7

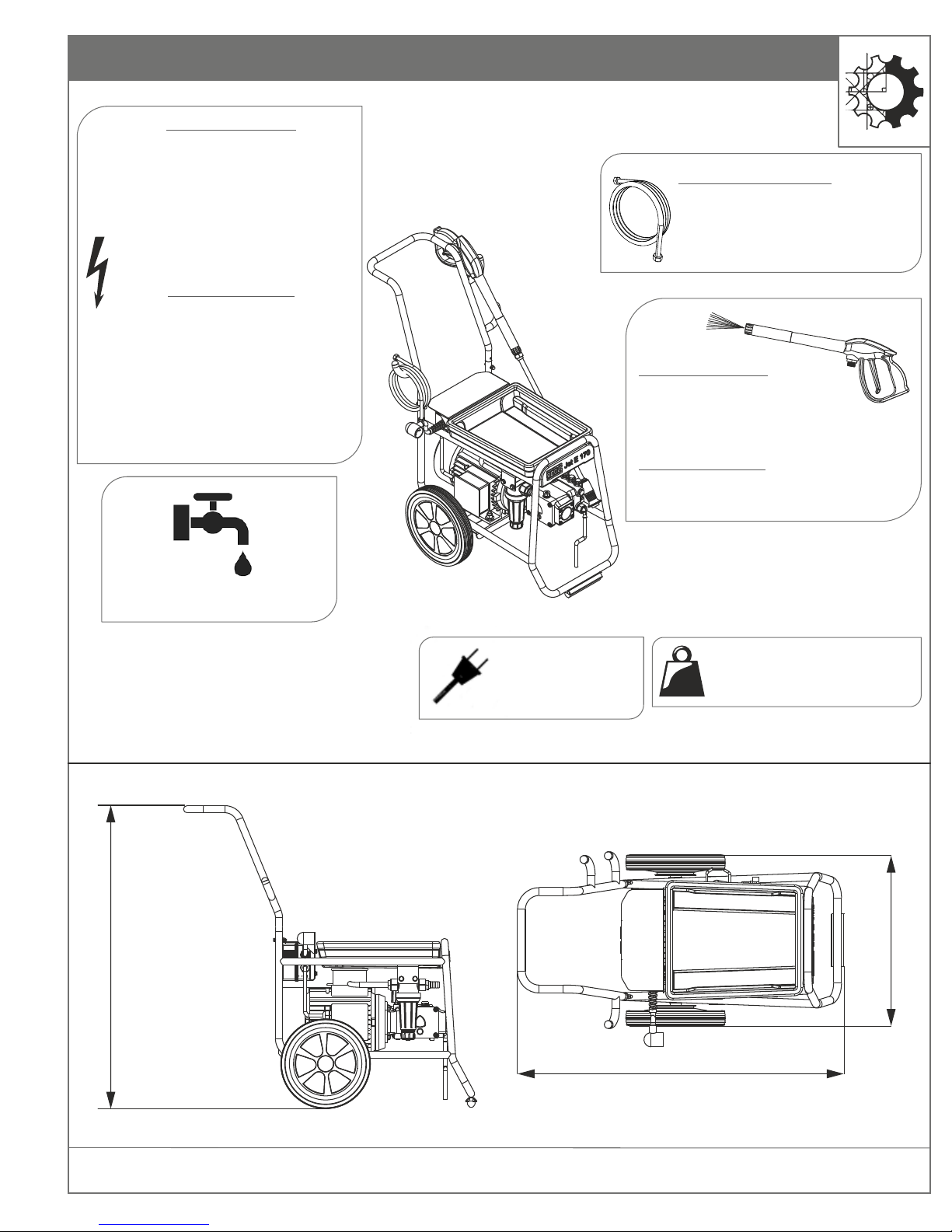

Jet E 130 / 170

Prior to first operation, read the manual carefully and strictly

comply with the instructions contained.

Read Manual

SAFETY INSTRUCTIONS

General Guidelines

ŸIn addition to the information contained in this manual,

generally applicable legal provisions for Safety and

Prevention of accidents must be adhered to.

ŸPlease go through the manual and the instructions contained

herein carefully, even if you possess prior experience in

operating similar cleaning equipment.

ŸSchedule some time for the careful and through perusal of

the manual contents .

ŸThe responsibility of all persons in the working area fall upon

the operator of the machine.

