K-20394

..

DISCHARGE

-~--

UNLOADING VALVE

DISCHARGE SNUBBER

~

ROVIDE

CONNECTIONS FOR

THERMOMETERS

AND PRESSURE OR

-

~~~~U~N~~?SEcSH~~~~~

TO

BLOWER

IPRESSURE

RELIEF

VALVE

\r

~

CHECK VALVE

~~~':t=6

CROSS

''-,L

FLEXIBLE

CONNECTORS

i_

ALTERNATE

ARRANGEMENT

OF

INLET

DRY

TYPE

INLET

FILTER

[

INLET

CLEANER-

SILENCER

INLET

SILENCER

--

_

Whispair blowers normally have aflattened bulge

on

one side of the cylinder with apipe connection extending

from it, as shown

in

Figure

1.

These units must be driven

with the correct rotation

to

make this connection

the

discharge. Figure 2shows

the

standard

drive shaft

locations as viewed from

the

drive end, and

the

correct

counterclockwise direction

of

rotation.

For

special con-

struction (drive shaft

at

the

top

or

right), correct rotations

would be opposite or clockwise. An arrow near

the

shaft

indicates

the

rotation

to

be used. Some few blowers

(1701,

1702,1704,1707)

do

not have cylinder bulge. These may be

operated in either direction, as necessary

to

produce

discharge

at

the more convenient connection.

Piping should

be

accurately

squa~ed

with

the

blower,

supported independently, and sized no smaller than

the

connections

on

the

blower. Use only clean, new pipe and

make certain

it

is free

of

scale, cuttings, weld beads,

dirt

or

any

other

foreign material. To guard against damage

to

blower, especially when an inlet filter is not used, install a

screen of

16

mesh backed with

hardware

cloth

at

or

near

the

inlet opening. Make provisions

to

clean

the

screen of

collected debris

after

afew hours operation, and

periodically thereafter. Install an inlet filter in dusty or

sandy locations.

Figure

3shows atypical complete installation

of

blower and accessories where

quietest

operation is wanted.

Note

the

absence of

throttle

or shut-off valves in either

dishcarge or intake piping.

If

it

is possible for air flow

to

be

cut off in either

of

these

lines, make provisions

to

add a

pressure

and/or

vacuum relief valve as discussed

under

OPERATING CHARACTERISTICS.

