3

3. Fluid and solvent can be highly flammable or combustible. Use in

well-ventilated spray booth and avoid any ignition sources, such as smoking,

open flames and decrial hazard. (see fig 3)

4.Disconnect tool from air supply hose before doing tool maintenance and during

non-operation, for emerge stop and prevention of unintended operation, a ball valve near the gun to air

supply is recommend.

5. Use clean, dry and regulate compressed air rated at 2.0bar, never exceed

maximum permissive operating pressure (see fig 4)

6. Never use homogenate hydrocarbon solvent, which can chemically react with

aluminum and zinc parts and chemically compatible with aluminum and zinc pats.

7. Never point gun at you and others at any time.

8. Before operating the tool, make sure all the screws & caps are securely tightened in case of leaking;

9. Before painting, make inspection for free movement of trigger and nozzle to insure tool can operate

well.

10. Never modify this tool for any applications. Only use parts, nozzles and accessories recommended

and accessories recommended by manufactures.

※Operating Instructions

This tool applies to operate on clean, dry and compressed air at regulated pressure at 2.0bar.Too low

or too high pressure is not allowed.

Check and replace any damaged or worn parts on the tool, make sure the trigger and nozzle can

operate well.

Connect the gun to air supply, fluid cap, container and air hose should be connected tightly with

spray gun.

