CropCare LG40 User manual

40 Gallon Spot Sprayer

40 Gallon Spot Sprayer

Model LG40

Owner's Manual

PaulB LLC | 50 Woodcorner Rd. | Lititz PA 17543

www.CropCareEquipment.com | (717) 738-7350

A Paul B Zimmerman Inc. Company

PaulB LLC thanks you for choosing to purchase one of our spot sprayer models. We

appreciate your business and want to personally fill all of your sprayer needs. We also desire to

provide you with the technical support and needed parts that will allow you to continue spraying

without disruption. See the Contact Us section on page 13.

Table of Contents

Before You Begin...................................................................................................................1

Safety Precautions.................................................................................................................2

General Guidelines..........................................................................................................2

Before Operation.............................................................................................................2

During Operation.............................................................................................................3

Following Operation........................................................................................................3

Pump Safety Precautions.................................................................................................3

Mounting the Sprayer.............................................................................................................3

Sprayer Unit....................................................................................................................4

Wiring Harness................................................................................................................4

Operating Instructions.........................................................................................................5

Before & During Operation.............................................................................................5

Following Operation........................................................................................................5

Maintenance Instructions.....................................................................................................6

Routine Maintenance.......................................................................................................6

Winterizing Your Sprayer...............................................................................................6

Troubleshooting......................................................................................................................7

Warranty.................................................................................................................................8

Sprayer Breakdown..............................................................................................................9

Parts List..........................................................................................................................10

Pump Breakdown....................................................................................................................11

Accessories.............................................................................................................................12

Contact Us...............................................................................................................................13

Before You Begin

Please read and understand this manual and its instructions and warnings

completely before operating the sprayer.

Be aware of all safety guidelines, warnings, and cautions including those of

any piece of equipment the spot spray may be mounted on.

Read and understand the chemical manufacturer's labels, warnings, and

instructions.

Know and fulfill all necessary state pesticide applicator license requirements

as some chemicals will require a license to purchase.

Page 1

! Safety Precautions !

General Guidelines

Every year many unnecessary accidents occur due to improper equipment handling and a

disregard for safety precautions. You, the operator, can avoid accidents by observing the precautions in

this section.

The operator should be a responsible

adult. Do not allow persons to

operate this sprayer until they

have displayed a thorough

understanding of sprayer safety precautions and

operational use!

All operators must fulfill all necessary state

pesticide applicator license requirements!

Never attempt to operate this sprayer when under the

influence of alcohol or drugs.

A chemical warning decal and an owner's manual

warning decal are located on the sprayer's tank. Be aware of their location. See Figure 1

and Figure 2. Always replace any warning decals that aren't legible or are missing.

If there is any portion of this manual that you do not fully understand, please contact

PaulB LLC.

Before Operation

Carefully study and understand this owner's manual.

Read and follow chemical manufacturer's labels, warnings, and instructions!

A material safety data sheet (MSDS) should be provided by the chemical manufacturer.

To avoid injury from chemical hazards, wear the proper protective clothing. Each

chemical manufacturer's clothing requirements are listed under the

“Personal Protective Equipment (PPE) section in the chemical instructions.

Never exceed the load rating of the piece of equipment that the spot sprayer is mounted

on. The 40 gallon spot sprayer weighs around 375 lbs. with a full tank.

Have all operators practice operating the sprayer until all persons are completely capable

of safe operation.

Give the sprayer a visual inspection for any worn parts, leaking hoses, or other

visible problems, and make the necessary repairs. See the maintenance section(page 6).

Page 2

Figure 1: Chemical Warning Decal(# DEMT3980)

Figure 2: Owner's Manual Decal(# DE39)

During Operation

Always be aware of bystanders, particularly children!

DO NOT allow passengers to ride on the equipment the sprayer is mounted on.

Be aware of dangerous terrain such as holes, slopes, drop-offs, banks, rocks, and hidden

hazards. Operate the equipment and sprayer up and down slopes, not across.

Never leave running equipment unattended!

Remember that accidents can even happen to seasoned operators. Always take your time

and follow all safety instructions.

Following Operation

Always rinse the tank and flush the pump of all harmful chemical residue.

Store the sprayer away from human and livestock activity and in an area protected from

the elements.

Do not permit children to play on or around sprayer.