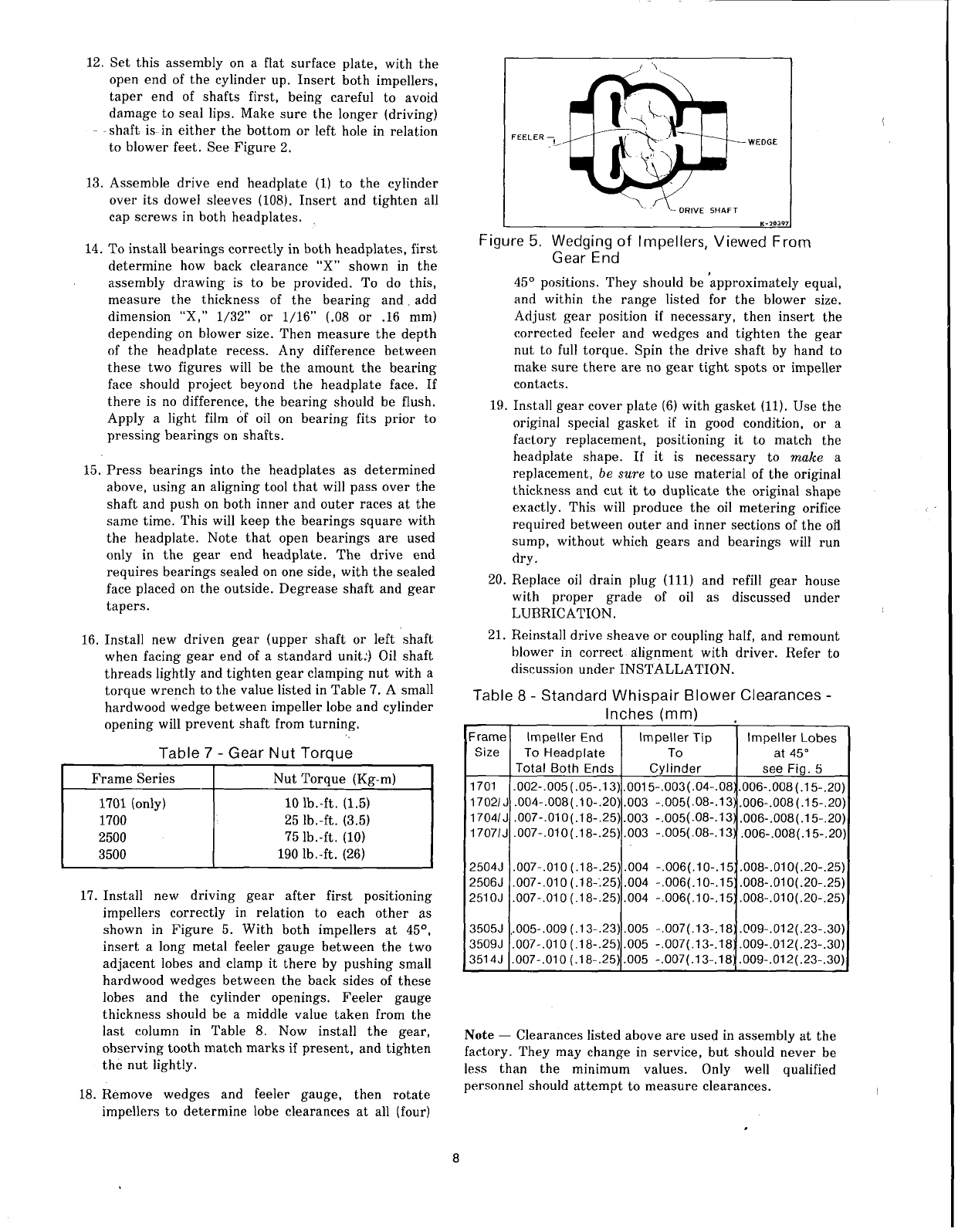

Figure 3. AComplete Blower Installation, With

Alternate Inlet Arrangement

In

some installations

it

may be desirable

to

use only an

inlet silencer-cleaner supported directly from

the

blower

connection. This is shown as an

alternate

arrangement

in

Figure

3.

Weight

must

be

kept

to

aminimum

to

prevent

blower casing distortion when

the

inlet is

on

the

side.

Ablower may be driven by direct coupling

to

the

driver, or by V-belt

to

obtain

other

speeds within

the

approved range. Refer

to

LIMITATIONS before selecting

the

drive speed. Also, be

sure

to

arrange for suitable

protective guards as discussed in PRECAUTIONS.

Lubricated couplings

are

the

preferred type,

but

Lovejoy Type Lor similar non-lubricated

type

may also be

used. Coupling halves

must

correctly fit blower and driver

shafts, so

that

only light

tapping

is required

to

install each

half. The two shafts

must

be as accurately aligned as

possible, both horizontally and vertically,

to

limit operating

strain on either shaft.

Proper

gap between coupling halves

must

be established with

the

motor

armature

on

its

electrical center. This will minimize

the

chance for end

thrust

on

the

blower shaft.

Figure

2.

Rotation and Discharge For Standard

Blower

t0

6.

Rotate

drive shaft

three

or four revolutions every

two weeks.

7.

Prior

to

startup,

remove flange covers

on

both inlet

and discharge and inspect internals

to

insure

absence of

rust,

check all internal clearances. Also,

at

this time, remove

gear

cover and inspect

gear

teeth

for

rust.

Install blower

in

aprotected indoor location, if

possible. However, an unprotected outdoor installation will

be satisfactory if correct lubrication for expected

temperatures

is provided.

Just

before

starting

the

installation, remove plugs

or

covers from inlet and

discharge connections. Inspect for

dirt

or

foreign objects

inside

the

blower,

then

turn

dirve shaft by hand

to

make

sure

that

it

rotates

freely.

Mount blower in alevel position. Use of arigid, solidly

supported, smooth flat plate is recommended. Make

sure

blower feet

rest

evenly

on

the

plate before fastening down.

Twisting

or

cramping

the

blower in mounting will cause

impeller contact and binding during operation.

On

blowers

having

two

feet, loosening

the the

screws (Item

123)

into

the headplate flanges should permit adjusting

the

feet for

even contact with

the

plate. Then fasten both feet

to

the

plate with screws and lockwashers, and

retighten

the

headplate screws carefully.

On

blowers with four feet, this

procedure may not be successful. Shimming

under

one or

more feet may then be required

to

produce asolid

mounting.

Ablower factory-mounted on abase should not require

the

above adjustments. The assembly can become twisted

in

shipping, however, and

it

might be wise

to

loosen

the

foot hold-down screws

to

check foot contact with

the

mounting surface. The base should

then

be

mounted on a

solid foundation or heavy flooring, using shims as necessary

at

bolting points

to

prevent

warping

the

assembly.

Transmission of small operating vibrations to a

supporting

structure

in

some cases may be objectionable.

Use of vibration isolators,

or

vibration absorbing materials,

can be effective in overcoming this problem. To avoid

blower casing distortion,

the

treatment

used should be

applied under the motor-blower common mounting plate or

base,

rather

than directly under

the

blower feet alone.

Blower feet

are

detachable

to

allow converting aunit

having side connections

to

one with top and bottom

connections. Smaller units

(1700

and

2500

series) have only

one foot on each end. These

must

be

unbolted and

transferred

individually

to

the

opposite ends when making

this conversion

..

On

larger

blowers having four feet,

the

two

at

each end

are

unbolted and moved

90

0to new

positions on

the

same end. Units arranged for flange

mounting directly

to

C-Frame electric motors

are

available

only with side connections.

4