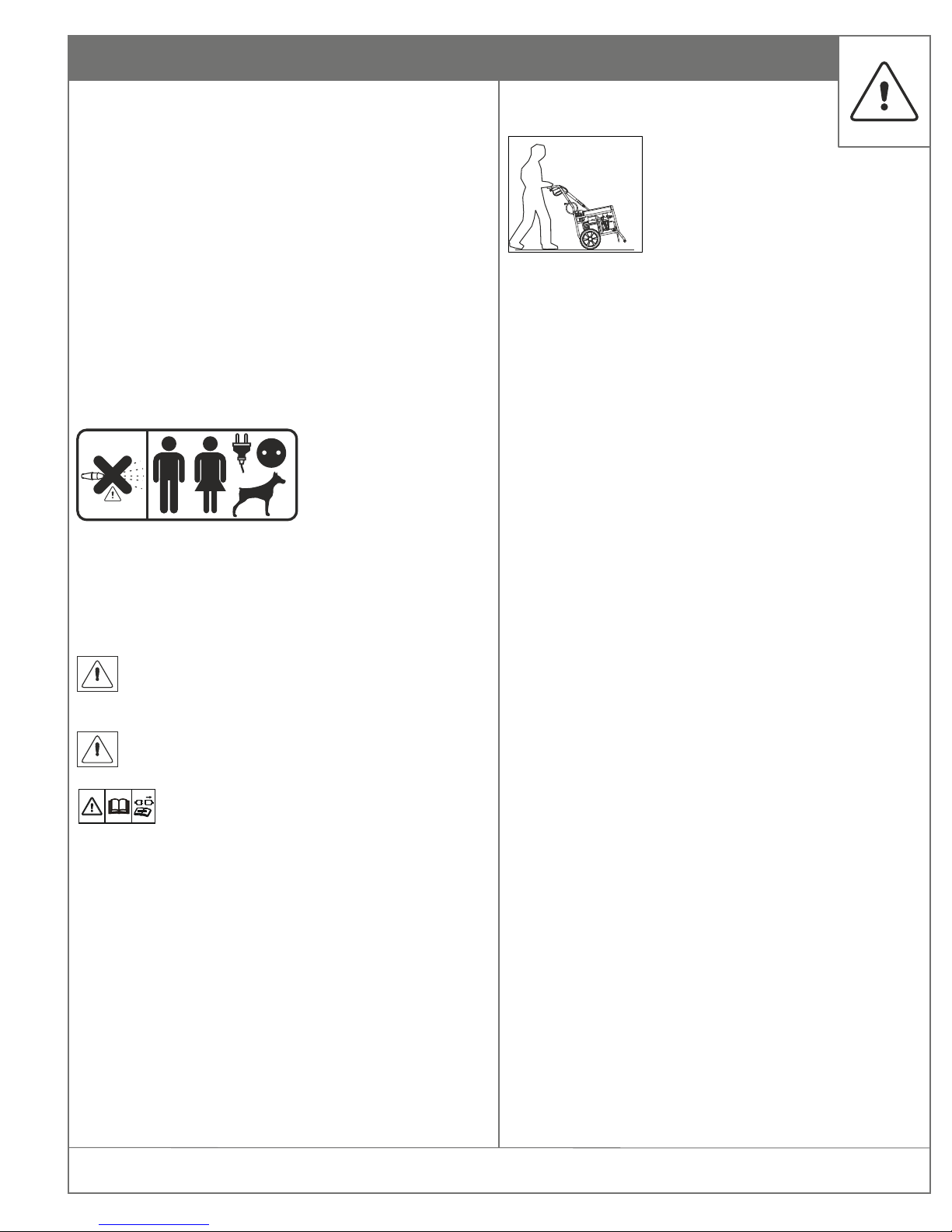

ŸNo persons, children included, should be allowed within the

zone of danger.

ŸThe warning and instruction plates attached to the machine

carry important advice on safe operation of the machine.

ŸLost or illegible stickers must be replaced at the earliest.

ŸPrior to operation of the machine, the operator must ensure

that the machine and its working implements are in proper

and safe operating condition.

ŸMachines with identified and known defects must not be

used.

ŸAdherence to the above general instructions will help avoid

the operator from having to read the manual while operating

the machine.

ŸThis machine must only be used for the manufacturer’s

approved application as described in this manual.

ŸThe machine must be kept clean and in good condition, if any

parts are damaged they shall only be replaced by an approved

part by the manufacturer, its service agent or a similar

qualified person in order to avoid a hazard.