Pump Safety Precautions

Never pump flammable, explosive, petroleum-based, or any other non-compatible

products such as gasoline, fuel oil, kerosene, etc. Such practices will void the

manufacturer's warranty.

DO NOT allow the pump to get wet or to be exposed to the elements. Allowing the

pump to get wet or to be exposed to the elements voids the manufacturer's warranty.

Note: The pump may be run dry for limited periods without resulting in damage.

Never attempt to adjust the pressure of the pump. Any unapproved pump adjustment will

void the manufacturer's warranty.

Always disconnect the power to the pump when working on the pump. Failure to do this

could result in electrical shock.

Mounting the Sprayer

This spot sprayer is designed to be mounted on the rack of an ATV, on a garden trailer, or on a

utility vehicle such as a John Deere GatorTM. Mounting the sprayer correctly and securely will ensure

consistent and safe spraying.

Page 3

Sprayer Unit

1. Before mounting the sprayer on any piece of equipment determine whether the sprayer

weight exceeds the equipment manufacturer's load rating. The 40 gallon spot sprayer

weighs around 375 lbs with a full tank.

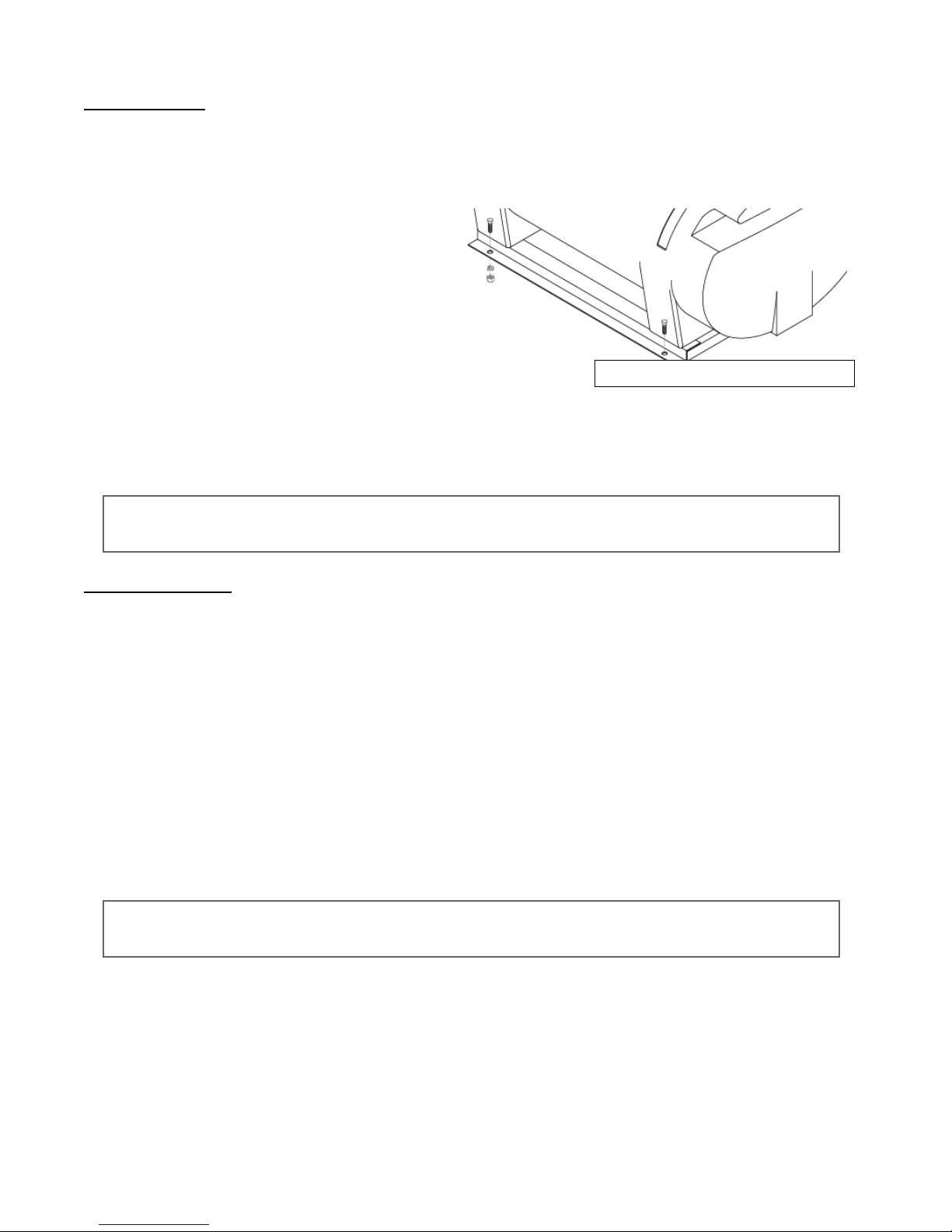

2. The sprayer tank is mounted on a steel

powder-coated frame with four pre-drilled

holes. For optimal stability mount the

sprayer with bolts using the pre-drilled

holes in the sprayer frame. See

Figure 3 on page 4. For some temporary

situations it may make more sense to strap

the spray down with heavy-duty straps. If you choose to strap the sprayer down ensure

that it is fastened securely.

Wiring Harness

1. The spot sprayer includes an eight foot wiring harness with a built in fuse and control

switch. The end of the wiring harness with a two-prong plug needs to be connected to

the pump's adapter plug.

2. The other end of the wiring harness needs to be attached a power source with at least a 10

amp and 12 volt capability. In most cases the power source is the 12 volt battery on the

piece of equipment being used(ex battery on an ATV, mower, utility vehicle). Attach the

red wire's ring terminal to a positive power source and the black wire's ring terminal to a

negative power source. See the Accessories section on page 12 if additional wire

length is needed.

3. The wiring harness also is equipped with an in-line on-off control switch. This control

switch should be positioned in a location that is easily accessible and will not interfere

with operation of the piece of equipment. The control switch can be strapped into place

if appropriate.

Page 4

Note: If you are permanently mounting the sprayer in an outdoors location that isn't protected

from the elements, it is important that you cover the pump to protect it.

Note: The end of the wiring harness with the ring terminals is detachable and can be left

