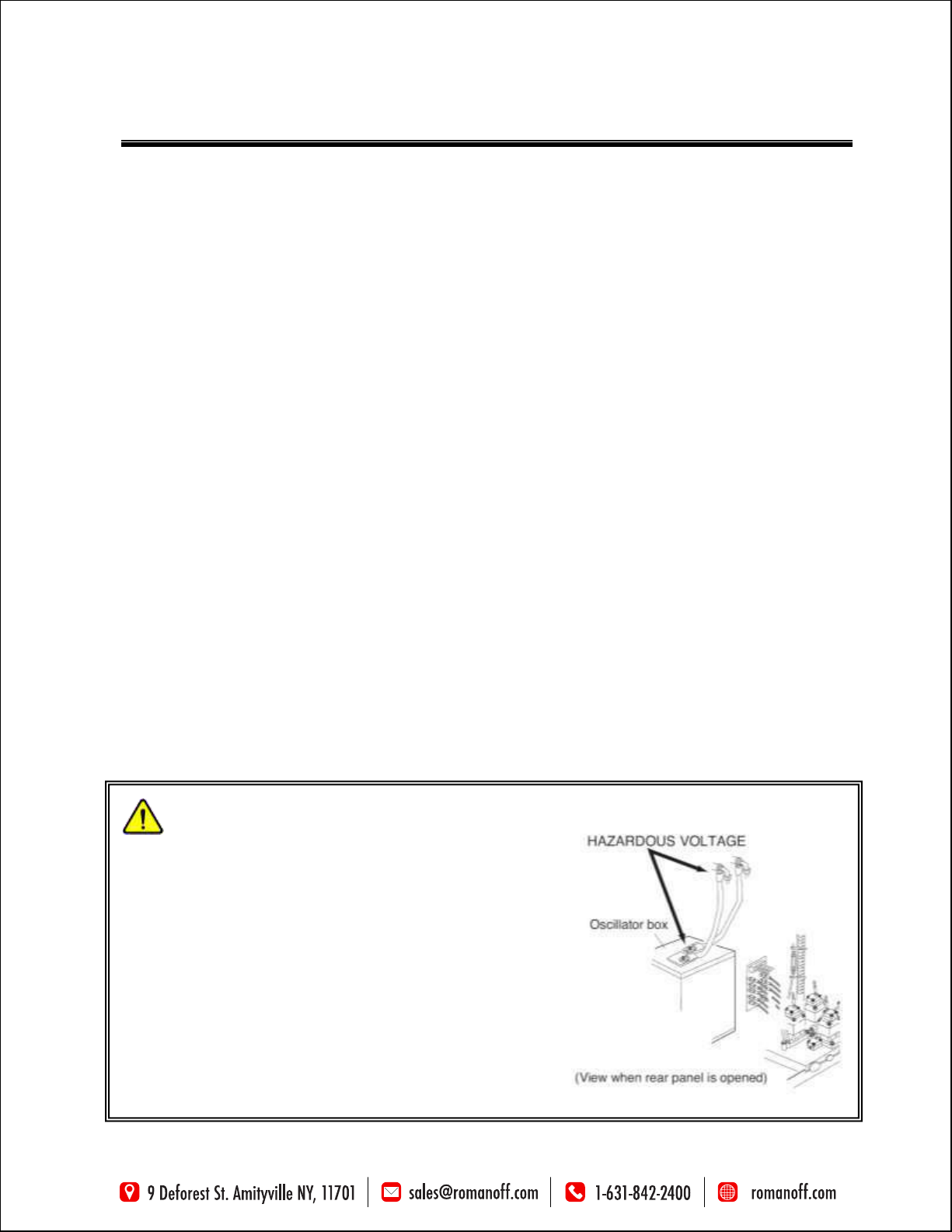

9-2. POWER SOURCE .......................................................................................................... 55

9-3. CONNECTING WATER HOSE ....................................................................................... 57

9-4. CONNECTING VACUUM PUMP .................................................................................... 58

9-5. SUPPLY OF INERT GAS ............................................................................................... 60

9-6. FLASK CHAMBER ......................................................................................................... 61