ŸOnly genuine accessories and spare parts provided with the

machine or those approved by the manufacturer should be

used. All repairs must be performed by a qualified service

agent.

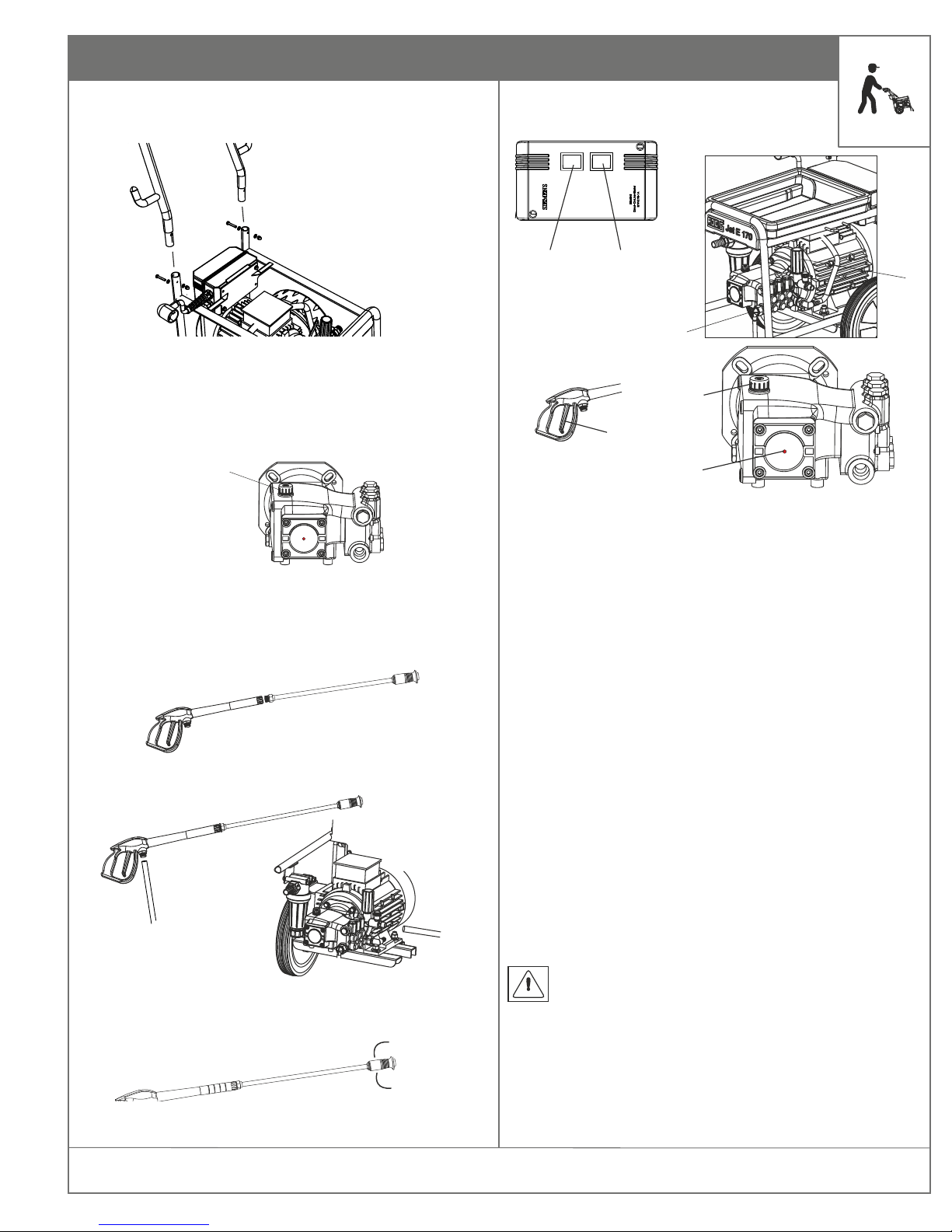

ŸIt is important that operators and all persons

likely to use the machine familiarize

themselves with all accessories and controls,

as well as their functions, before commencing

operation.

Use only genuine spare parts as specified by the

manufacturer. Use of brushes other than those

indicated may affect safety.

Never touch the mains plug with wet hands.

Safety during Jet Cleaner operation

ŸAlways switch on the machine with trigger in open condition.

ŸCheck flow of water to the filter inlet (2 - 3 bar gravity

pressure recommended).

ŸThe machine may be operated by qualified personnel only.