attached to the battery for convenience purposes.

Figure 3: Sprayer unit mounting

Operating Instructions

Before operating the sprayer, it is important that you read this entire manual and know all safety

precautions. Always take your time and be alert when operating your sprayer. This will allow you to

safely spray without accident or interruption.

Before and During Operation:

1. Before operation it is important to give the sprayer unit a thorough inspection, which

covers the hoses, wiring harness, and other sprayer components. Ensure that the suction

strainer and the tank are rinsed out.

2. Before using any chemical or product ensure that it isn't a petroleum-based product or a

non-compatible chemical for the pump. Using petroleum-based products or non-

compatible chemicals voids the manufacturer's warranty. If you are unsure of the

acceptableness of a chemical or substance, contact PaulB LLC.

3. Fill the sprayer tank with the amount of water and chemicals as instructed by the

manufacturer of the chemical being used.

4. Connect the wiring harness to an approved power source as directed in the Mounting the

Sprayer section on page 3. Turn the control switch to the on position and allow the pump

to run until it reaches its maximum pressure. The pump will automatically turn off when

its maximum pressure is reached. The pump does not need to manually turned off with

the control switch.

5. When you are ready to spray, point the gun in the desired direction and squeeze the

trigger on the spray gun. The pump will automatically start when the spray gun is

engaged.

6. The spray gun's liquid flow can be adjusted by turning the spray tip at the end of the

spray gun wand. The spray gun's trigger can also be locked in the “on” position by

sliding the plastic tab on the top of the trigger towards yourself.

Following Operation:

1. Thoroughly rinsing the sprayer of any chemical residue is an important activity. It is

recommended to fill the tank with fresh water and engage the spray gun until the system

is entirely free of chemical residue. It is important not to rinse the sprayer in an area

where humans, animals, or sensitive plants could come in contact with chemical residue.

2. Store the sprayer in a location where it will be away from human or animal activity. Do

not allow children to play on or near the sprayer.

Page 5

Maintenance Instructions

Routine Maintenance

It is very important to perform routine maintenance on your sprayer before and after each use.

Good maintenance practices will help to guard against any unnecessary sprayer breakdowns or

accidents.

1. It is recommended to perform a visual and physical inspection for any worn parts,

damaged hoses, or other visible problems. Make all necessary repairs before spraying.