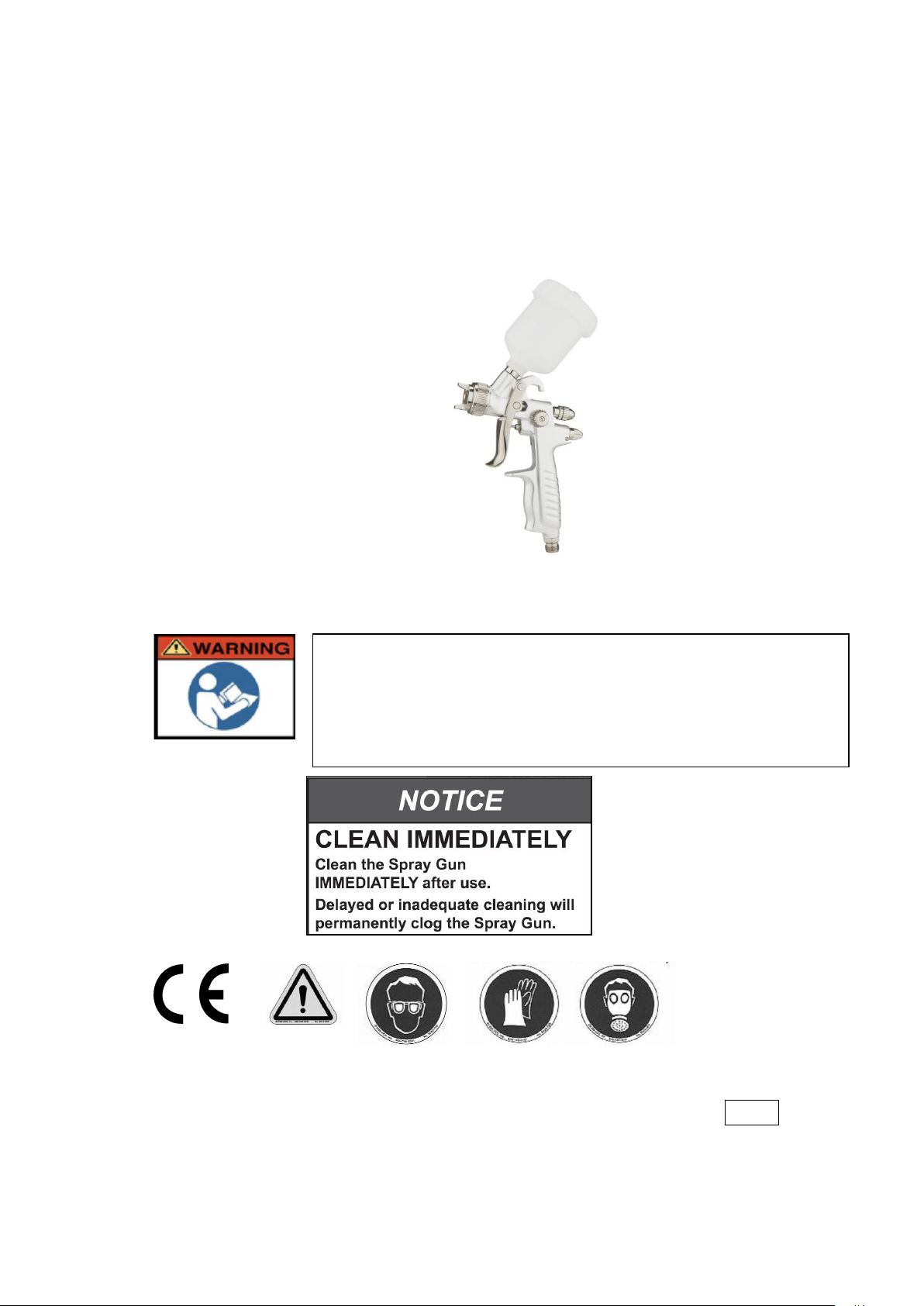

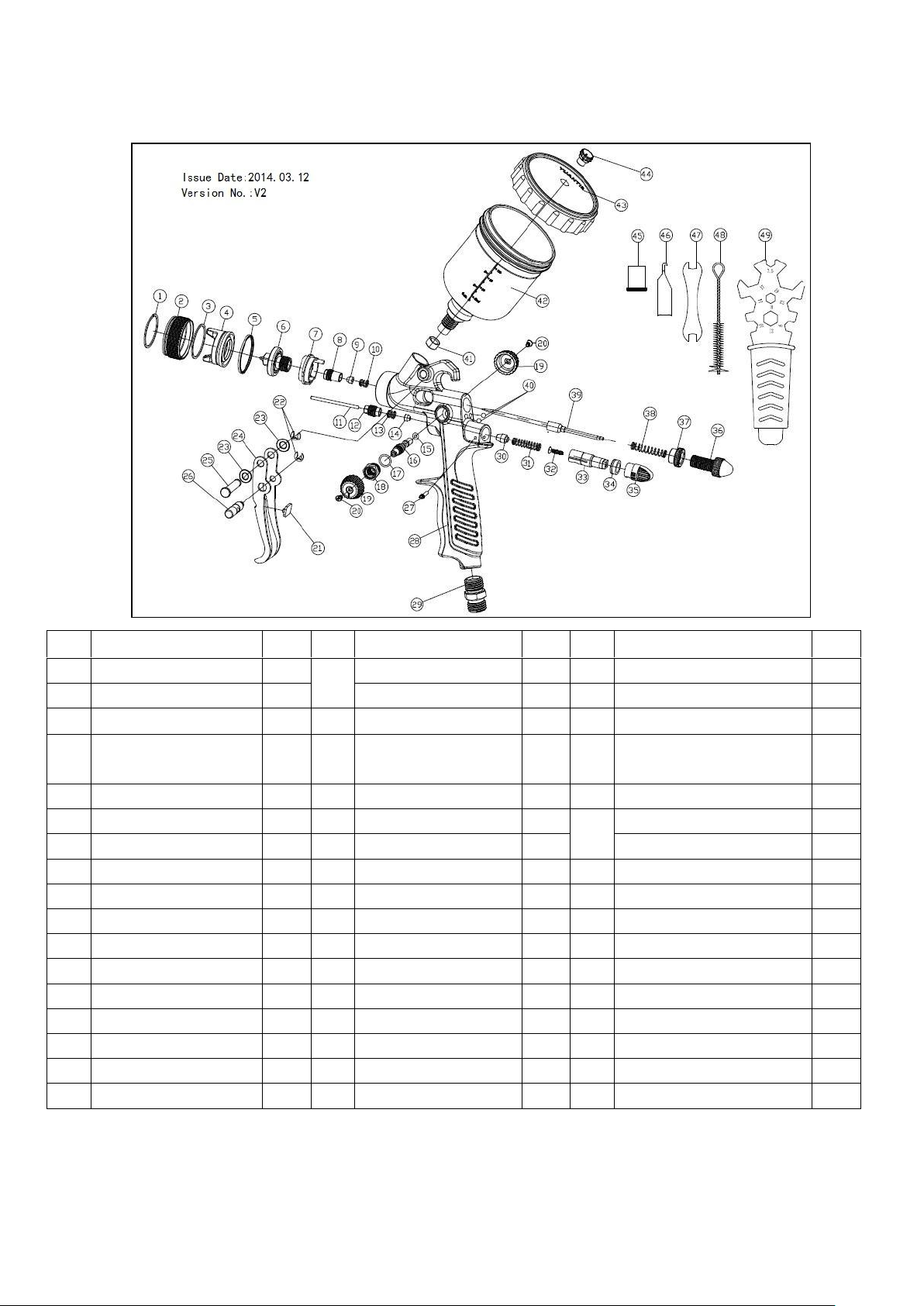

When painting, Grip the gun keeping perpendicular with spraying area then move it parallel for

several times, the trigger should be locked before the stroke ended. Keep the appropriate distance of

6-8 inches between gun and raying area, according the atomization pressure and work demand. Just

like the fig5 show.

Fig 5