ŸThe machine may be used for cleaning only such surfaces that

have been approved by the owner or the authorized

representative.

ŸThe operator must use the machine in accordance to its

intended fields of application.

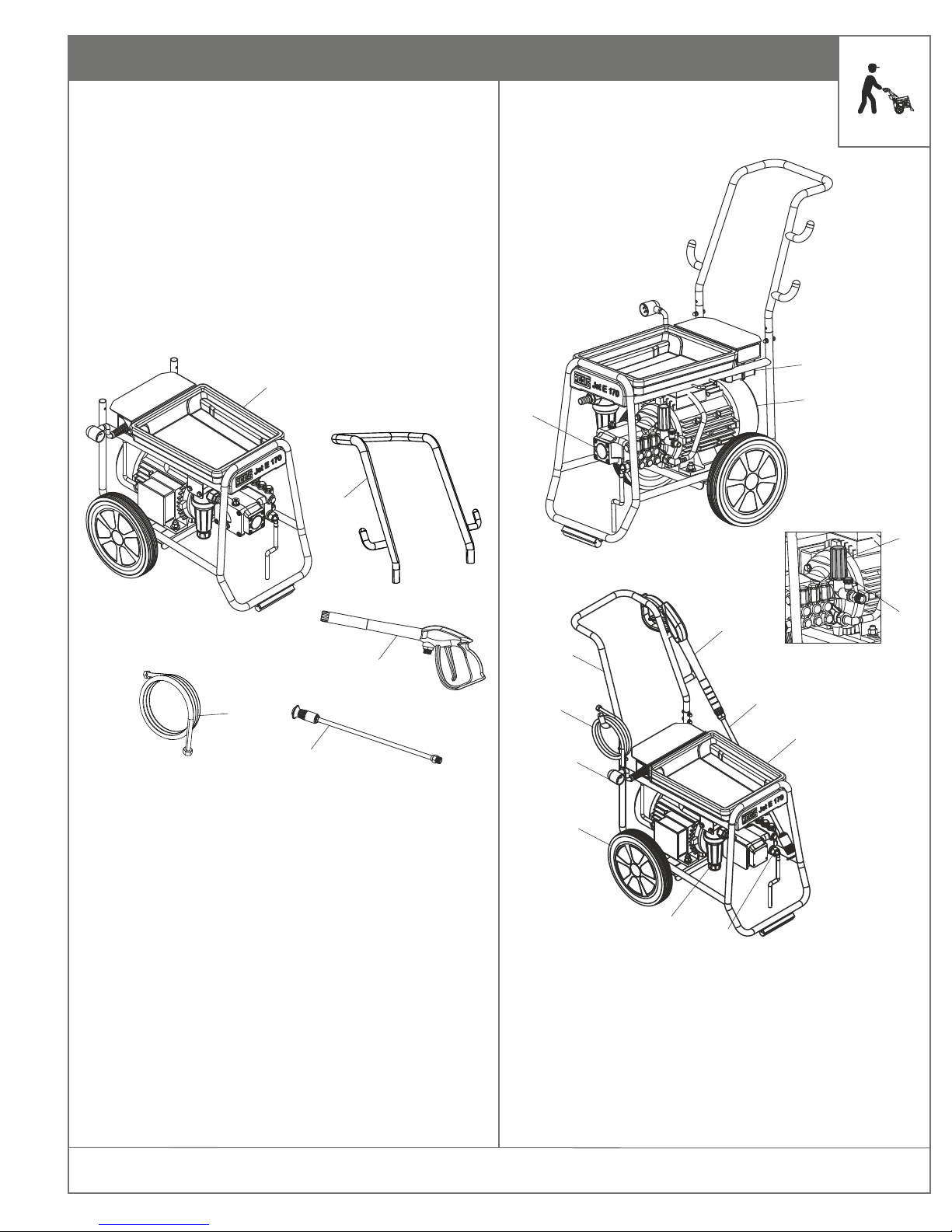

ŸThe machine must be unpacked and assembled in

accordance with these instructions before connecting to the

electrical supply.

ŸThis machine should always be connected to a fully earth

power supply of the right voltage and frequency.

ŸWhen working on the electrical system, always disconnect

the cable.

ŸKeep the power supply cord away from moving parts.

ŸRegularly check the power cord for damages, such as cracks

or aging. If it is damaged, the cable must be replaced before

further use.

ŸIt is not permitted to use aggressive and corrosive cleaning

agents.