See the Contact Us section (page 13) for instructions on ordering parts and getting

technical help.

2. After each use it is important to rinse the pump and all components by running water

through the system. Fill the tank with a sufficient amount of fresh water and engage the

spray gun. Rinsing the pump with fresh water will greatly improve the life of the pump!

3. The suction strainer should be taken out and rinsed regularly.

4. Always follow all pump safety precautions and warnings (page 3). Following these

guidelines will help to ensure many years of smooth and trouble-free pumping.

Winterizing your Sprayer

To avoid damage from freezing and corrosion, it is important to winterize your sprayer before

temperatures grow too cold.

1. Verify that the tank is empty and rinsed out. Dump a ½ gallon of RV nontoxic antifreeze

into the tank. It is not recommended to use standard antifreeze. Standard antifreeze

can be harmful to humans, animals, crops, and the environment.

2. Engage the pump and spray with the spray gun for several minutes. Ensure that the

antifreeze has been pumped through the entire system.

3. Store the sprayer in a dry location away from the elements.

4. Before spraying in the spring it is recommended to flush the sprayer with fresh water to

cleanse it of the antifreeze and any other buildup. It would also be beneficial to do a

thorough inspection of all sprayer components before spraying.

Page 6

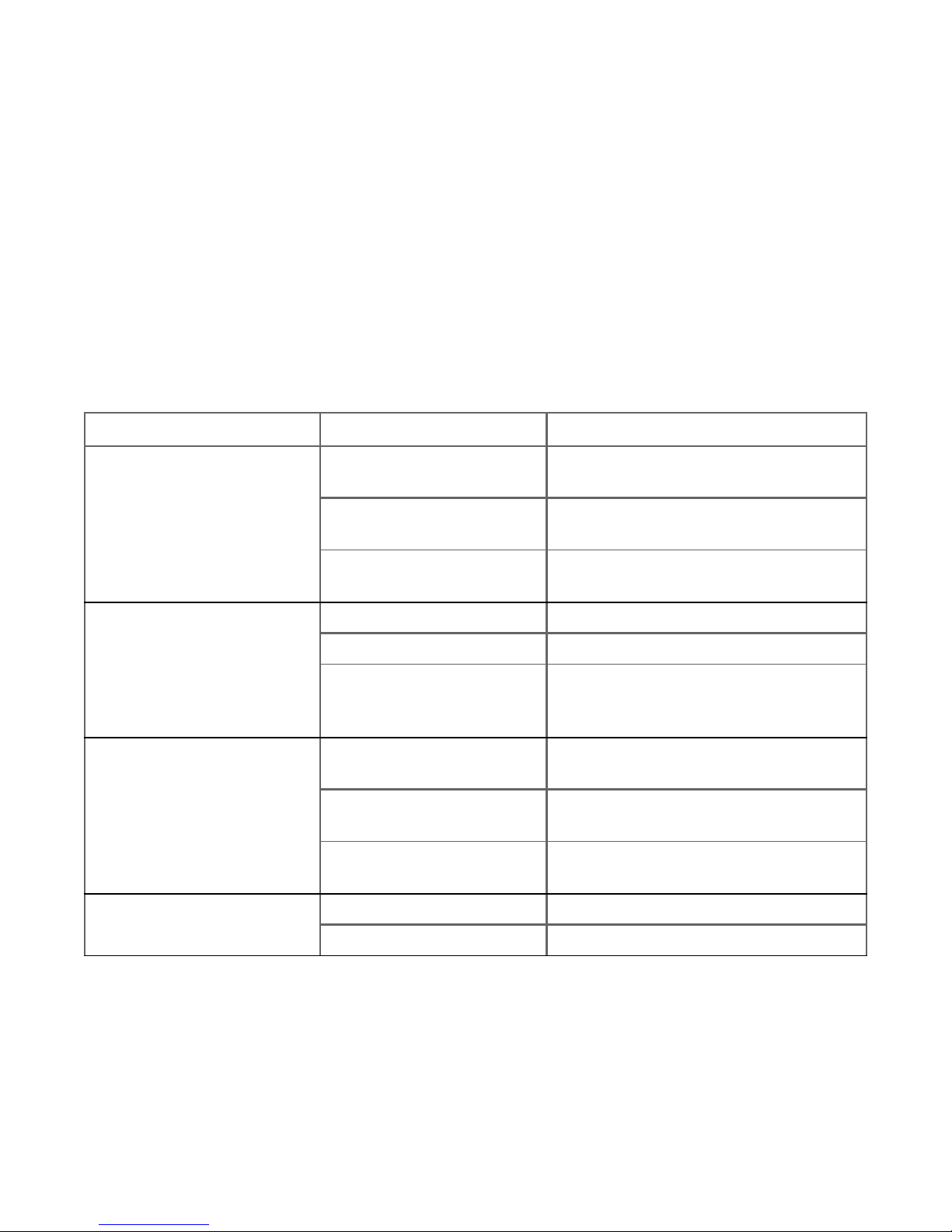

Trouble Shooting

During the many years you will use your spot sprayer, it is possible that you will encounter

minor problems that can be easily fixed. The following problems and respective causes and solutions

should cover most of the potential problems that you may face. If you are having problems please

attempt to use this troubleshooting section to solve the problem. If you are unable to fix the problem

please contact our trained sprayer technicians for technical advice at no charge or to have one of our

technicians repair your spot sprayer. See the Contact Us section on page 13 for ordering parts and

contact information.

Common Troubleshooting

Problems/Symptoms Possible Causes Solutions

Low Rate of Flow

Suction strainer is partially

clogged Remove the suction strainer and rinse.

Pump valves are

damaged/bad Replace the valves(ref# 4) or See PaulB

LLC for repairs.

Low voltage Use a power source with at least 10 amps

and 12 volts.

Pump Doesn't Prime

Suction line is clogged Inspect the suction line for debris.

