necessary). Flammable vapors are often heavier than air. Floor area must be extremely well ventilated. The

pump contains arcing parts that emit sparks and can ignite vapors.

•Plastic can cause static sparks. Never hang plastic to enclose spray area. Do not use plastic drop cloths when

spraying flammable material.

•Fire extinguisher equipment shall be present and working.

•Do not aim the gun at, or spray any person or animal.

•Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any part

of the body.

•NEVER put your hand in front of the gun. Gloves will not provide protection against an injection injury.

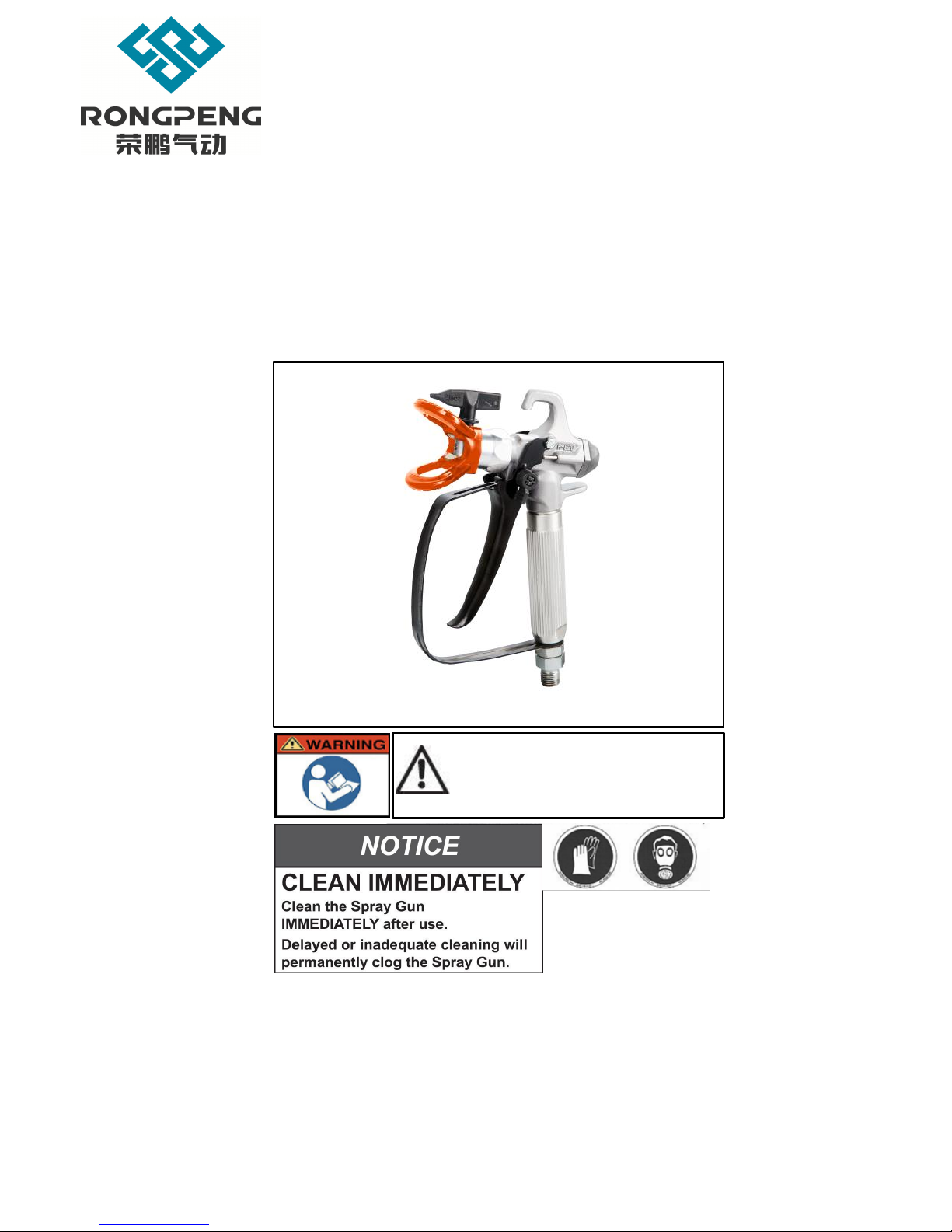

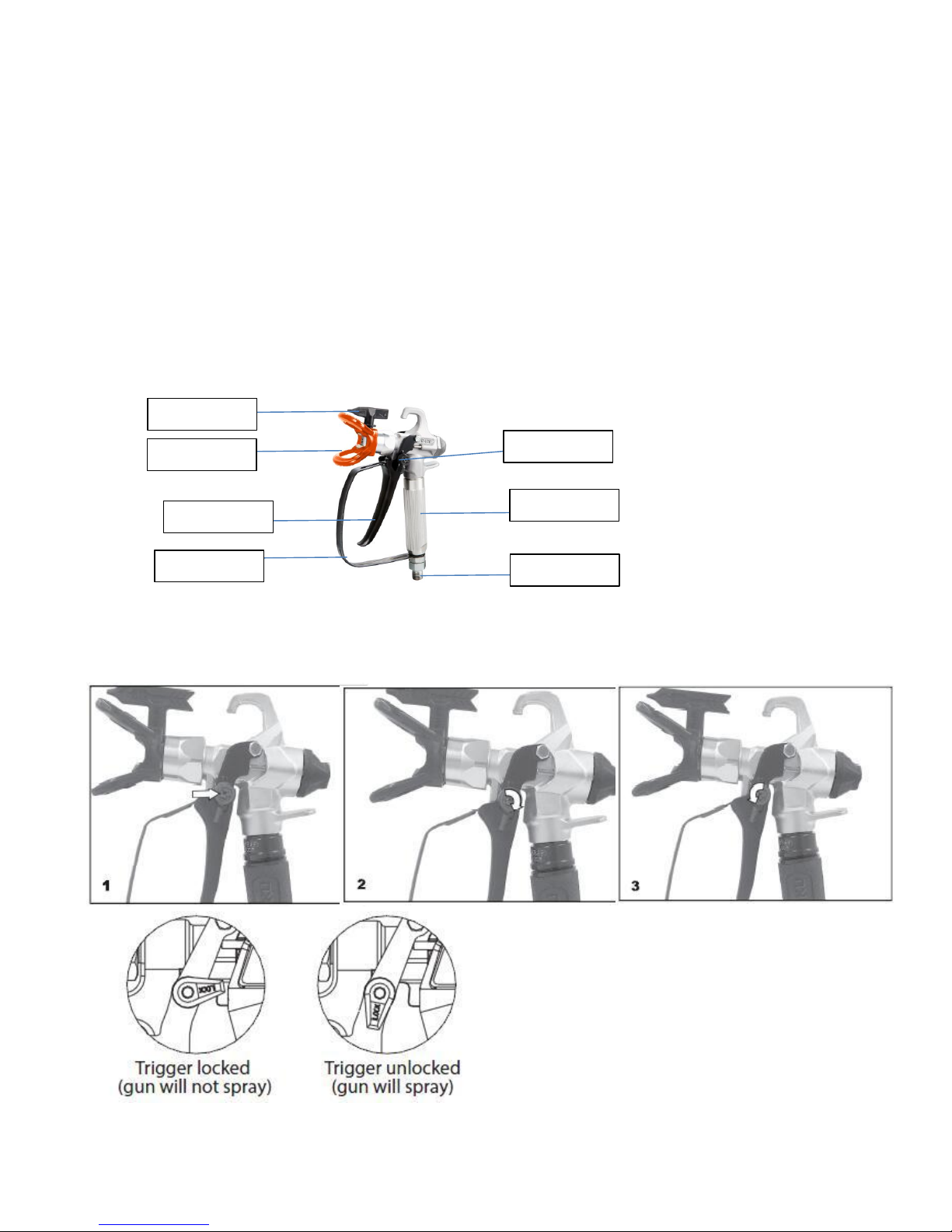

•ALWAYS keep the tip guard in place while spraying. The tip guard provides some protection but is mainly a

warning device.

•Only use a nozzle tip specified by the manufacturer.

•Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump off, and release all pressure before servicing, cleaning tip or guard, or

changing tip. Pressure will not be released by turning off the motor. The PRIME/SPRAY valve or pressure bleed

valve must be turned to their appropriate positions to relieve system pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

•Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn off the

unit and relieve the pressure in accordance with the manufacturer’s instructions.

•High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

•Check hoses and parts for signs of damage, a leak can inject material into the skin. Inspect hose before each

use. Replace any damaged hoses or parts. Only use TITAN original-high-pressure hoses in order to ensure

functionality, safety and durability.

•This system is capable of producing 3600psi / 248 Bar. Only use replacement parts or accessories that are

specified by the manufacturer and that are rated a minimum of 3600 PSI. This includes spray tips, nozzle

guards, guns, extensions, fittings, and hose.

•Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

•Verify that all connections are secure before operating the unit.

•Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls. Pressure will

not be released by turning off the motor. The PRIME/SPRAY valve or pressure bleed valve must be turned to

their appropriate positions to relieve system pressure. Refer to PRESSURE RELIEF PROCEDURE described

in the pump manual.

•Always remove the spray tip before flushing or cleaning the system.

•Always wear appropriate gloves, eye protection, clothing and a respirator or mask when painting.

•Do not operate or spray near children. Keep children away from equipment at all times.