GENERAL SAFETY INSTRUCTION

ŸAbiding by the above general instructions can help

Ÿyou avoid having to read this book while trying to run

Ÿthe machine.

Safety during machine operation

ŸThe machine is applicable for DRY sweeping only.

ŸGround cleaning machines may be run by qualified

personnel only.

ŸThe machine may be used for cleaning such

surfaces approved by the owner or this authorized

representative.

ŸThe operator must use the machine in accordance

to its intended fields of application.

ŸDuring operation, the operator must take account of

local conditions (stairs, obstacles) and of other

persons, particularly children.

Use only genuine spare brooms as specified by

the manufacturer. Use of other than the indicated

broom types may affect safety.

Never collect explosive fluids, undiluted acids

and solvents. This includes e.g. gasoline paint

thinners or fuel oil, which-when combined with

air, may form explosive vapors or mixtures.

Acetone, undiluted acids and solvents can be

aggressive to the material used for the machine

components.

The machine may be used only on indoor

hard floorings and for operation on level

grounds with a maximum inclination of up

to 2 %.

- Do not clean the machine by means of vapour

jet or high pressure cleaning equipment.

- Do not USE the machine on steps.

- Use of the machine in areas prone to explosion

hazards is strictly forbidden.

Transport

ŸIncorrect lifting techniques may create an personal

injury, When transporting the machine ensure that all

components and removable parts are securely

fastened.

ŸDo not lift or transport the machine whilst containing

dirt as this will add considerable weight.

ŸTake extreme care when moving the machine up or

down steps or stairs.

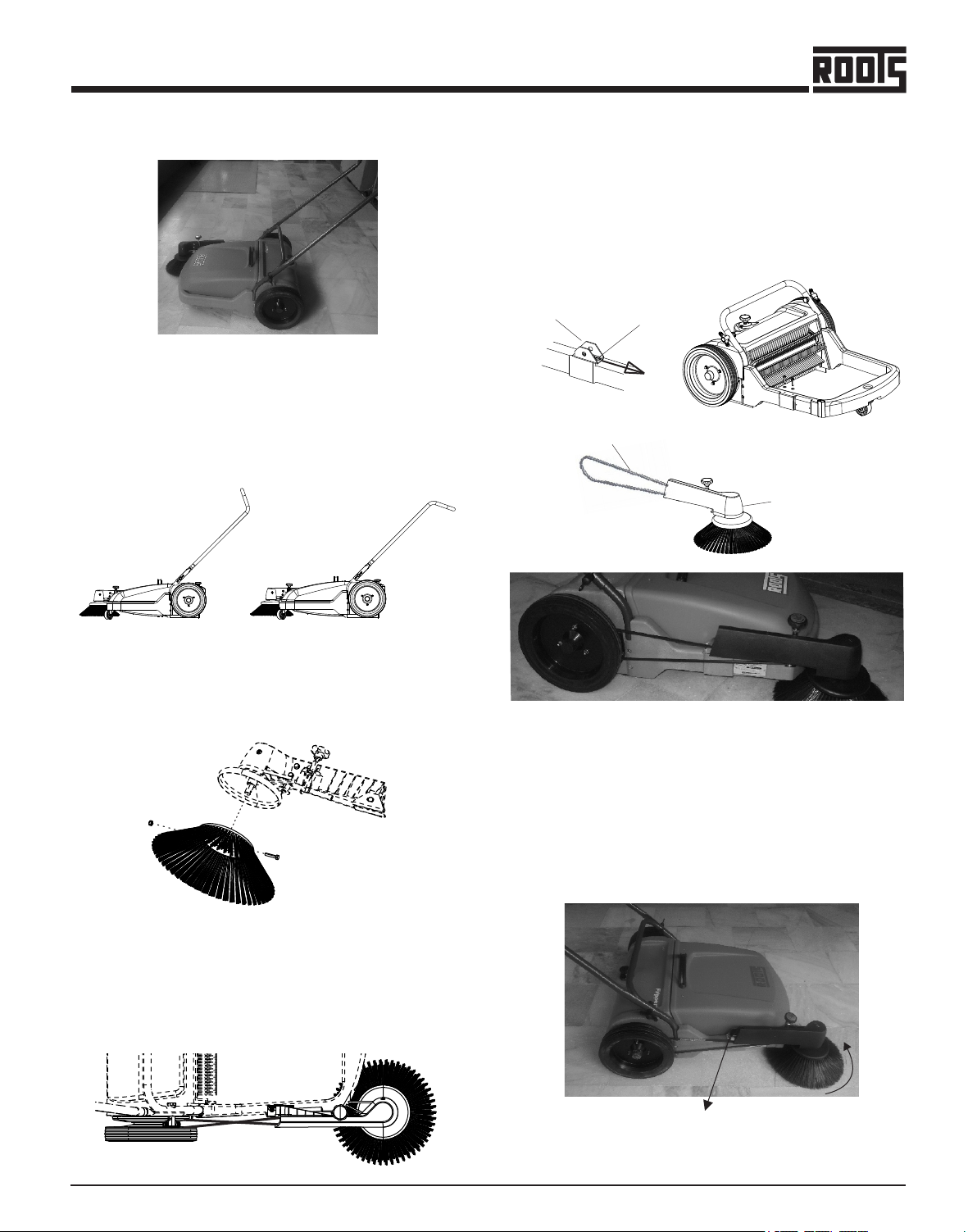

B u m p i n g o v e r

thresholds, kerbs and

similar obstacles can

damage the machine.

Small obstacles can

b e o v e r c o m e b y

pulling the machine

backwards.

Safety & Warning Symbols

All paragraphs in this manual referring to you personal

safety, the safety of your machine and the environment

protection are attributed one of the following warning

symbols.

Symbol

(Hazardous for) Description

Safety Provisions

Caution

Ecological hazard

Read Manual

(persons and goods)

(the machine)

(the environment)

Prior to first operation, read the

manual carefully and strictly

comply with the instructions

contained.

Due to use of substances

re p r e s e n t i n g a n i n he r en t

d a n g e r t o h e a l t h o f

environment.

Im p o r t a n t i n fo r ma ti o n o n

handling the machine in order

to maintain operability.

Safety provisions in dangerous

situation caused by misuse

i n a c c u r a t e a d h e r e n c e o f

i n s t r u ct i o n o r p re s c r i b ed

work routine.

Safety Instructions

ŸApart from information contained in this manual,

generally applicable legal provisions for safety and

prevention of accidents must be adhered to.

ŸDo not put this manual aside without having read it,

even if you have already operated similar ground

cleaning equipment before.

ŸAllow yourself the time to do so in order to save time

at a later time.

ŸThe operator is responsible for all persons in the

working area.

ŸChildren must be kept away from the machine during

operation.

ŸNo person must be allowed to stay in the zone of

danger.

ŸThe warning and instruction plates attached to

machine give important advice on safe operation.

ŸReplace lost or illegible stickers.

ŸBefore starting to work, the operator has to check

that the machine and its working implements are in

proper and safe operating condition.

ŸMachines with known defects must not be used.

ŸIt is important for operators and all persons likely to

use the product, to familiarize themselves with all

accessories and controls, as well as their functions,

before starting operations.

5

+

Flipper