Suction strainer is clogged Remove the suction strainer and rinse.

Pump damaged from

chemicals that weren't

rinsed out properly

See PaulB LLC for service and pump

repairs.

Pump Doesn't Run

Fuse is blown Replace the fuse on wiring harness (ref#

26).

Incorrect voltage Ensure you are using a 10 amp, 12 volt

power source.

Pump pressure switch is

malfunctioning Replace the pressure switch(ref# 1) or

see PaulB LLC for repair.

No Spray Flow Spray tip clogged Remove the spray tip and rinse it out.

Suction strainer is clogged Remove the suction strainer and rinse.

Page 7

PaulB LLC Limited Warranty

40 Gallon Spot Sprayer: Model LG40

Warranty Coverage

PaulB LLC hereby provides a Limited One (1) Year Warranty on the 40 gallon spot sprayer model

LG40 manufactured by PaulB LLC from the date of original purchase. Spot sprayers built by PaulB

LLC are warrantied against any manufacturer's defects that may occur to any of the sprayer's

components in the 12 months following the original date of purchase. This warranty covers the

purchaser of this spot sprayer and any other owners who own it during the one year warranty period. To

retain the warranty, the spot sprayer must be operated and maintained as ascribed by its owner's manual.

Warranty is void if:

1. The spot sprayer has been subjected to, in the opinion of PaulB LLC, negligent handling, misuse,

an accident or if the instructions in the owner's manual were not followed.

2. The spot sprayer's components have been altered in any manner or repairs have taken place with

unapproved parts. Alterations include adjusting the pressure setting of the pump.

3. The spot sprayer and its components were subject to freezing or freezing conditions. The spot

sprayer must have been winterized as per the maintenance instructions to retain the warranty.

4. The spot sprayer was powered by a power source other than a 10 amp, 12 volt DC power source.

5. A non-compatible chemical(including petroleum-based or flammable liquids) was used and/or if

the sprayer operator failed to rinse all chemical residue out of the sprayer's components after use.

6. The pump was allowed to get wet repeatedly or was unprotected from the elements.

Getting Service

All spot sprayer warranty claims must be made through PaulB LLC. All warranty claims must be

submitted with an invoice or a proof of purchase that denotes the purchase date and place. If you have

any questions or comments concerning this warranty, please contact PaulB LLC.