ŸNever use excessive foaming or highly corrosive cleaning

solutions.

ŸEnsure all parts are fitted properly before operation.

ŸCheck minimum fuse strength of the socket.

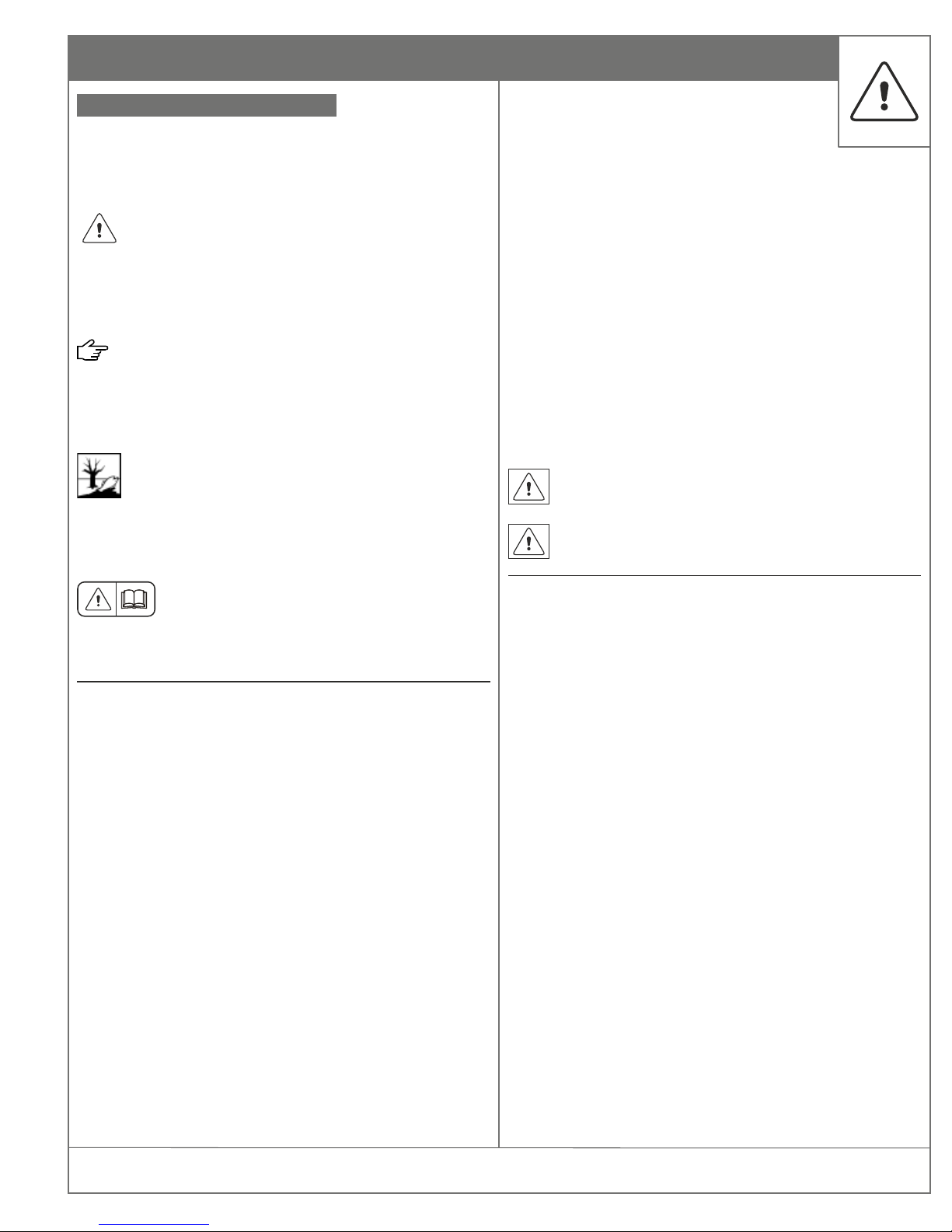

All paragraphs in this manual referring to you personal safety, the

safety of your machine and the environmental protection are

attributed one of the following warning symbols:

Safety provisions in dangerous situation caused by misuse

inaccurate adherence of instruction or prescribed work routine.

Safety Provisions (persons and goods)

Due to use of substances representing an inherent danger to

health of environment.

Ecological Hazard (the environment)

Important information on handling the machine in order to

maintain operability.

Caution (the machine)

SAFETY & WARNING SYMBOLS