Page 8

Sprayer Breakdown

Page 9

8

7

4

20 15

21

21

15

22

23

5

24

26

3

2

3

2 1

17

14

15

16

18

7

6

10

19

25

9

14

13

12

11

Spot Sprayer Parts List

Ref # Qty. Part Number Description

11 T233 Tank frame, 25 gallon lawn & garden tank

2 4 H5C516*34 Hex cap screw, 5/16” x 3/4”, grade 5

3 4 LW516 Lock washer, 5/16”

4 1 10959 40 gallon lawn & garden tank, yellow (includes ref# 5)

5 1 60322* Threaded tank lid, 5”, black

6 1 C13201 Grip clip

7 2 MR1024*38S Machine screw, 10-24 x 3/8”, stainless, round

8 1 N189472 Grip clip, 3/8” - 5/8”, zinc

9 1 DE46 Crop Care logo decal

10 1 DEMT3980 Chemical warning decal

11 1 DE39 Owner's manual warning decal

12 1 10416D Suction strainer, 3/8” fpt, 40 mesh

13 1 3A3838 Hose adapter, 3/8” barb x 3/8” mpt

14 19” 6106 Vinyl reinforced tubing, 3/8”, 250 psi

15 3 62602 Hose clamp, 1/4” - 5/8”, stainless steel

16 1 3EL3838 Hose adapter elbow, 3/8” mpt x 3/8” barb, poly

17 1 8000-543-936** SHURflo®12 volt pump, 1.4 gpm

18 4 MR1024*1S Machine screw, 10-24 x 1”, stainless, round

19 4 FW14S Flat washer, 1/4”, stainless

20 1 3A3838 Hose adapter, 3/8” barb x 3/8” mpt

21 15' 6106 Vinyl reinforced tubing, 3/8”, 250 psi

22 1 5080015PP406 Triggerjet®spray gun, 15” extension (includes ref# 23)

23 1 38720PPBX18* Adjustable conejet spray tip, orange

24 1 SPT-SWH-9615 Wiring harness with switch

25 1 SPT-BCG-1215 Detachable pig tail wiring harness w/ fuse

26 1 ATC-15* Buss fuse, 15 amp

*Part is included in a complete assembly.

**See complete pump breakdown on page 11.

Page 10

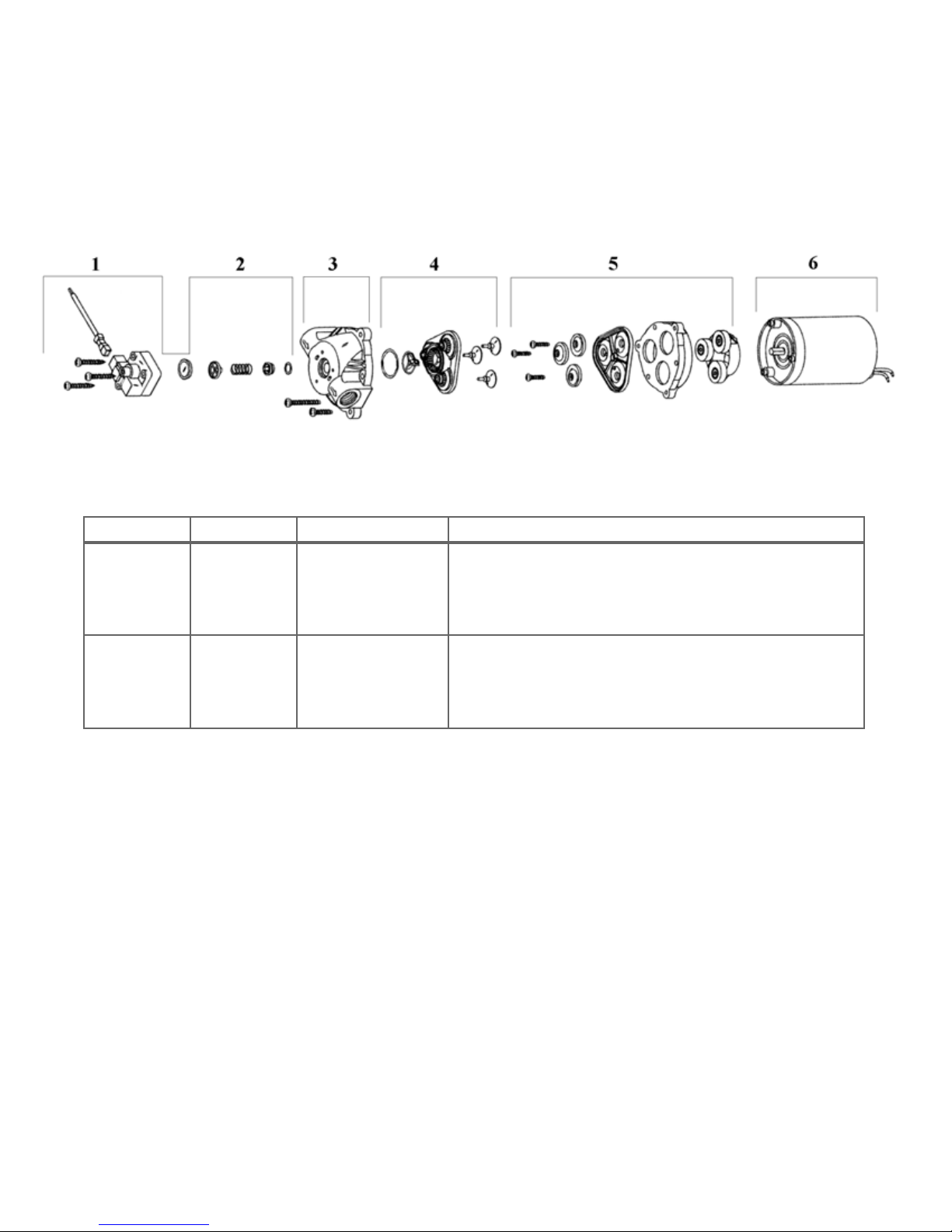

SHURflo®Pump Breakdown

Part # 8000-543-936

Ref # Qty. Part Number Description

1 1 9437505 Switch kit, viton, 60 psi

2 1 9437405 Check valve kit

3 1 9437900 Upper housing kit

4 1 9439005 Valve kit, viton

5 1 9438532 Diaphragm & drive kit, santoprene

6 1 1111100 SHURflo®motor, 12 volt

Page 11

Accessories

There are many beneficial accessories that can complement your spot sprayer and help you to

optimize your operation. If you need parts or accessories that aren't listed in this owner's manual, please

contact us and we will attempt to fill all of your needs. See the Contact Us section on page 13 for

information on ordering and shipping.

Page 12

Adjustable Brass Spray Tip

Part Number: 5500X18

3/8” Vinyl Reinforced Hose

Part Number: 6106

10' Wiring Harness Extension

Part Number: 9428 Triggerjet®Spray Gun

Part Number: 22670PP1514

Upgrade your spray gun

with this durable brass

spray tip. This spray tip is

adjustable and will increase

the performance of your

spray gun.

Need an additional

length of wire? A 10'

wiring harness

extension simply plugs

into your existing

wiring harness giving

you the length you

need.

Additional hose comes

in handy for reaching

those hard to get to

places. This durable

hose can be cut to

length and is available

in additional sizes.

Increase your spraying performance by

replacing your existing spray gun with a

Triggerjet®spray gun. This spray gun

features a 15” wand and can be repaired

with replacement parts.

TM

Contact Us

We desire to give you continuing service in the best manner possible. This includes

listening to your comments, suggestions, and problems. We will do our best to answer all

questions thoroughly and in a timely manner. We have trained sprayer technicians who are

more than willing to listen to any questions or problems and help you to find a feasible solution.

Ordering Parts

We have a fully-stocked parts department that will be able to meet all of your parts needs.

Our trained salespersons will ensure that all purchases are processed smoothly and shipped in a

timely manner. Our hardware store also has a plumbing, electrical, automotive, paint, lawn &

garden, and a power tool department. We are set up to ship our products via UPS and would be

glad to work with you on the best shipping solution. If you desperately need a part, we are able

ship UPS Next Day Air for many locations.

PaulB LLC

A Paul B Zimmerman Inc. Company

50 Woodcorner Road

Lititz PA 17543

Parts Dept (717) 738-7355 ext 2000

Corporate Office (717) 738-7350

Fax (717) 738-8061

www.CropCareEquipment.com

Page 13

Note: When ordering parts, please provide our sales staff with the correct part number

and description listed on the parts list. To directly reach our parts department,

please call (717) 738-7355 ext 2000.

Form OM0018

10/06

Other manuals for LG40

1

Table of contents

Other CropCare Paint Sprayer manuals